Compressor dynamic anti-surge control method based on variable working condition running

A control method and compressor technology, which is applied in pump control, machine/engine, mechanical equipment, etc., can solve the problems of centrifugal compressor vibration and displacement rise, centrifugal compressor damage, pressure oscillation, etc., and achieve accurate panting prevention Vibration control, increase automation rate, and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

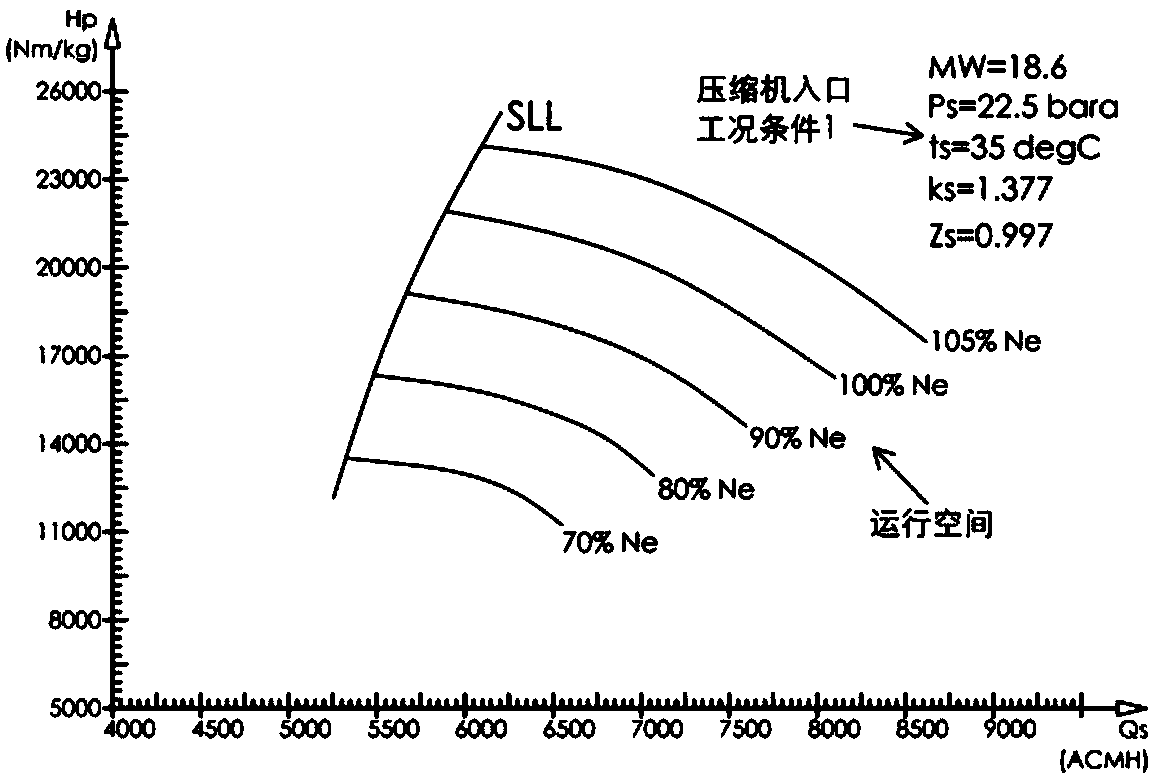

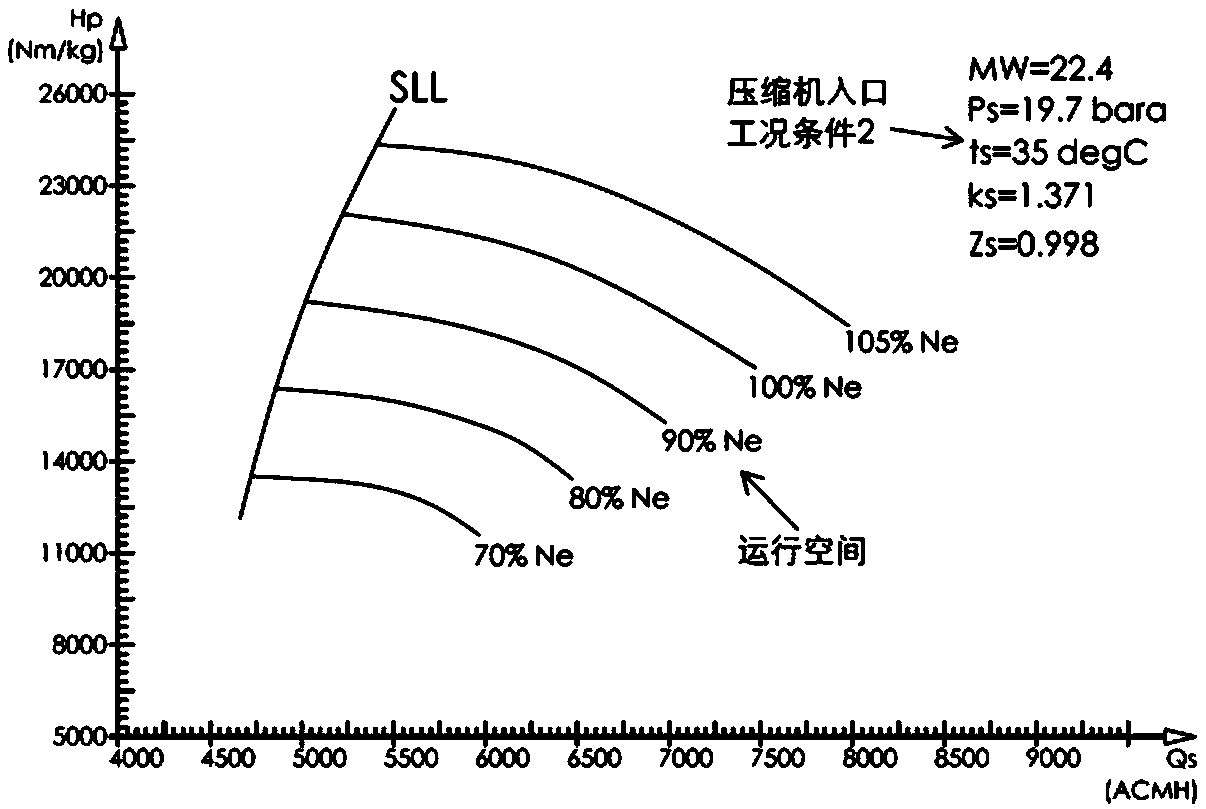

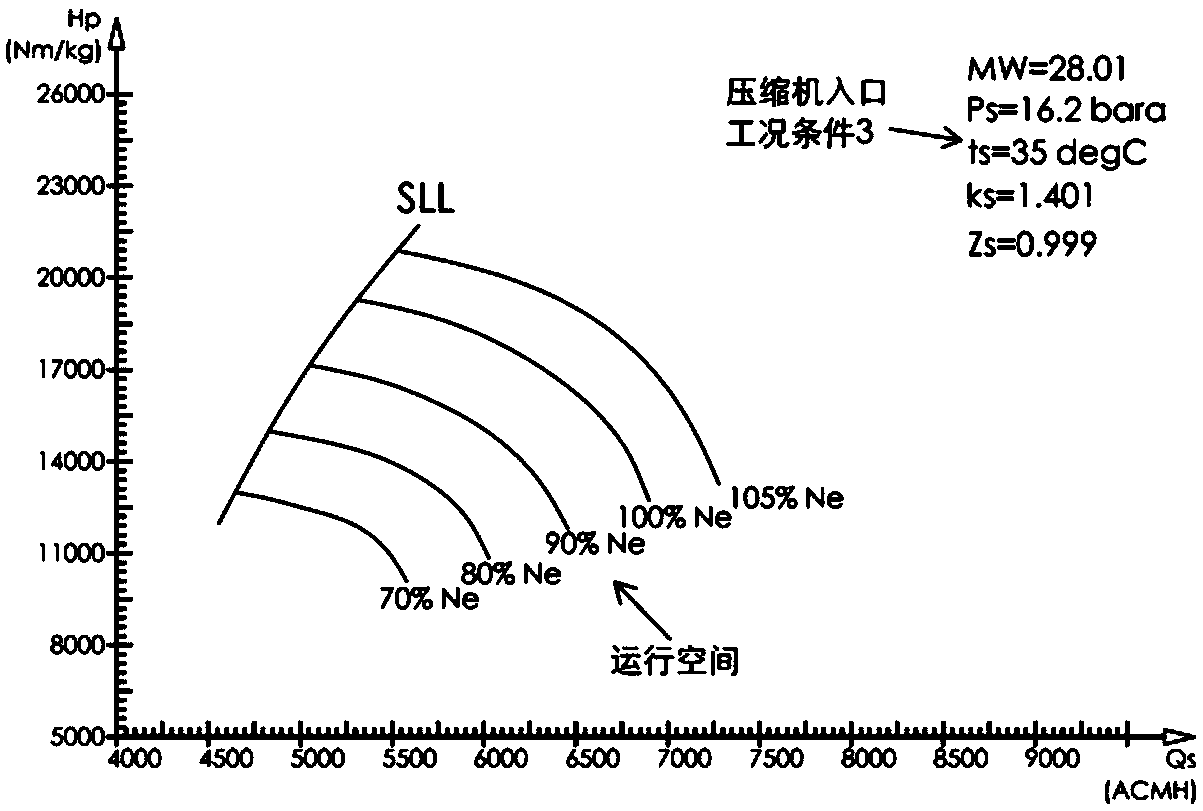

[0067] The present disclosure provides a dynamic anti-surge control method of a compressor based on variable working conditions. In the petrochemical process industry, a large number of centrifugal compressors are widely used to pressurize and transport various process gases to meet the production requirements of various chemical process devices. However, in the petrochemical industry, the gas molecular weight MW of the process gas compressor usually changes drastically, especially during the start-up stage of the device and different stages of the production cycle, the gas molecular weight MW may vary from several times to ten times, accompanied by many A large degree of variation of the inlet pressure Ps. Usually, if the molecular weight of the process gas changes by more than 20% ΔMW, it will cause great difficulties to the anti-surge control of the centrifugal compressor, and cause the anti-surge control of the centrifugal compressor to be unable to achieve accurate, safe,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com