Fixed angle iron waste-material-free punching forming method, mold and production line

A technology for fixing angle irons and forming methods, applied in forming tools, manufacturing tools, metal processing equipment, etc., can solve problems such as increased production costs, waste of raw materials, and complicated stamping machines, to save time, reduce production costs, and fast forming Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

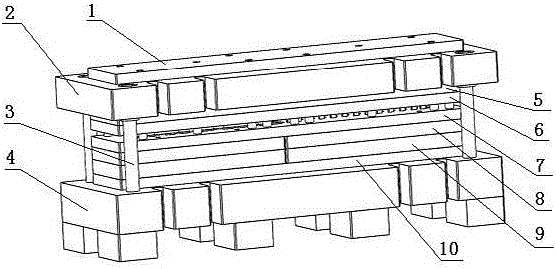

[0032] The present invention will be described in further detail below with reference to the accompanying drawings and an embodiment.

[0033] The punching and forming method of the present invention includes the following steps: 1), directly purchasing a steel strip coil with a required width as the raw material 14; 2), placing the raw material 14 on the material rack 16, and then punching through the feeder 12 and the punching machine 11 in sequence Fold into shape.

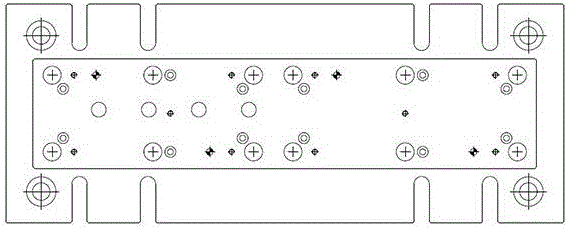

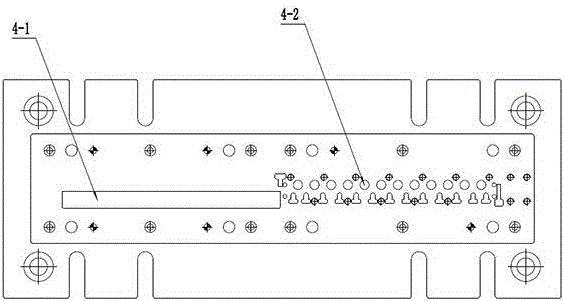

[0034] Further, the raw materials 14 on the material rack 16 are first leveled by the leveling device 15 , and then passed through the feeding induction rack 13 for sending feeding signals to the material rack 16 , and then the raw materials 14 are fed into the punching machine 11 through the feeder 12 . On the fixed angle iron non-waste punching and folding die, first punch holes on the punching die 9-5 in the front half of the concave plate 9 of the die, and then feed, and the punched material enters the fold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com