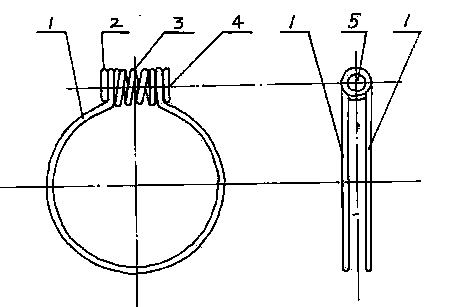

Pipe clamp

A pipe clip and auxiliary pipe technology, applied in the field of pipe clips, can solve problems such as loose pipe clips and out-of-branch elasticity, and achieve the effects of high production efficiency, simple structure, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] specific implementation

[0010] The pipe clip is a steel wire wound from the middle end (for the convenience of description, the description is started from the middle end, and the spring universal machining program is not like this). After the fixed end 2, a fixed hole 5 is naturally formed, and the fixed end 2 is folded into one in the process of winding. Tube clip round vertical fixed end 2 . After the two strands of steel wires from the fixed end 2 are wound into the corresponding perimeter of the pipe clip, one end of the steel wire is wound into a spring-type auxiliary pipe clip 3, and the shape of the spring-type auxiliary pipe clip 3 has a shape corresponding to the pipe clip circle. For the curvature, the head of its design can be slightly lowered, so that the inner hole of the auxiliary pipe clamp 3 is larger than the diameter of the screw, so the auxiliary pipe clamp 3 can keep this curvature and fit the fixed pipe tightly. Similarly, after the two strands ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com