Processing and production method of dough sheets

A production method and technology of face leaf, applied in the field of face leaf processing and production, can solve problems such as easy generation of waste and inability to achieve continuity, and achieve the effects of reducing pollution, improving production quality, and improving lubricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

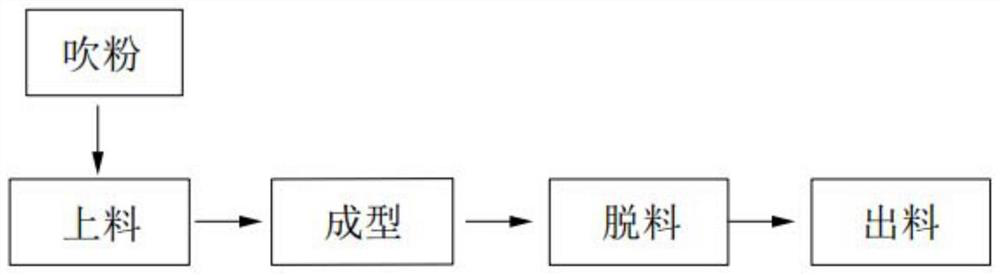

[0078] Such as figure 1 Shown, a kind of face leaf processing production method, it comprises the following steps:

[0079] Step 1, the feeding process, the first conveying mechanism 1 conveys the dough 10 along its conveying direction;

[0080] Step 2, powder blowing process, the first conveying mechanism 1 conveys the dough to the second conveying mechanism 2, and the bottom of the dough 10 is blown by the powder blowing device 3 below the second conveying mechanism 2;

[0081] Step 3, forming process, the second conveying mechanism 2 conveys the dough 10 to the first base 41, the driving member 45 drives the first forming part 42 to move upward, and at the same time, the first rack 441, the second rack 442 and the gear 443 Mesh with each other, the second forming part 43 moves downward synchronously, the second cutter 52 cuts off the dough 10, the first forming plate 442 cooperates with the second forming plate 432 to press the dough into an M shape, and the track 4336 con...

Embodiment 2

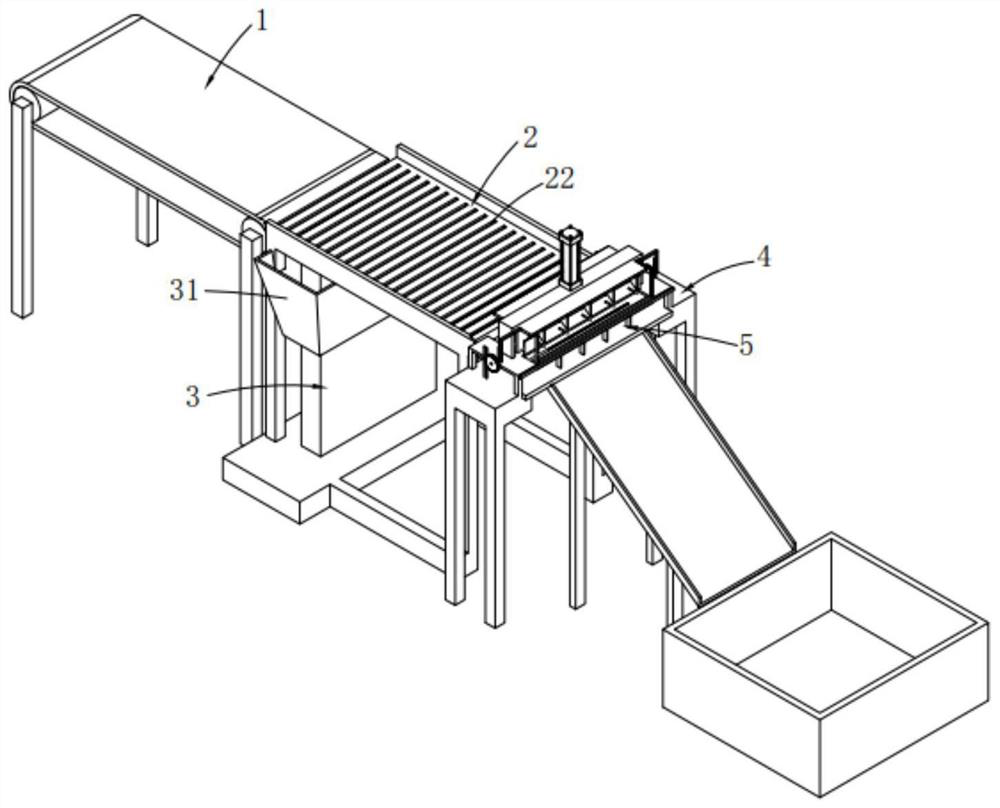

[0100] Such as Figures 2 to 5 Shown, a kind of butterfly surface processing production device, it comprises:

[0101] The first conveying mechanism 1, the first conveying mechanism 1 conveys the dough 10 along its length direction;

[0102] The second conveying mechanism 2, the second conveying mechanism 2 is arranged at the output end of the first conveying mechanism 1 along the conveying direction of the first conveying mechanism 1;

[0103] A powder blowing device 3, the powder blowing device 3 is located below the second conveying mechanism 2, and it blows powder on the dough 10 on the second conveying mechanism 2;

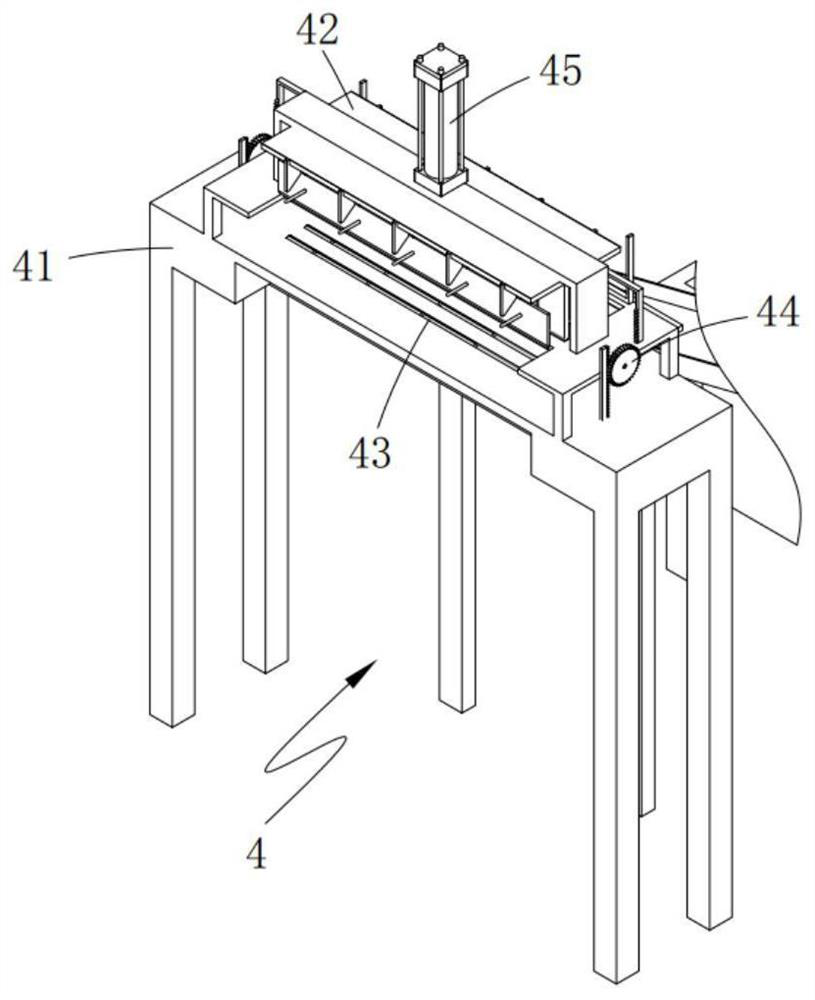

[0104] The forming mechanism 4 is located at the output end of the second conveying mechanism 2 along the conveying direction of the second conveying mechanism 2, and the forming mechanism 4 includes a first base 41, a first molding 42, a second Forming part 43, linkage assembly 44 and driving part 45, the first forming part 42 is slidably arranged below th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com