Laminated slab upending machine

A technology of flipping machine and laminated board, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of primitive and backward production methods, low efficiency, unable to meet the needs of industrialization of residential buildings, etc., to improve the factory prefabrication rate and automation rate. , The effect of advanced production technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

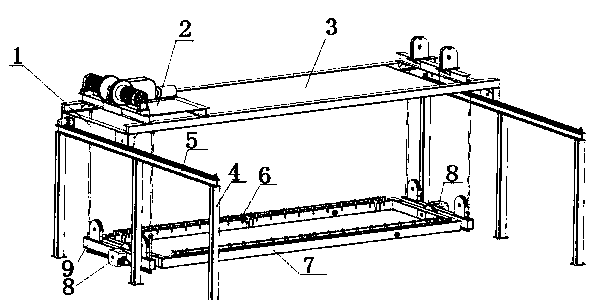

[0015] see figure 1 , the laminated plate turning machine of the present invention, the column 4 is installed and fixed on the ground, the support beam 5 is installed on the upper end of the column 4, the main beam and the walking platform 3 guide and walk on the supporting beam through the walking mechanism 1, and the main beam and the walking platform 3 are installed There is a double-drum hoisting mechanism 2, and the double-drum hoisting mechanism 2 is hoisted with a fixed frame 9 through a wire rope and a pulley. The fixed frame 9 is equipped with an overturning frame 7 and an overturning machine 8, and the overturning machine 8 is connected to drive the overturning frame. The hydraulic clamping device 6 for clamping the steel trolley and the workpiece is installed on the overturning frame 7 .

[0016] The above-mentioned double-drum hoisting mechanism is installed at both ends of the main beam and the walking platform, and the double-drum hoisting mechanism lifts or low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com