Dehydration device and dehydration method for plastic film fragments

A technology of plastic film and dehydration device, which is applied in the direction of the device where the axial direction of the swirling flow can be reversed, plastic recycling, swirling flow device, etc., can solve the problems that cannot be used in large-scale industrial production, and achieve good dehydration effect and simple operation , Improve the effect of water removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

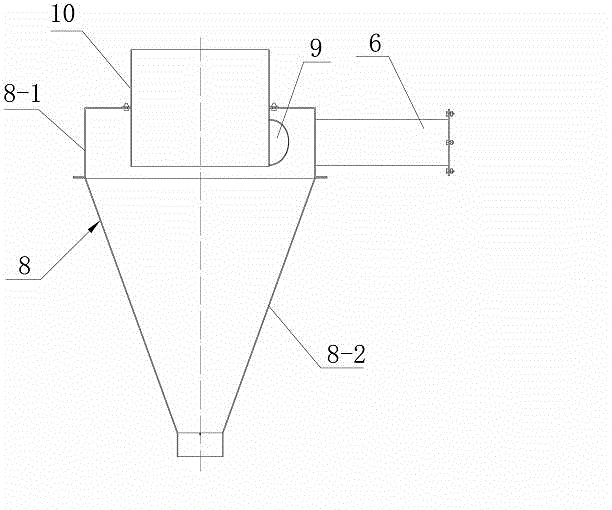

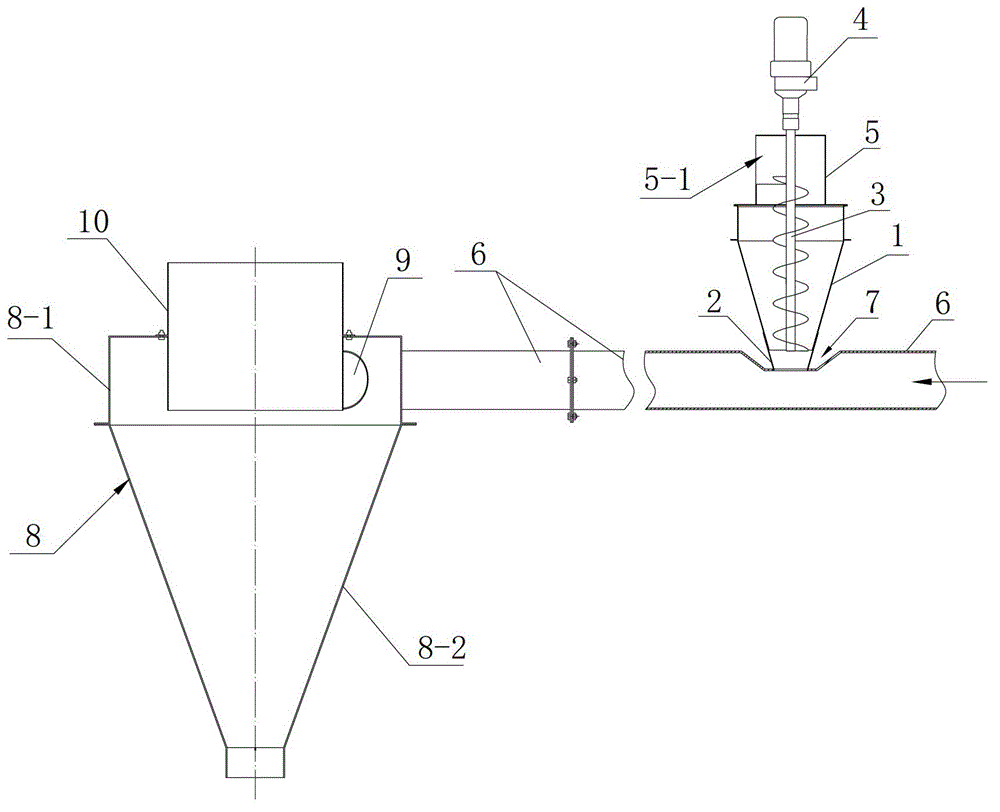

[0028] see figure 1 , The dehydration device of the plastic film fragments of the present embodiment is mainly composed of a dehydration cylinder 8, an air supply pipe 6, a discharge pipe 10 and a feeding mechanism.

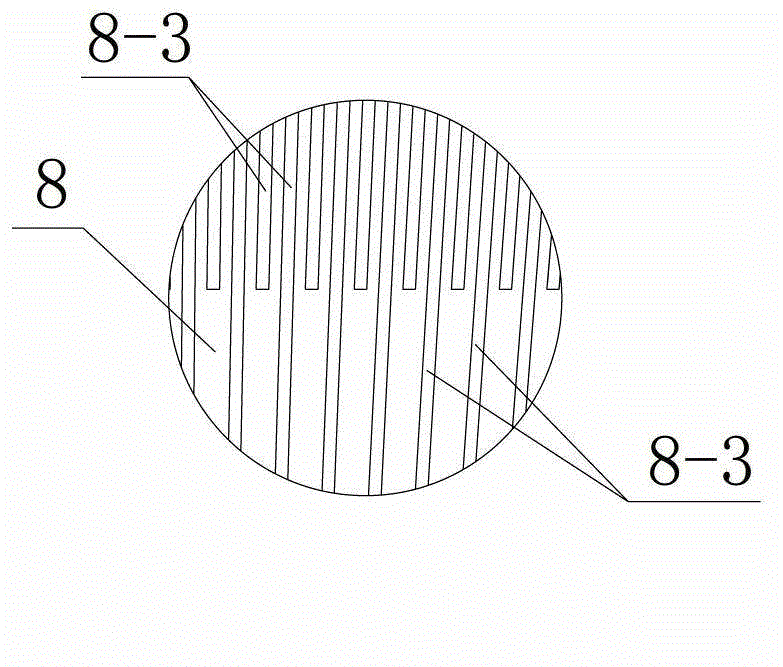

[0029] Referring to Fig. 2, the dehydration cylinder 8 is formed by bolting the upper circular section 8-1 and the lower conical section 8-2, wherein the circular section 8-1 is provided with a The air supply pipe 6 that the inner wall of circular section 8-1 is tangential, and forms air inlet 9 on the wall of circular section 8-1; The top (being the top of circular section 8-1) of dehydration cylinder 8 is provided with The end cover, the discharge pipe 10 is arranged coaxially with the circular section 8-1 and fixed on the end cover, the discharge pipe 10 passes through the end cover and extends downward into the circular section 8-1 , the lower port of which extends downward beyond the air inlet 9 . The lower end of the tapered section 8-2 is provided with a...

Embodiment 2

[0039] see Figure 7 , The difference between this embodiment and Embodiment 1 is that the groove structure is formed by a combination of strip structures 8-4 protruding outward on the cylinder wall.

[0040] Embodiments other than the above in this embodiment are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com