Automatic processing and forming production device of farfalle

A technology for processing molding and production equipment, which is applied in dough molding and cutting equipment, dough processing, packaging item types, etc. The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

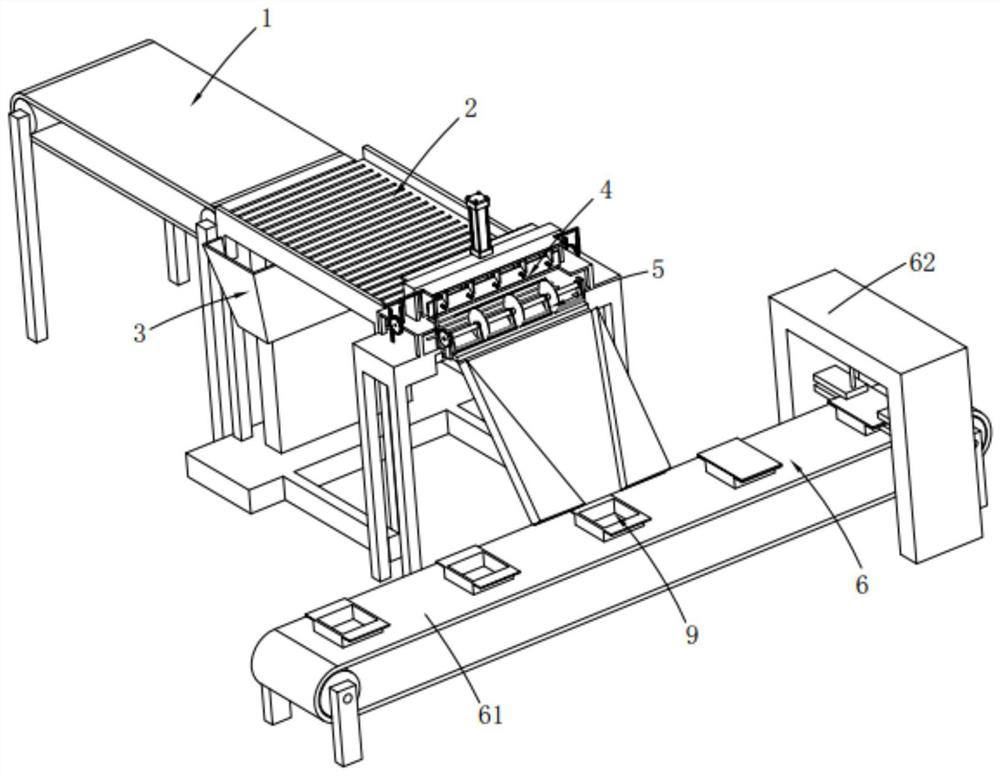

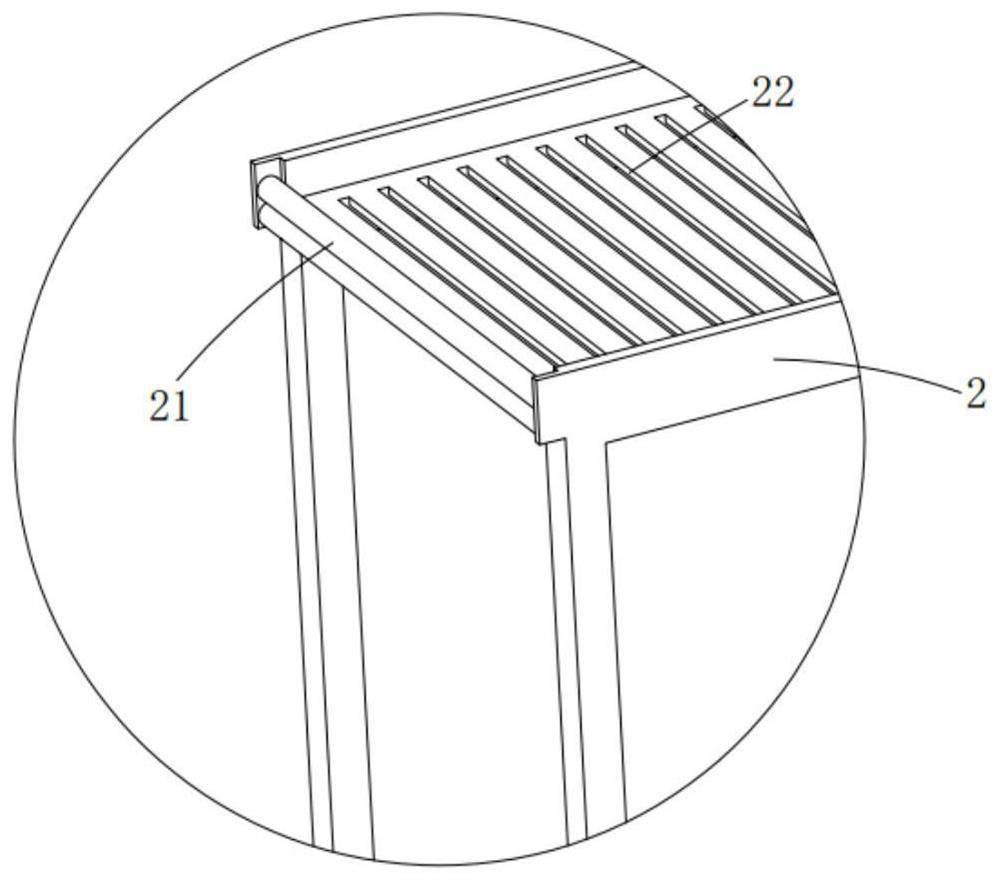

[0057] Such as Figures 1 to 4 As shown, a butterfly noodle automatic processing and forming production equipment includes a first conveying mechanism 1, and a second conveying mechanism 2 arranged at the output end of the first conveying mechanism 1 along the conveying direction of the first conveying mechanism 1, so The powder blowing device 3 is arranged below the second conveying mechanism 2, and it also includes:

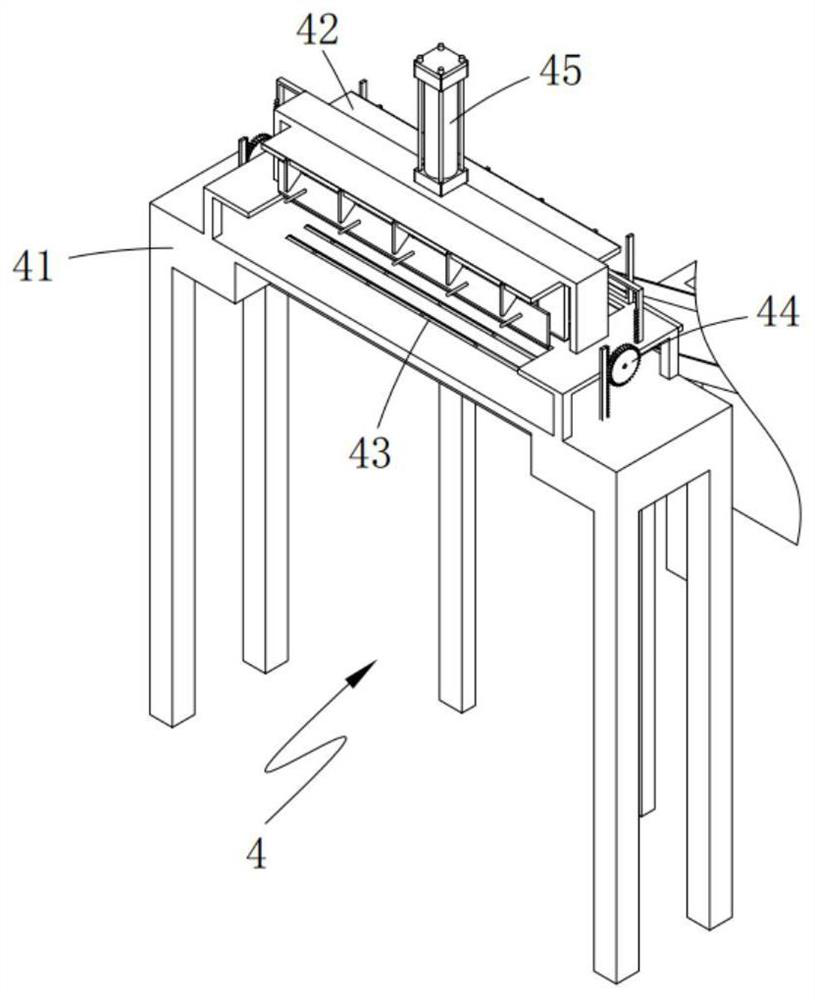

[0058] The profiling mechanism 4, the profiling mechanism 4 is arranged on the output end of the second conveying mechanism 2 along the conveying direction of the second conveying mechanism 2, the profiling mechanism 4 includes a first base 41, a first molding 42. The second forming part 43, the first linkage assembly 44 and the driving part 45, the first forming part 42 is slidably arranged below the first base 41 along the height direction of the first base 41, the The second forming part 43 is slidably arranged above the first base 41 along the height direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com