Electromechanical integrated induction heating numerical control hot-machining equipment

An induction heating and body technology, which is applied in the field of electromechanical integration induction heating numerical control thermal processing equipment, can solve the problems of inability to store process parameters, low control precision, and poor movement stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

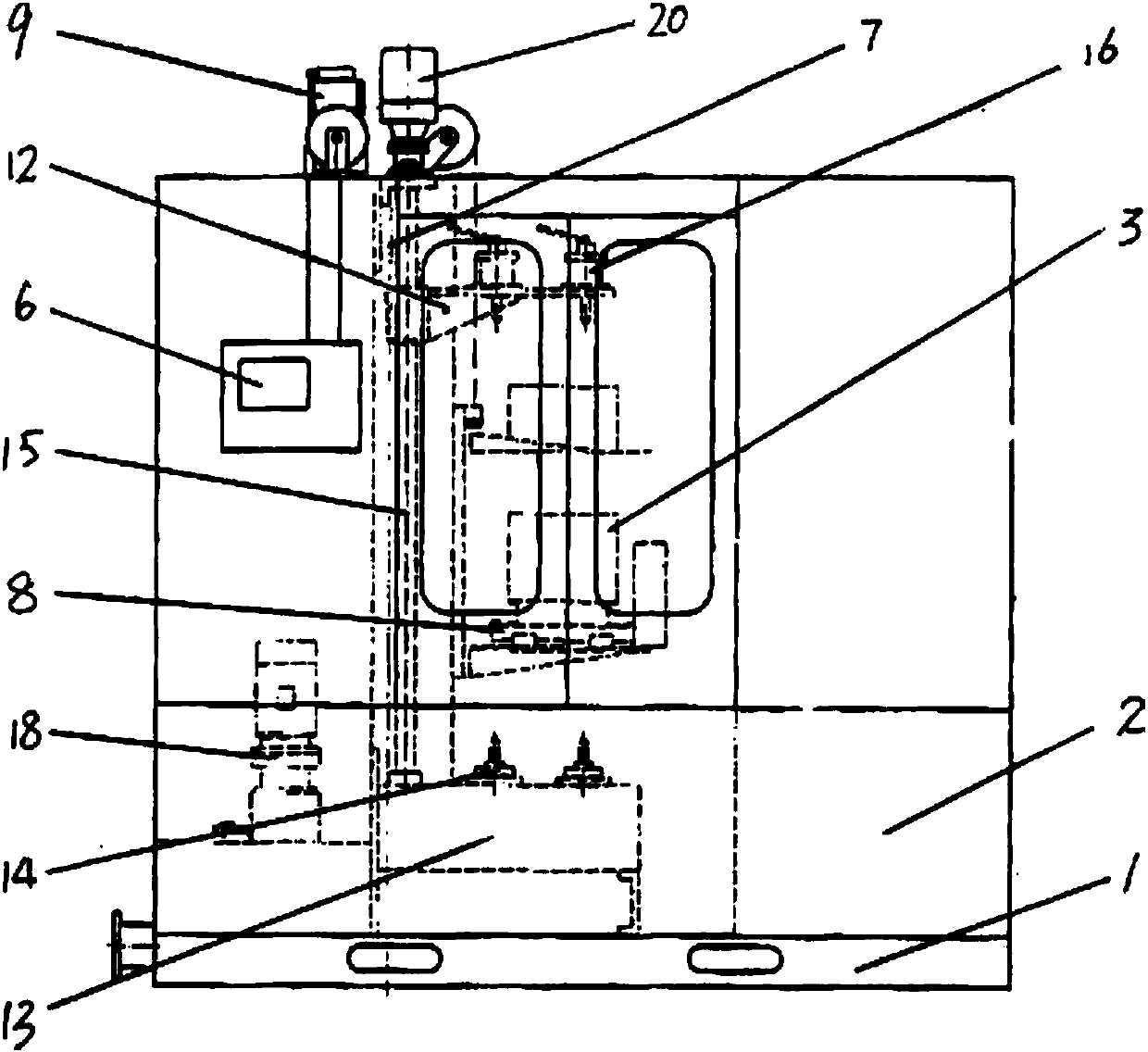

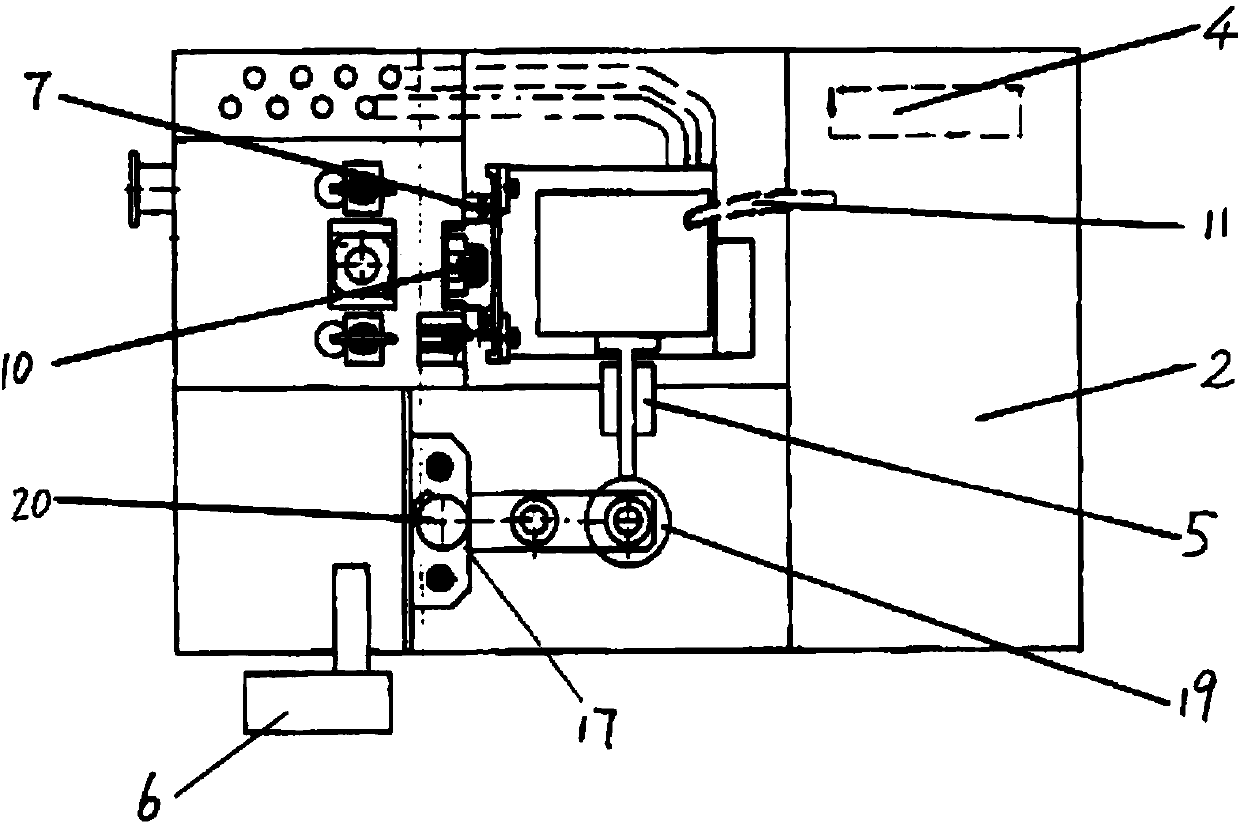

[0008] The figure includes a bed body 1, a transistor frequency conversion power supply 2, an induction heating load part 3, a cooling waterway 4, a quenching waterway 5, a numerical control electrical device 6, etc., and is characterized in that: there is a lifting guide rail 7 on the bed body 1, and the lifting guide rail There is a horizontal two-dimensional (X, Y axis) horizontal platform 8 on the 7, and an induction heating load part 3 is arranged on the horizontal platform 8; the horizontal platform 8 is driven by a ball screw 10 driven by a servo motor 9 on the bed body 1; The induction heating load part 3 is connected to the transistor frequency conversion power supply 2 by the cable 11, the induction heating load part 3 and the transistor power supply 2 are equipped with a cooling water circuit 4, and the quenching water circuit 5 is installed on the induction heating load part 3, on the other side of the lifting guide rail 7 , is the workpiece clamping device, and its...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com