Automatic wrapper production line

An automatic production line and dough technology, applied in the direction of dough forming and cutting equipment, can solve the problems of inability to achieve continuity and easy generation of waste, and achieve the effect of improving production efficiency and production quality, reducing pollution and improving utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

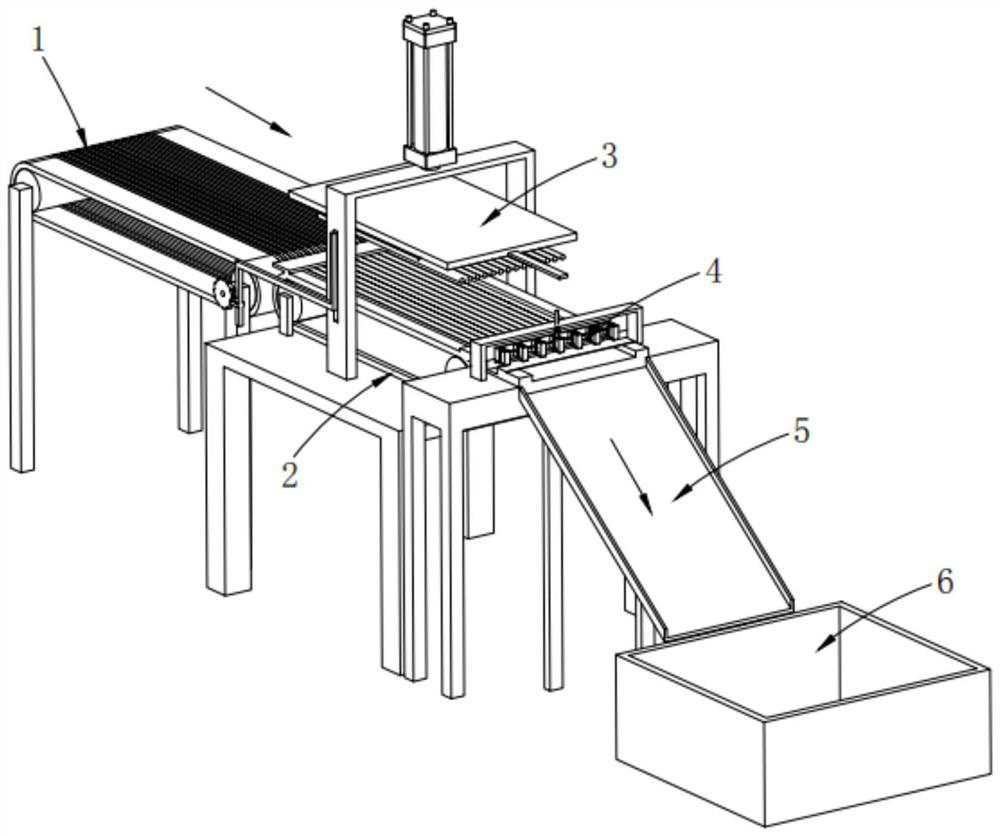

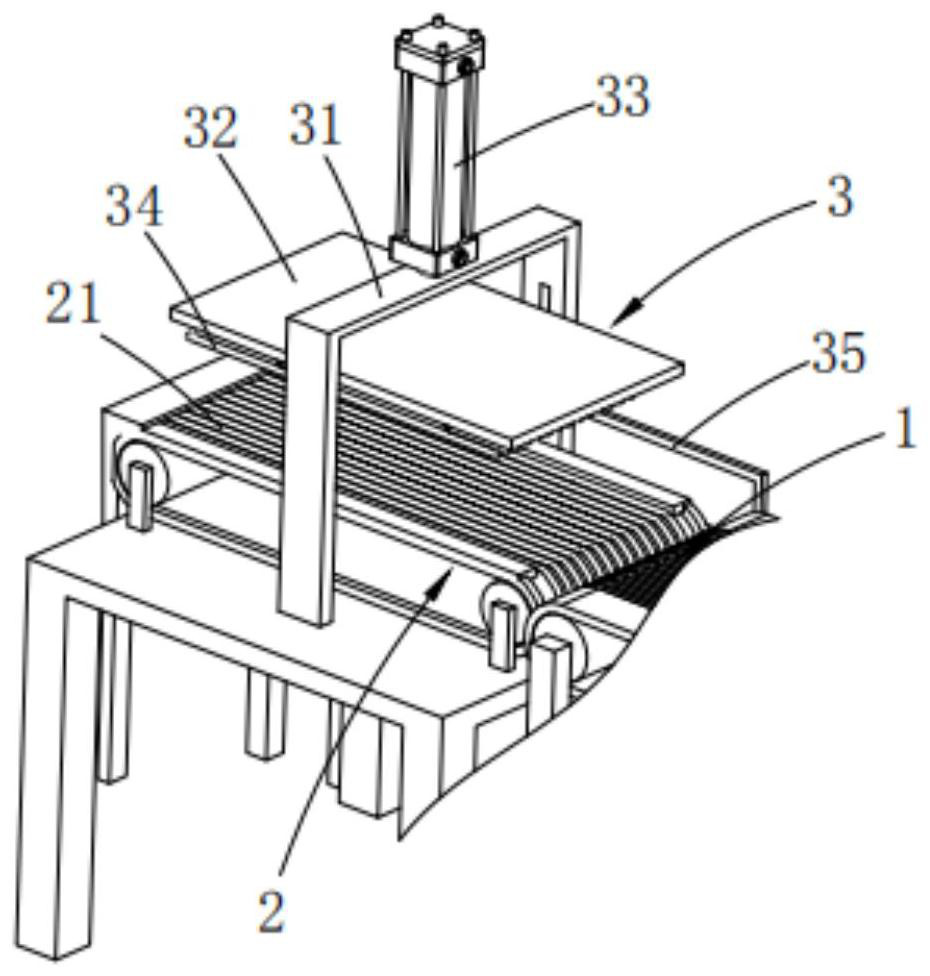

[0059] Such as figure 1 and 3 Shown, a kind of dough automation production line, it comprises:

[0060] The first conveying mechanism 1, the first conveying mechanism 1 conveys the dough 10;

[0061] The second conveying mechanism 2, the second conveying mechanism 2 is arranged at the output end of the first conveying mechanism 1 along the conveying direction of the first conveying mechanism 1;

[0062] A forming mechanism 3, the forming mechanism 3 is arranged above the second conveying mechanism 2, and the forming mechanism 3 cooperates with the second conveying mechanism 2 to press the dough 10 into a wave shape;

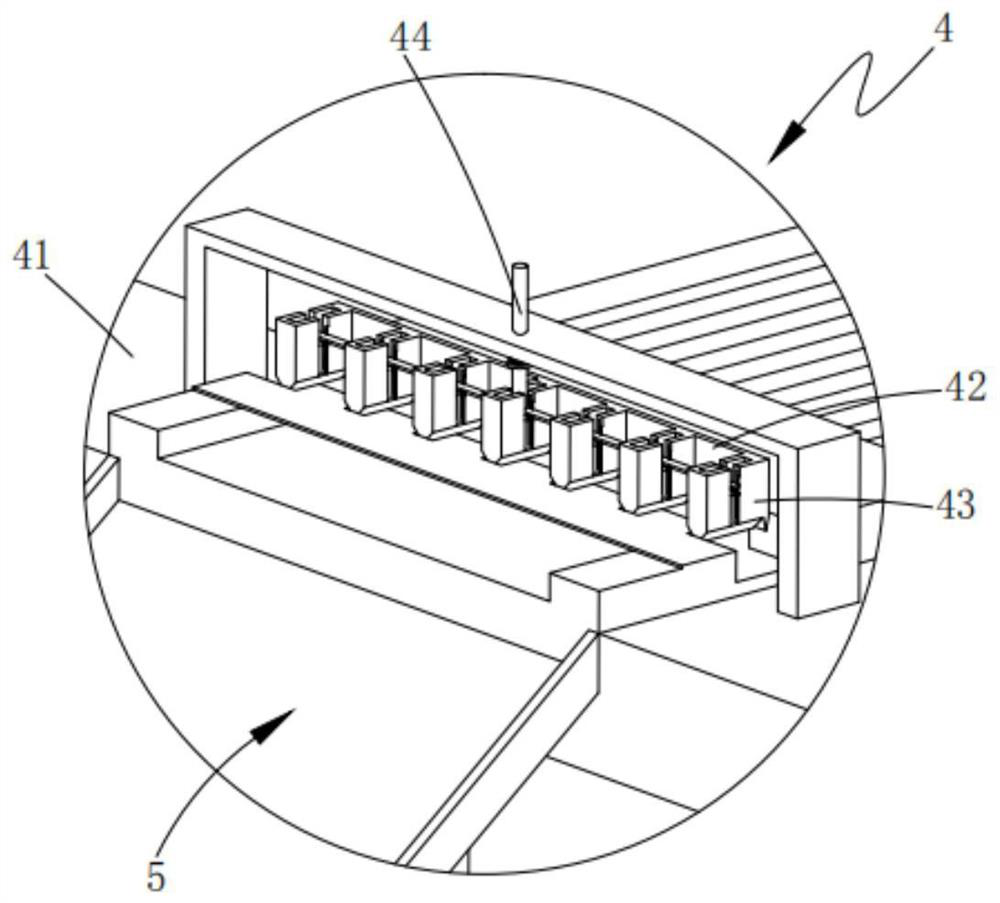

[0063] Cutting mechanism 4, described cutting mechanism 4 is arranged on the output end of second conveying mechanism 2 along the conveying direction of described second conveying mechanism 2, and this cutting mechanism 4 comprises first base 41, first cutter 42, cutter assembly 43 and a cutting assembly 44, the first cutting knife 42 cuts off the transverse d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com