Drying method of silicon dioxide vacuum insulated panel

A technology of vacuum insulation panels and silicon dioxide, which is used in drying and heating to dry solid materials, dry solid materials, etc., can solve problems such as affecting the drying effect of products and unfavorable water loss, saving drying costs, The effect of shortening drying time and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The drying method combined with microwave and hot air circulation drying tunnel is used to produce silicon dioxide vacuum insulation panels, which specifically includes the following steps:

[0025] (1) adopting powder processing technology to prepare massive silica powder core material with smooth surface and regular corners;

[0026] (2) Pack the block silica powder core material prepared in step (1) into the cut non-woven bag to form the silica core material, and weigh its weight (m1), then first Dry at 150°C for 15 minutes by microwave drying, then quickly transfer to a circulating heating oven heated to 130°C for 15 minutes, take it out and weigh it (m2);

[0027] (3) For the dried silicon dioxide core material, prepare a silicon dioxide vacuum insulation board by packaging and vacuumizing, and test the thermal conductivity.

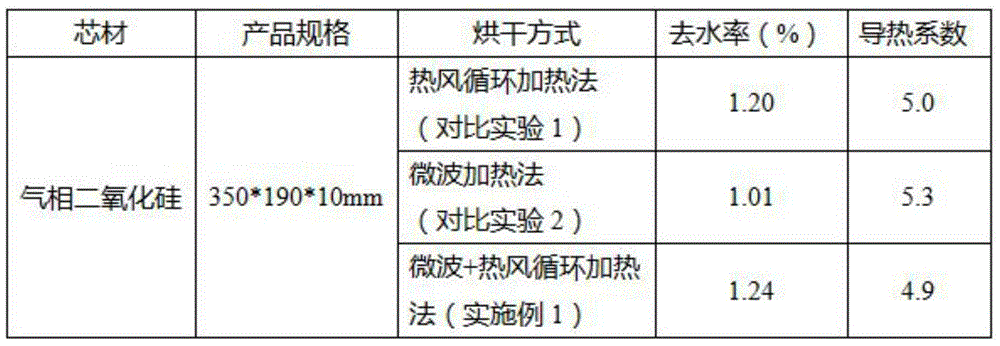

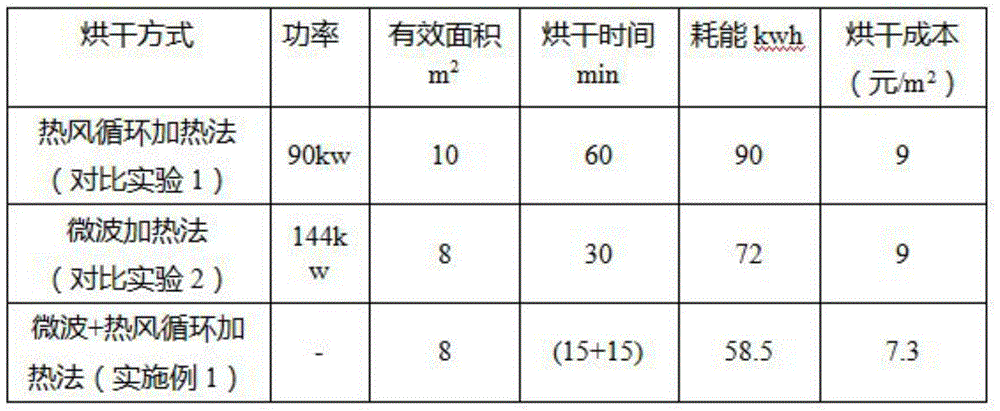

[0028] The influence of three different drying methods (circulation heating method, microwave drying method, microwave + circulation heatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com