Antibacterial mildew-proof polypropylene composition, polypropylene film and preparation method thereof

A technology of polypropylene composition and polypropylene film, which is applied in the preparation of antibacterial and anti-mildew polypropylene film, and in the field of anti-bacterial and anti-mildew polypropylene film, which can solve the problems of harsh conditions, poor control of product shape and particle size, and high energy consumption. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

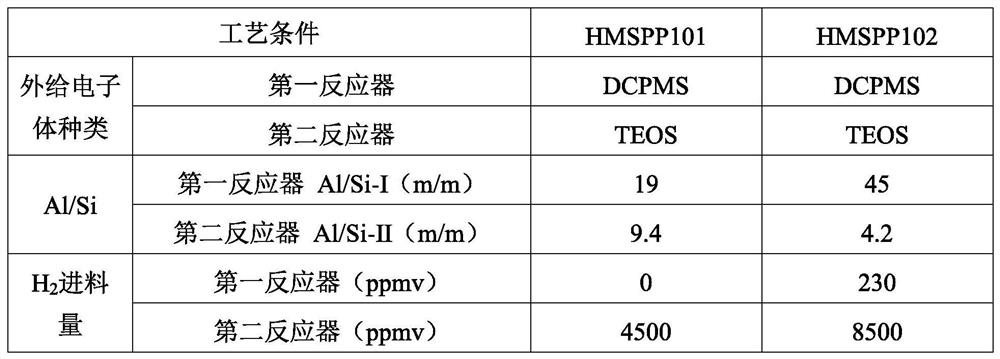

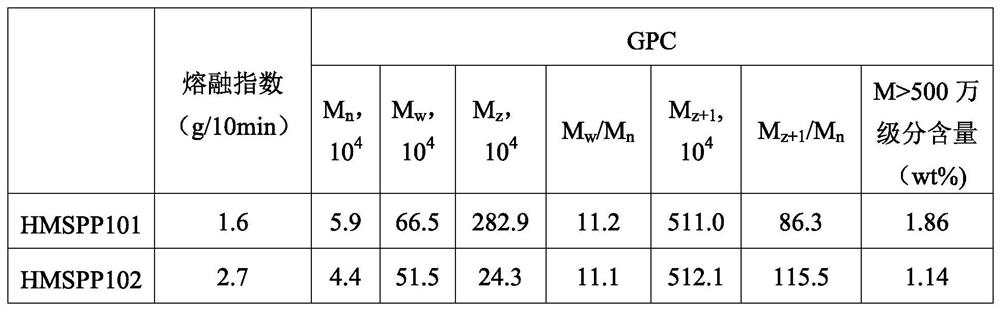

Method used

Image

Examples

preparation example Construction

[0055] According to the present invention, the preparation method of described guanidinium salt composite antibacterial agent comprises the following steps:

[0056] a, the aqueous solution of guanidinium salt polymer is contacted with the aqueous solution of zinc salt and / or copper salt, forms transparent liquid mixture;

[0057] b. mixing the liquid mixture obtained in step a with the latex solution crosslinked by radiation, and then adding an anti-migration agent to obtain a mixture;

[0058] c. Spray-dry the mixture obtained in step b to obtain a solid powder, which is then mixed with a dispersant to obtain the guanidinium salt composite antibacterial agent.

[0059] Wherein, the latex can be determined according to the type of final required powder rubber, and the latex can be styrene-butadiene latex, carboxylated styrene-butadiene latex, nitrile latex, carboxylated nitrile latex, acrylate latex, ethylene vinyl acetate latex, silicon At least one of rubber latex and styr...

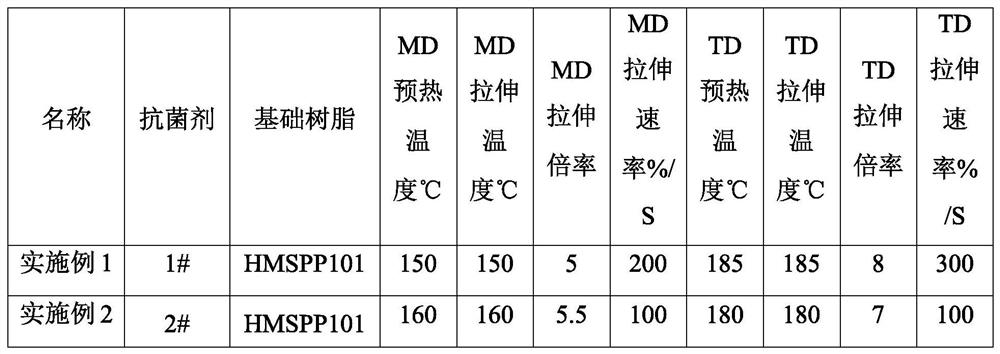

Embodiment 1

[0103] (1) Preparation of guanidinium salt composite antibacterial agent

[0104] a, polyhexamethylene guanidine hydrochloride (Shanghai Shande Industrial Co., Ltd.) 1000.0g is dissolved in water and is mixed with the aqueous solution of mass concentration 20%; 50.0g zinc sulfate is mixed with the aqueous solution that mass concentration is 25%, 125.0 The g styrene-butadiene latex solution was directly used after radiation crosslinking, and the concentration was 40%. b. Add the prepared guanidinium salt polymer aqueous solution into the container containing the zinc-containing aqueous solution, and stir while adding until uniformly mixed to form a transparent liquid mixture. c. Add the liquid mixture in step b to the latex solution, and stir while adding until the mixture is uniform. Then, add 5.0 g of anti-migration agent (Covestro 2794 XP). d. Dry the mixture obtained in step c with a spray dryer to obtain a solid powder; transfer the obtained solid powder to a high-speed...

Embodiment 2

[0123] (1) Preparation of guanidinium salt composite antibacterial agent

[0124] a, polyhexamethylene guanidine propionate (Shanghai Shande Industrial Co., Ltd.) 1000.0g is dissolved in water and is mixed with the aqueous solution of mass concentration 40%; 100.0g zinc acetate is mixed with the aqueous solution that mass concentration is 15%, 150.0 The g nitrile latex solution was directly used after radiation crosslinking, and the concentration was 30%. b. Add the prepared guanidinium salt polymer aqueous solution into the container containing the zinc-containing aqueous solution, and stir while adding until uniformly mixed to form a transparent liquid mixture. c. Add the liquid mixture in step b into the latex solution, and stir while adding until the mixture is uniform. Then, 5.0 g of anti-migration agent (Covestro 2794 XP). d. The mixture obtained in step c is dried by a spray dryer to obtain a solid powder; the obtained solid powder is transferred to a high-speed mix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com