A method for making computer embroidery shaped shoe uppers

A production method and embroidery technology, applied in the field of shoes, can solve problems such as blindness, damage to kidney function, symptoms of respiratory diseases, etc., and achieve the effects of small production engineering, improved aesthetics and visual effects, and high automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

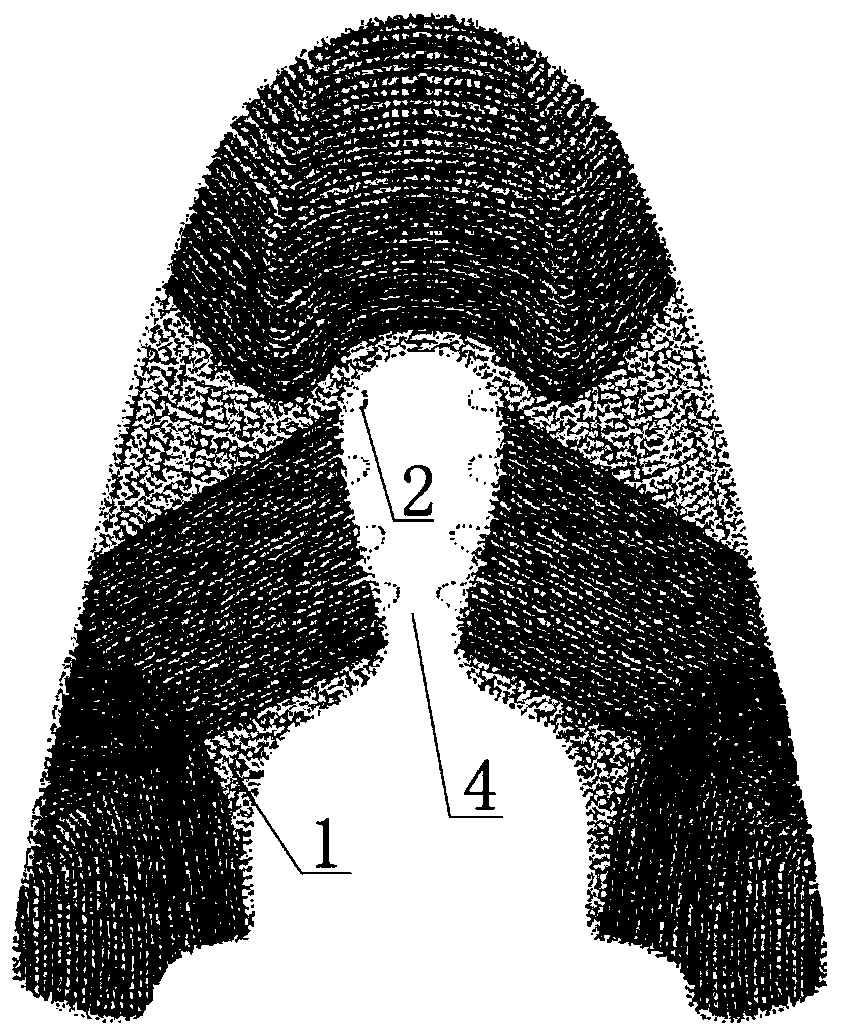

[0040] Such as figure 1 As shown, two layers of wrapped yarn are embroidered on the head, middle and tail of the vamp body 1, the second layer of wrapped yarn embroidered on the head is generally bow-shaped, and the stitches are wavy; the embroidery is in the middle of the vamp The second layer of wrapping yarn is close to a parallelogram as a whole, and the stitches are parallel straight lines; the second layer of wrapping yarn embroidered on the tail of the shoe upper is almost semicircular as a whole, and the stitches are arc-shaped. The second layer of wrapped yarn embroidered in the middle of the shoe upper is partially embroidered on the second layer of wrapped yarn at the tail to form a third layer of wrapped yarn, and the third layer of wrapped yarn is visually presented as a fan-shaped pattern.

Embodiment 2

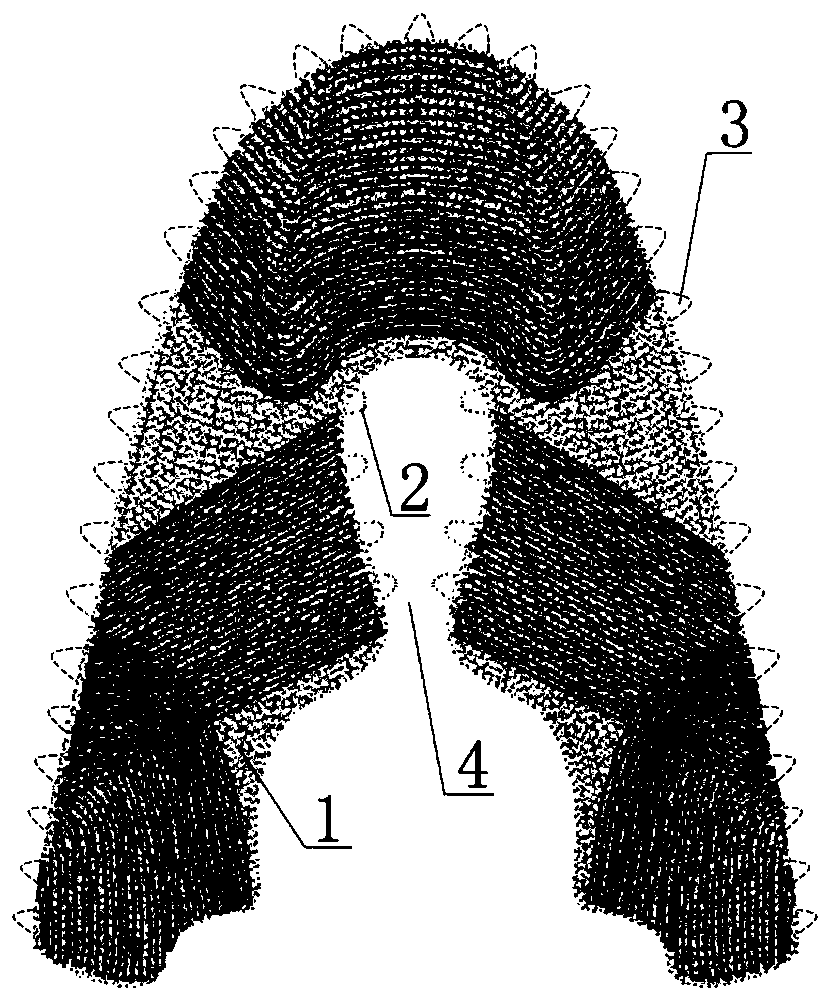

[0042] Such as figure 2As shown, the inner periphery of the notch 4 of the upper body 1 is provided with an inner ring 2 for tying shoelaces. On the basis of Embodiment 1, an outer ring 3 is provided on the outer periphery of the upper body 1. The outer ring 3 is connected with the vamp body 1 as a whole. When making finished shoes, the outer ring 3 can be embedded in the sole, and the outer ring 3 is used as a reinforcing rib arranged between the upper and the sole, which can disperse the stress on the joint between the upper and the sole during the use of the shoe. Pull to avoid opening. The test results show that the maximum tensile force that can be borne between the vamp and the sole increases by 40-70% after the outer ring 3 is added.

Embodiment 3

[0044] The upper thread and bottom thread made of polyester, and the wrapping yarn made of polyester wrapped in polyester are selected as production materials, and the upper thread and the bottom thread are embroidered on the hot-melt lining by using a computer winding embroidery machine to embroider the wrapping yarn on the hot-melt lining to form a shoe upper. The embroidery layers, patterns and stitches of the upper are as follows figure 2 shown. Put the embroidered upper into the hot-melt glue machine for dissolution and shaping. The results show that when the temperature is set to 200°C, the hot-melt lining is completely dissolved in about 9s. After taking out the upper, its spatial structure is stable, and all indicators meet the production standards.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com