Nanofiber cluster membrane dryer

A technology of nanofibers and dryers, applied in chemical instruments and methods, separation of dispersed particles, separation methods, etc., can solve problems such as high manufacturing costs and complex structures, and achieve low cost, small volume, innovative effect and life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below in conjunction with embodiment the present invention is further described.

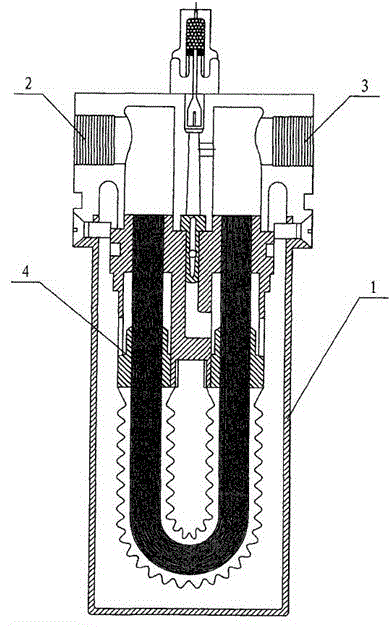

[0011] As shown in the figure, there are air inlets 2 and air outlets 3 on both sides of the cavity tube 1, and nanofiber bundles 4 are arranged in the cavity tube. The wet compressed air to be dried enters from the inlet 2 and passes through the inner hole of the nanofiber bundles. It is discharged from the air outlet 3, and the water in the gas to be measured will permeate from the inner wall to the outer wall due to the pressure difference between the inner and outer walls of the fiber bundle by using the membrane permeation principle of the polymer fiber. The nanofiber bundles 4 are twisted in the cavity, the sealing plugs at both ends are bonded by polymer glue, and the fiber bundles are made of nanopolymer materials. The gas to be dried enters from the gas, and is discharged from the gas outlet after passing through the inner hole of the nanofiber bundle. Using the membrane permeati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com