Preparation device for preparing anticorrosive coating on outer surface of pipeline

A technology for preparing a device and an anti-corrosion layer, which is applied in the direction of pipeline anti-corrosion/anti-rust protection, pipeline protection, damage protection, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

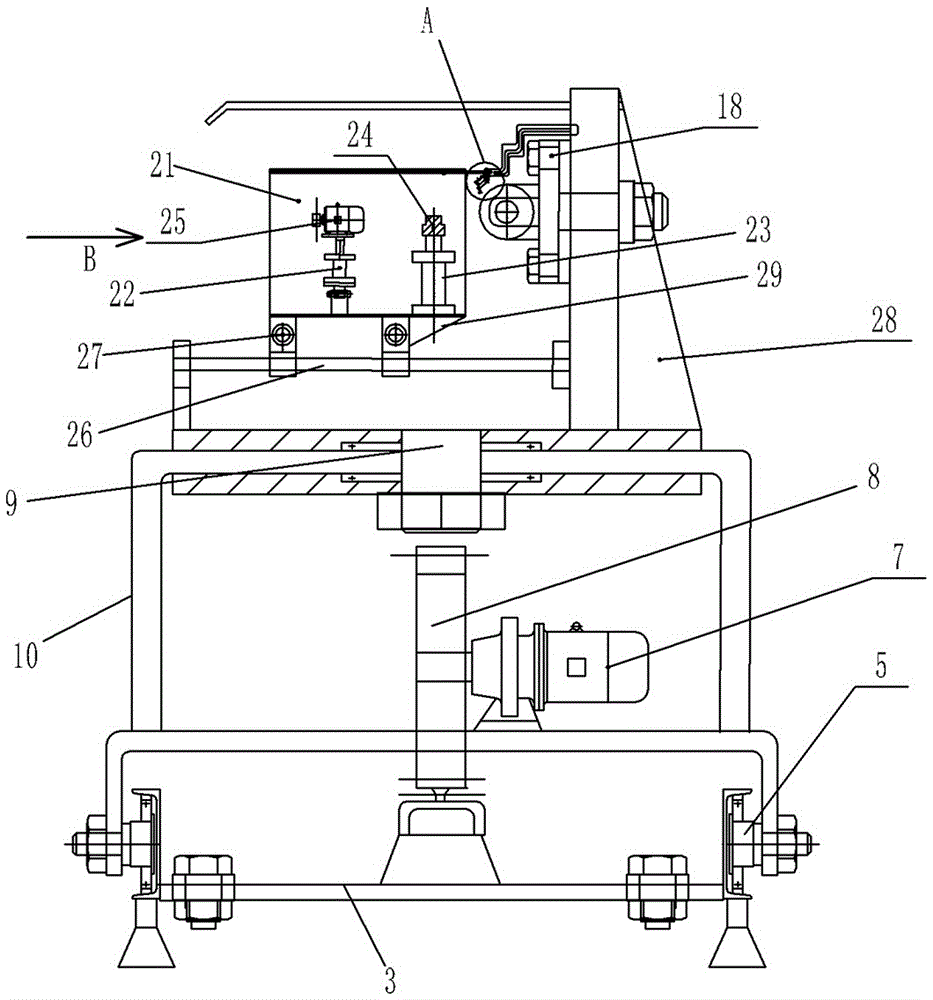

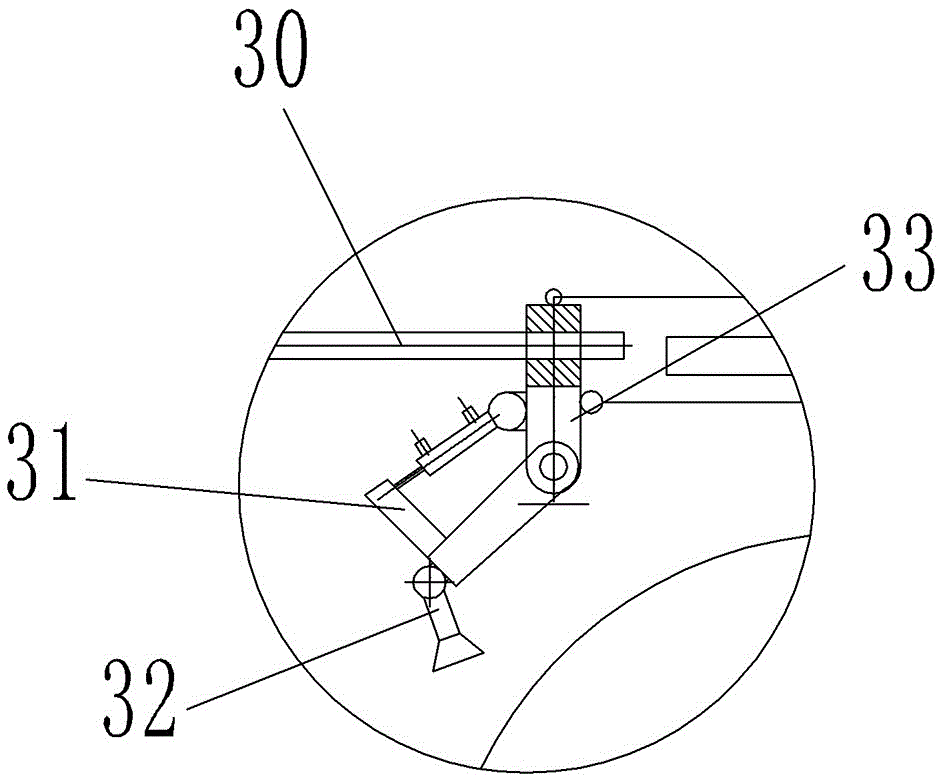

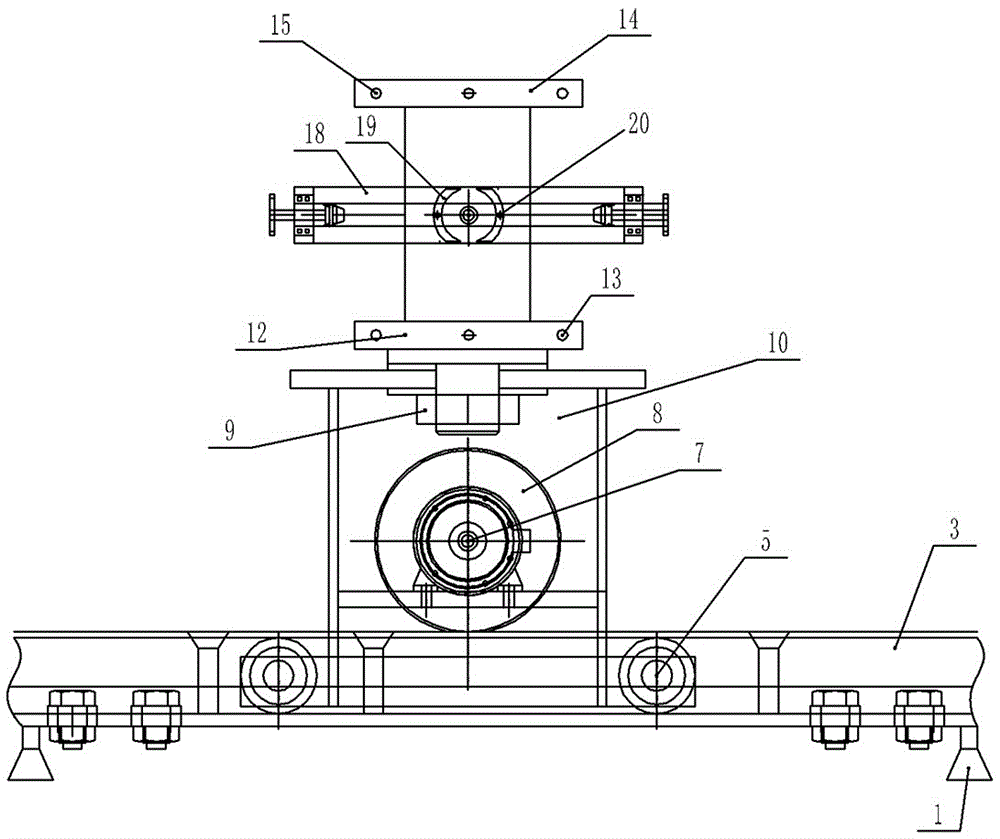

[0030] Such as Figure 1 to Figure 4 As shown, an embodiment of a preparation device for preparing an anticorrosion layer on the outer surface of a pipeline, the preparation device in this embodiment includes a track 3 extending axially along the pipeline to be prepared with an anticorrosion layer, and the bottom of the track 3 is provided with supporting feet 1. A support frame 10 is installed on the track 2 for guiding movement. The support frame 10 is rotatably equipped with a bottom frame 28 through a slewing mechanism extending up and down through the central axis of rotation. The bottom frame 28 is provided with a cloth for installing a cloth roll Roll mounting frame 18, also be provided with paint spraying mechanism on the bottom frame 28, the paint spraying mechanism here comprises the primer spraying mechanism 12 that is used to spray primer on the pipeline outer peripheral surface of rotation and is used for being wound on the pipeline peripheral surface The outer la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com