Lower discharging device of powder and particle material transport vehicle

A technology of a discharging device and a transport vehicle, which is applied in the direction of object transport vehicles, transportation and packaging, and transporting objects, and can solve the problem of dead angles between the discharge port and flange parts, excessive volume of the discharge port, and insufficiently simple structure, etc. problem, to achieve the effect of no dead angle, small size and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

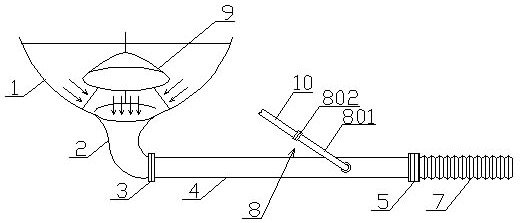

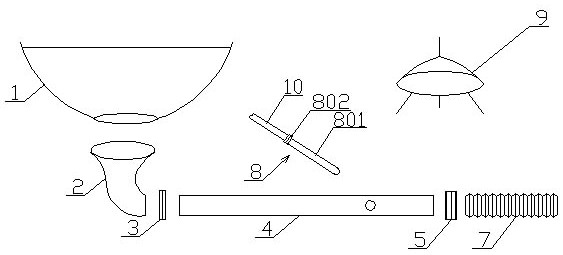

[0025] as attached figure 1 , 2 , 5, a discharge device under a powder material transport vehicle of the present invention, its structure includes a variable diameter elbow 2 arranged on the tank body 1, the variable diameter elbow 2 is arc-shaped, and one port diameter is relatively The diameter of the other port is relatively large, the large diameter end communicates with the bottom of the tank body 1, the small diameter end communicates with the feed end of the connection material pipe 4 through the flange 3, and the discharge end of the connection material pipe 4 passes through The discharge butterfly valve 5 is connected with the discharge hose 7, the connecting material pipe 4 is a straight material pipe, and a material booster 8 is arranged on the connecting material tube 4, and the material booster 8 includes a A booster pipe 801 connected to each other, and a booster valve 802 connected to the external air source 10 is arranged on the booster tube 801 .

[0026] A ...

Embodiment 2

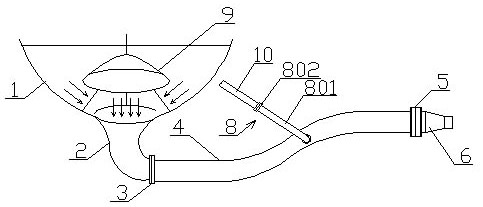

[0028] as attached image 3 , 4 As shown, a discharge device under a powder material transport vehicle of the present invention has a structure including a reducing elbow 2 arranged on the tank body 1, the reducing elbow 2 is arc-shaped, and the diameter of one port is relatively small , the diameter of the other port is relatively large, the large-diameter end communicates with the bottom of the tank body 1, the small-diameter end communicates with the feed end of the connection material pipe 4 through the flange 3, and the discharge end of the connection material pipe 4 passes through the discharge The butterfly valve 5 is connected with the quick connector 6, the connecting material pipe 4 is an S-shaped material pipe, and a material boosting device 8 is arranged on the connecting material tube 4, and the material boosting device 8 includes an auxiliary material connected with the connecting material tube 4. The push tube 801 is provided with a boost valve 802 connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com