Manufacturing method of large-diameter thin-wall circular ring of pressure bearing equipment

A technology of pressure-bearing equipment and manufacturing methods, which is applied in the field of manufacturing thin-walled rings, can solve the problems of low production efficiency, high material costs and high manufacturing costs, and achieve the effects of reducing consumption, reducing material costs and manufacturing costs, and improving material utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

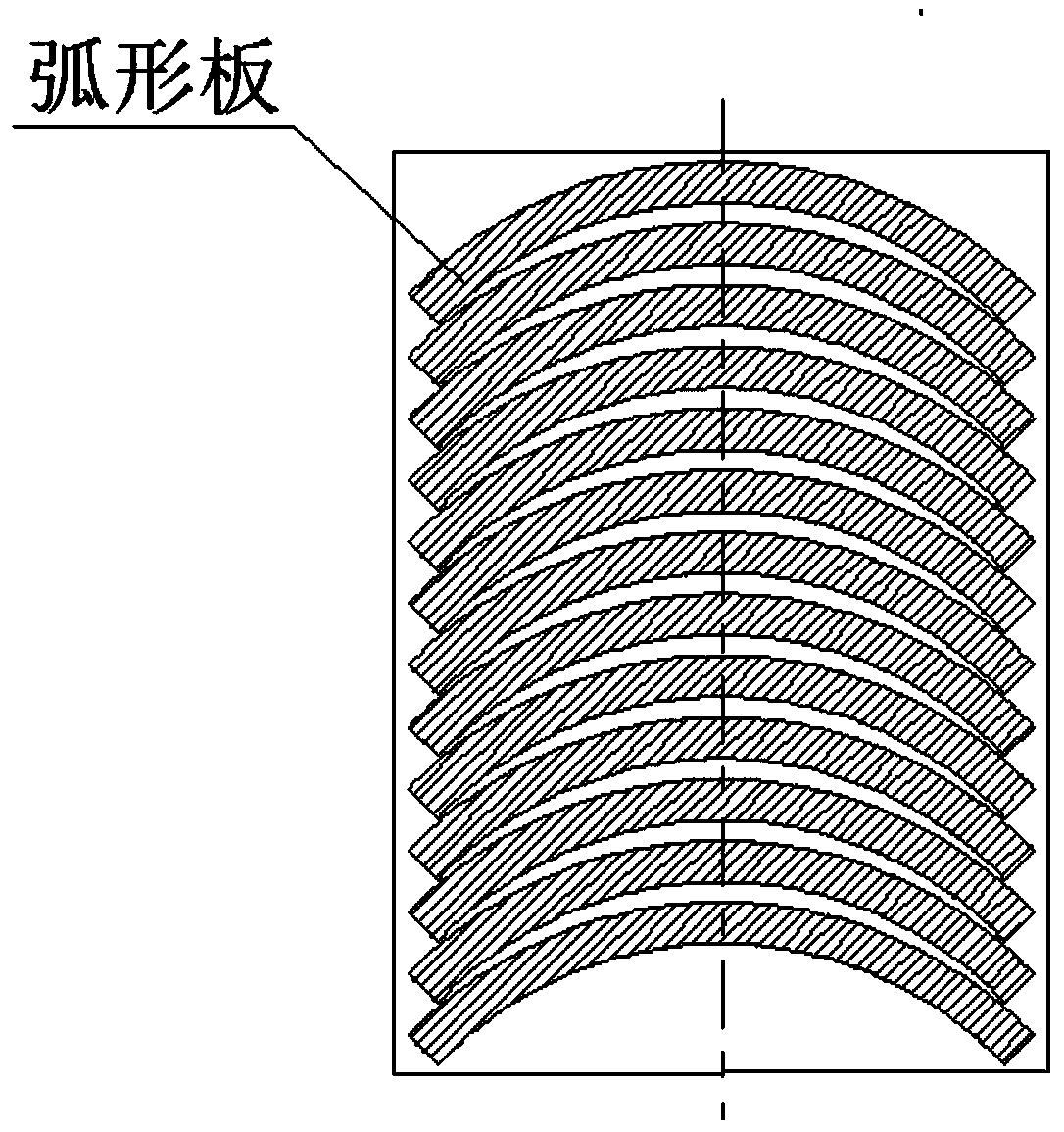

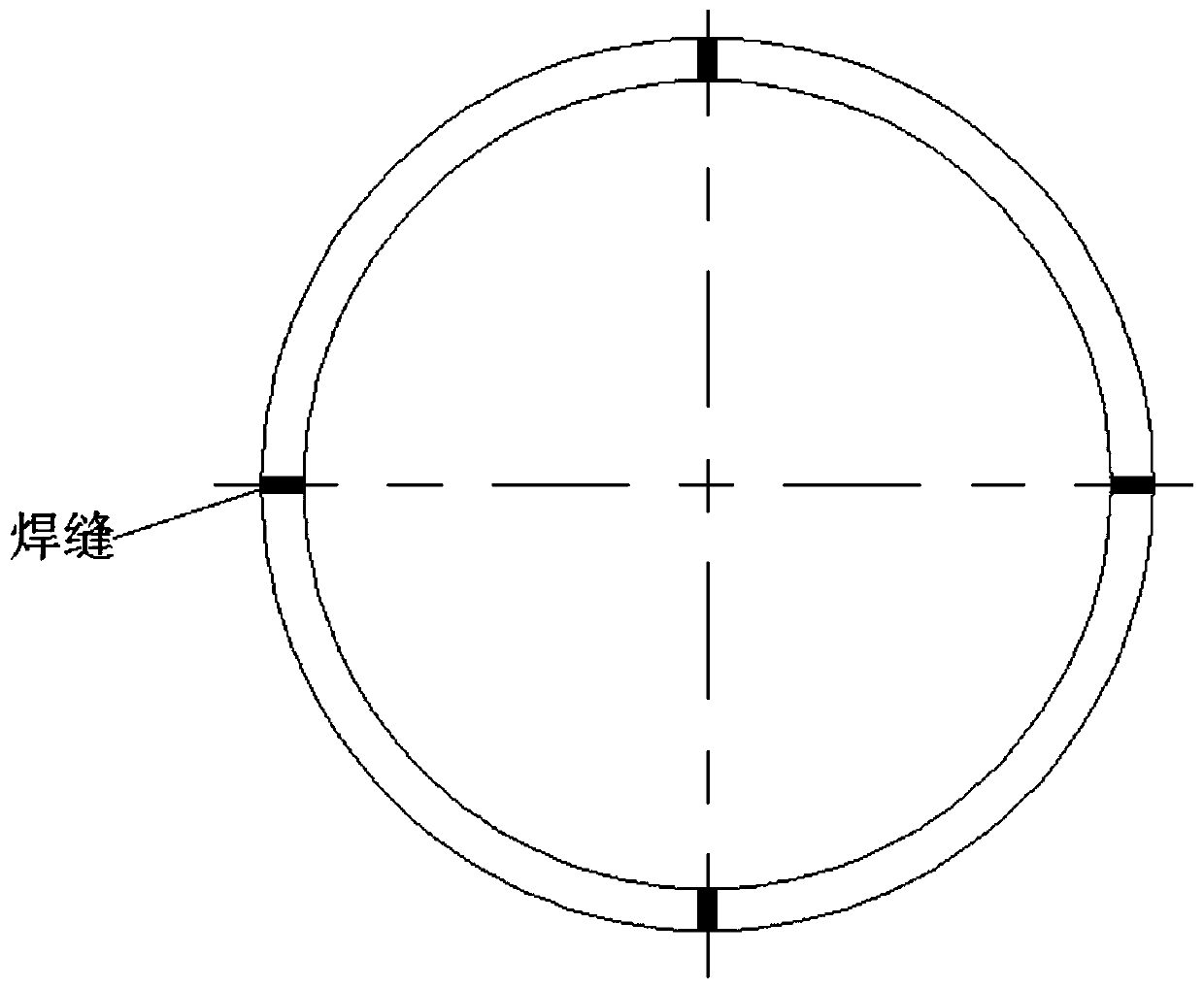

[0024] Specific implementation mode 1: The manufacturing method of the large-diameter thin-walled ring of the pressure-bearing equipment in this implementation mode is carried out according to the following steps:

[0025] 1. Scribing and cutting the steel plate to obtain a rectangular steel plate, and process the groove of the longitudinal seam;

[0026] 2. Roll the steel plate obtained in step 1 into a cylinder;

[0027] 3. Tailor welding the longitudinal seam and grinding the weld seam;

[0028] 4. Correct the roundness of the cylinder;

[0029] 5. Install and weld rigid support components in the cylinder;

[0030] 6. Fix one end of the cylinder on the lathe chuck;

[0031] 7. Cut the cylinder into multiple rings with a turning tool on a lathe;

[0032] 8. Grinding the welding point between the rigid support component and the cylinder to remove the rigid support component and obtain multiple thin-walled rings;

[0033] Nine, grinding edges and burrs.

[0034] This imp...

specific Embodiment approach 2

[0035] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the rigid support assembly described in step 5 includes a plurality of axial support rods 1 welded to the inner wall of the cylinder, and the axial support rods 1 between the axial support rods 1 A plurality of radial rod-shaped support components vertically fixed to the support rod 1. Other steps and parameters are the same as those in the first embodiment. The rigid support component is welded with the cylinder body. The rigid support component can ensure the rigidity, roundness and dimensional stability of the cylinder body. After processing, the rigid support component can be removed by grinding. The rigid support component can be cut with surplus material to reduce costs;

specific Embodiment approach 3

[0036] Embodiment 3: The difference between this embodiment and Embodiment 2 is that the radial rod-shaped support assembly is composed of a plurality of radial support rods 2 , and the plurality of radial support rods 2 are arranged radially and their ends are mutually Fixed. Other steps and parameters are the same as in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com