Sediment sludge dewatering device

A technology for dewatering equipment and sludge, which is used in water/sludge/sewage treatment, sludge treatment, dehydration/drying/concentrated sludge treatment, etc. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

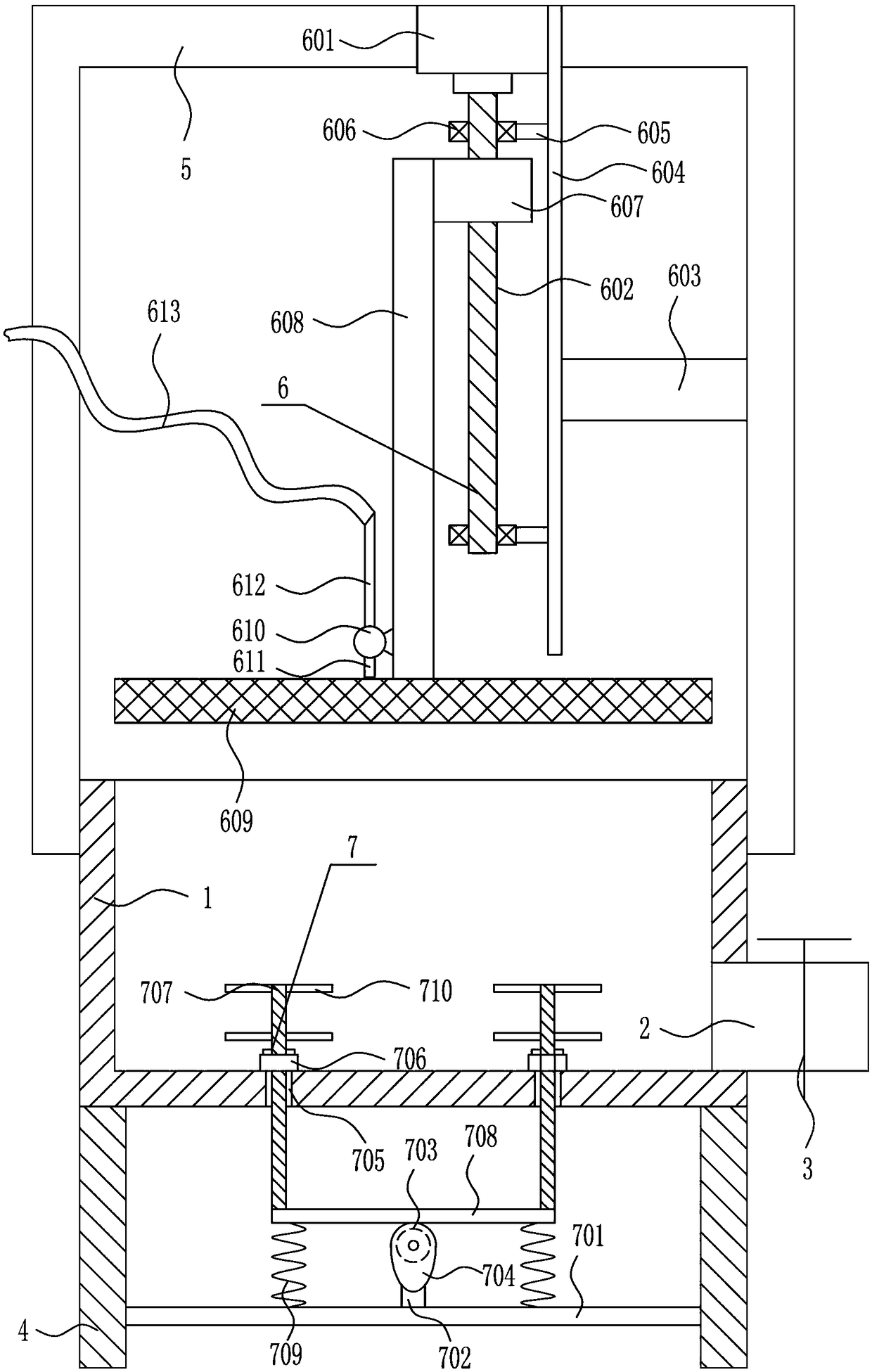

[0026] A sedimentation sludge removal equipment, such as Figure 1-2As shown, it includes a treatment box 1, a feed pipe 2, a valve 3, a leg 4, a protection frame 5, a pressing mechanism 6 and a shaking mechanism 7, and the right side of the treatment box 1 is provided with a feed pipe 2, and the feed pipe 2 is provided with a valve 3, the bottom of the processing box 1 is provided with a leg 4, the top of the processing box 1 is provided with a protective frame 5, and a pressing mechanism 6 is installed inside the protective frame 5, and a shaking mechanism 7 is installed on the processing box 1. .

Embodiment 2

[0028] A sedimentation sludge removal equipment, such as Figure 1-2 As shown, it includes a treatment box 1, a feed pipe 2, a valve 3, a leg 4, a protection frame 5, a pressing mechanism 6 and a shaking mechanism 7, and the right side of the treatment box 1 is provided with a feed pipe 2, and the feed pipe 2 is provided with a valve 3, the bottom of the processing box 1 is provided with a leg 4, the top of the processing box 1 is provided with a protective frame 5, and a pressing mechanism 6 is installed inside the protective frame 5, and a shaking mechanism 7 is installed on the processing box 1. .

[0029] The pressing mechanism 6 includes a first motor 601, a screw mandrel 602, a first pole 603, a first fixed pole 604, a second pole 605, a bearing seat 606, a nut 607, a second fixed pole 608, a mesh plate 609, Water pump 610, first conduit 611, second conduit 612 and water conduit 613, the middle of protection frame 5 top is installed with first motor 601, is connected wi...

Embodiment 3

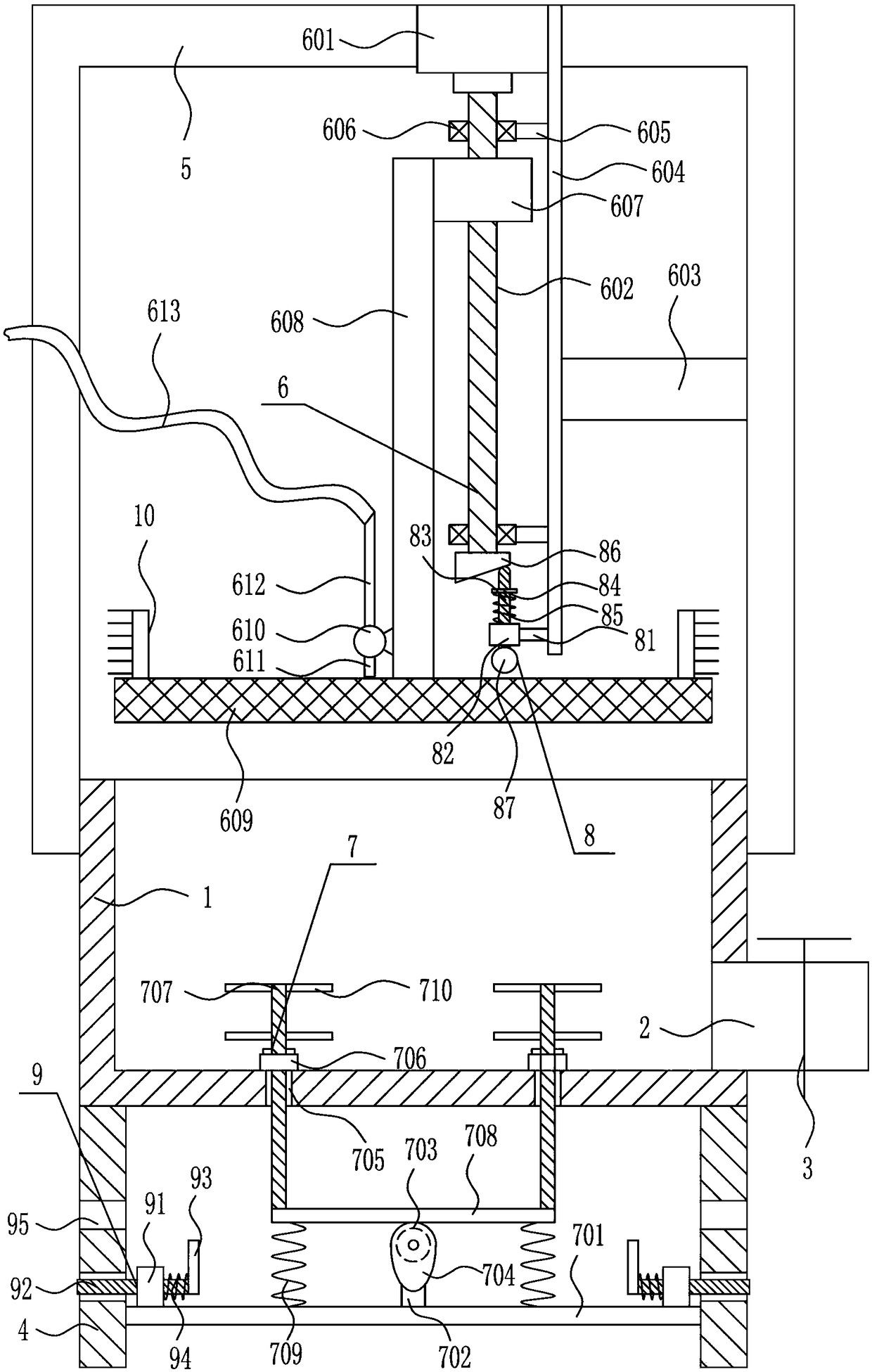

[0031] A sedimentation sludge removal equipment, such as Figure 1-2 As shown, it includes a treatment box 1, a feed pipe 2, a valve 3, a leg 4, a protection frame 5, a pressing mechanism 6 and a shaking mechanism 7, and the right side of the treatment box 1 is provided with a feed pipe 2, and the feed pipe 2 is provided with a valve 3, the bottom of the processing box 1 is provided with a leg 4, the top of the processing box 1 is provided with a protective frame 5, and a pressing mechanism 6 is installed inside the protective frame 5, and a shaking mechanism 7 is installed on the processing box 1. .

[0032] The pressing mechanism 6 includes a first motor 601, a screw mandrel 602, a first pole 603, a first fixed pole 604, a second pole 605, a bearing seat 606, a nut 607, a second fixed pole 608, a mesh plate 609, Water pump 610, first conduit 611, second conduit 612 and water conduit 613, the middle of protection frame 5 top is installed with first motor 601, is connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com