Dough sheet production device and puff production equipment

A technology of production device and production equipment, applied in the field of dough sheet production device and puff production equipment, can solve the problems of complicated production process, waste of leftovers and the like, and achieve the effects of improving utilization rate, improving production efficiency and facilitating cleaning of forming cups

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

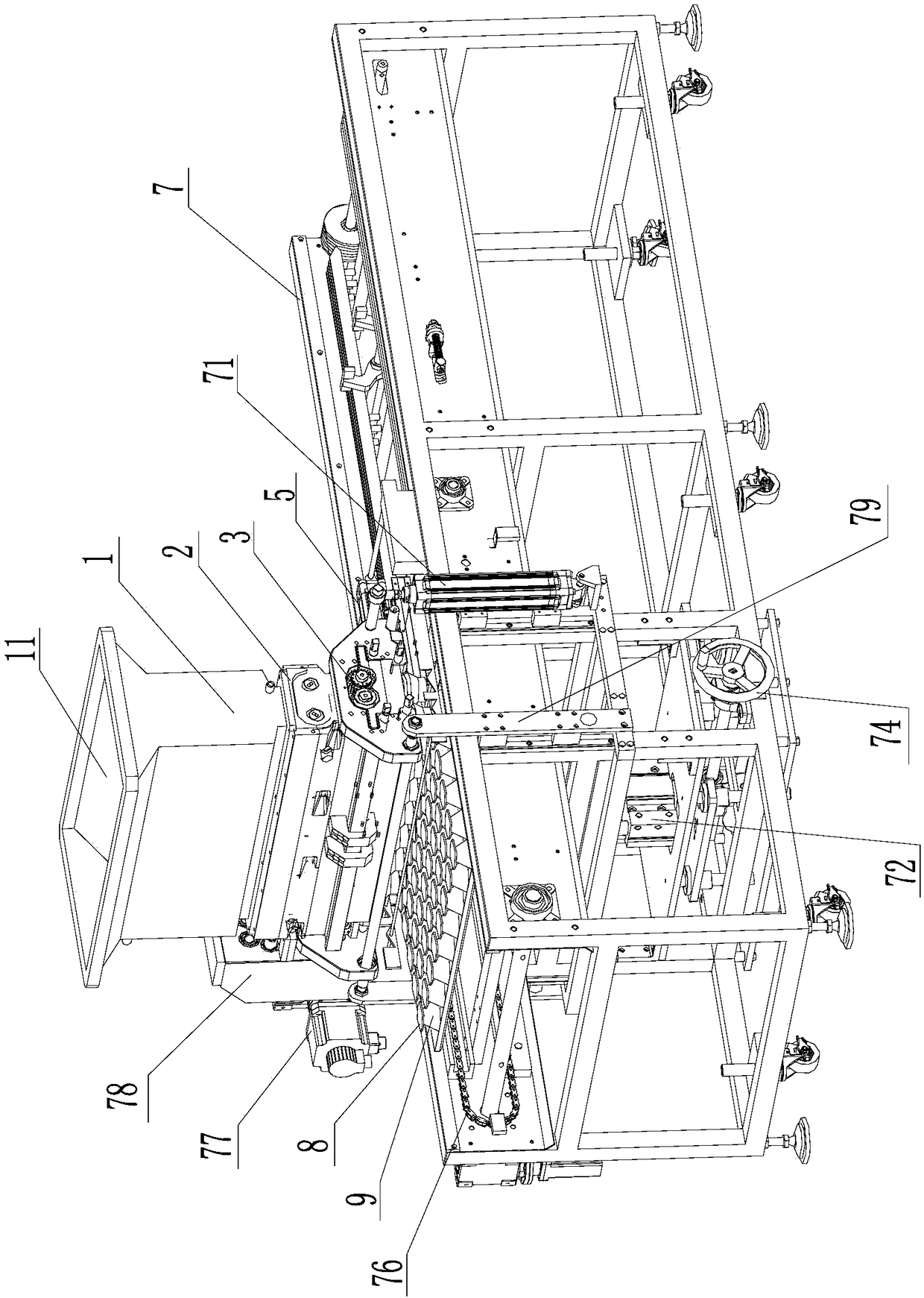

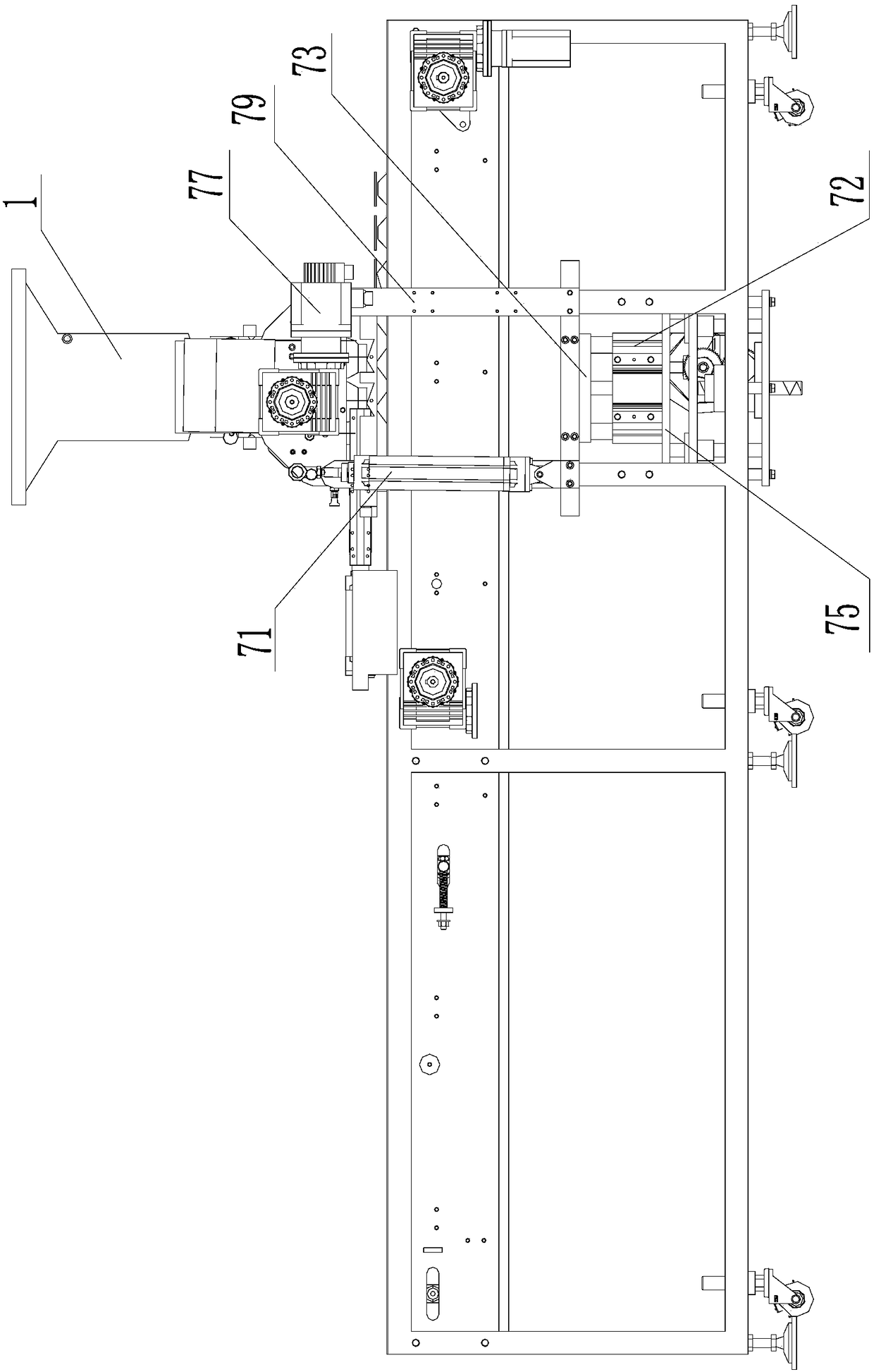

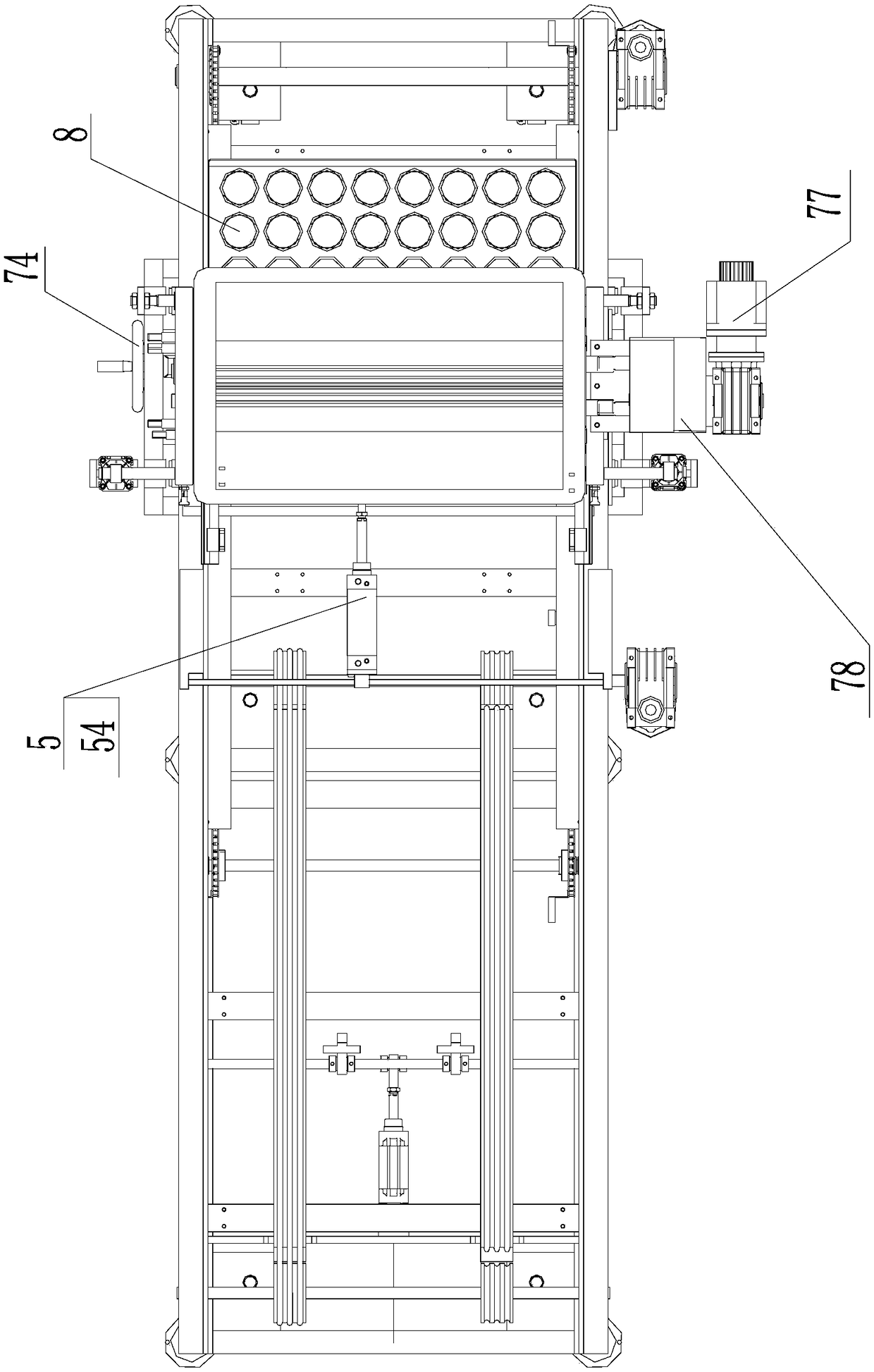

[0047] like Figure 1-4 As shown, the puff production equipment of an embodiment of the present invention includes the noodle production device of the present invention and the puff conveying device 76. The puff conveying device 76 includes a plate that sets off the puffs 9 and a chain that drives the plate to move back and forth. The chain Driven by a motor 77 . The puff conveying device 76 is positioned at the below of the noodle production device. When the puff 9 passes through the noodle 8 production equipment, the noodle 8 produced by the noodle production device is covered on the puff 9 to form a "pineapple skin".

[0048] The dough sheet 8 production equipment of the present invention comprises a hopper 1, a feeding roller 2, a feeding pump 3, a forming cup 4 and a cutting device 5. In this embodiment, the hopper 1, the feeding roller 2, the feeding pump 3, the forming cup 4 and the cutting device 5 are arranged in order from top to bottom, and the hopper 1, the feedin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com