Automatic forming method and device for rubber sealing ring blank

A rubber sealing ring and automatic molding technology, which is applied to other household appliances, household appliances, household components, etc., can solve the problems of high flexibility, affecting the performance of rubber rings, and low molding efficiency, so as to achieve high flexibility and blanks. The effect of high utilization rate and strong versatility of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] An automatic forming method for a rubber sealing ring blank, which specifically comprises the following steps:

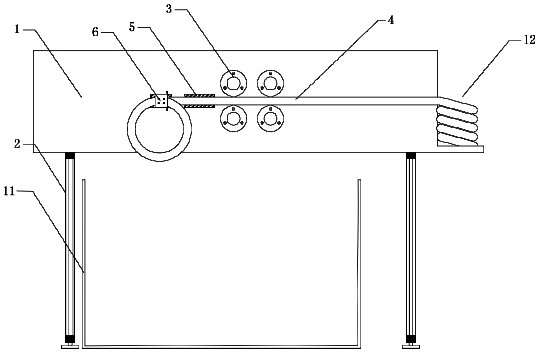

[0047] S1. After the rubber billet is compounded, it is extruded into a billet strip 4 by a rubber extruder, and then wound on the billet bobbin 12;

[0048] S2, pulling the blank strip 4 on the blank spool 12 into the guide wheel 3, and controlling the guide wheel 3 to transport the blank strip 4 forward;

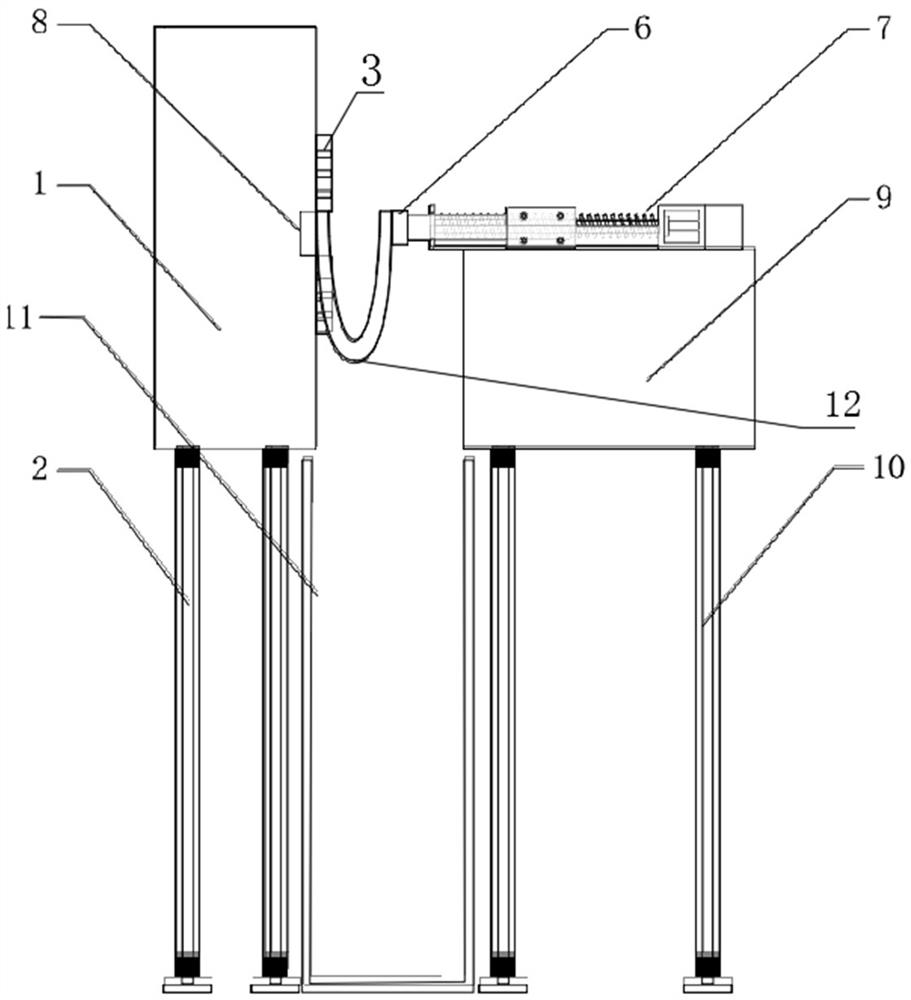

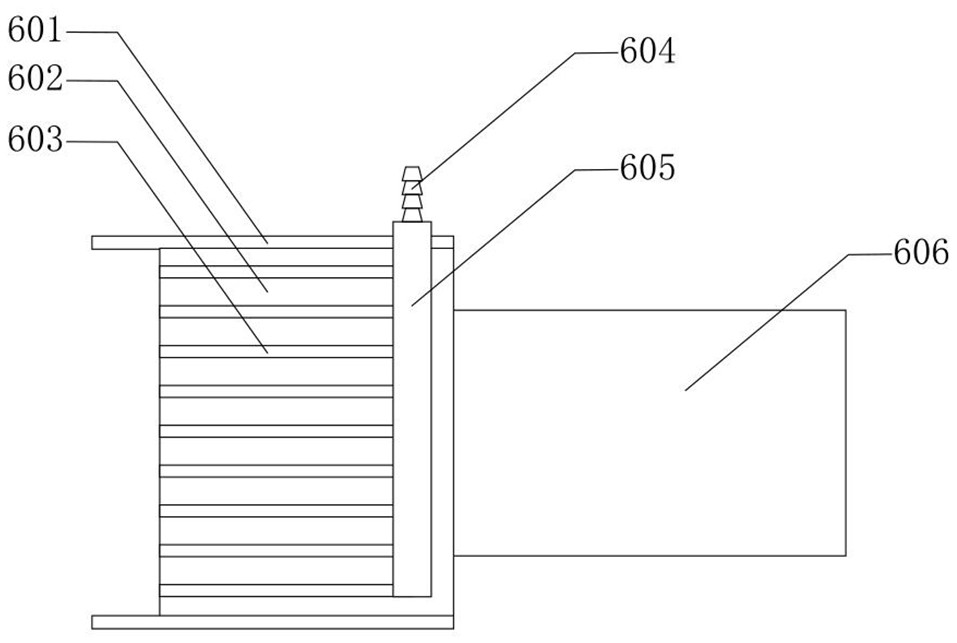

[0049] S3. After the blank strip 4 is guided by the guide groove 5, its end is adsorbed by the component air hole array 603 of the blank forming component 6 in the forming area, and is driven by the sliding table module 7 to move away from the equipment main body 1. Direction, At the same time, the guide wheel 3 transports the blank forward, and at the same time, the rotating mechanism 606 drives the blank forming assembly 6 to rotate along a plane that forms a ninety-degree angle with the moving direction of the slide module 7;

[0050] S4, the blank fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com