Kitchen waste recovery and treatment system

A technology for recycling and processing food waste, which is applied to organic fertilizers, climate change adaptation, and solid waste removal. It can solve the problems of organic fertilizer quality reduction, high water content, and low efficiency of solid-liquid separation at one time, so as to improve moisture content. Cleaning rate and effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with specific embodiment and accompanying drawing, the present invention is further elaborated and illustrated:

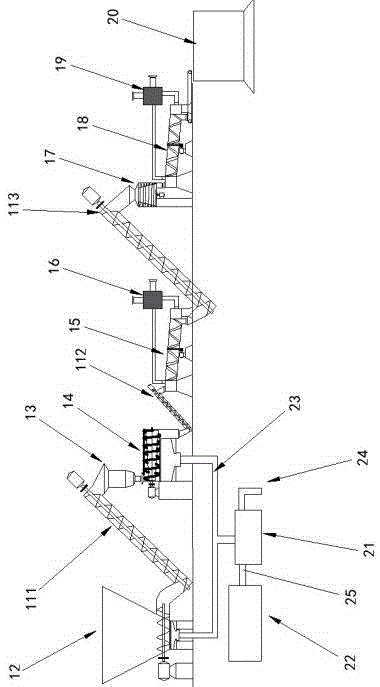

[0032] Please refer to figure 1 , the food waste recovery and treatment system, including a waste storage box 12, a transmission mechanism, a pulverizer 13, a screw press 14, a first dryer 15, a first energy recovery mechanism 16, a screw granulator 17, a second drying machine Machine 18, second energy recovery mechanism 19, fertilizer storage tank 20, oil-water separator 21, oil storage tank 22 and waste water connecting pipe 23. The conveying mechanism includes a first screw conveyor 111 , a second screw conveyor 112 and a third screw conveyor 113 .

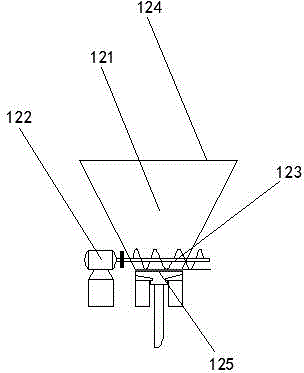

[0033] Please refer to figure 2 , the garbage storage box 12 includes a box body 121, a push motor 122 and a push screw 123, the push screw 123 is provided with a helical groove, the push screw is located in the box 121, and one end of the push screw 123 is provided At the output end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com