Automatic manufacturing device for spiral tube and producing method

An automatic production and driving device technology, applied in glass production, glass molding, glass reshaping, etc., can solve problems such as inability to guarantee the quality of lamp tube production, unstable lamp quality, and difficult to accurately control time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

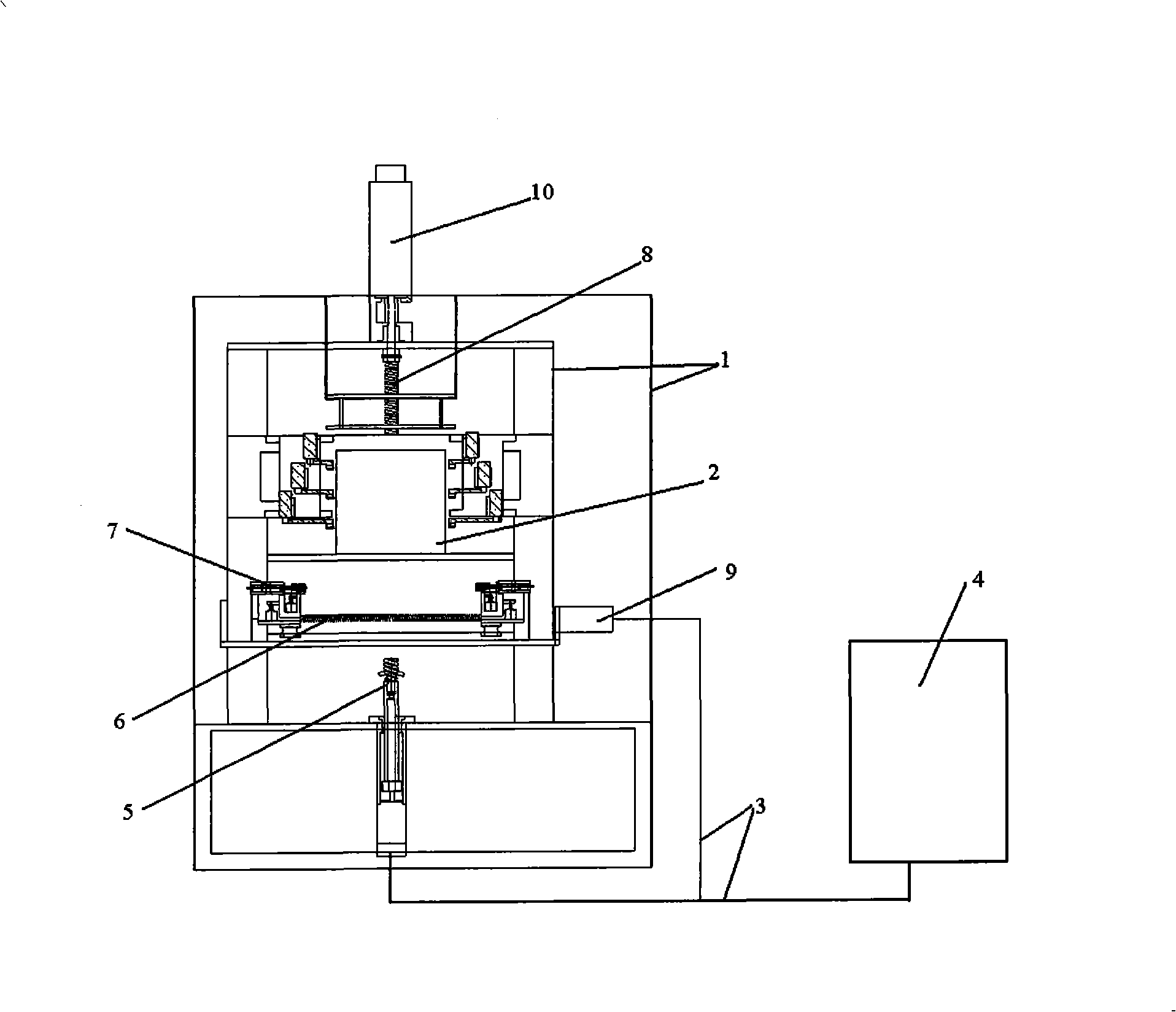

[0070] Such as figure 1 As shown, the automatic production device for spiral lamp tubes in this embodiment includes a frame 1 and a heating furnace 2 installed on the frame, an air-filled claw 7, and a spiral tube mold 5. The outer surface of the spiral tube mold is provided with a spiral groove, and through the automatic The rotating and lifting device is connected with the frame, and the inflatable claw is connected with the frame 1 through the horizontal lead screw 6 and the longitudinal lead screw 8. The automatic production device also includes a control device, which is composed of a console 4, a control circuit 3 and a driving device. The console 4 is connected to the driving device through the control line 3, and the driving device controls the actions of the inflatable claw 7 and the rotary tube mold 5 to be connected with each other when processing the lamp tube. The control device can realize numerical control automation in the production of lamp tubes, and achieve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com