Patents

Literature

33results about "Pneumatic programme control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

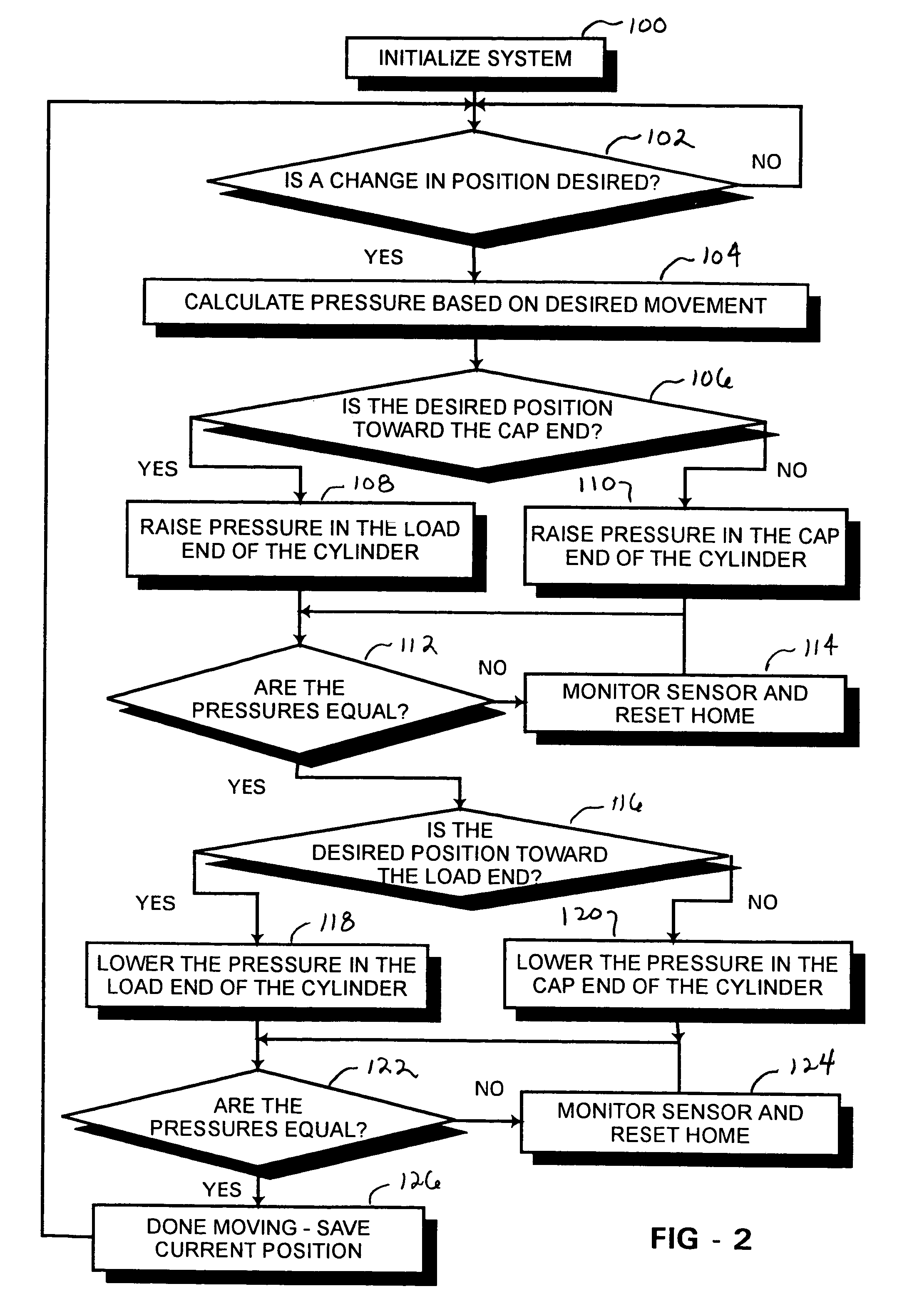

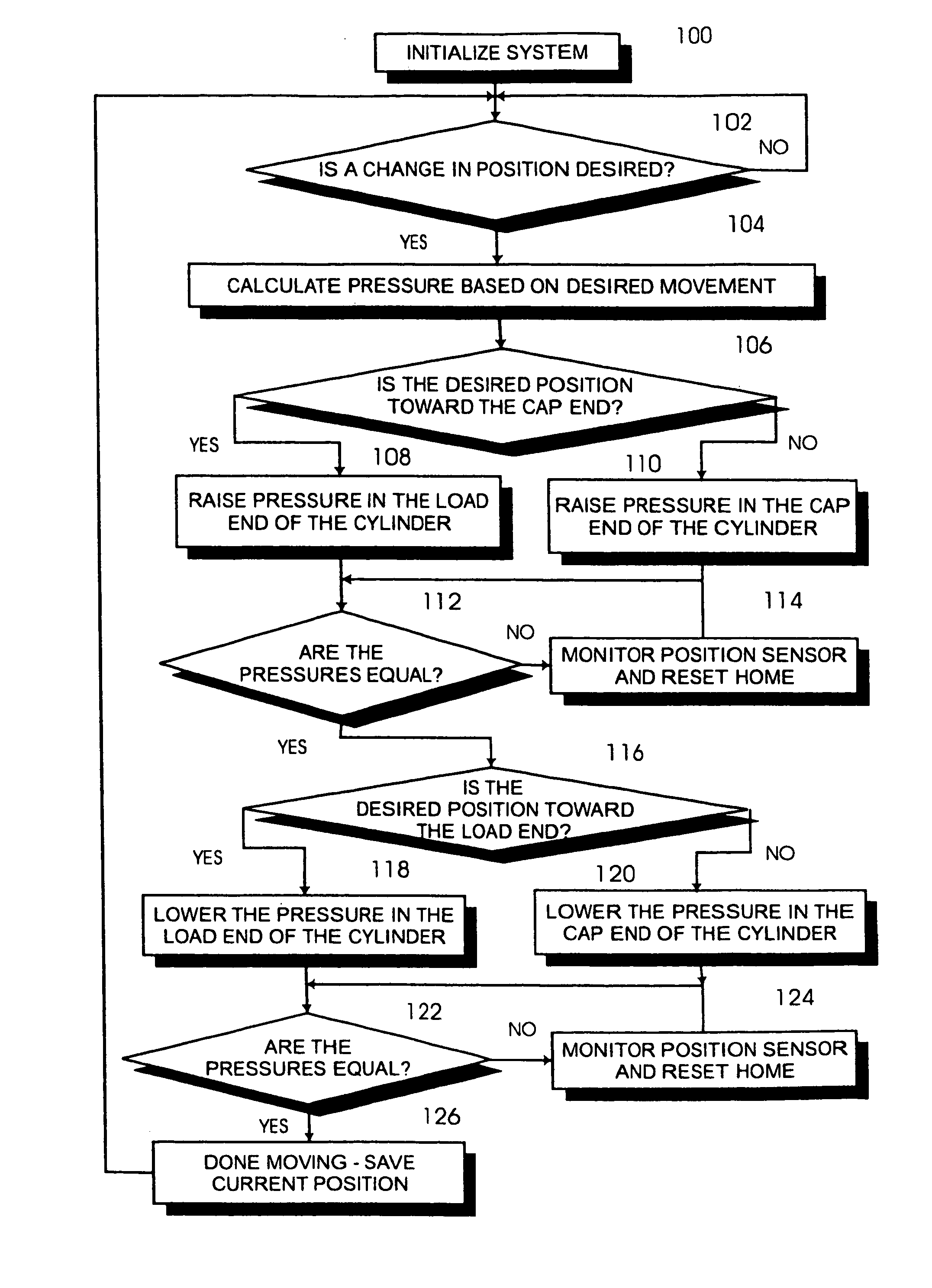

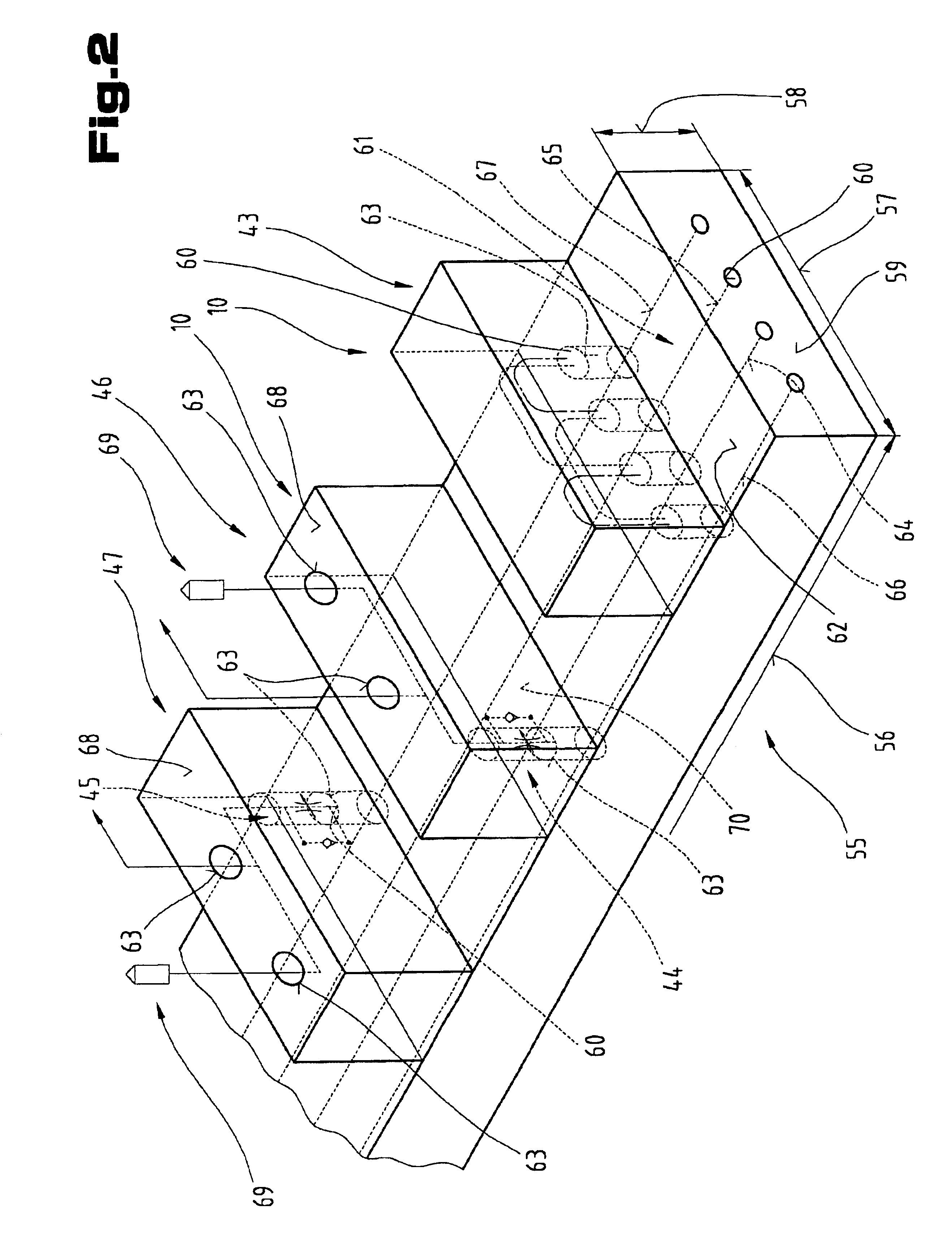

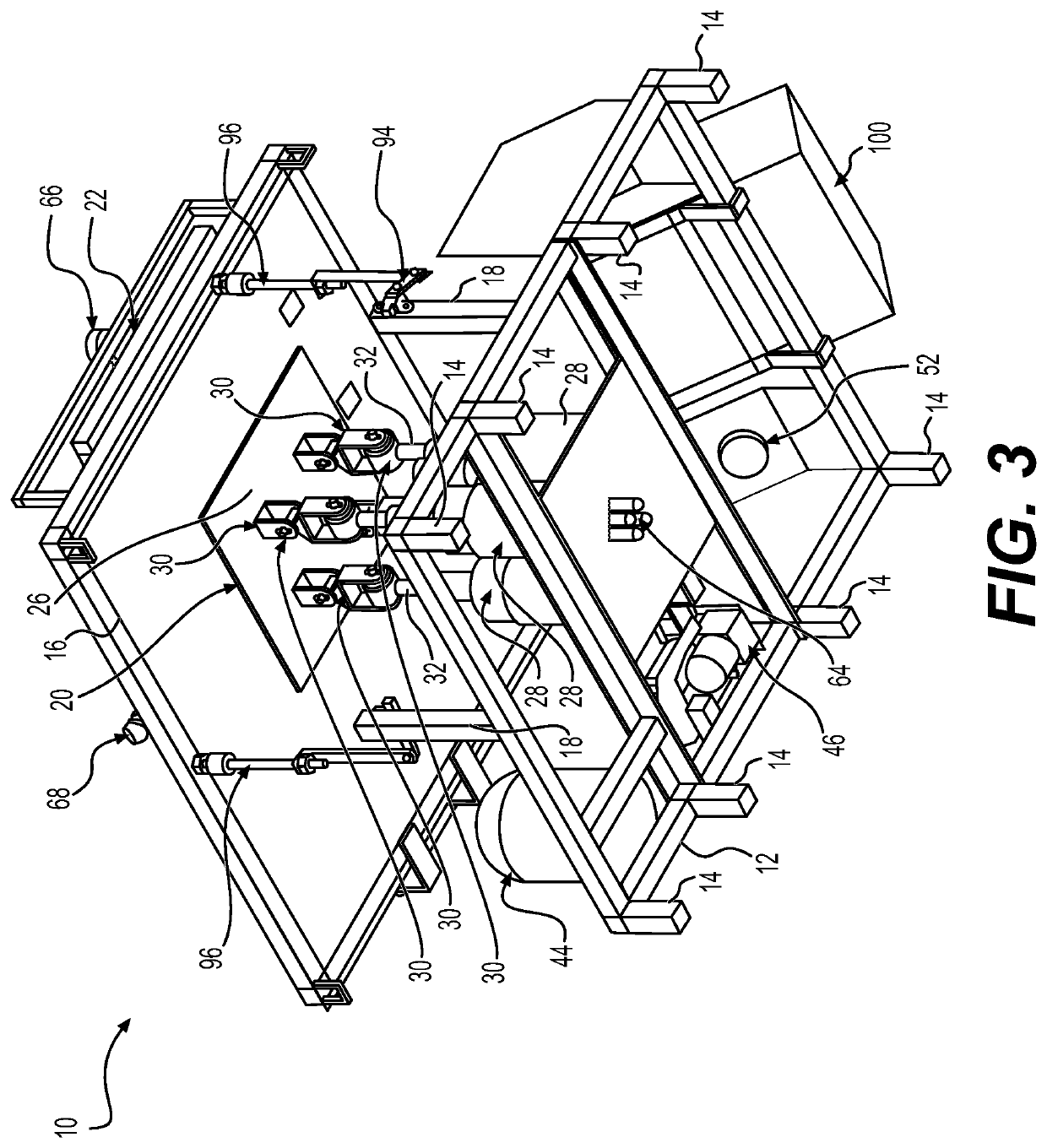

Accurate fluid operated cylinder positioning system

InactiveUS7021191B2Low costSimple cuttingPneumatic programme controlServomotor componentsControl valvesPosition sensor

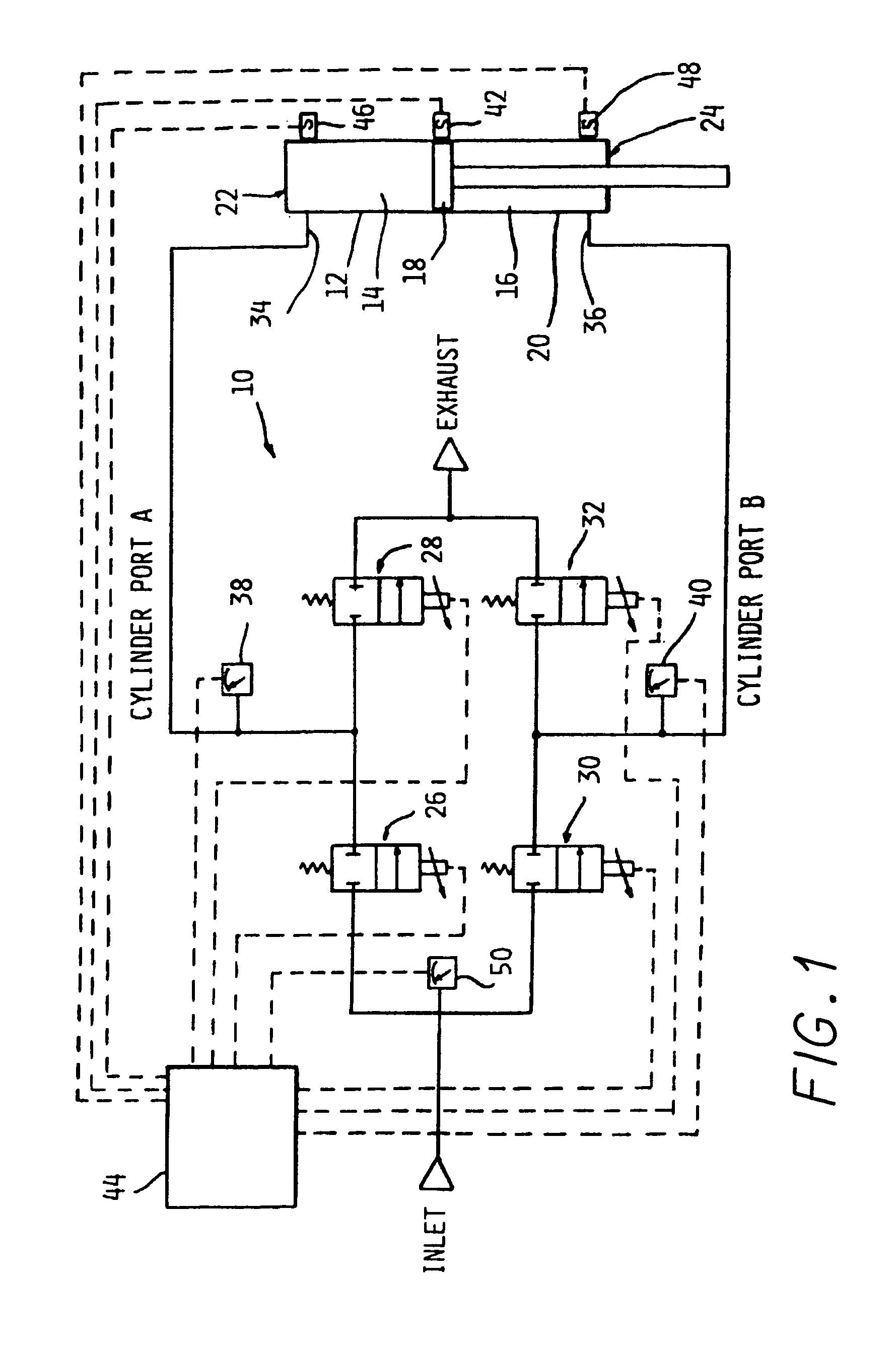

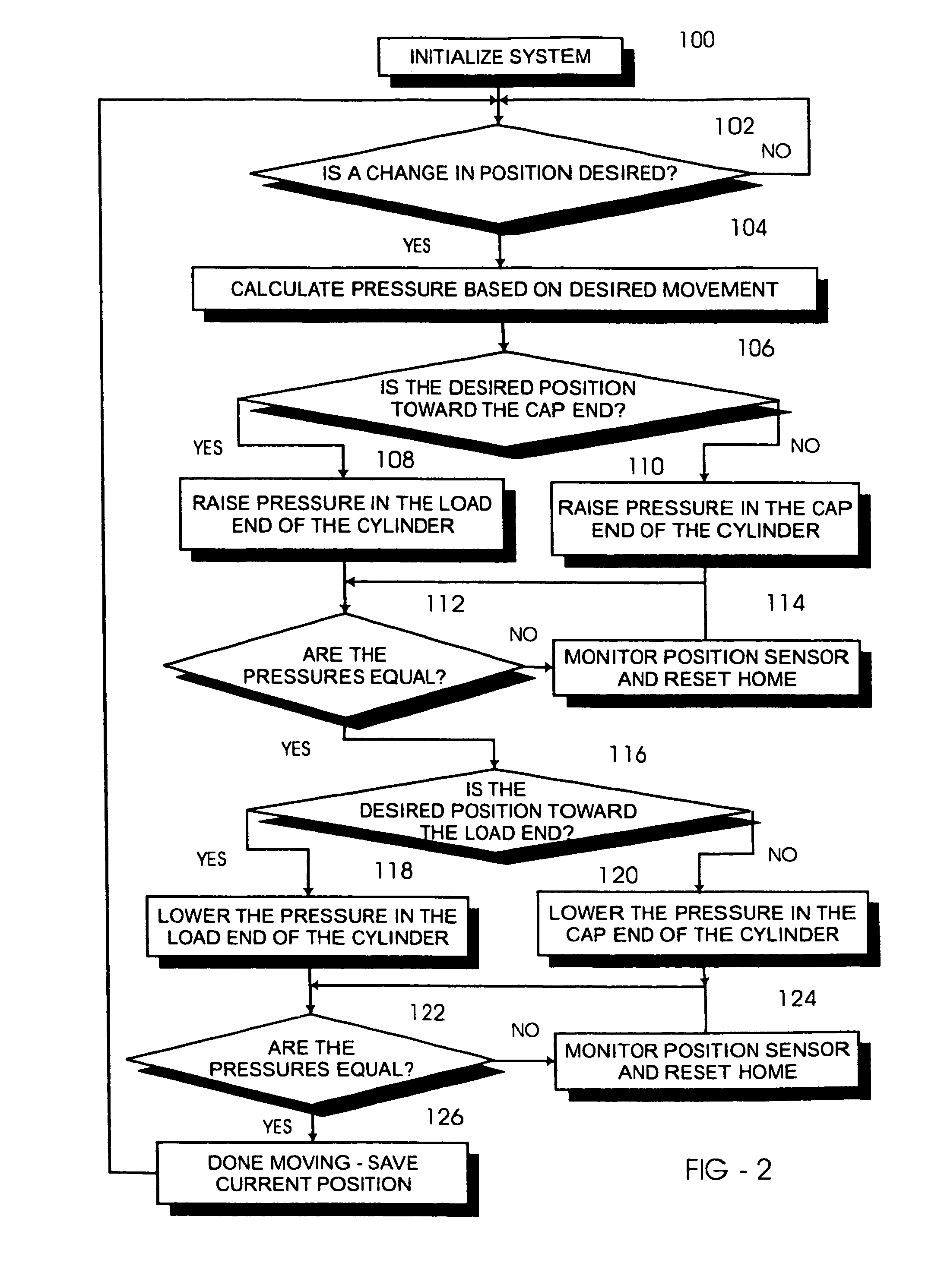

A position control system is used for controlling a fluid operated cylinder having at least one fluid chamber defined by a piston located within a housing for movement between first and second end limits of travel. The system includes at least two electrically actuated proportional flow control valves connected to each port of the cylinder for selectively and proportionally controlling fluid flow into and out of the at least one chamber. At least one pressure sensor is provided for measuring fluid pressure with respect to each chamber. At least one discrete position sensor is located adjacent a midpoint of the cylinder for sensing a discrete centered position of the piston. A controller includes a program and is operably connected for controlling actuation of the at least two valves in response to pressure measured by the at least one pressure sensor and location measured by the at least one position sensor.

Owner:PARKER INTANGIBLES LLC

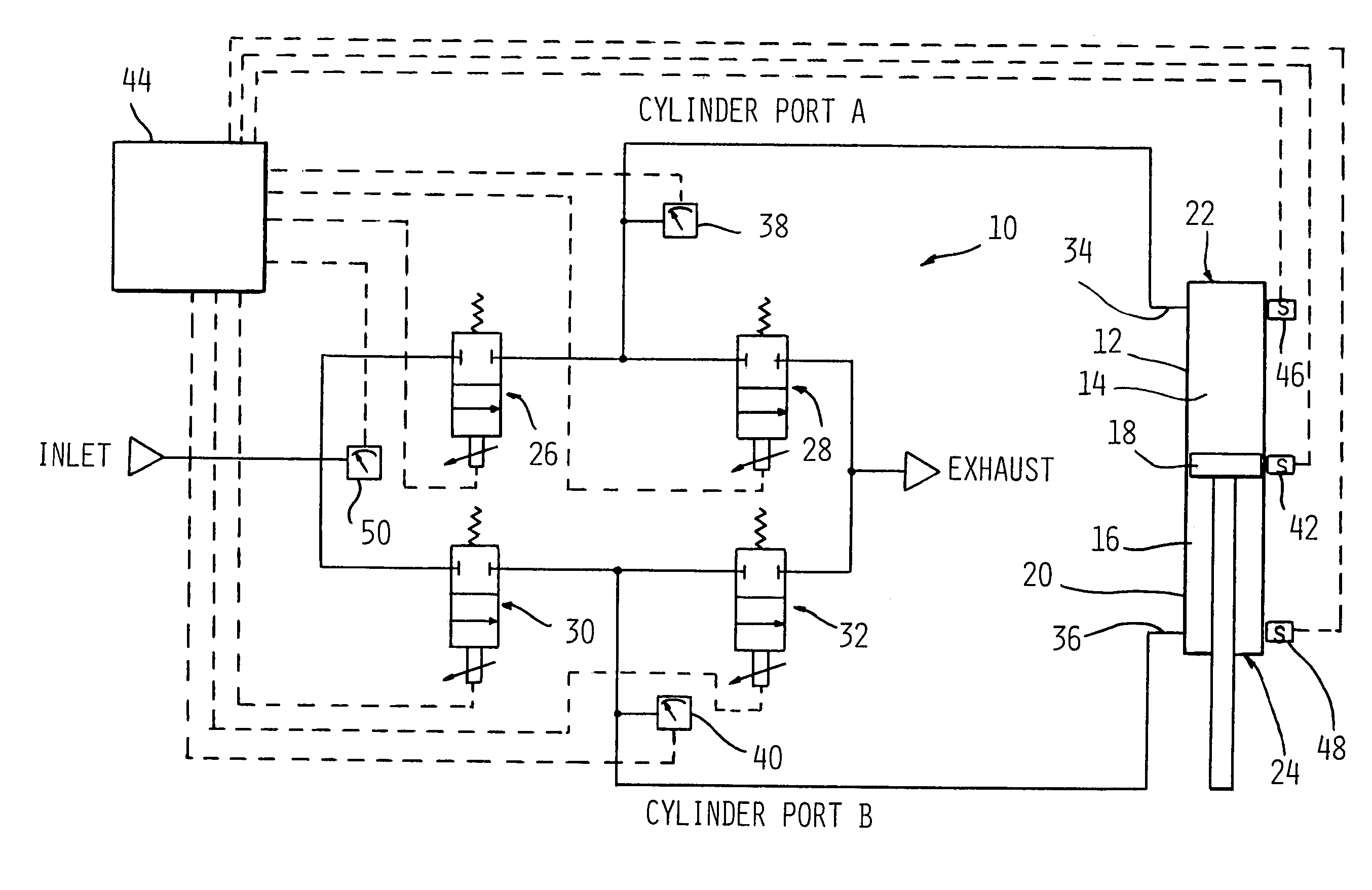

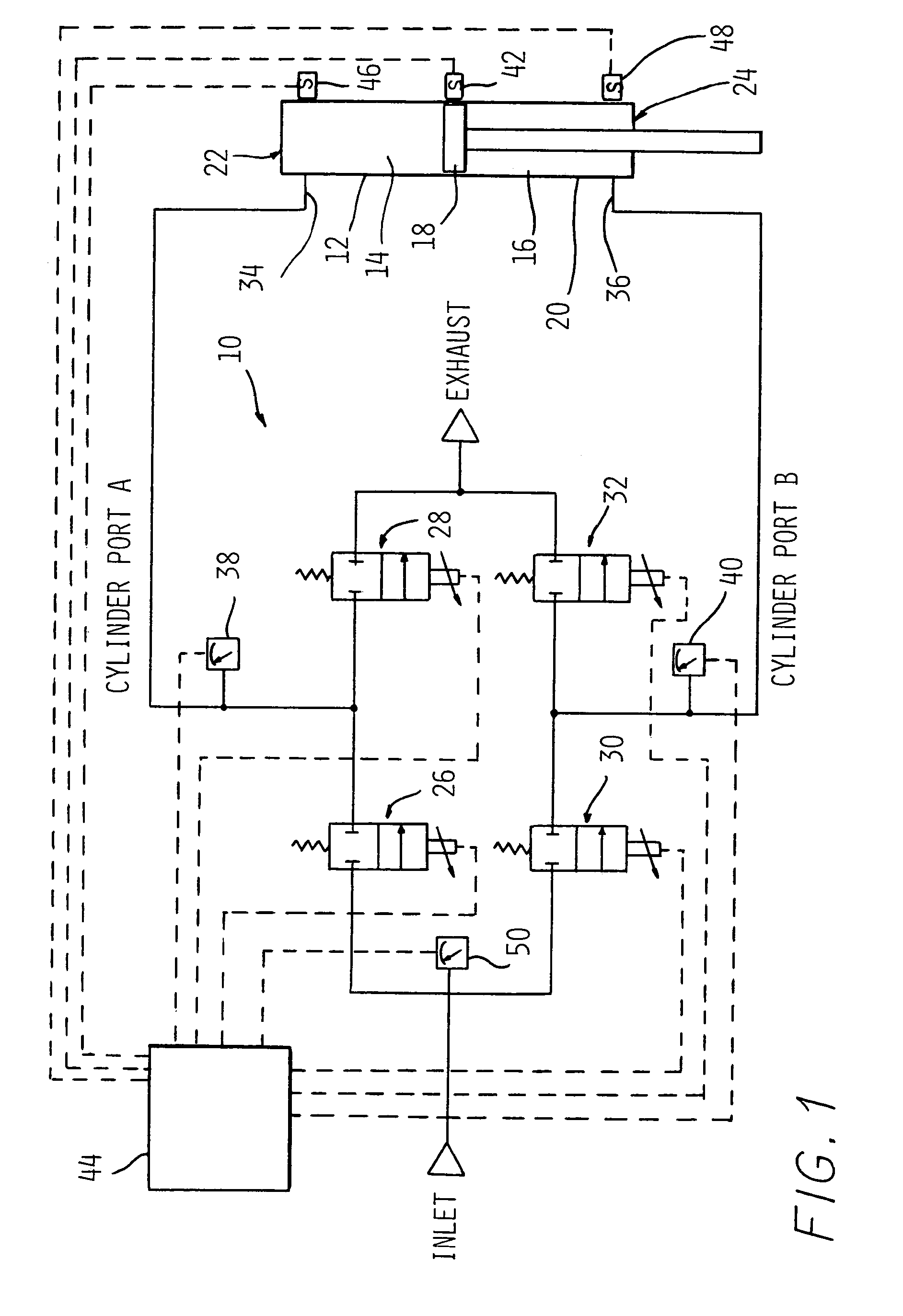

Multi-valve fluid operated cylinder positioning system

InactiveUS7353743B2Inexpensive and accurate fluid operated cylinder positioningLow costPneumatic programme controlServomotor componentsMulti-valveEngineering

A position control system is used for controlling a fluid operated cylinder having at least one fluid chamber defined by a piston located within a housing for movement between first and second end limits of travel. The system includes at least two electrically actuated proportional flow control valves connected to each port of the cylinder for selectively and proportionally controlling fluid flow into and out of the at least one chamber. At least one pressure sensor is provided for measuring fluid pressure with respect to each chamber. At least one discreet position sensor is located adjacent a midpoint of the cylinder for sensing a discreet centered position of the piston. A controller includes a program and is operably connected for controlling actuation of the at least two valves in response to pressure measured by the at least one pressure sensor and location measured by the at least one position sensor.

Owner:PARKER INTANGIBLES LLC

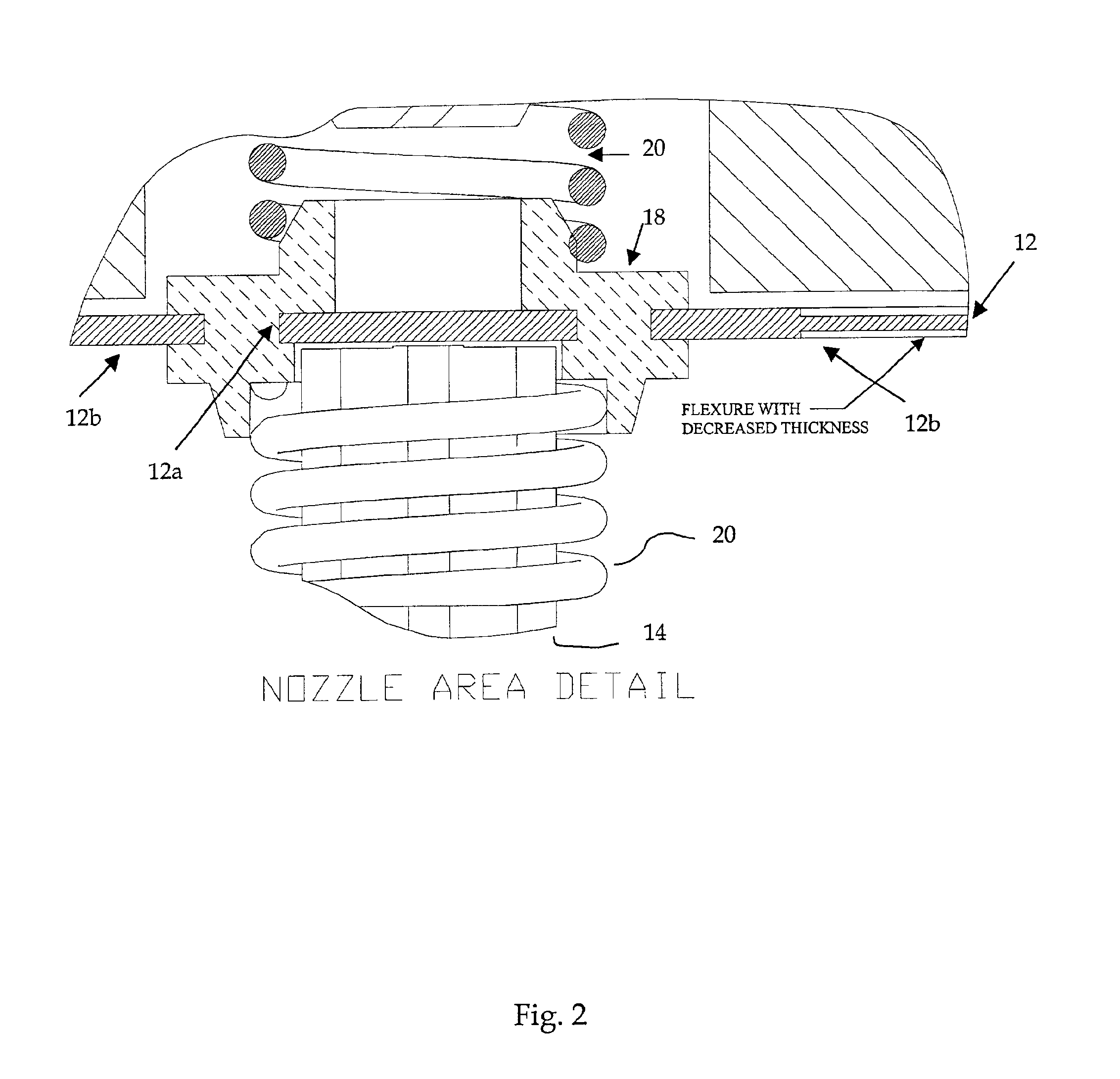

Dynamic current-to-pneumatic converter and pneumatic amplifier

InactiveUS6957127B1Reliable steady state amplifier performanceAvoid flowFluid-pressure actuator testingLevel controlAudio power amplifierEngineering

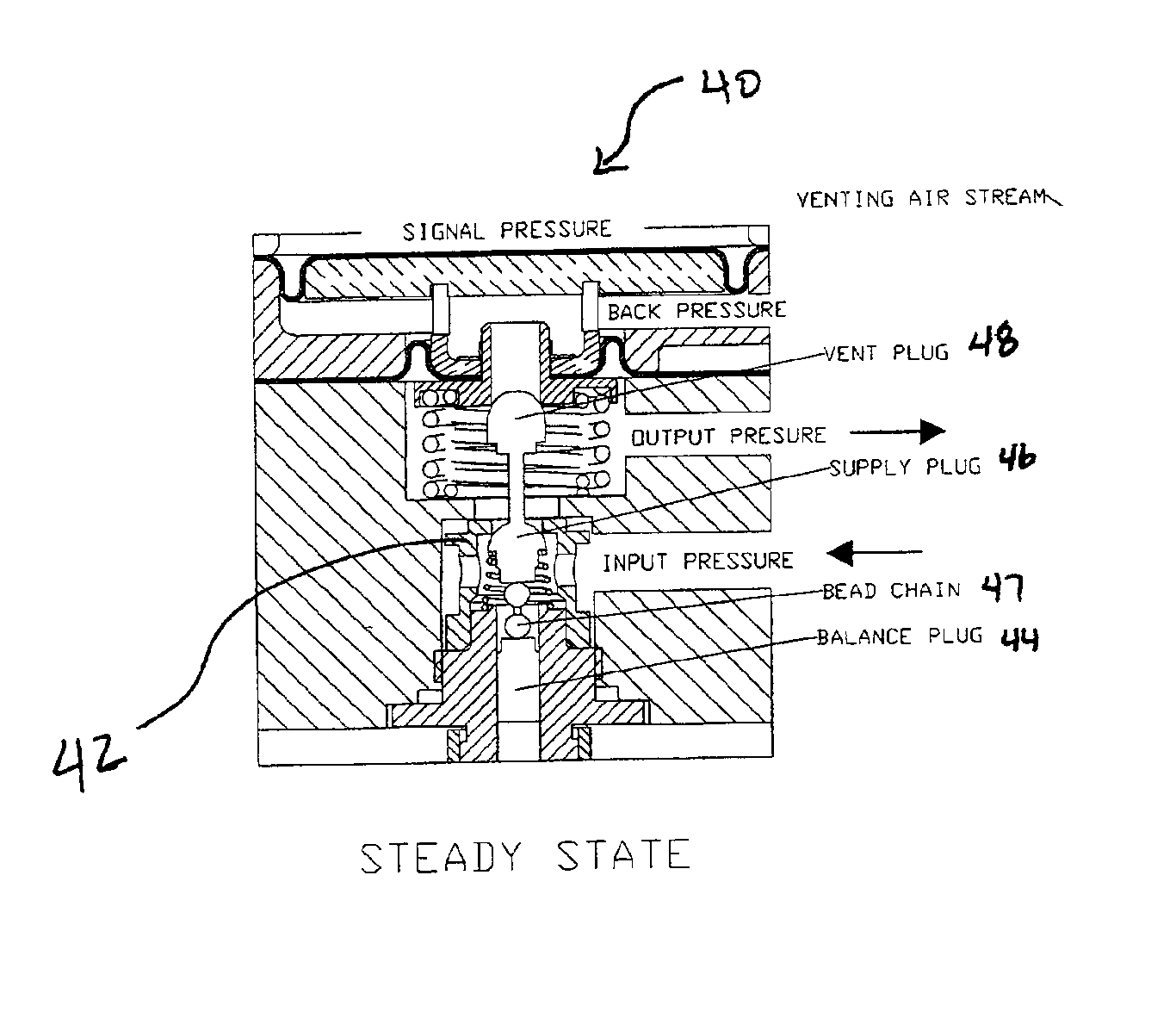

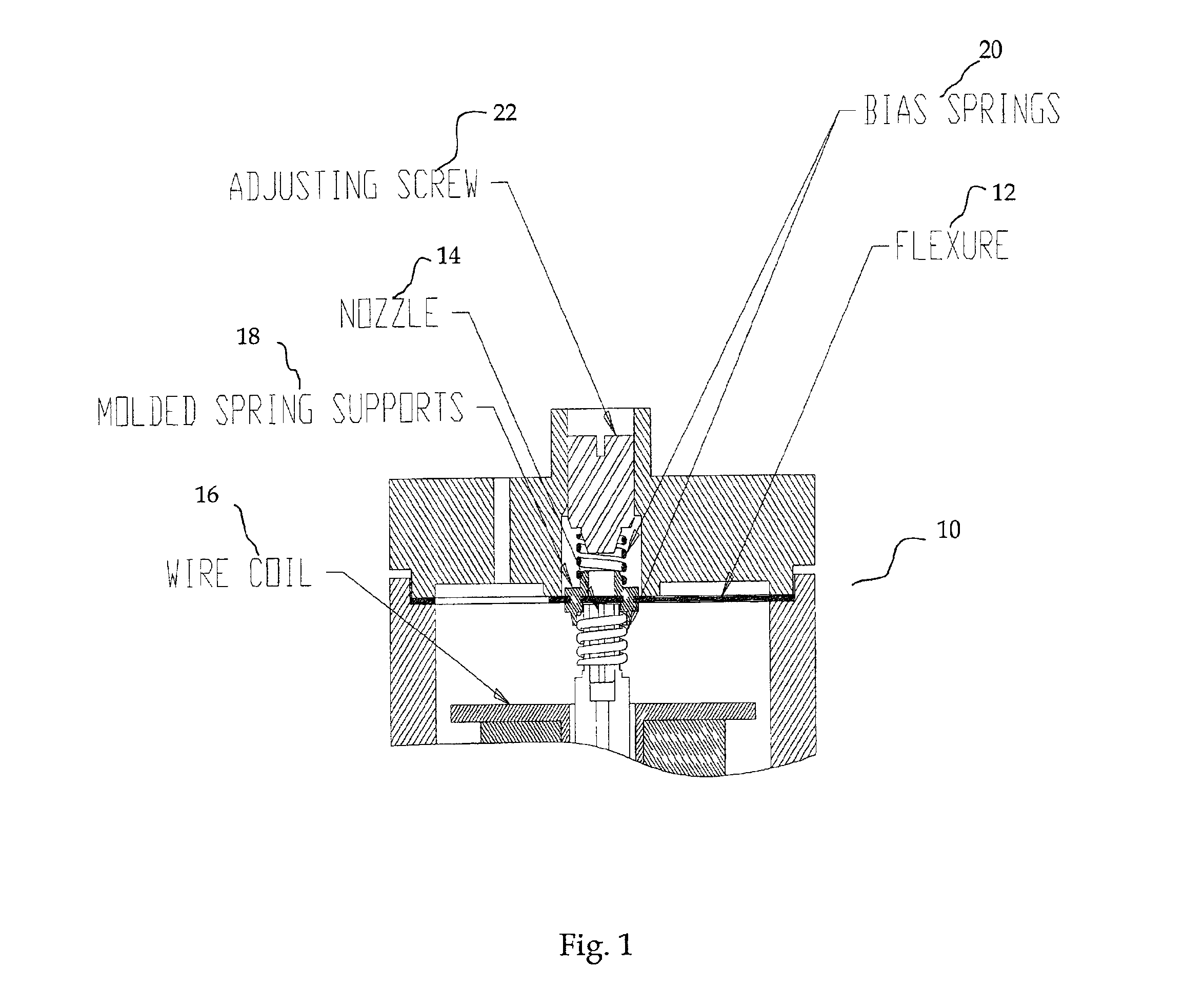

A dynamically balanced pneumatic relay amplifier and a current-to-pneumatic converter are disclosed. The relay has a balance plug, a supply plug positioned on top of the balance plug, a bead chain connecting the balance plug and the supply plug, and a vent plug positioned on top of the supply plug. The relay also includes a baffle positioned on top of the vent plug. The converter, used in an electro-pneumatic positioner, comprises a flat strip made of magnetic material located in proximity to a nozzle, and a flow regulator having a flat spring securing a plug in a seat within the regulator. The converter also includes a cantilevered flexure integrally secured to a molded spring support, a first bias spring positioned on a first side of the flexure, and a second bias spring positioned on a second side of the flexure. The thickness of the flexure is locally reduced in an area not integrated into the molded spring support.

Owner:DRESSER IND INC

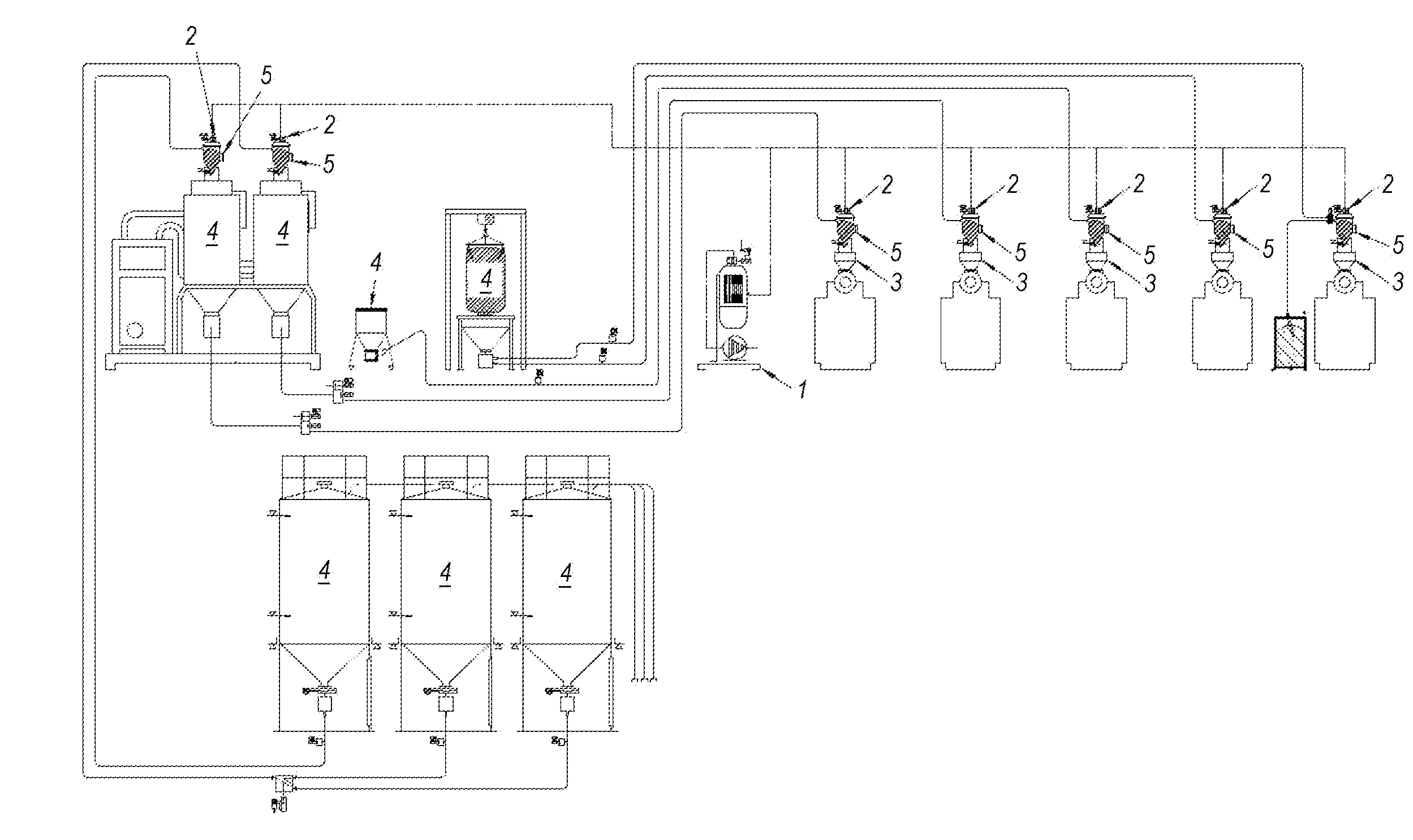

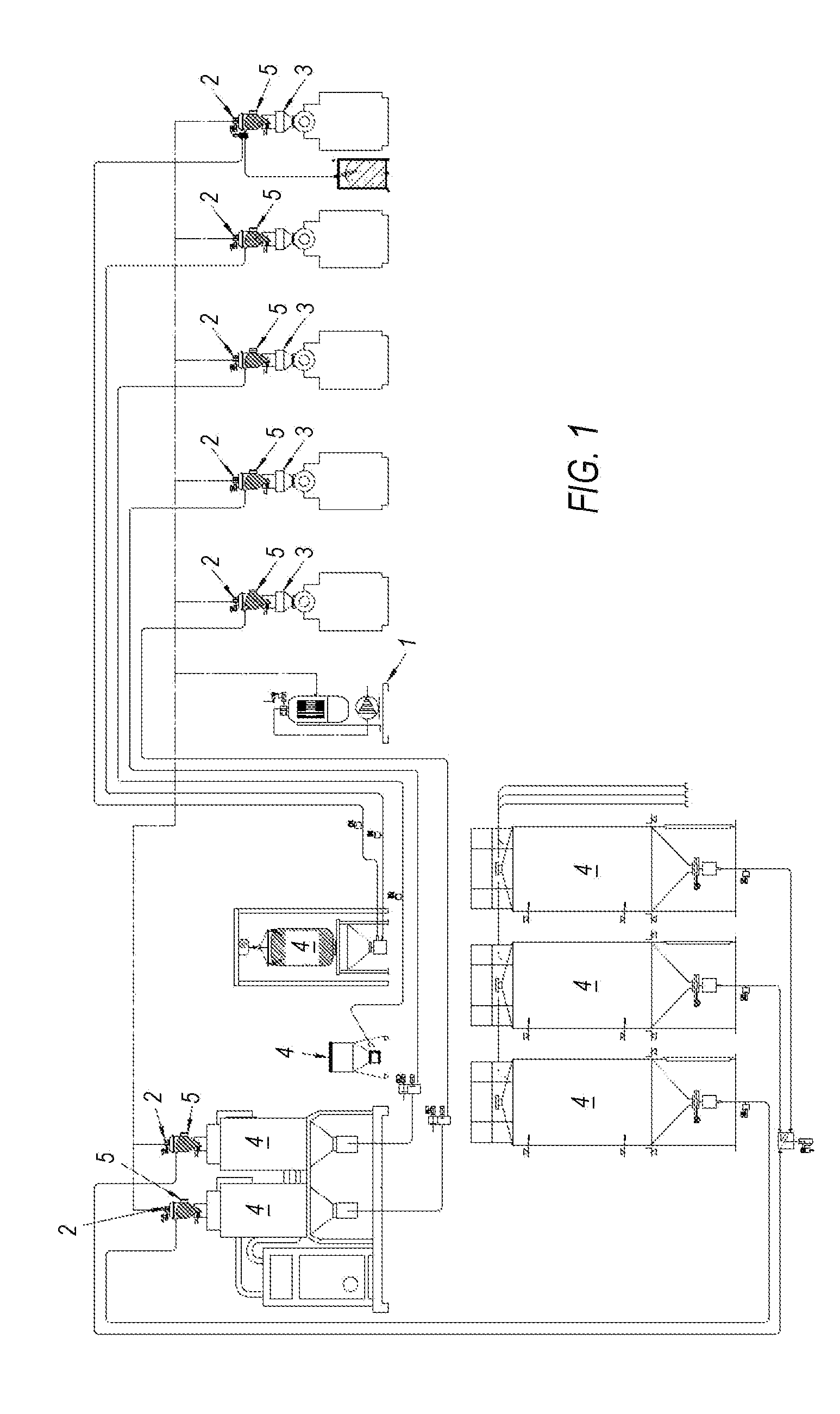

Control system for granular material transport system

InactiveUS20100234983A1Reduce system costReduce installation costsPneumatic programme controlDigital data processing detailsTransport systemControl system

A control system for a pneumatic transport system of granular material, which includes a plurality of containers, is configured to manage the filling cycle of each container automatically by monitoring the weight of the transported material continuously, and by optionally monitoring the state of the granular material, for example temperature and humidity of the granular material. The information generated by the control system is provided to a centralized management system, which may be operated entirely or partially through radio signals transmitted by wireless technology.

Owner:PIOVAN

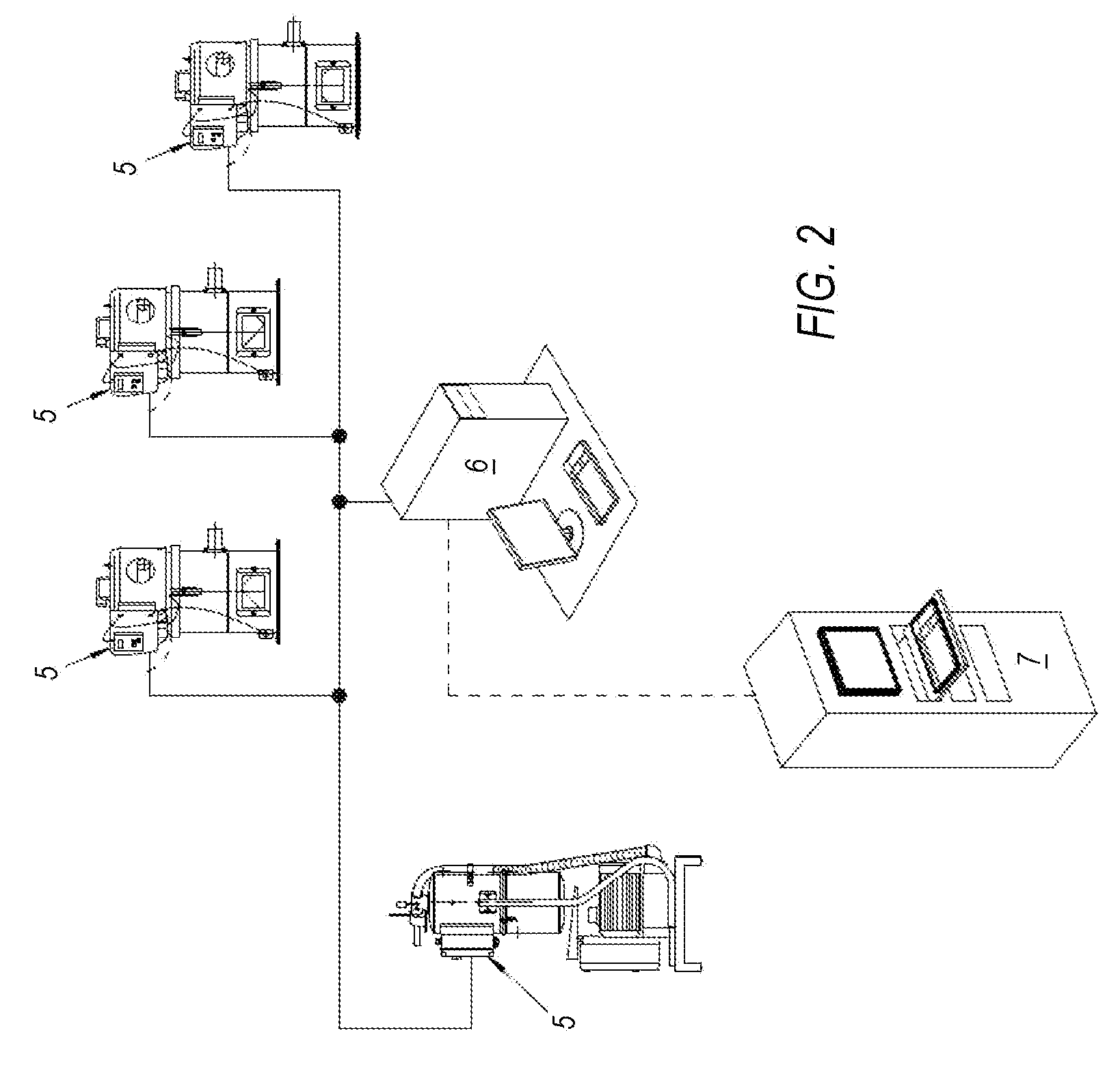

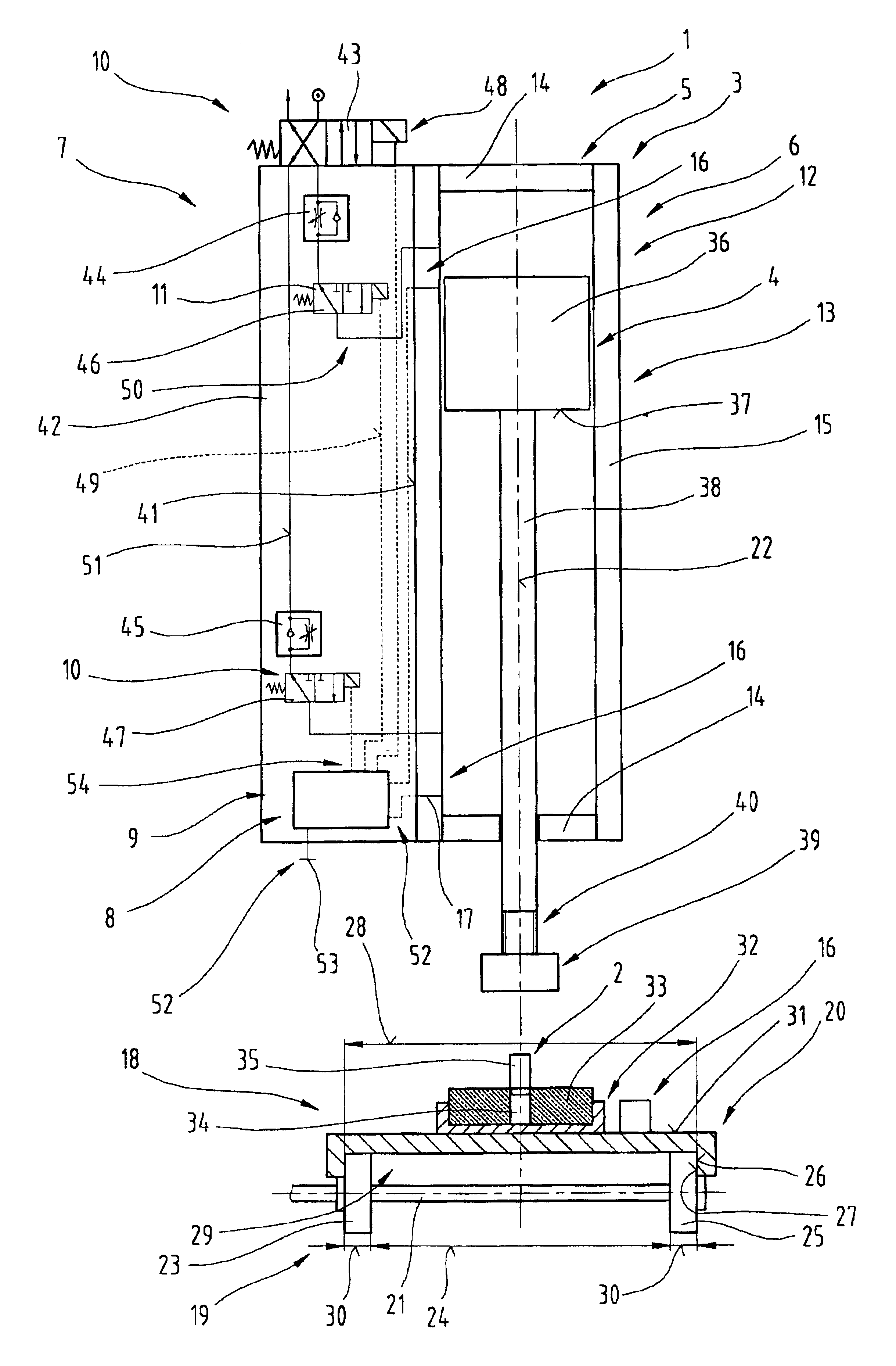

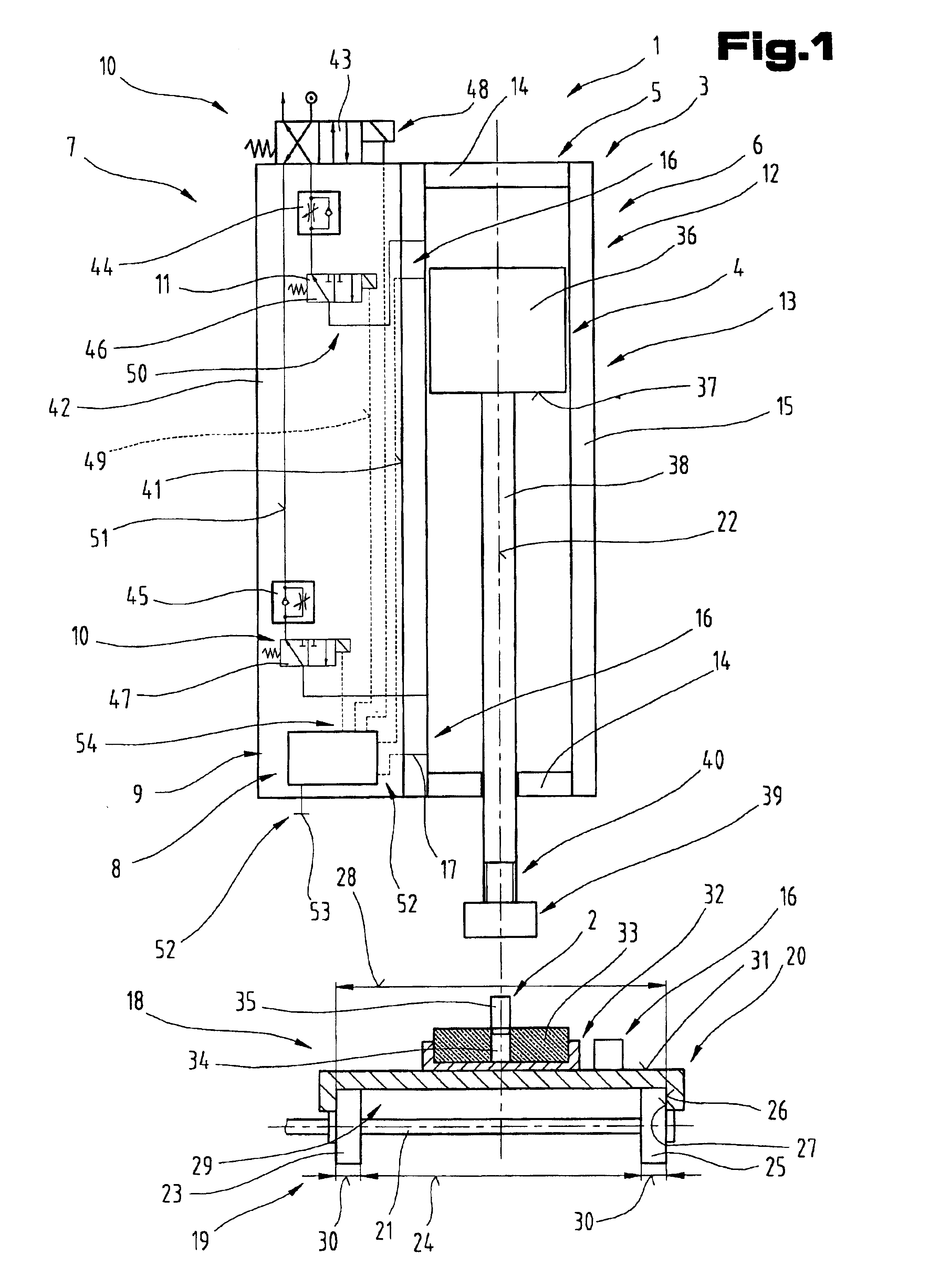

Displacement unit

InactiveUS6839957B1Reduce expensesPrevents undesired dampingPneumatic programme controlAutomatic control devicesProcess logicControl system

The invention describes a displacement unit (1) for example for supply, manipulation, guiding or control systems of mounting parts (2), with components (3, 4) that can be adjusted relative to one another by means of a drive unit (5) and with at least one guiding device (6) for at least one of the components (3; 4) and a control unit (7). At least one member (8) of the control unit (7) used for processing logic information or bus information is integrated into the drive unit (5) and / or into at least one of the components (3; 4) and / or is mounted on one of the components (3; 4).

Owner:STICHT WALTER

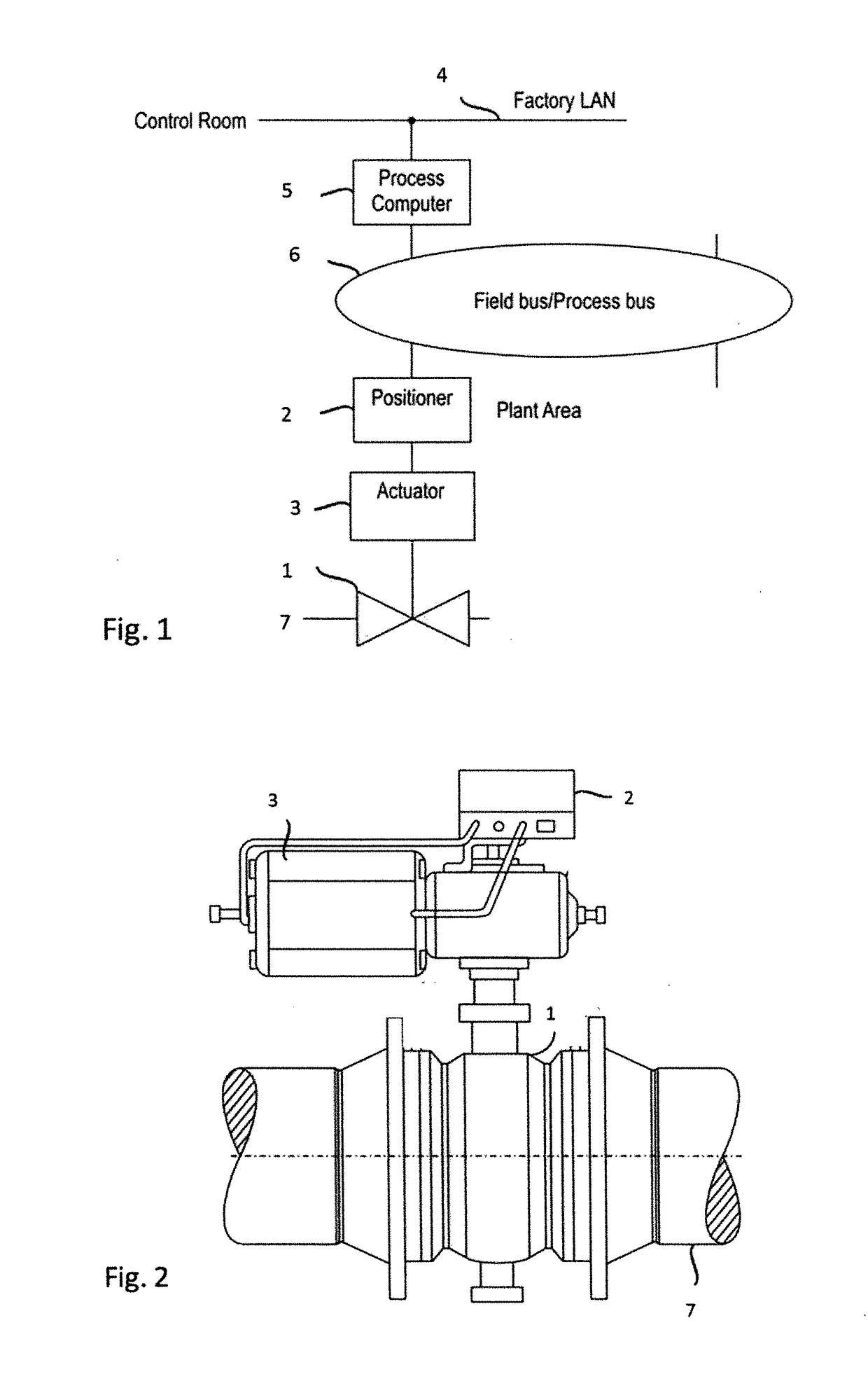

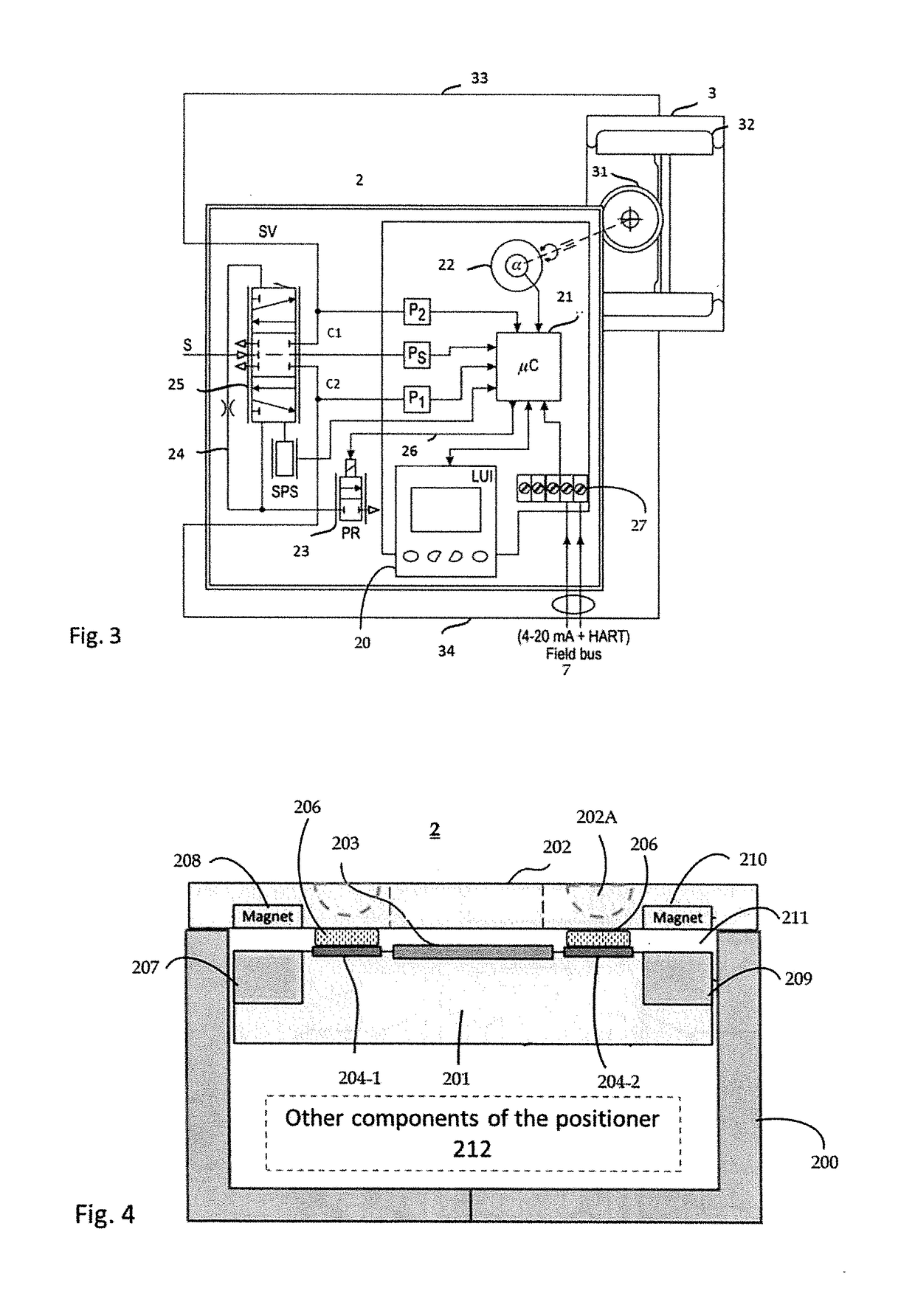

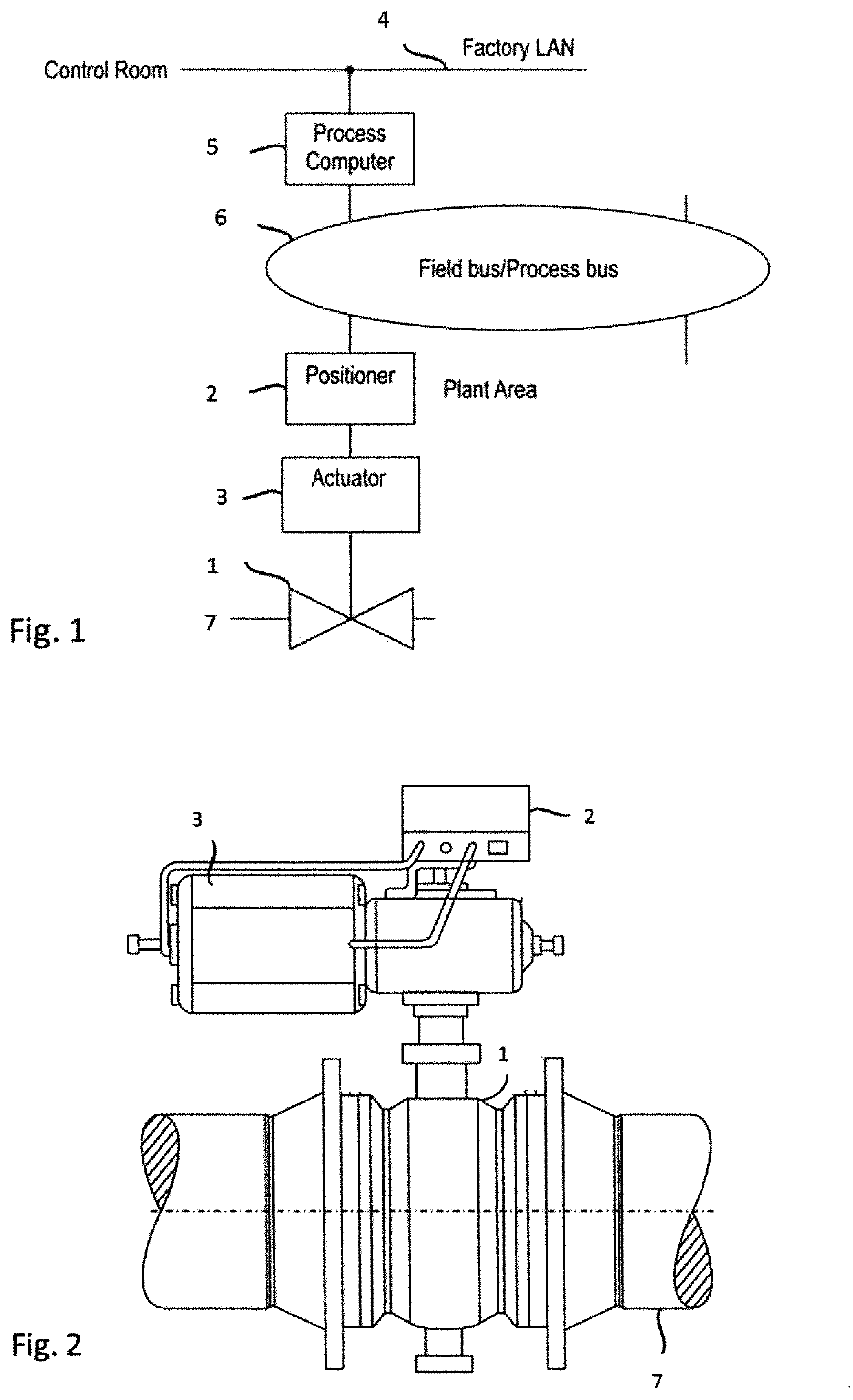

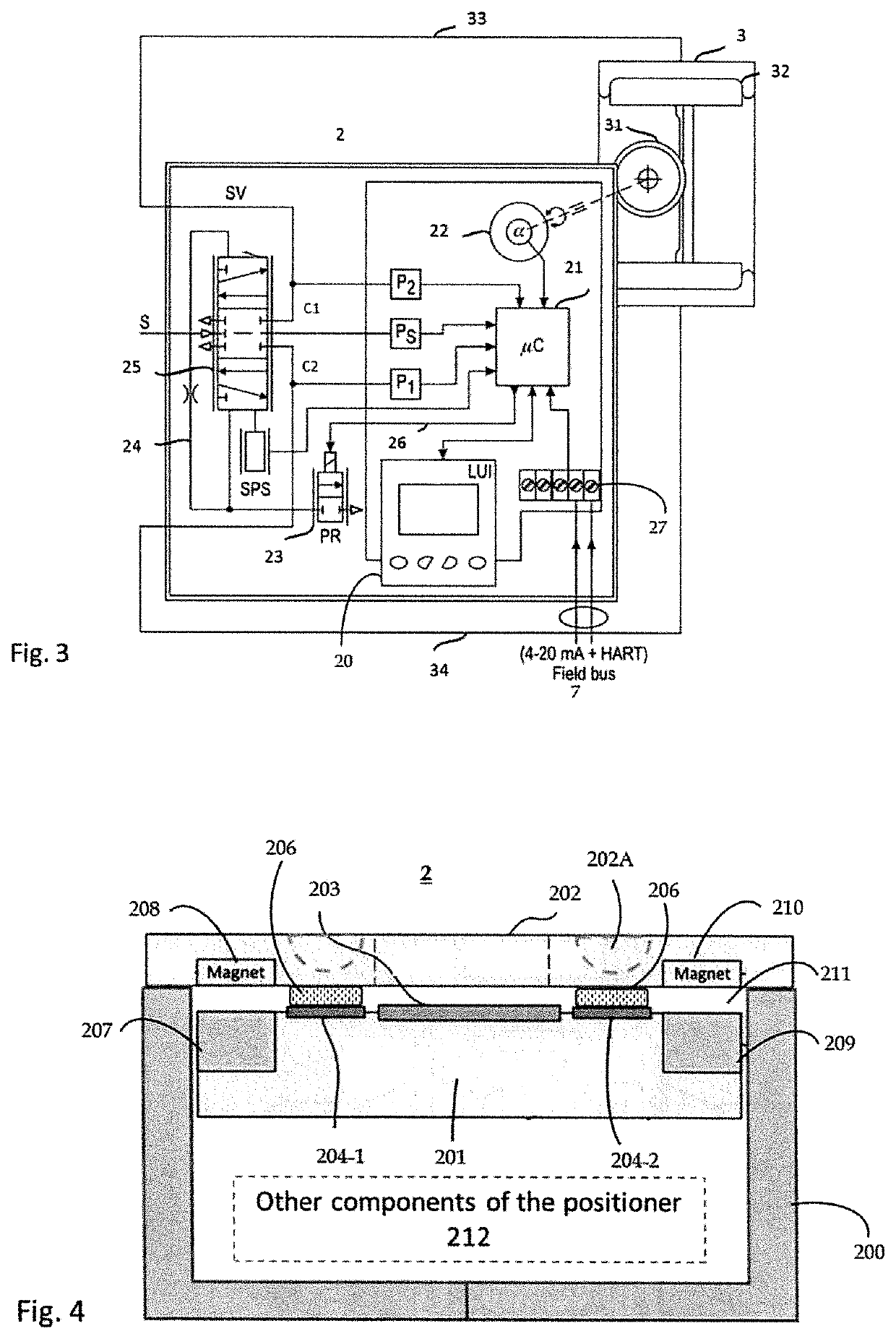

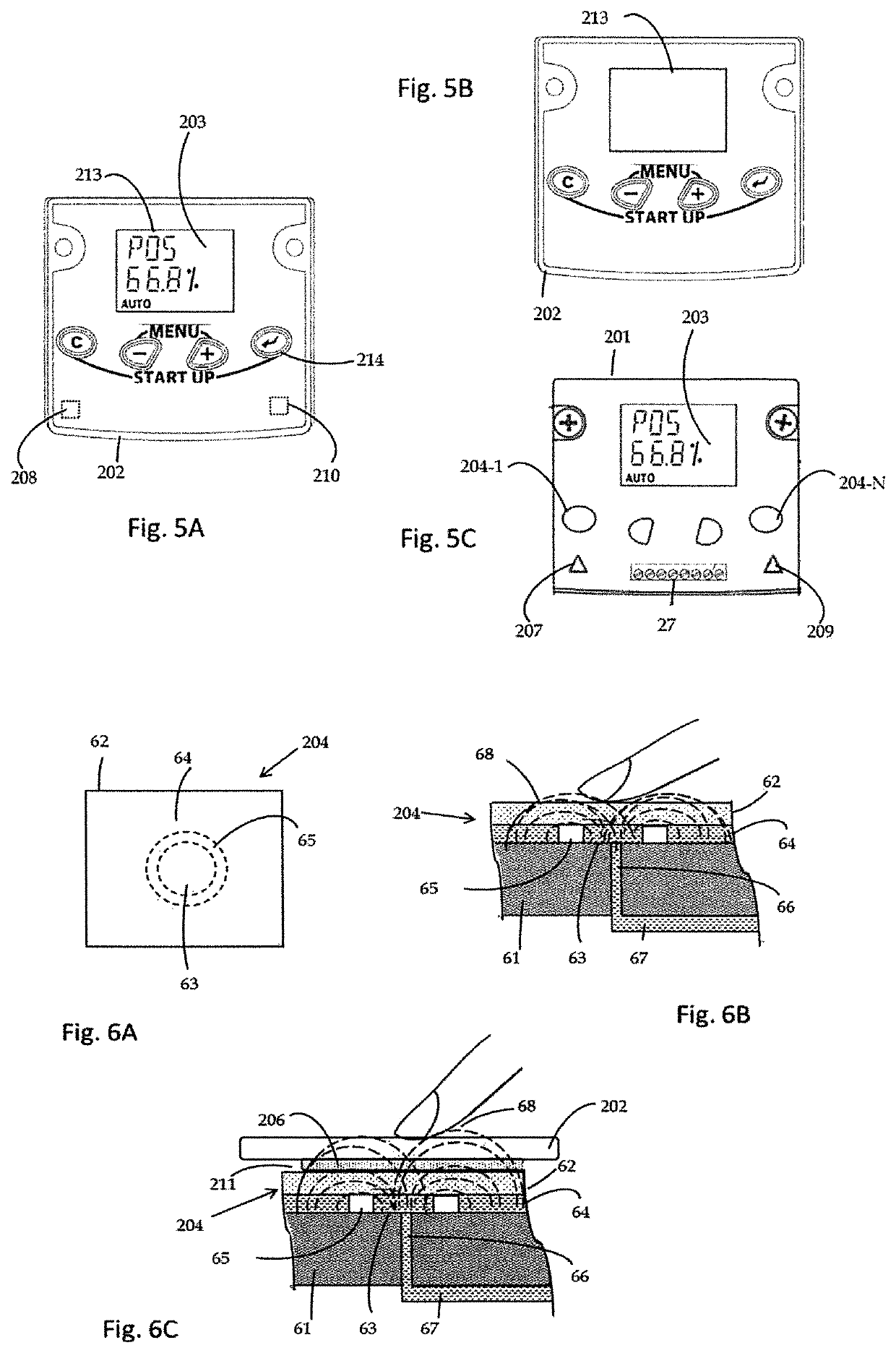

Valve positioner

ActiveUS20180129338A1Reduce crosstalkPneumatic programme controlOperating means/releasing devices for valvesDetentDisplay device

A smart valve positioner is provided with a local user interface with non-mechanical touch buttons and a display inside a positioner housing under a housing cover for locally operating the valve positioner. The touch buttons are user-operable by touching the touch buttons when the housing cover is open. The housing cover is arranged to make the touch buttons user-operable from outside the housing by touching the housing cover, when the housing cover is closed.

Owner:NELES FINLAND OY

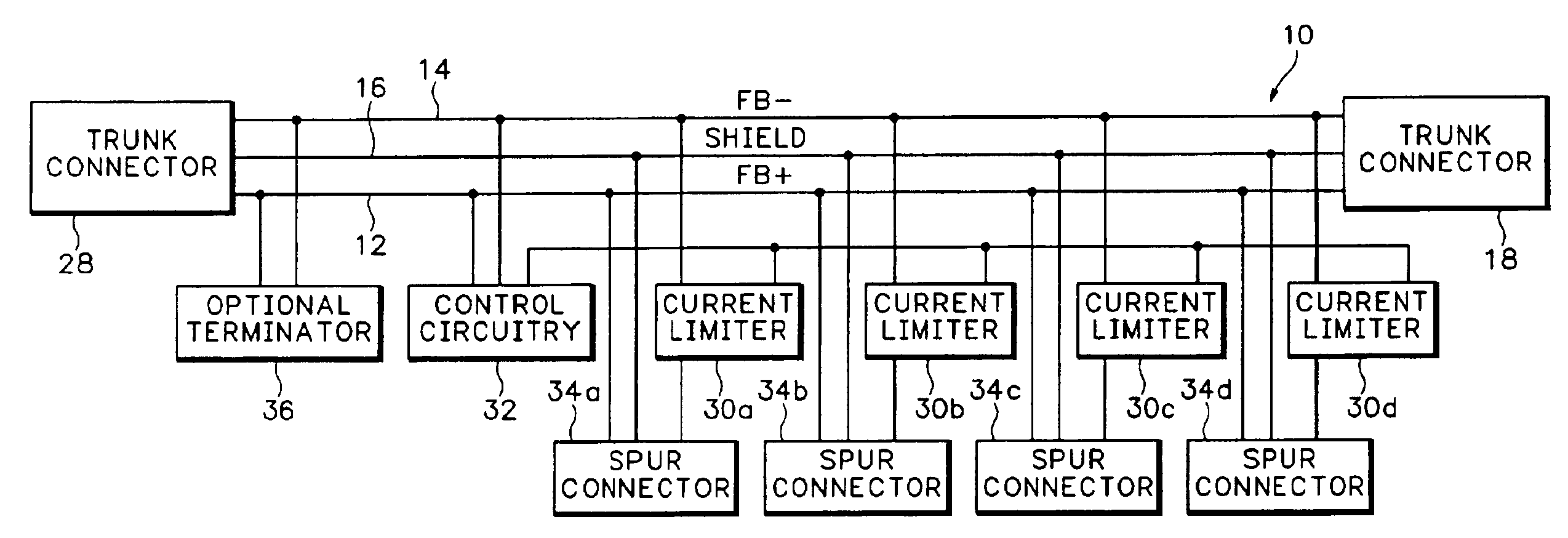

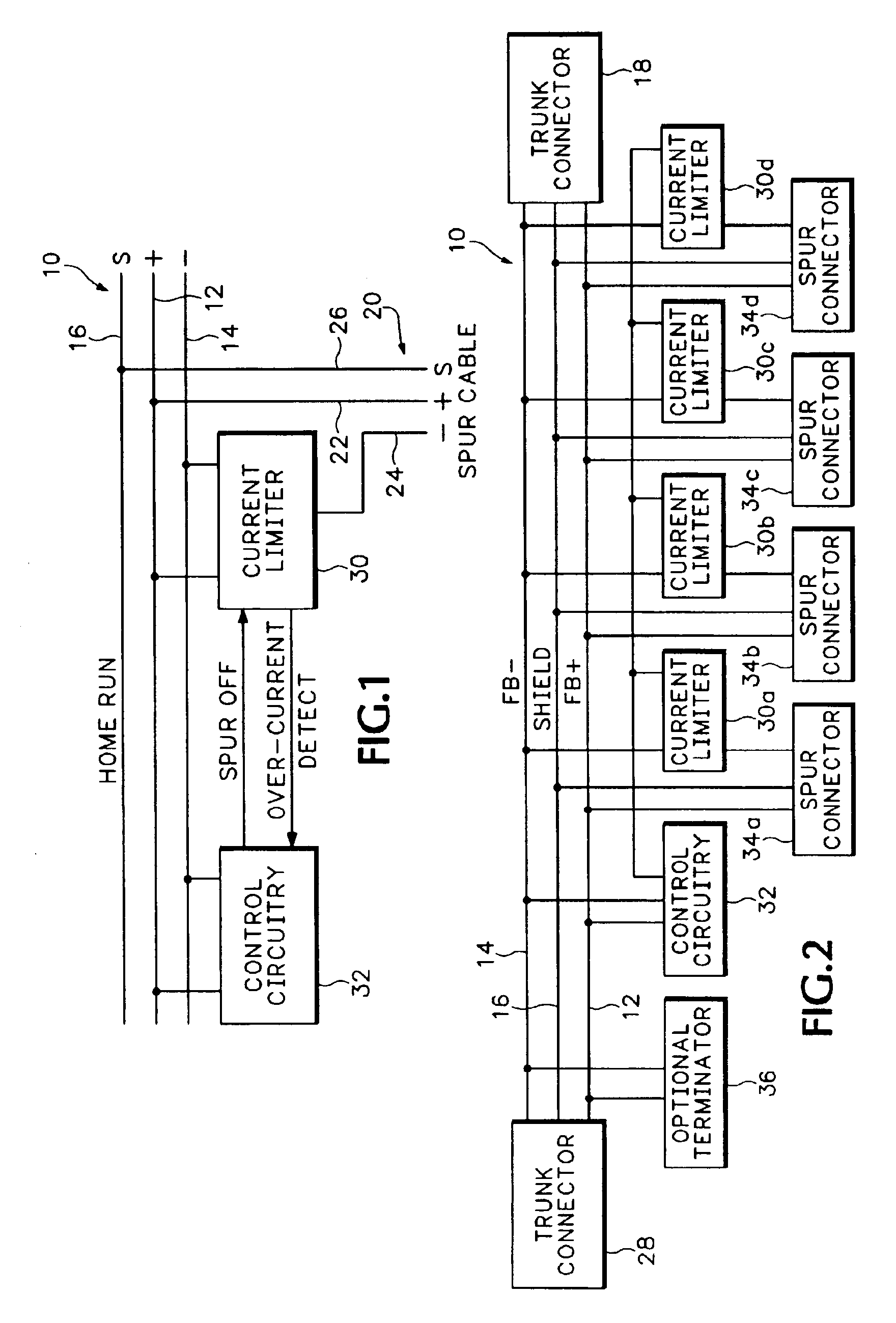

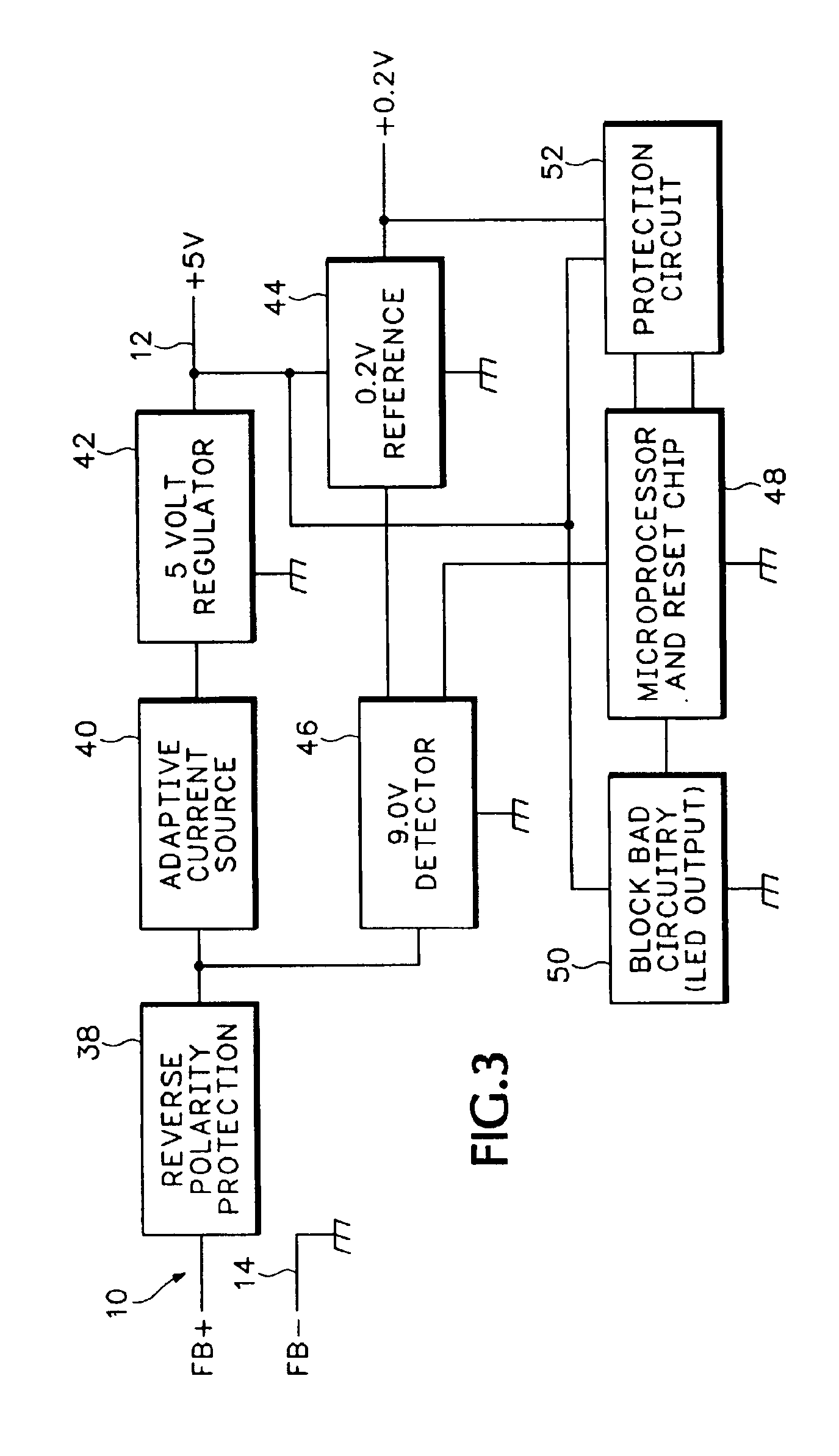

Enhanced spur cable circuit protection device and method for its implementation

The circuit of the invention provides protection for both a spur circuit and the network while allowing other spurs on the network to continue operation and is applicable to any type of fieldbus network including both FF and ASi type networks. A control circuit monitors a current limiter coupled to each spur circuit. If the spur circuit goes into an overcurrent condition for a preset period of time, the control circuit turns it off. After a second period of time has elapsed, the control circuit turns the current limiter back on permitting current to flow in the spur once again while continuing to monitor the current limiter.

Owner:RELCOM

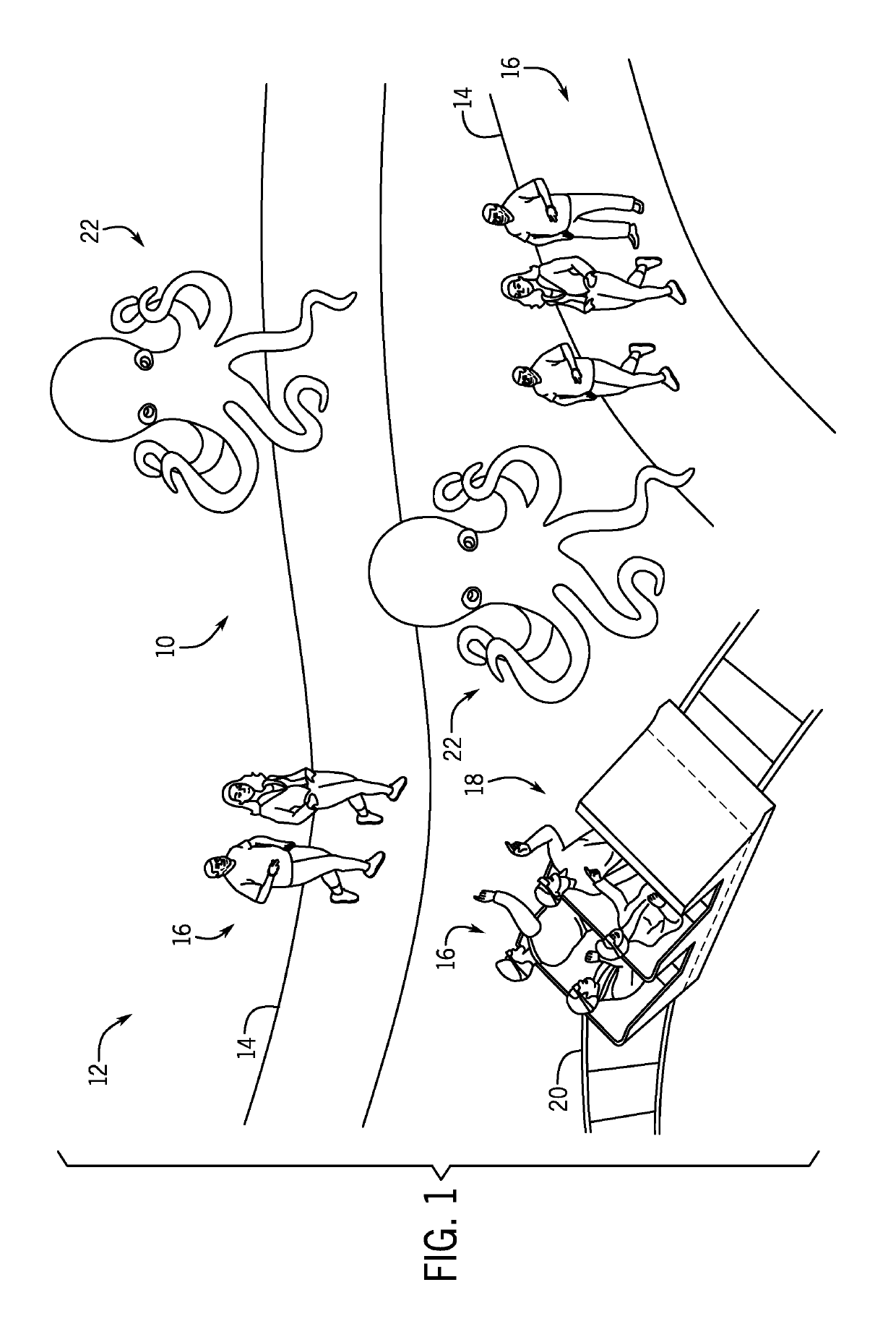

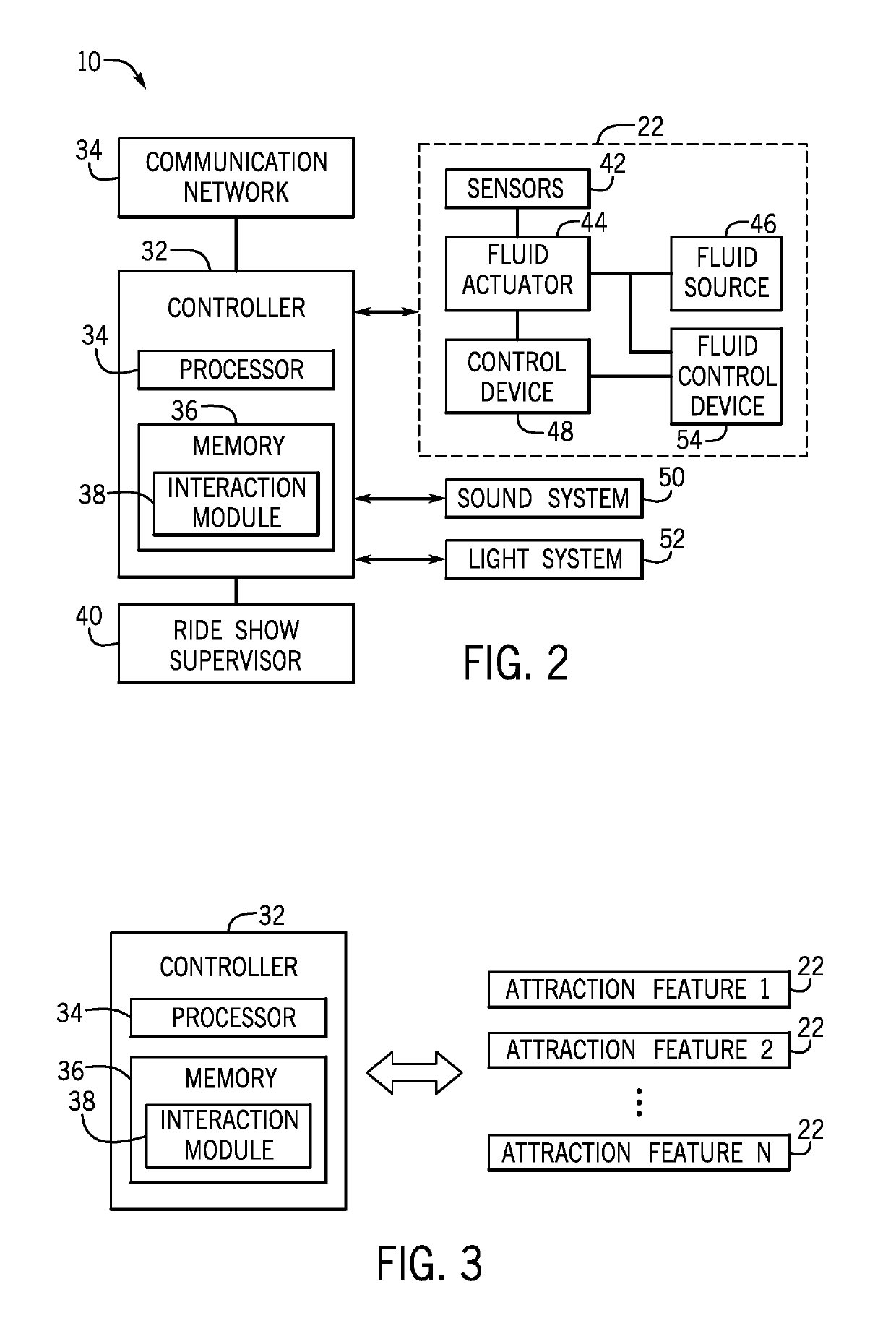

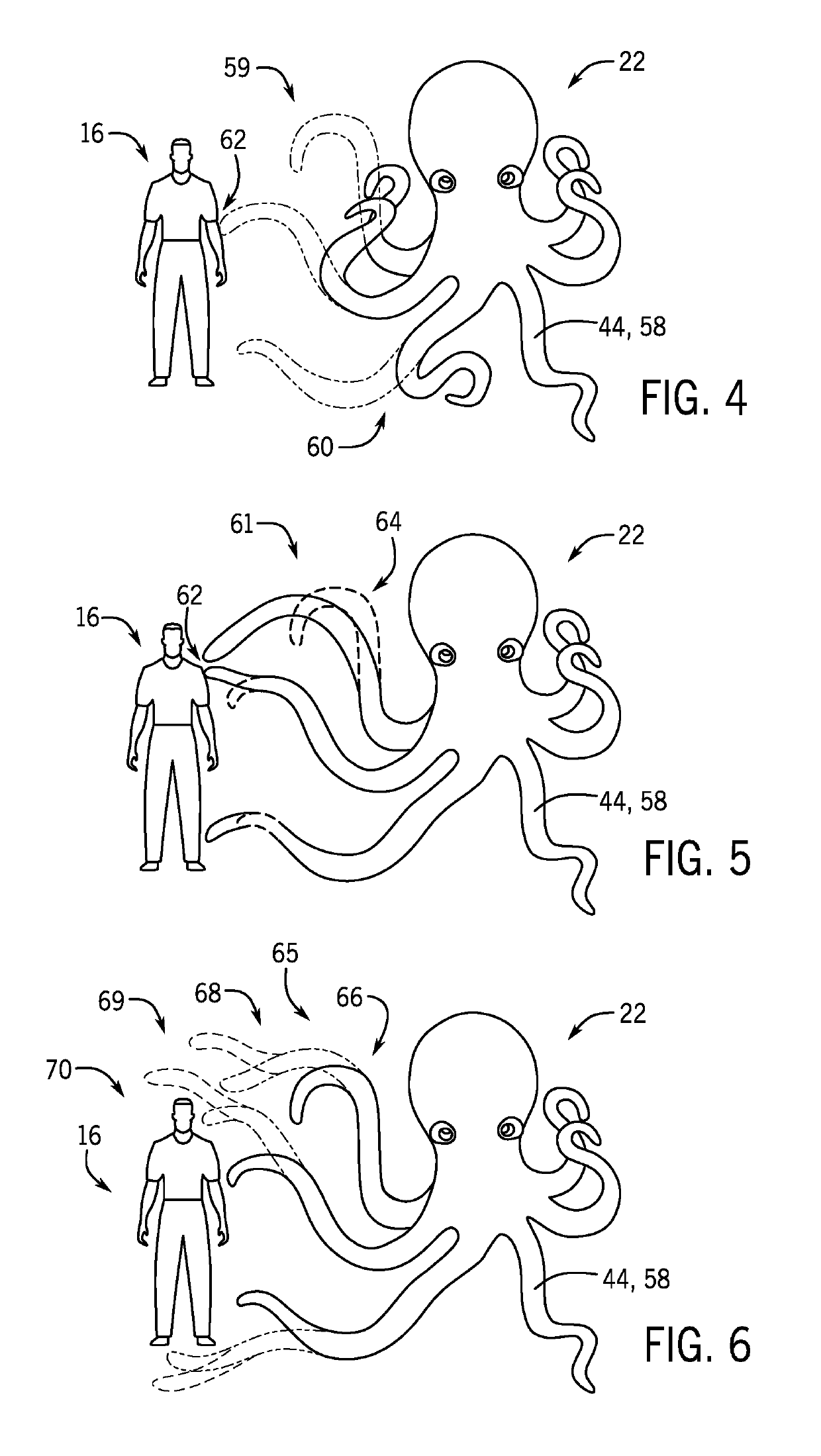

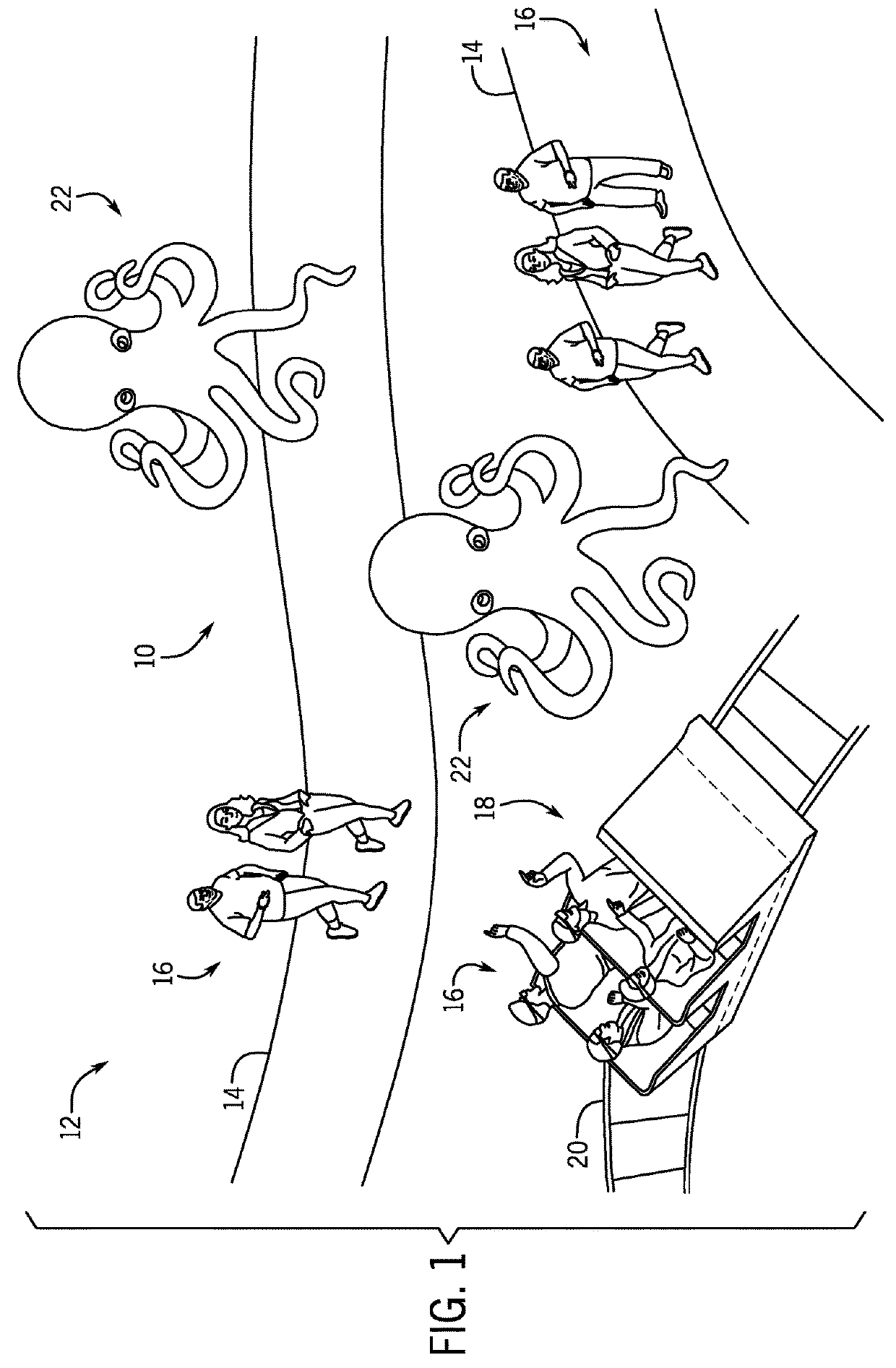

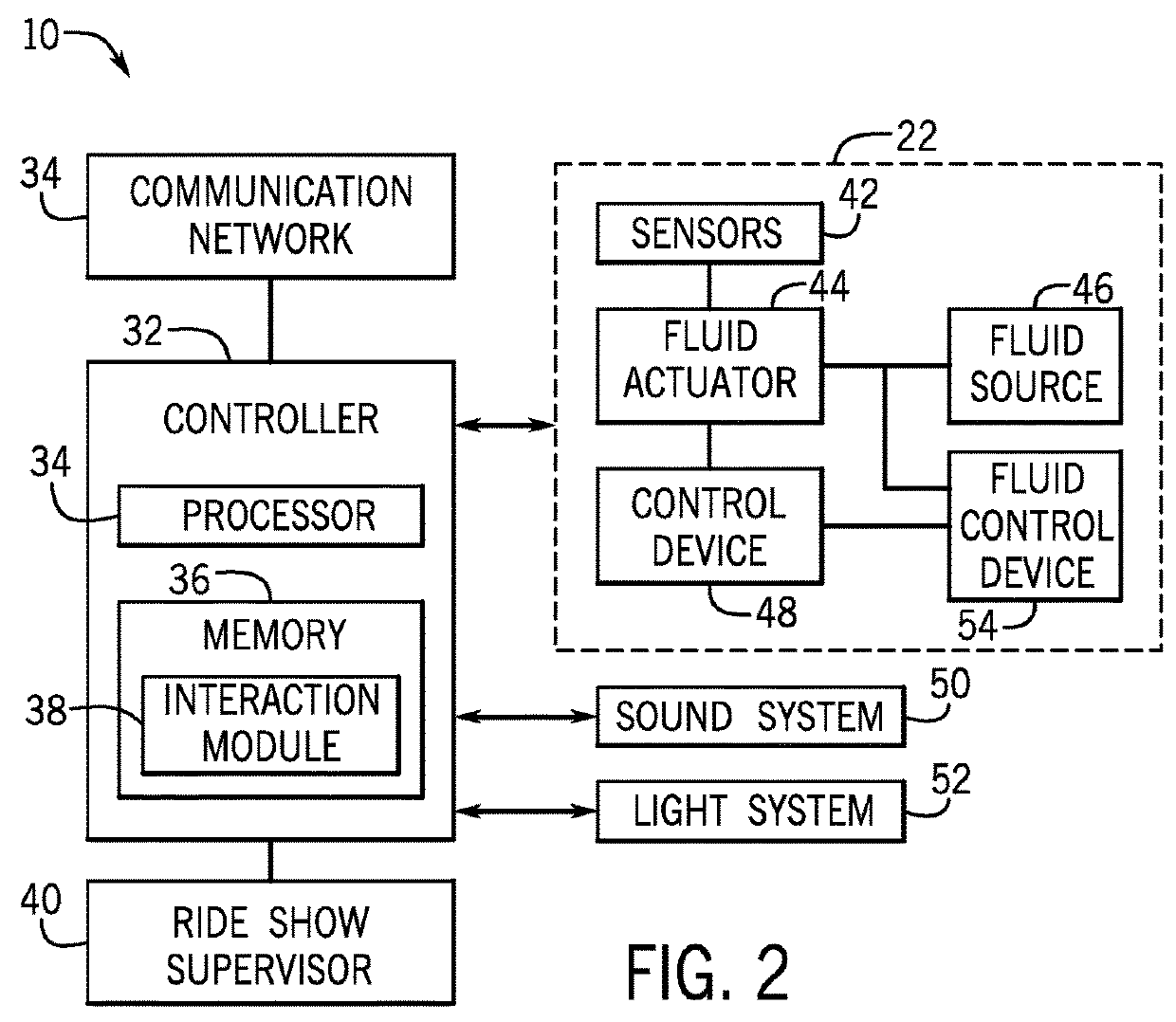

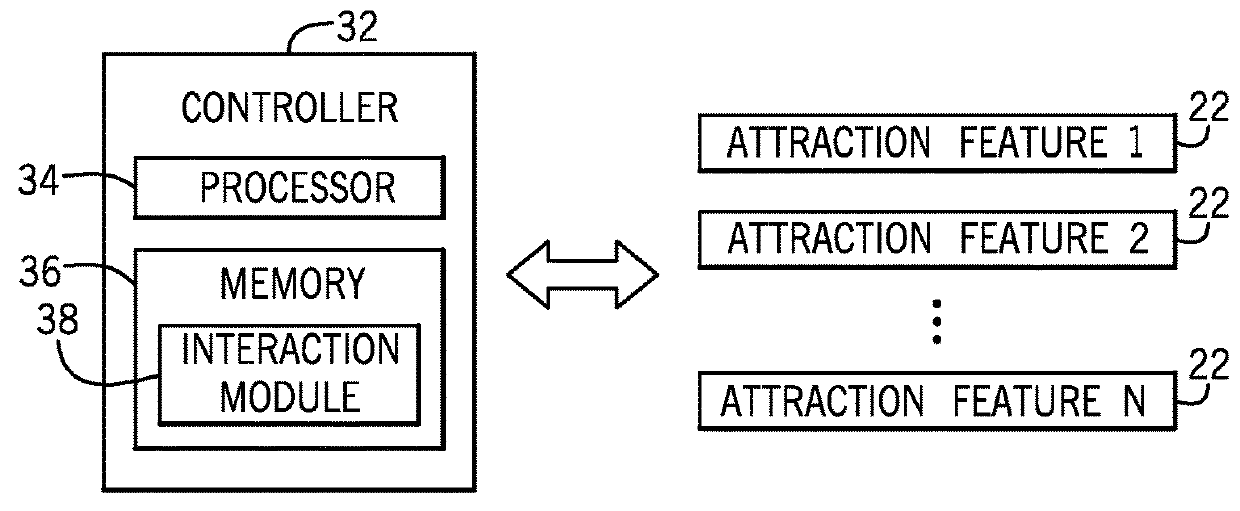

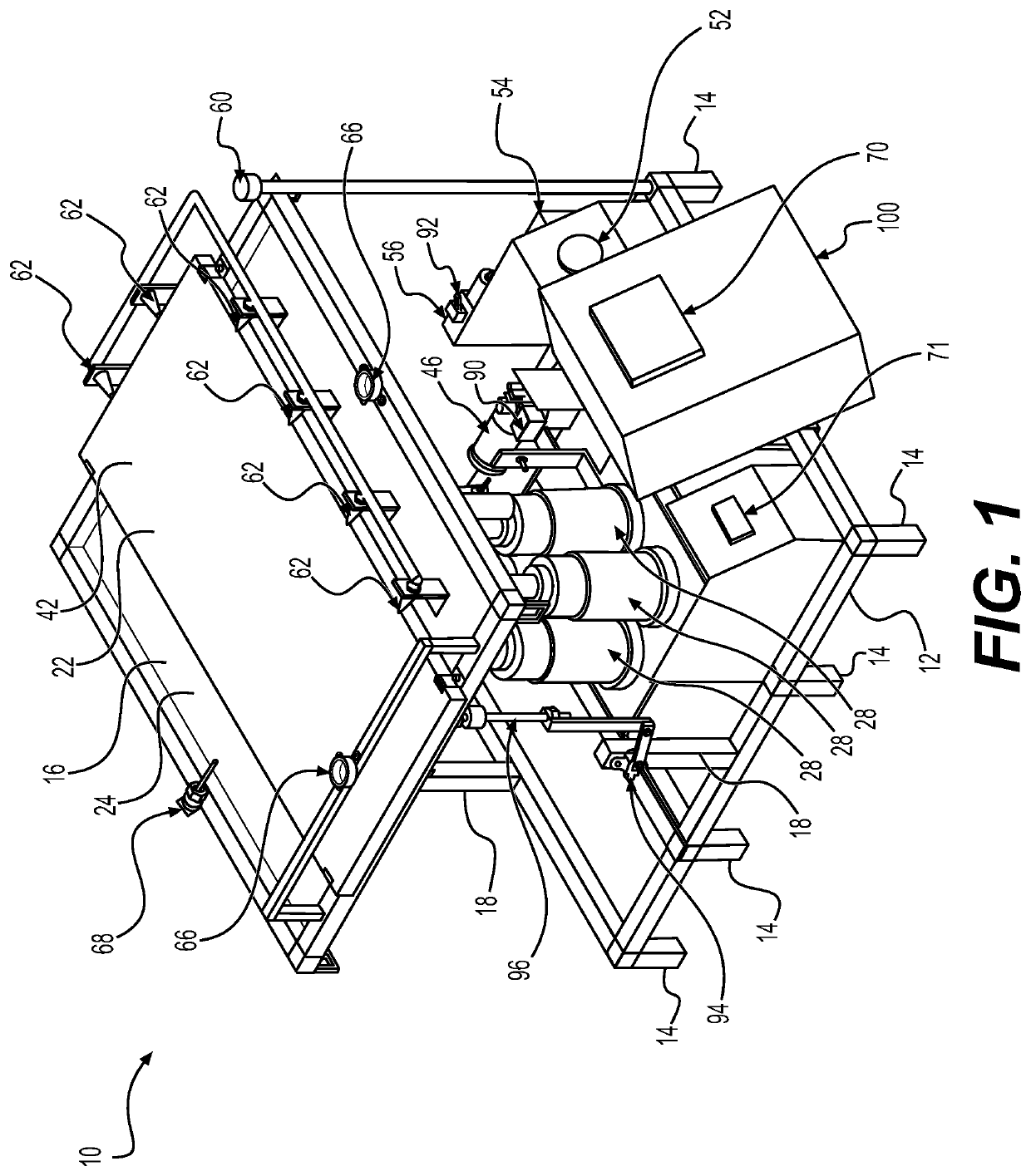

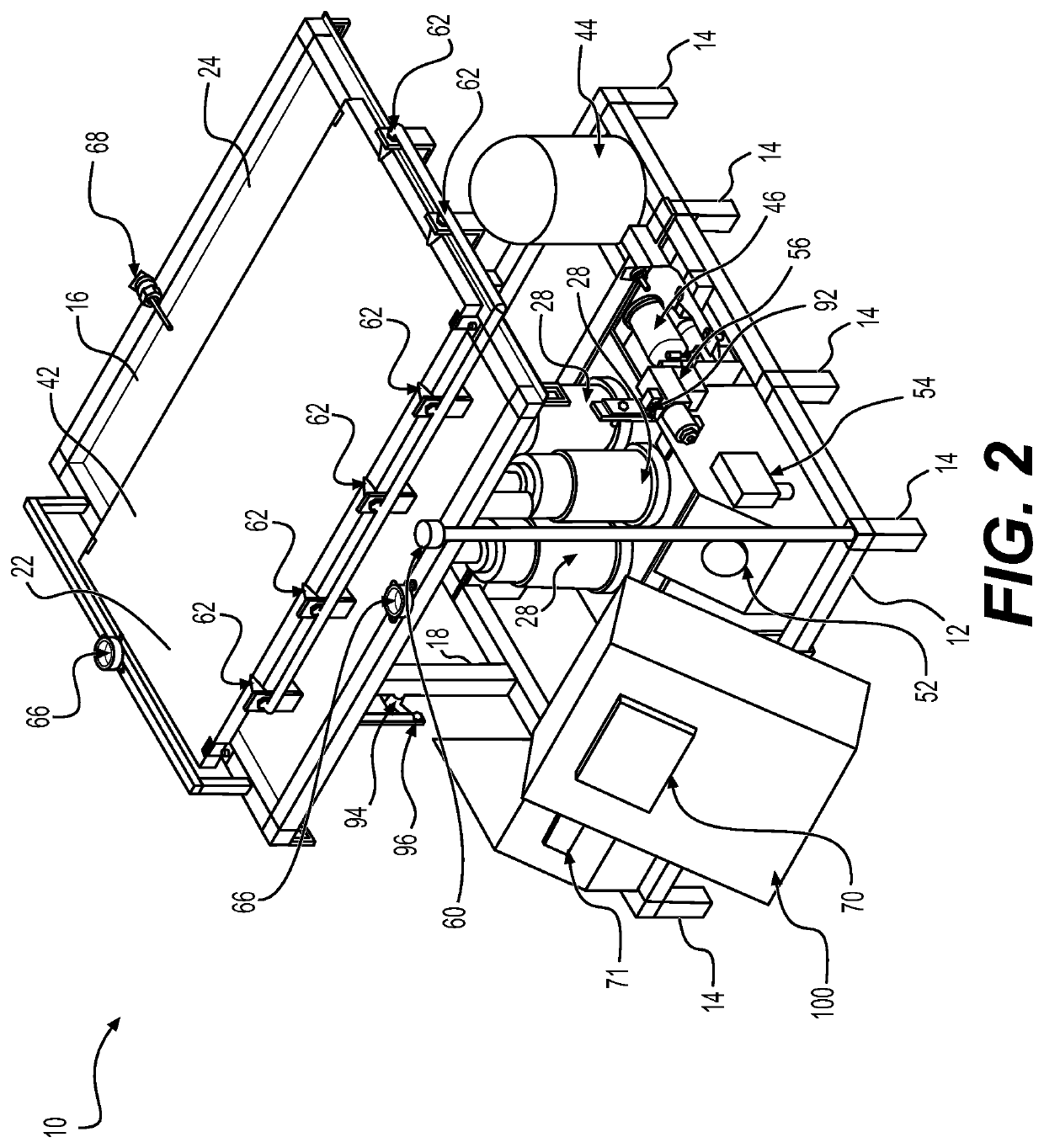

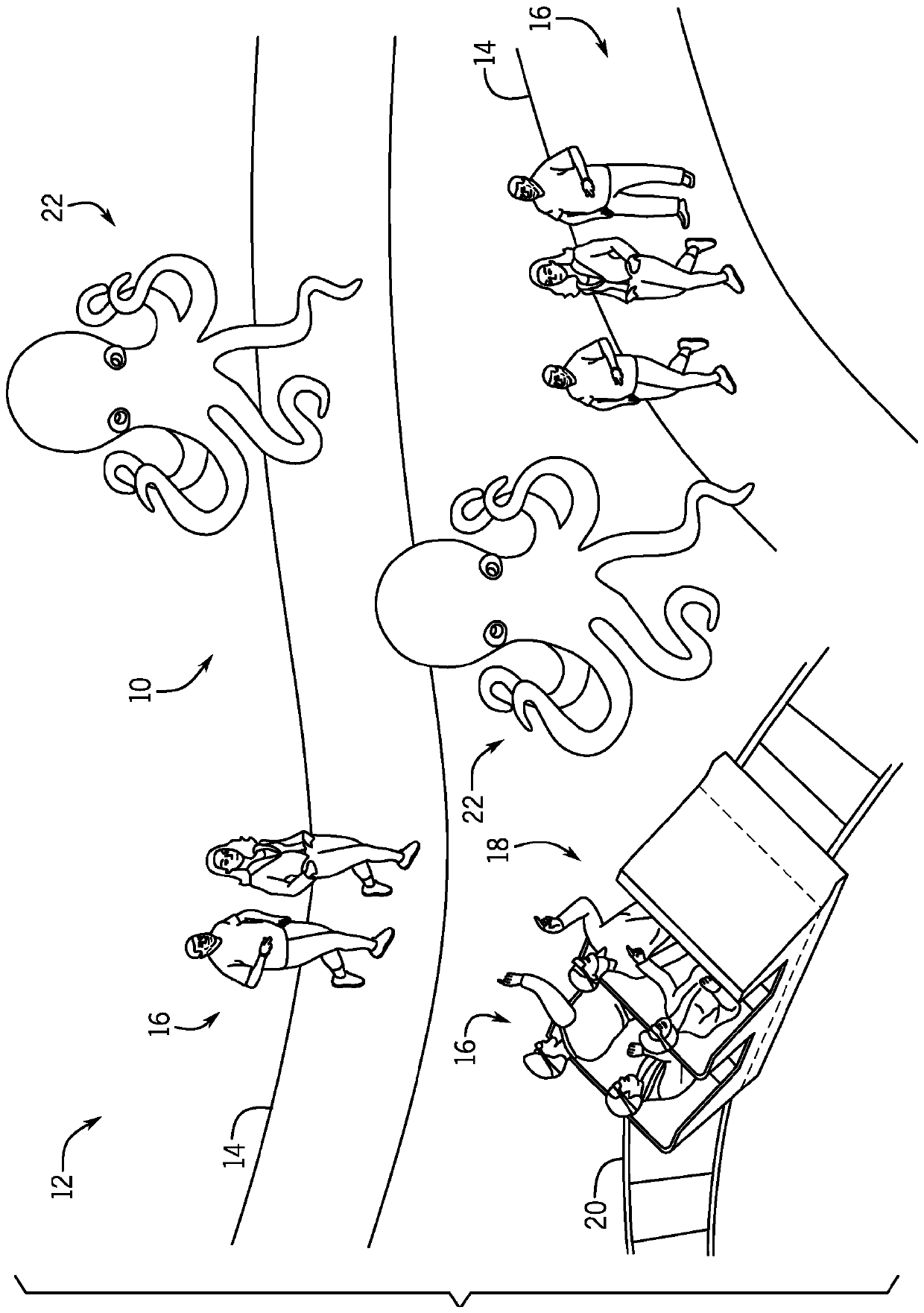

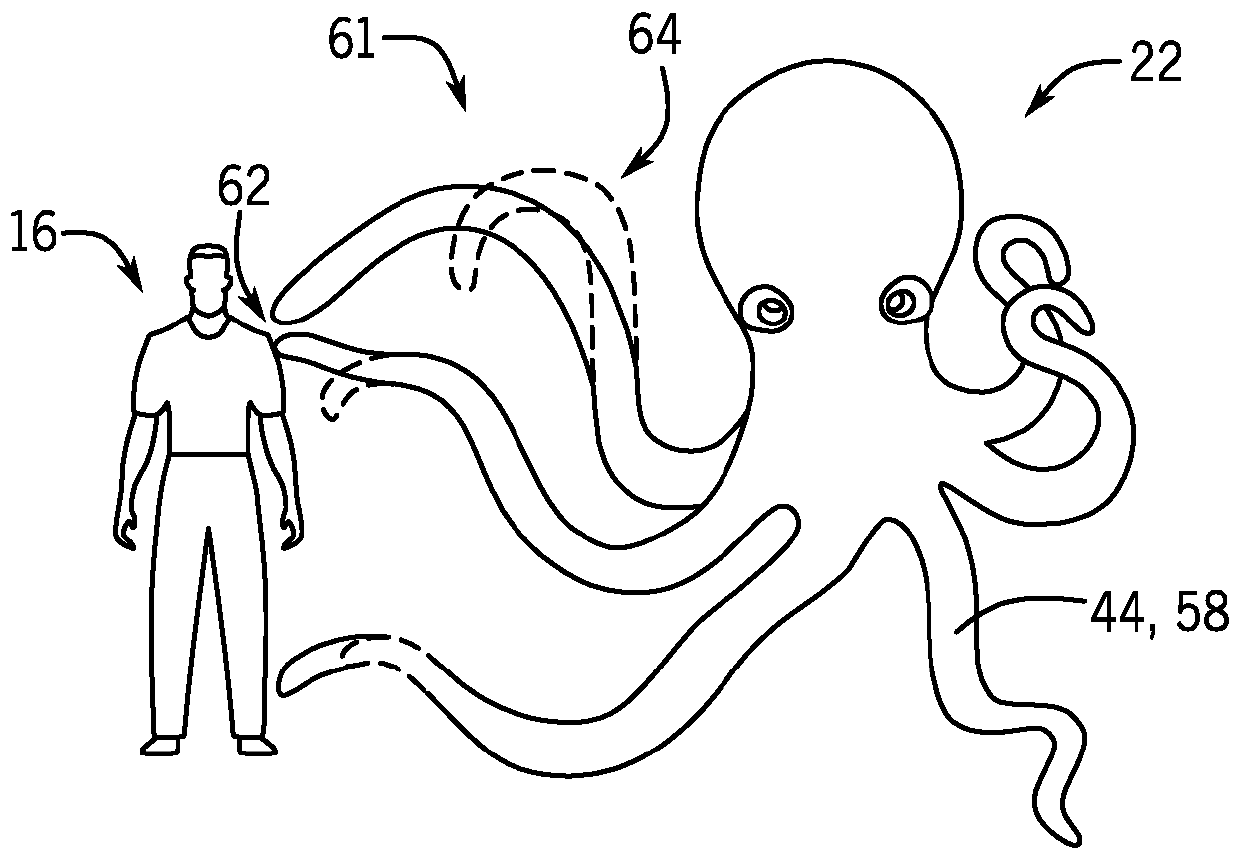

Soft robot system and method

An amusement park attraction includes an attraction feature. The attraction feature includes a fluid actuator having an inflatable mass, the inflatable mass being fluidly connected to a source of pressurized fluid to enable inflation of the inflatable mass. Fluid control devices are configured to adjust inflation of the inflatable mass, and sensors are configured to monitor state properties of the fluid actuator. A controller is communicatively coupled to the fluid control devices and the sensors. The controller is configured to controllably inflate the inflatable mass based at least on feedback from the sensors to cause the fluid actuator to impact an object. The controller is configured to control the inflation of the inflatable mass to adjust parameters of the fluid actuator to maintain a force exerted by the fluid actuator on the object to within a predetermined range.

Owner:UNIVERSAL CITY STUDIOS LLC

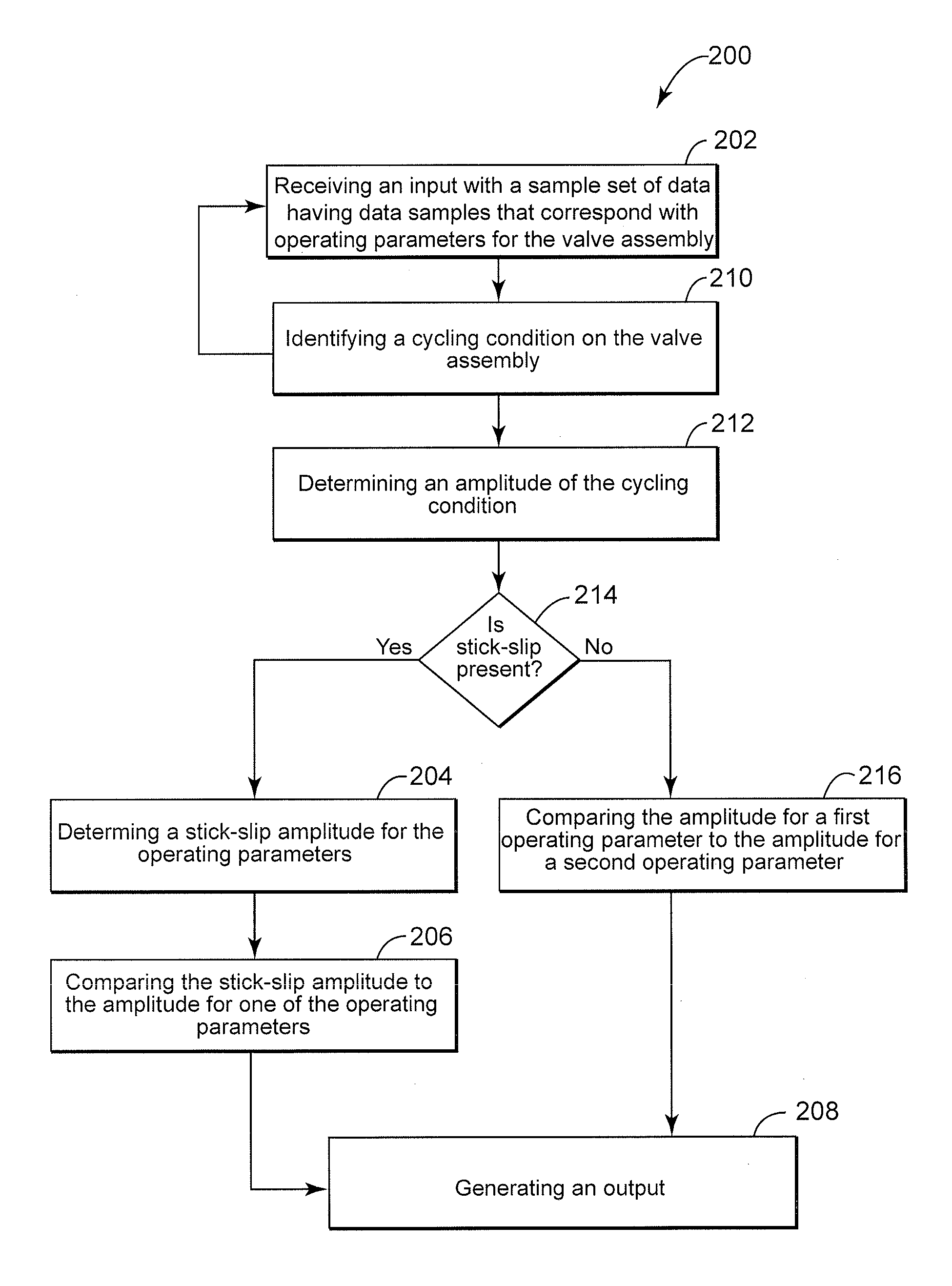

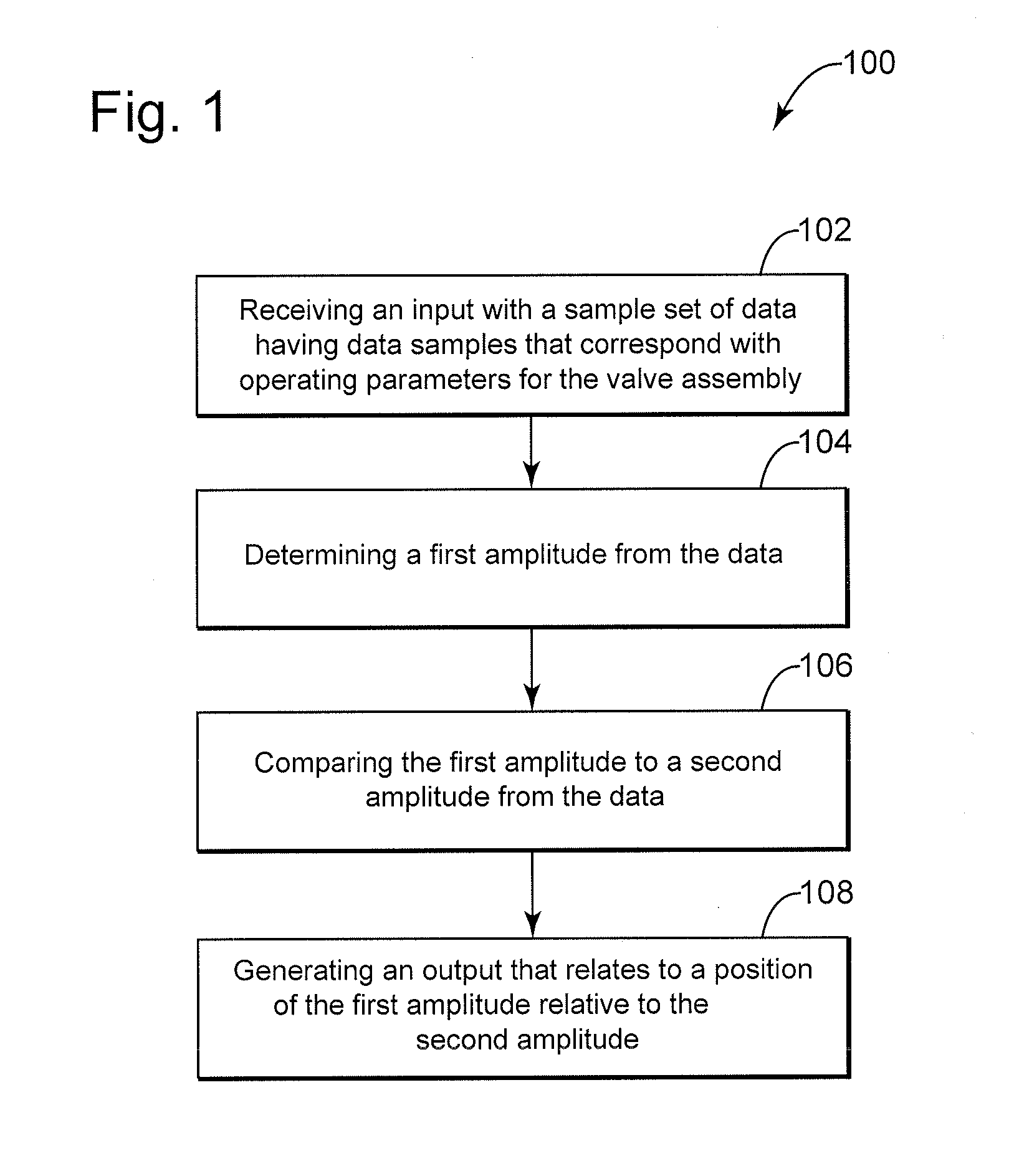

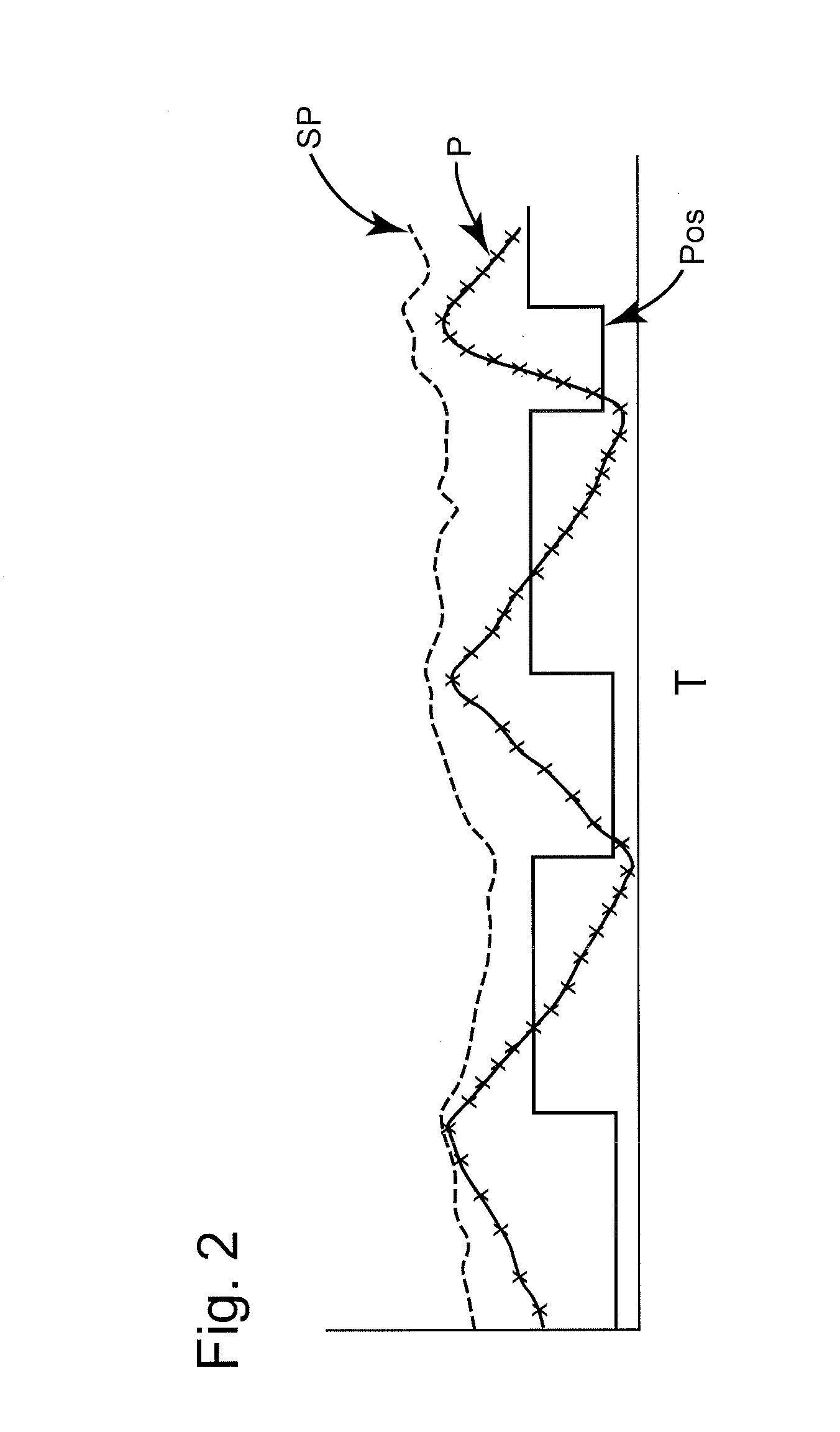

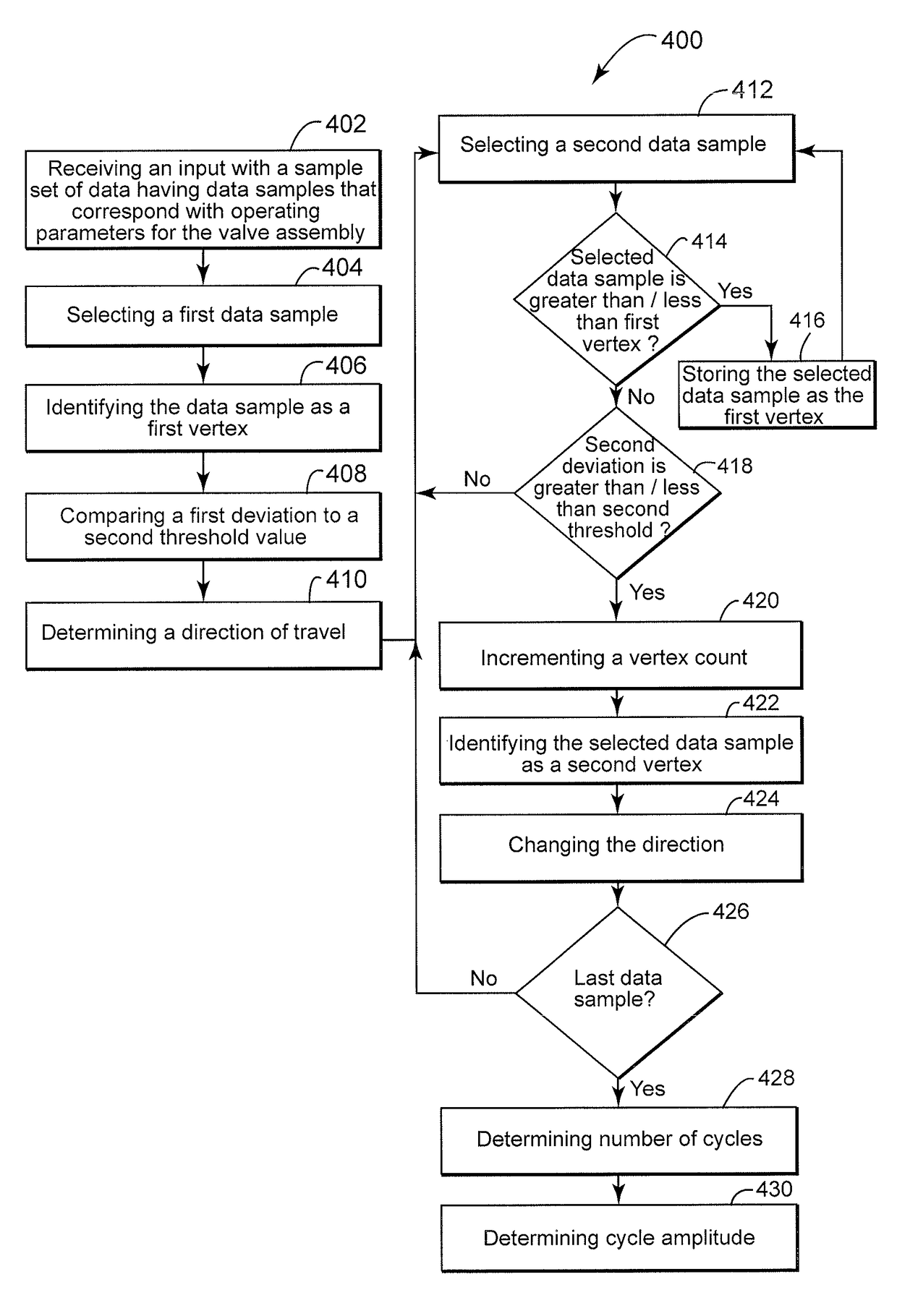

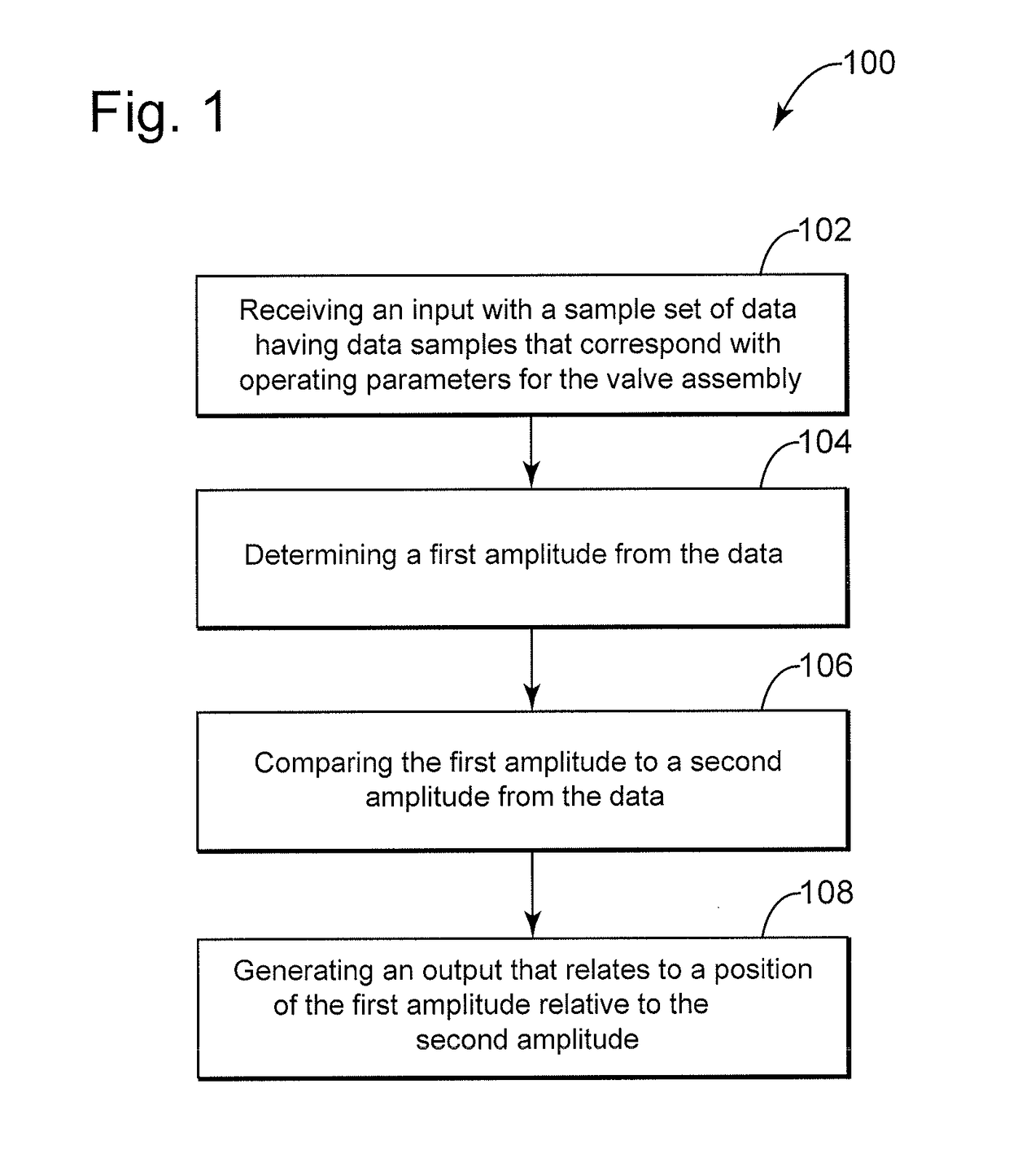

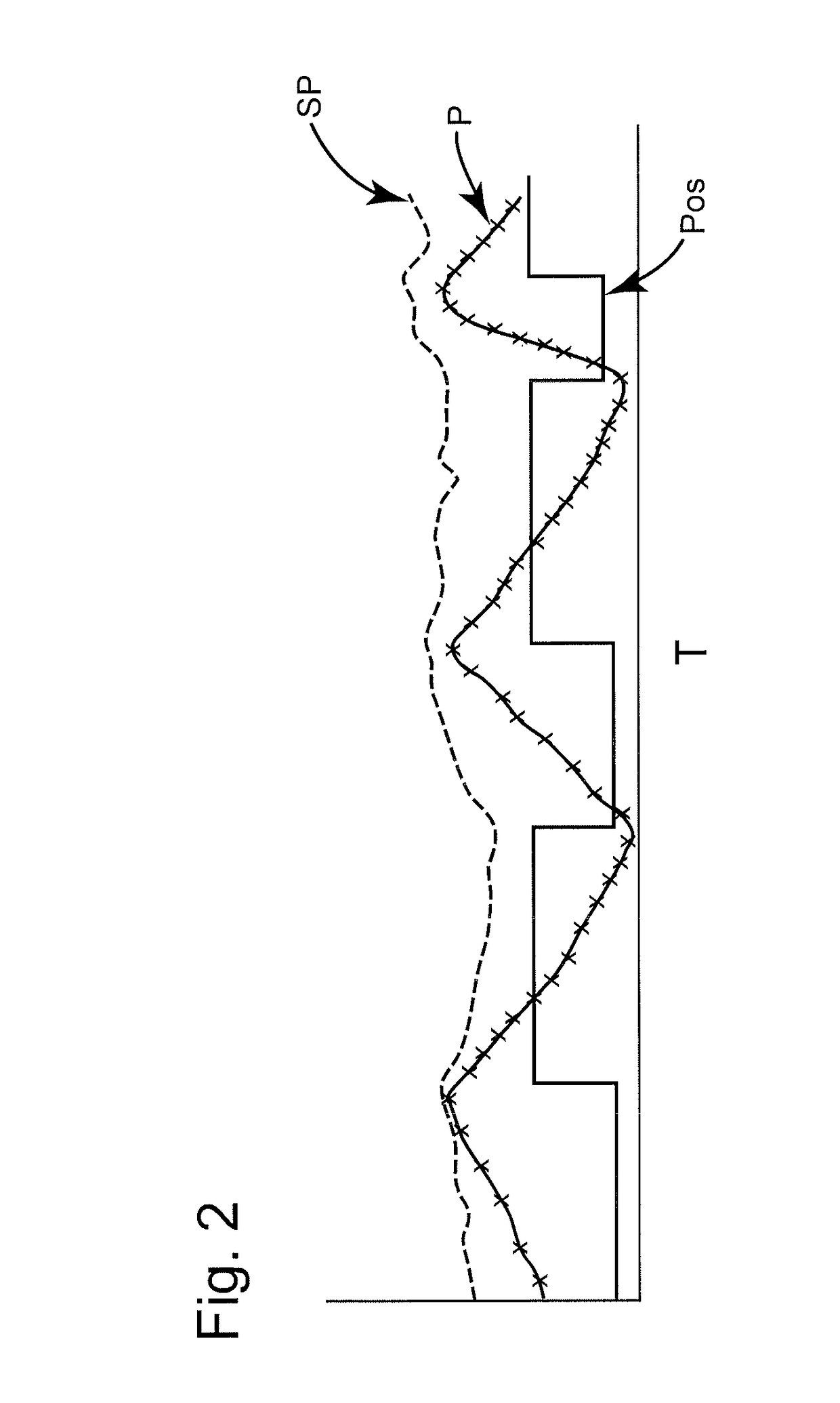

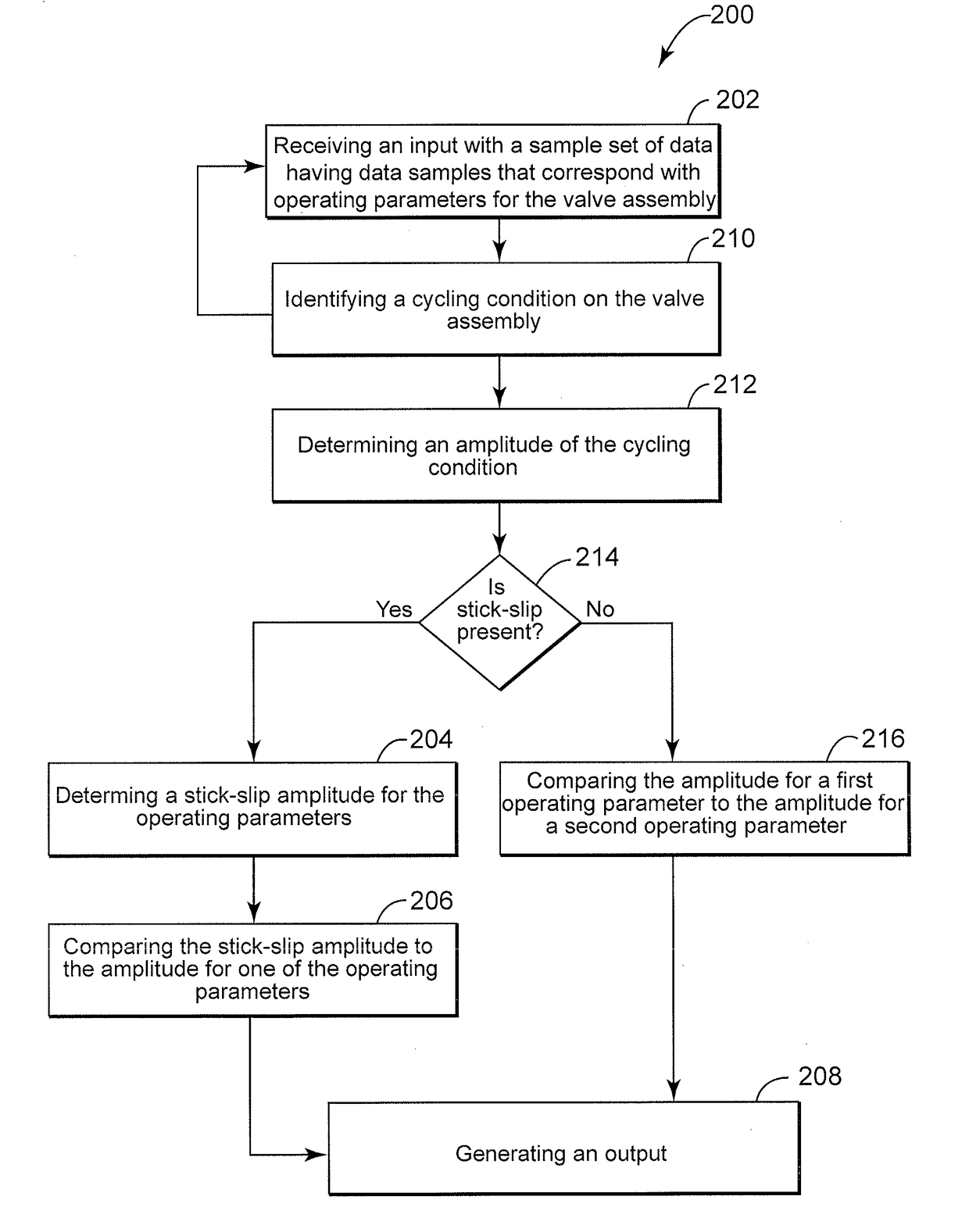

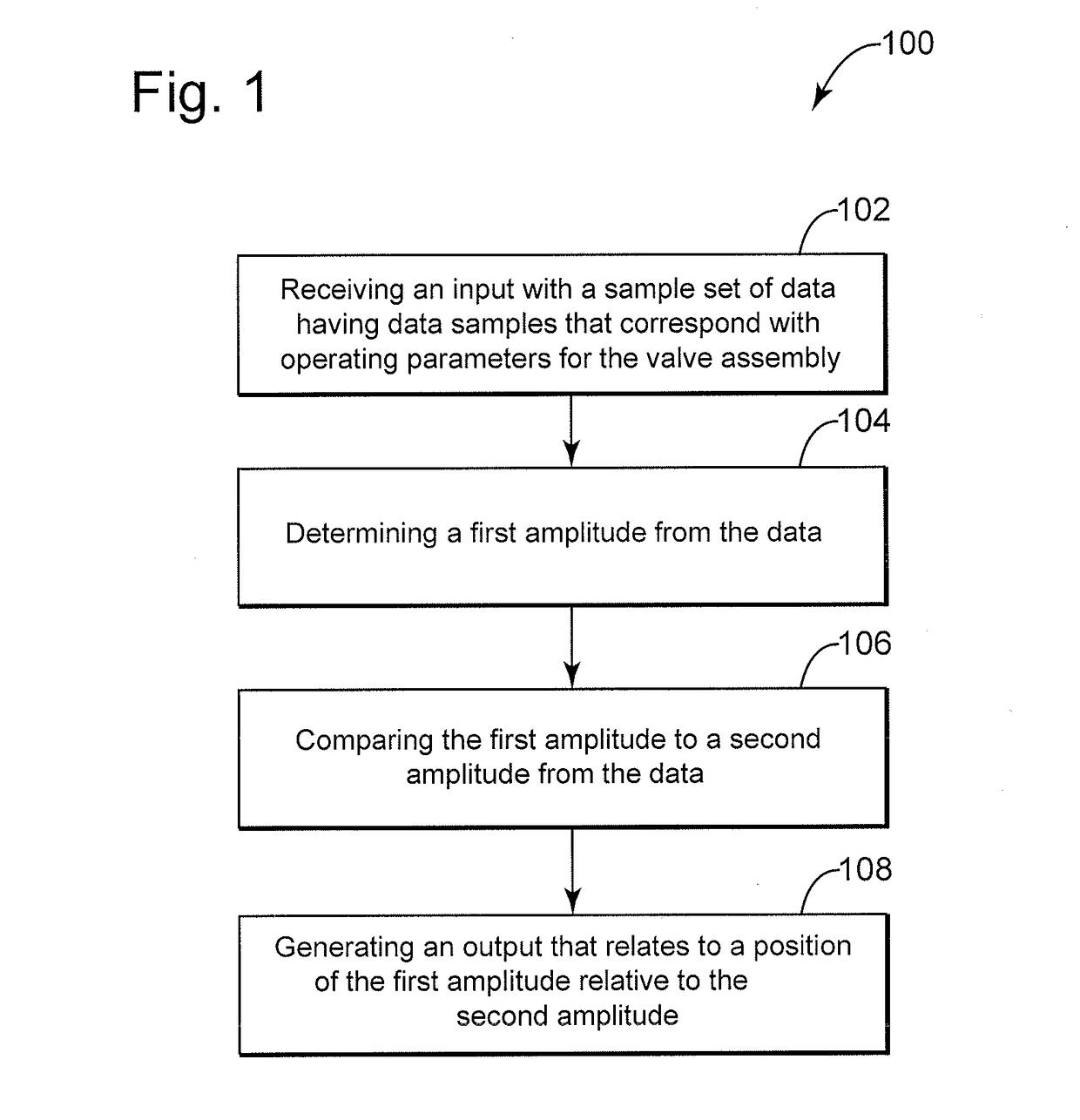

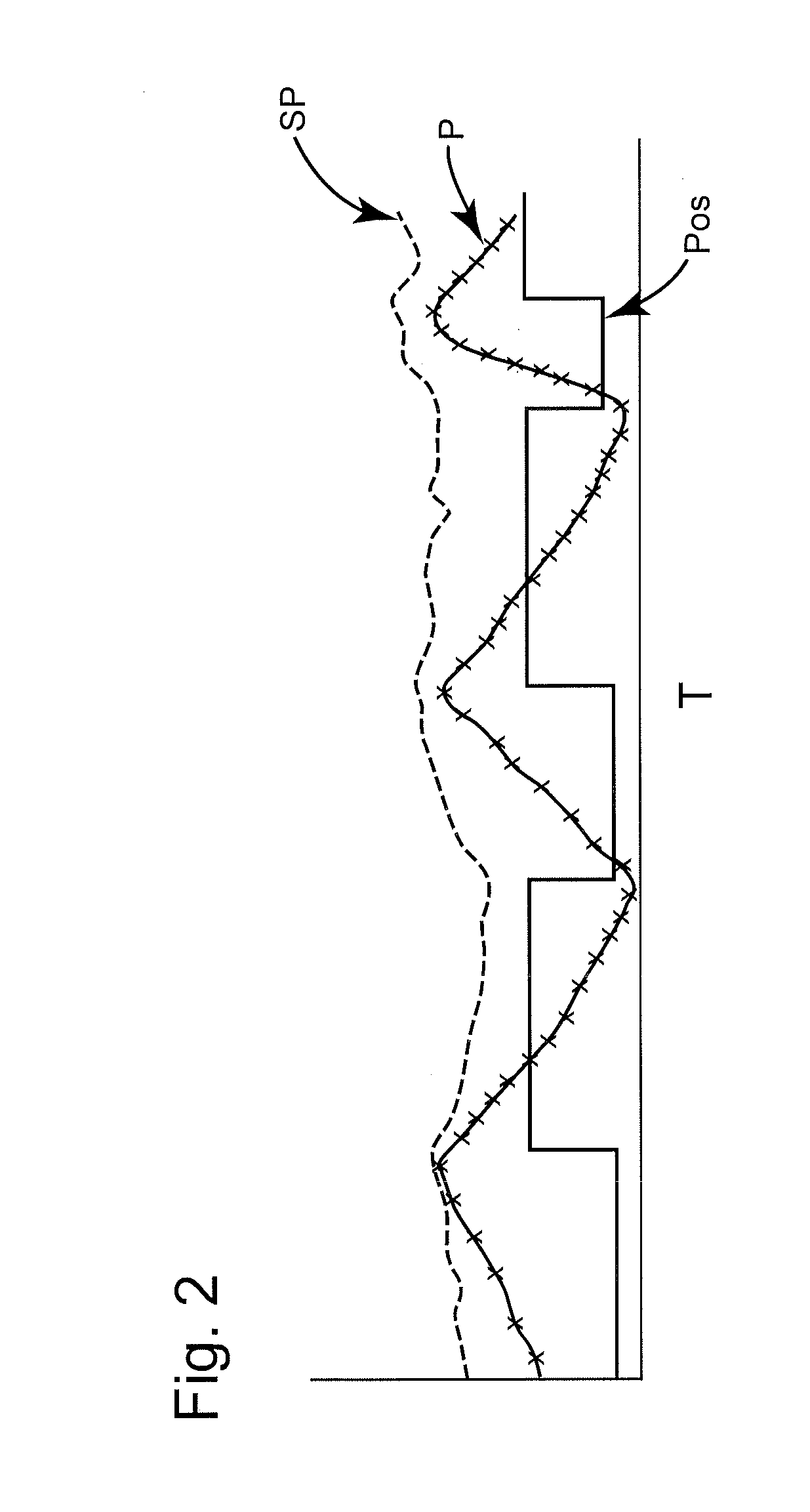

Method for determining amplitude of stick-slip on a valve assembly and implementation thereof

ActiveUS20150276087A1Disrupt stability of processDisrupting stabilityPneumatic programme controlValve arrangementsRoot causeValve stem

A method for processing operating data (e.g., position, setpoint, and pressure) for a valve assembly. The method is configured to associate characteristics of operation for the valve assembly with a root cause and / or a contributing factor. In one embodiment, the method can assign a first amplitude with a value that quantifies movement or “jump” of the valve stem that results from stick-slip on the valve assembly. The method can also assign a second amplitude with a value that quantifies a change in the data for the setpoint. The method can further ascertain the relationship or “position” of the first amplitude relative to the second amplitude, or vice versa. The method can use the relationship between the first amplitude and the second amplitude to indicate the root cause of the operation of the valve assembly.

Owner:DRESSER LLC

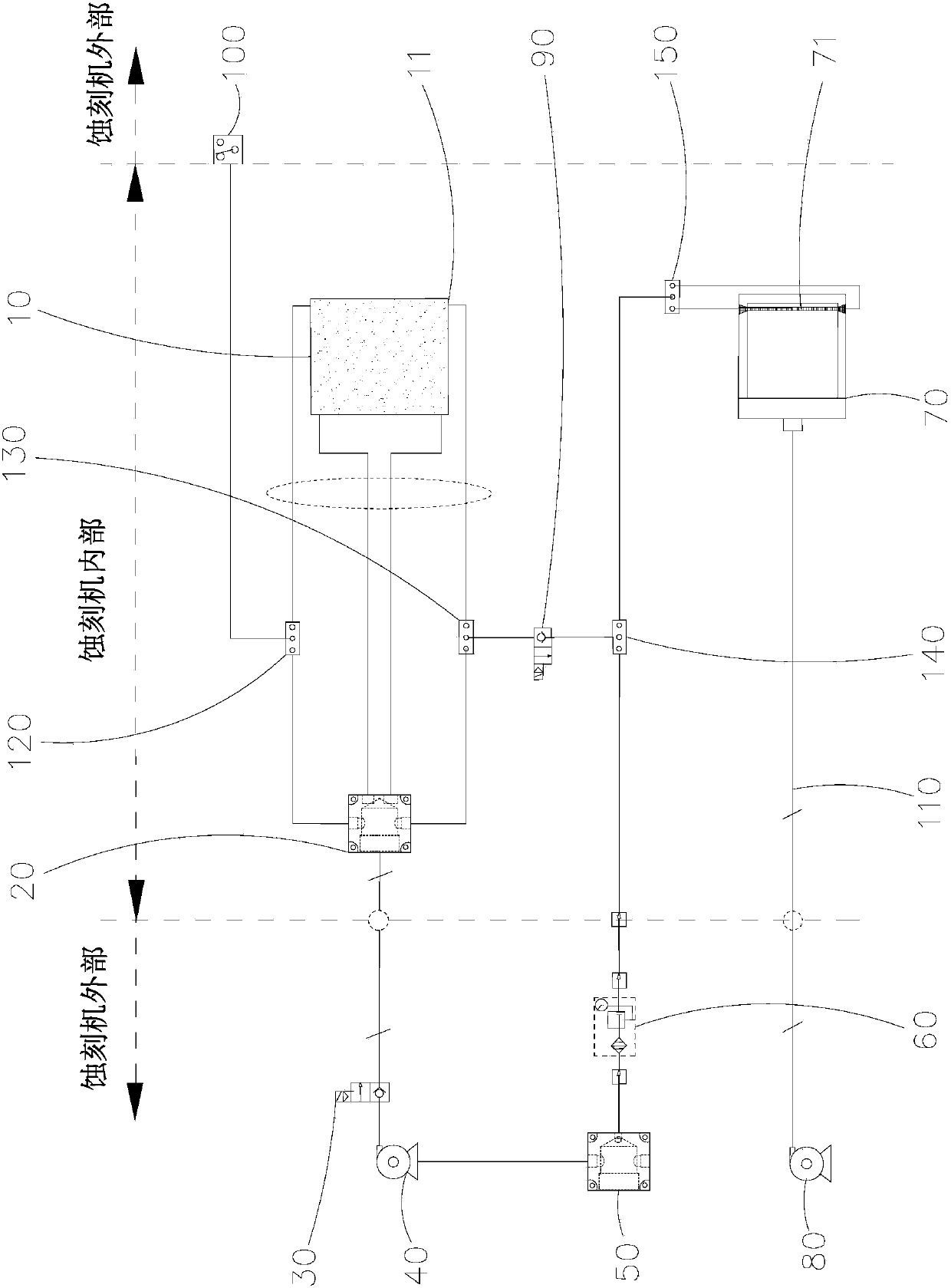

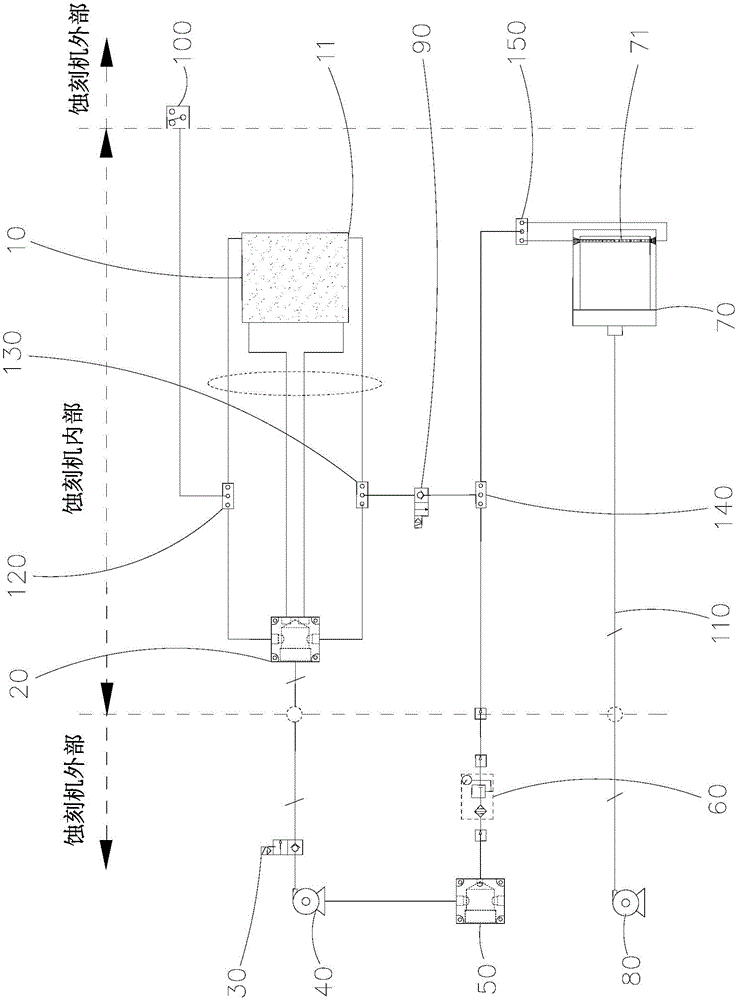

Air path control system of vacuum absorption platform

The invention discloses an air path control system of a vacuum absorption platform. The air path control system of the vacuum absorption platform comprises a vacuum absorption workbench, a first air division seat, a direct current valve, a first vortex air pump, a second air division seat, a pressure regulating filter, a flue gas purification cover, a second vortex air pump and an electromagnetic valve. The vacuum absorption workbench, the first air division seat, the direct current valve, the first vortex air pump, the second air division seat, the pressure regulating filter, the flue gas purification cover and the second vortex air pump are sequentially connected in series through a plurality of air pipes. The two ends of the electromagnetic valve are connected with the first air division seat and the pressure regulating filter respectively. In the time of processing, the vacuum absorption workbench is in a negative pressure state. After materials are processed, air blown from the first vortex air pump enters the vacuum absorption workbench from the electromagnetic valve. The problem that after processing by an etching rack is finished, materials are difficult to take out under the influences of negative pressure is solved.

Owner:GUANGDONG HANS YUEMING LASER GRP CO LTD

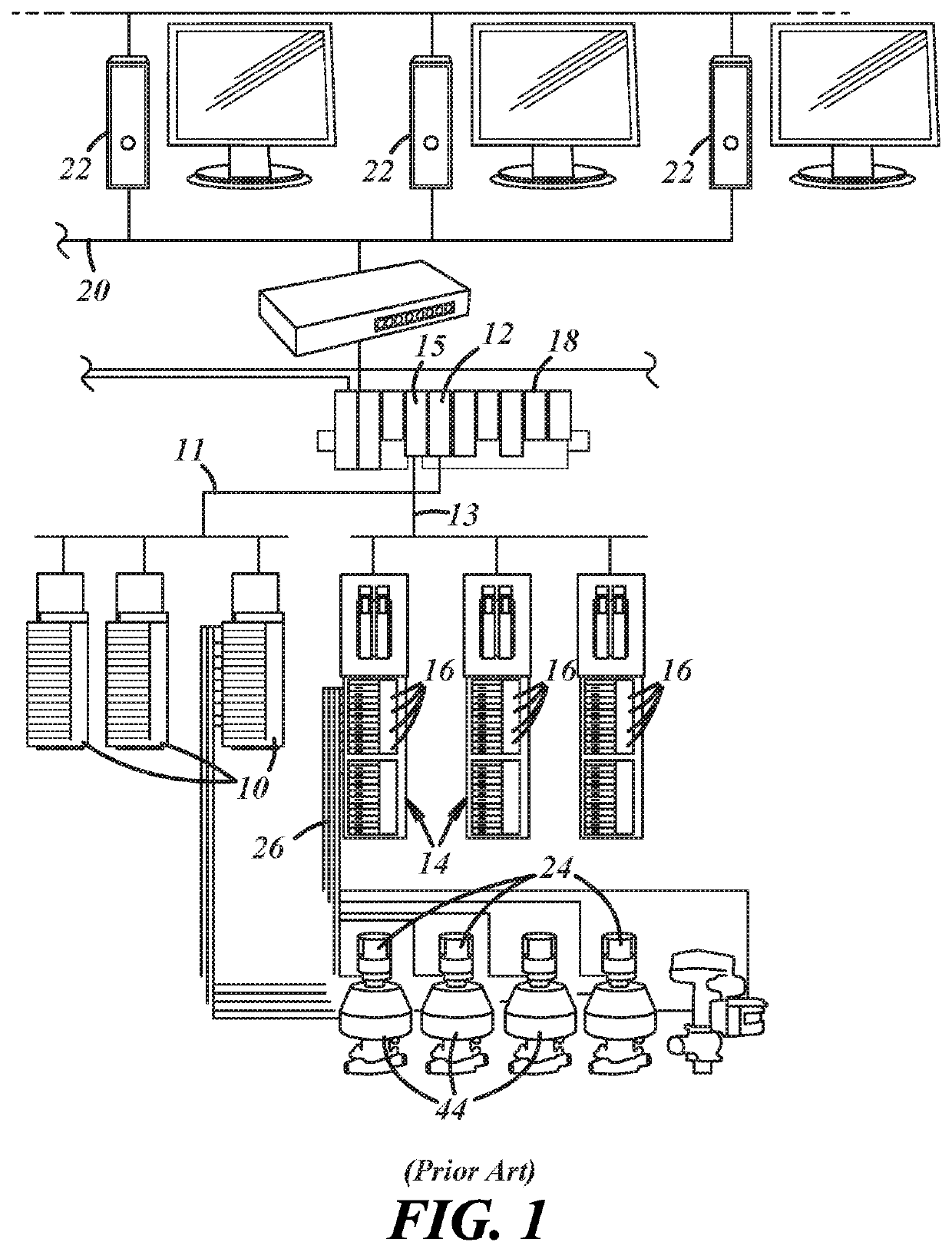

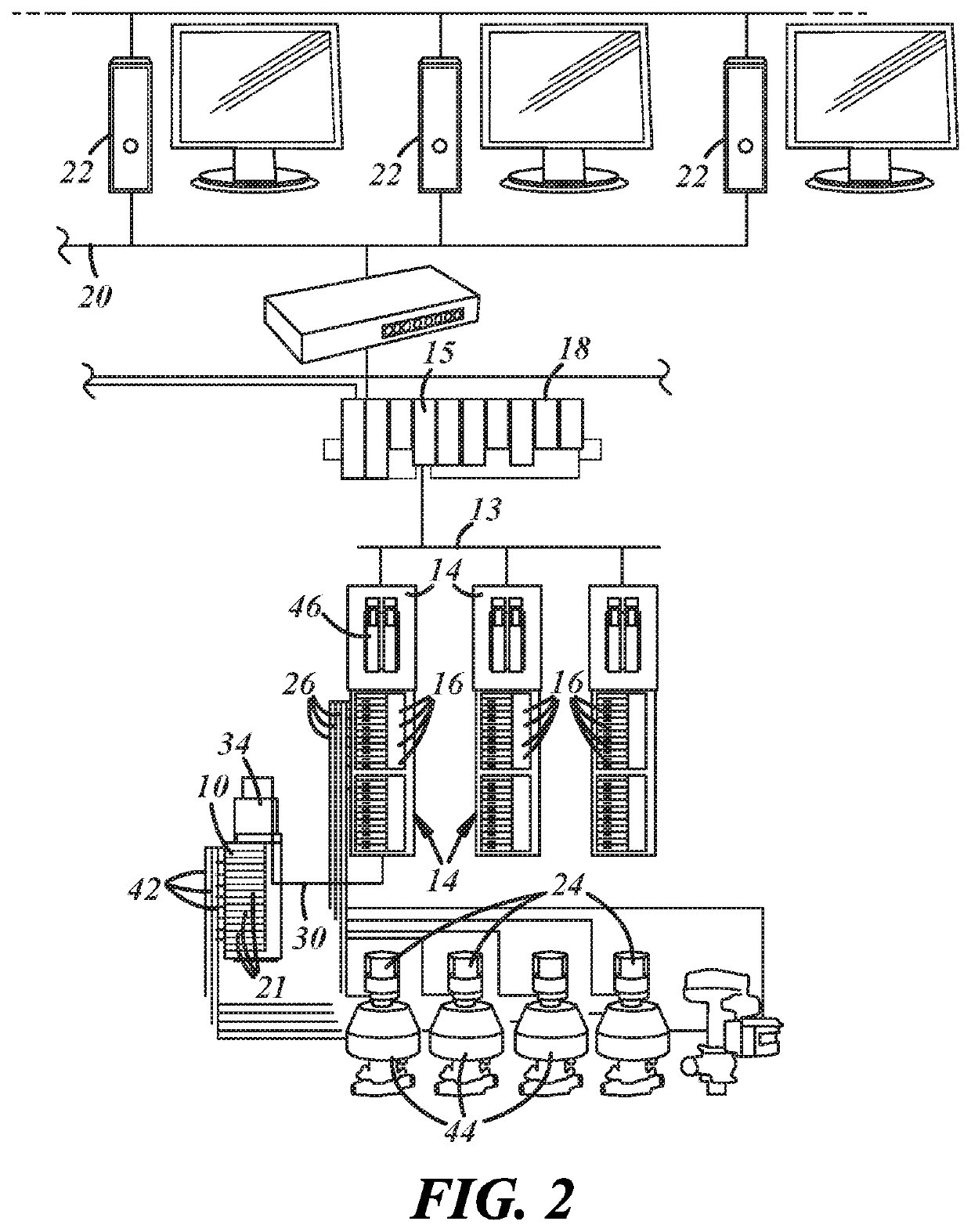

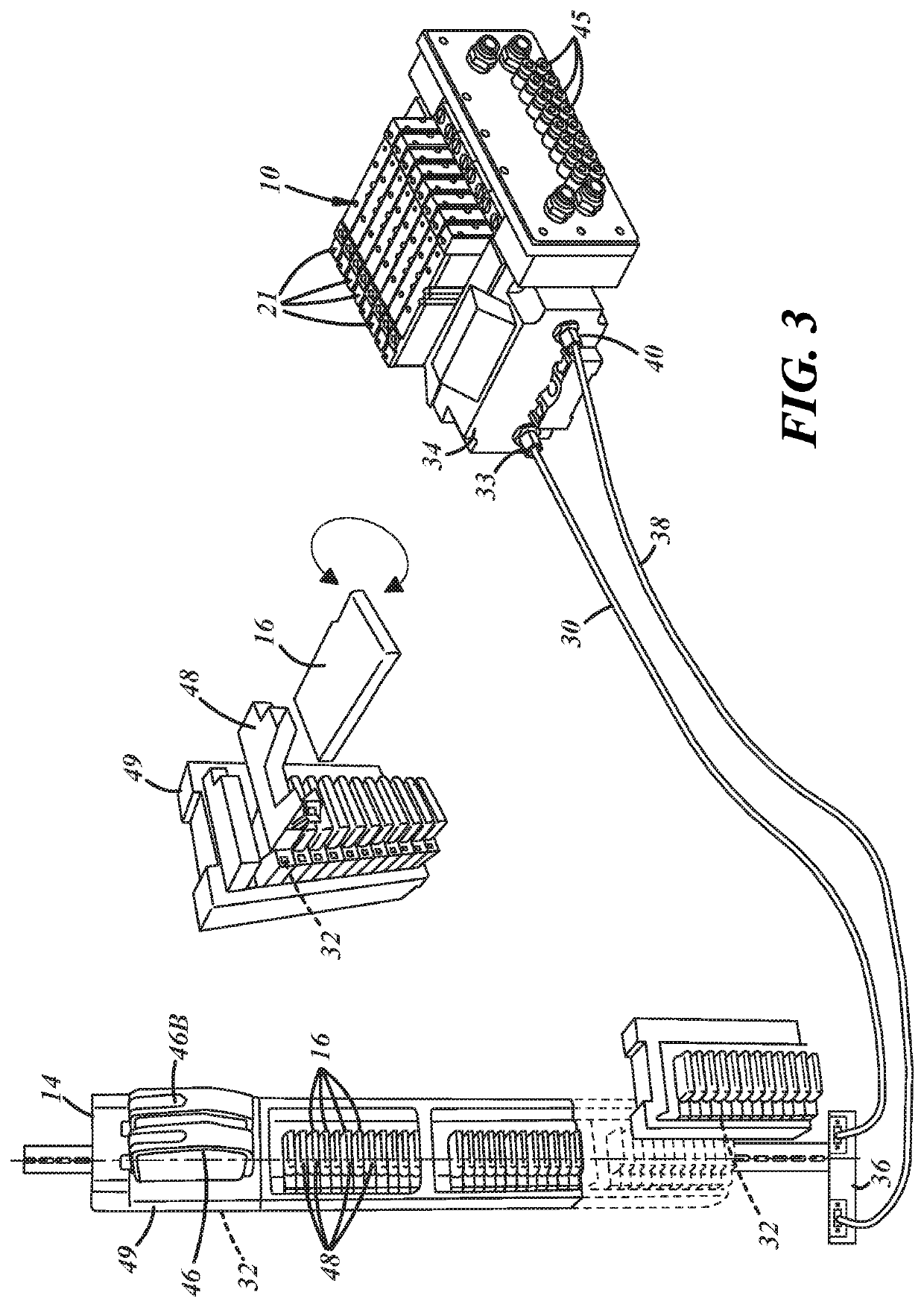

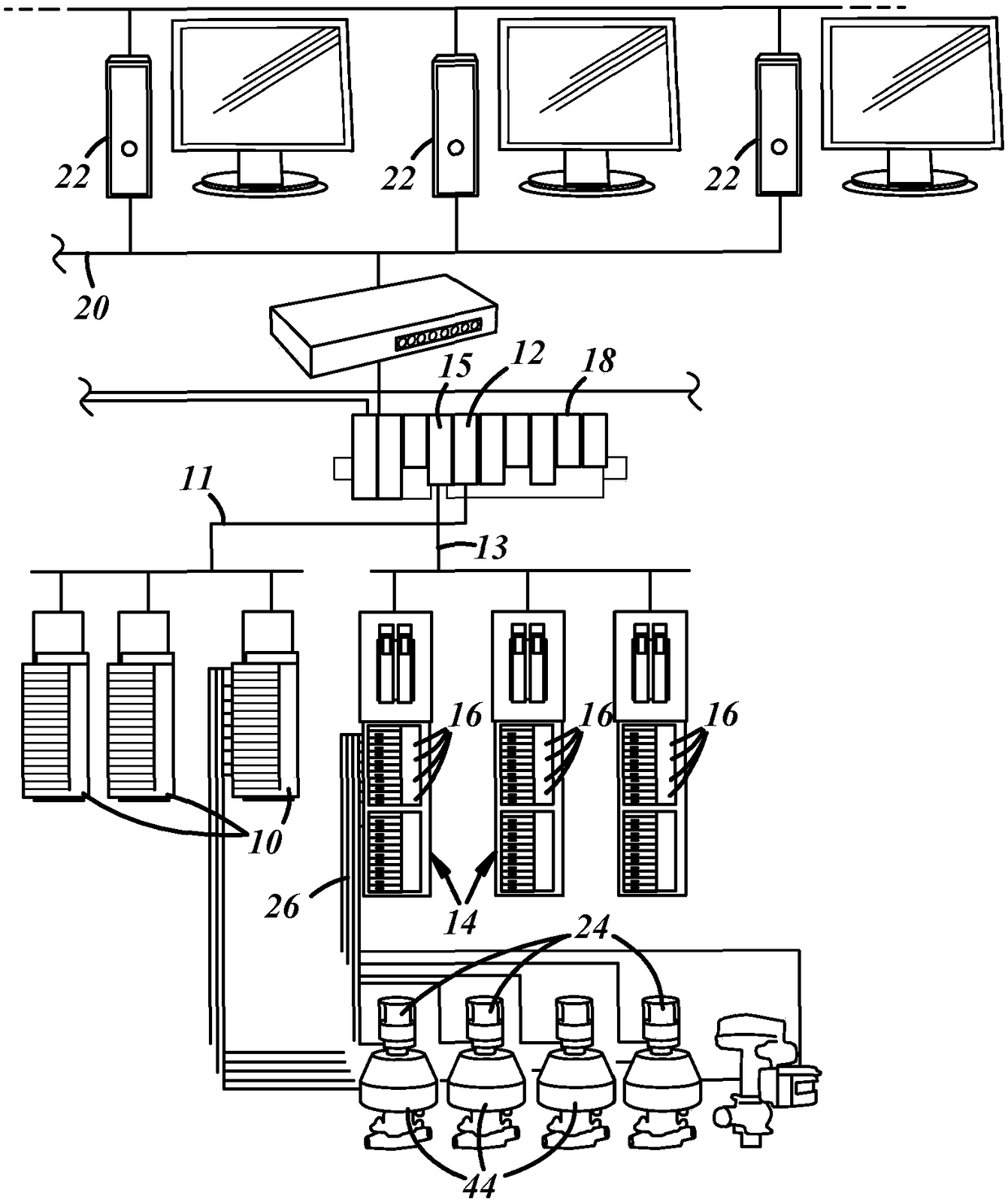

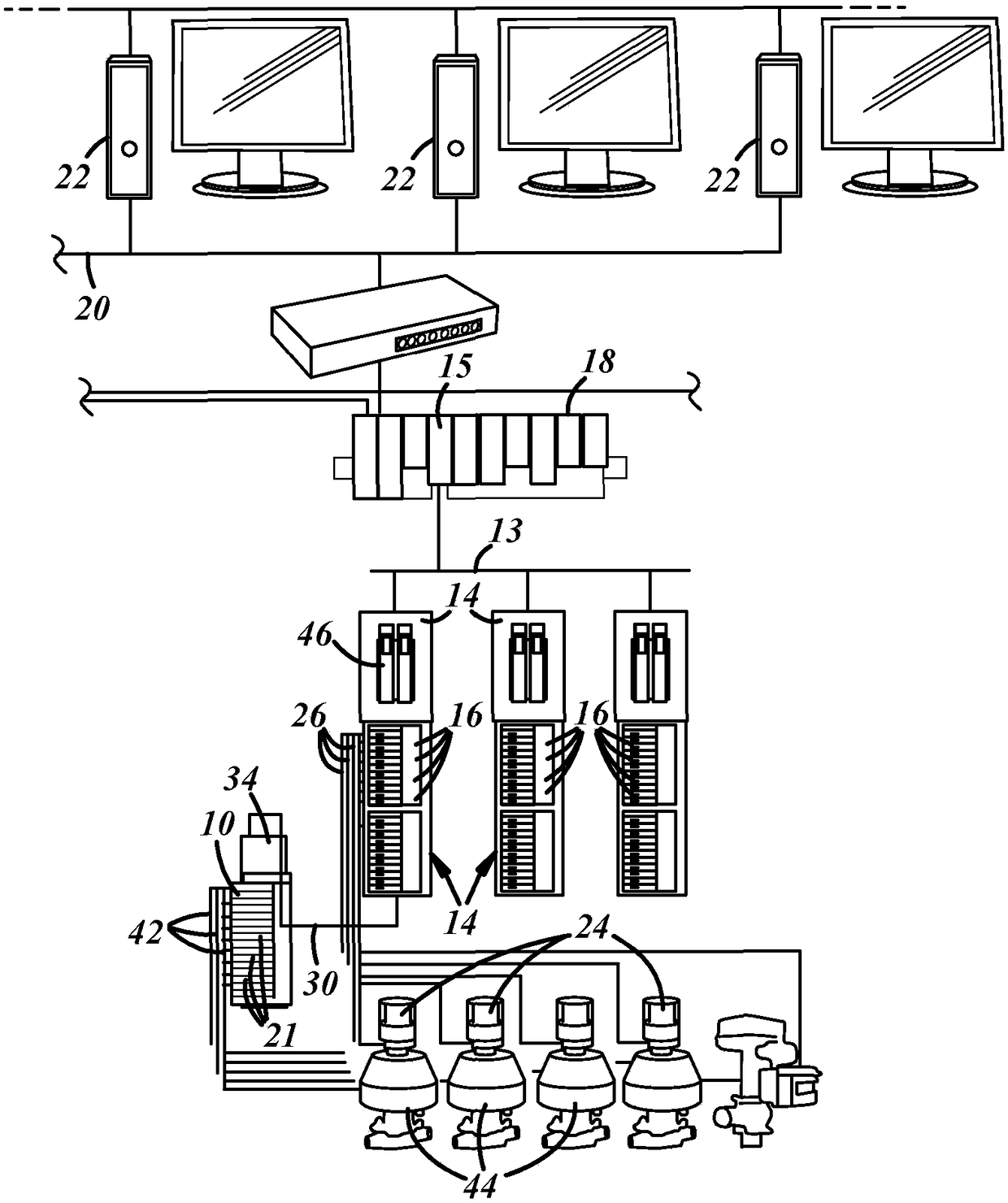

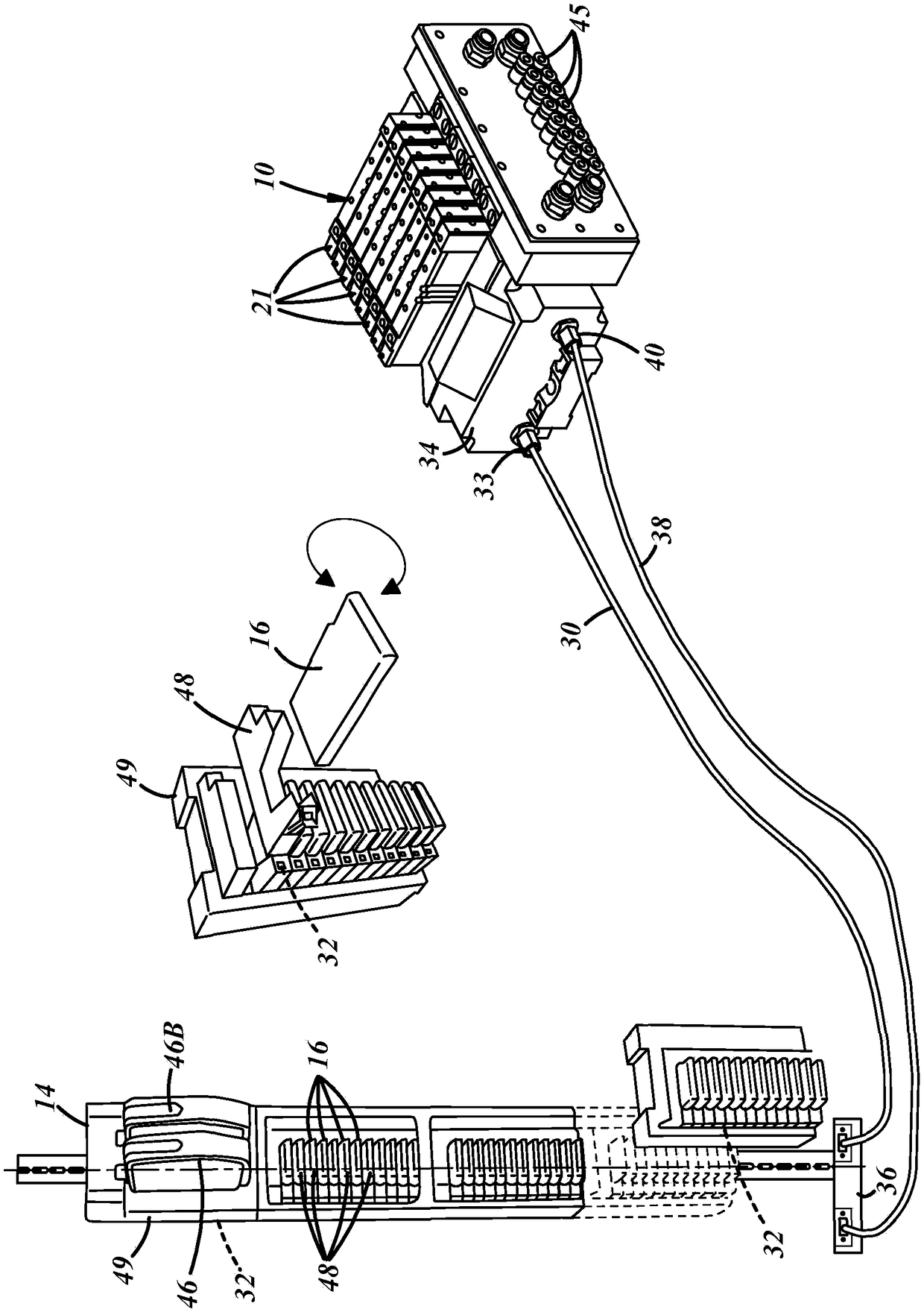

Valve manifold serially mounted to a distributed control system assembly

ActiveUS10555432B2Pneumatic programme controlPLC for automation/industrial process controlTelecommunicationsSolenoid valve

A control system has an I / O bank with a communication module controlling a plurality of Input / Output modules operably connected to its communication backplane and a valve manifold having a communication module serially connected to the backplane of the I / O bank. The I / O bank with a plurality of Input / Output modules is constructed to be connected to a plurality of field sensors or loads. The valve manifold with a plurality of solenoid valves is constructed to be pneumatically connected to a plurality of field devices.

Owner:ASCO LP

Method for determining amplitude of stick-slip on a valve assembly and implementation thereof

ActiveUS9920856B2Accurately distinguish cyclingPneumatic programme controlValve arrangementsRoot causeValve stem

A method for processing operating data (e.g., position, setpoint, and pressure) for a valve assembly. The method is configured to associate characteristics of operation for the valve assembly with a root cause and / or a contributing factor. In one embodiment, the method can assign a first amplitude with a value that quantifies movement or “jump” of the valve stem that results from stick-slip on the valve assembly. The method can also assign a second amplitude with a value that quantifies a change in the data for the setpoint. The method can further ascertain the relationship or “position” of the first amplitude relative to the second amplitude, or vice versa. The method can use the relationship between the first amplitude and the second amplitude to indicate the root cause of the operation of the valve assembly.

Owner:DRESSER LLC

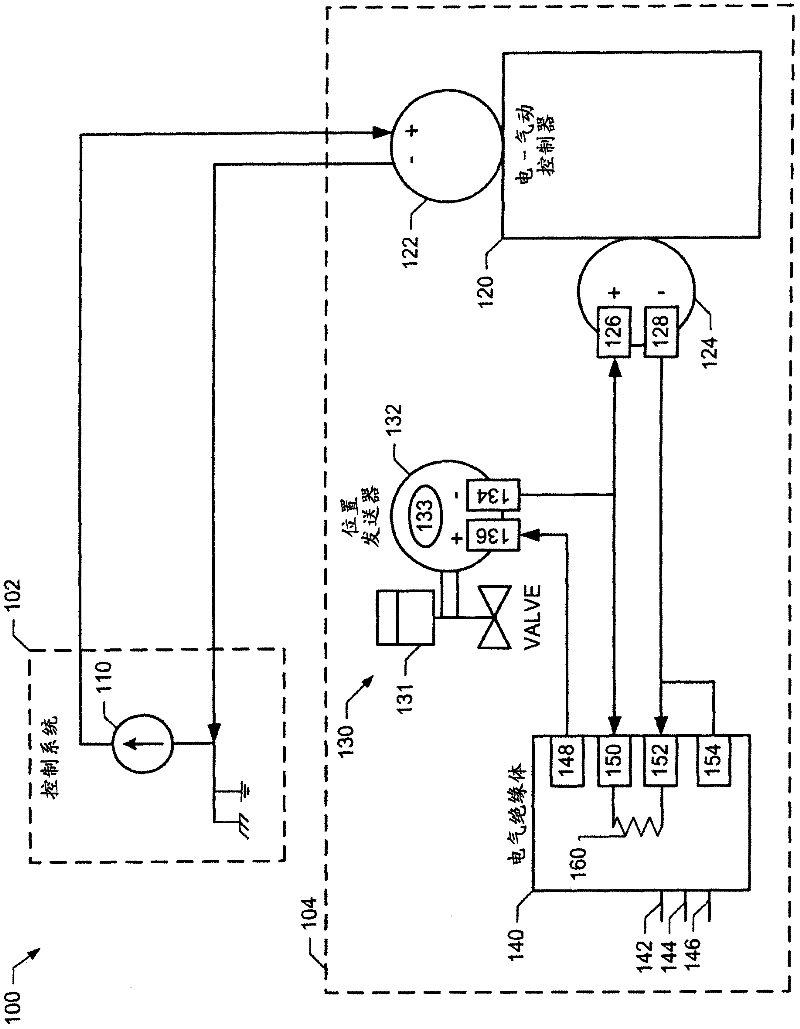

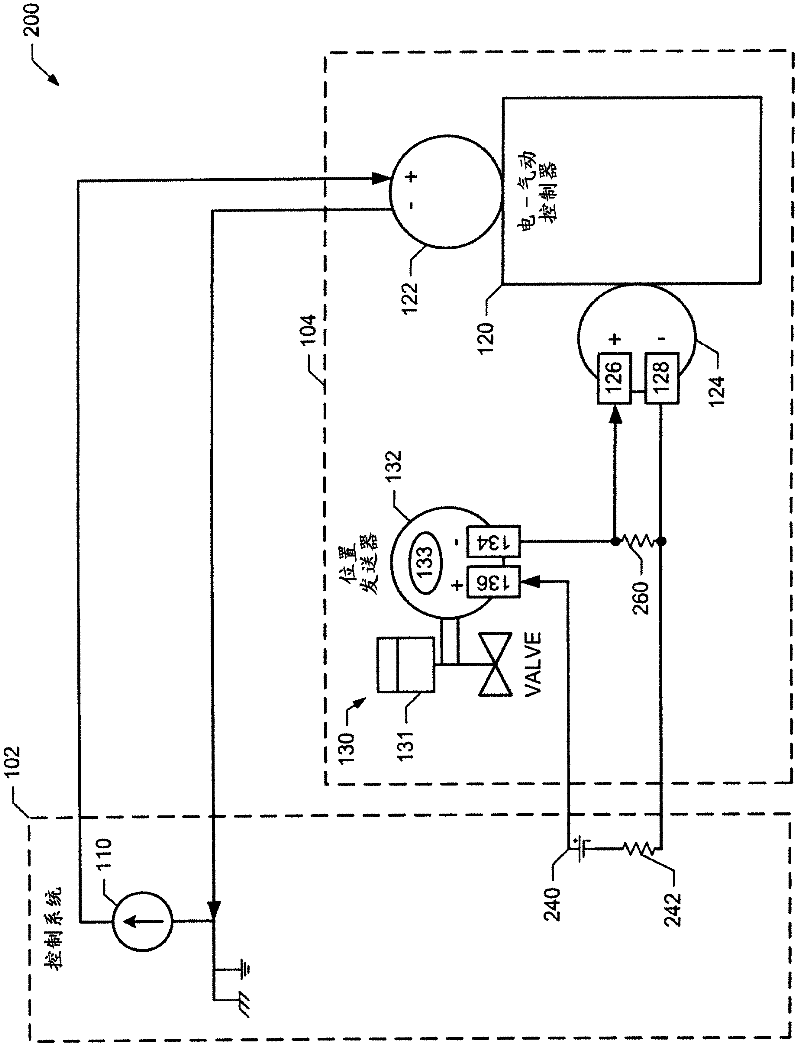

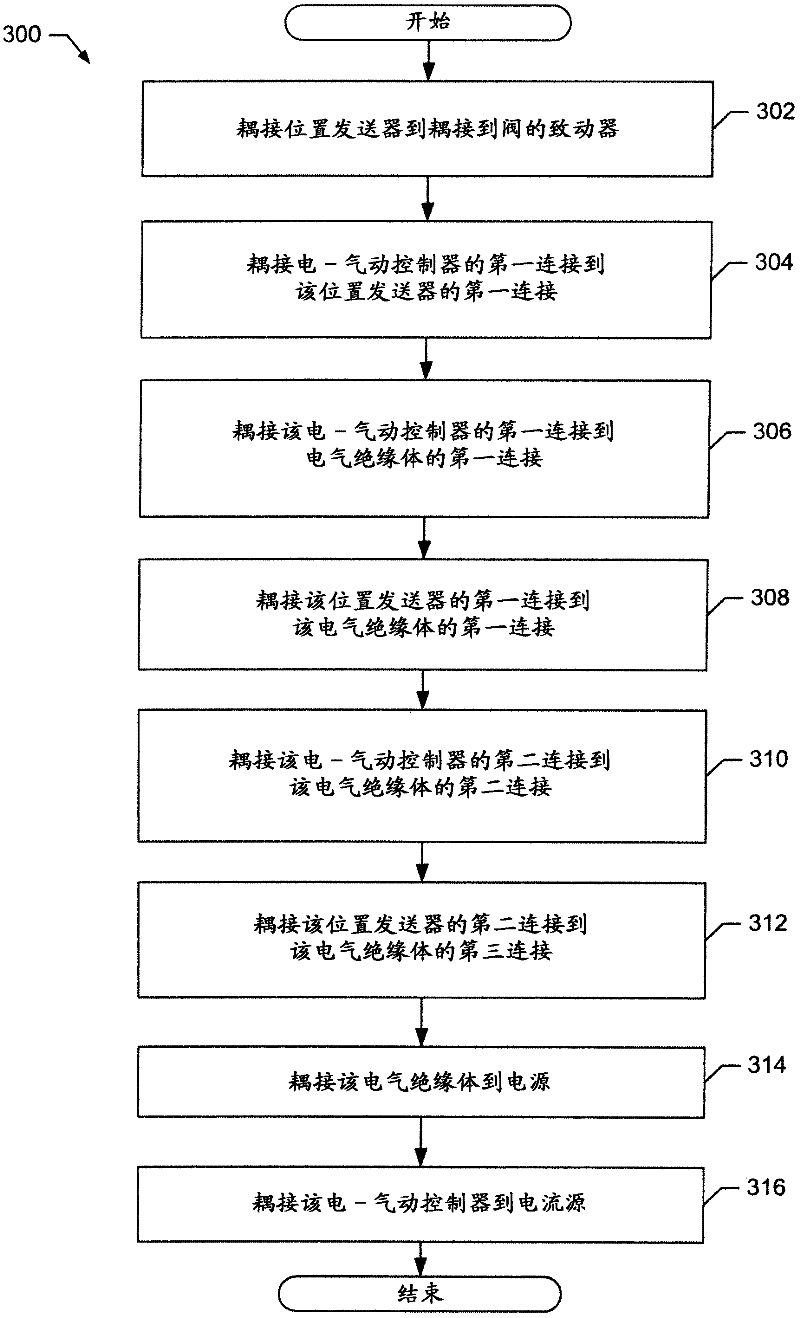

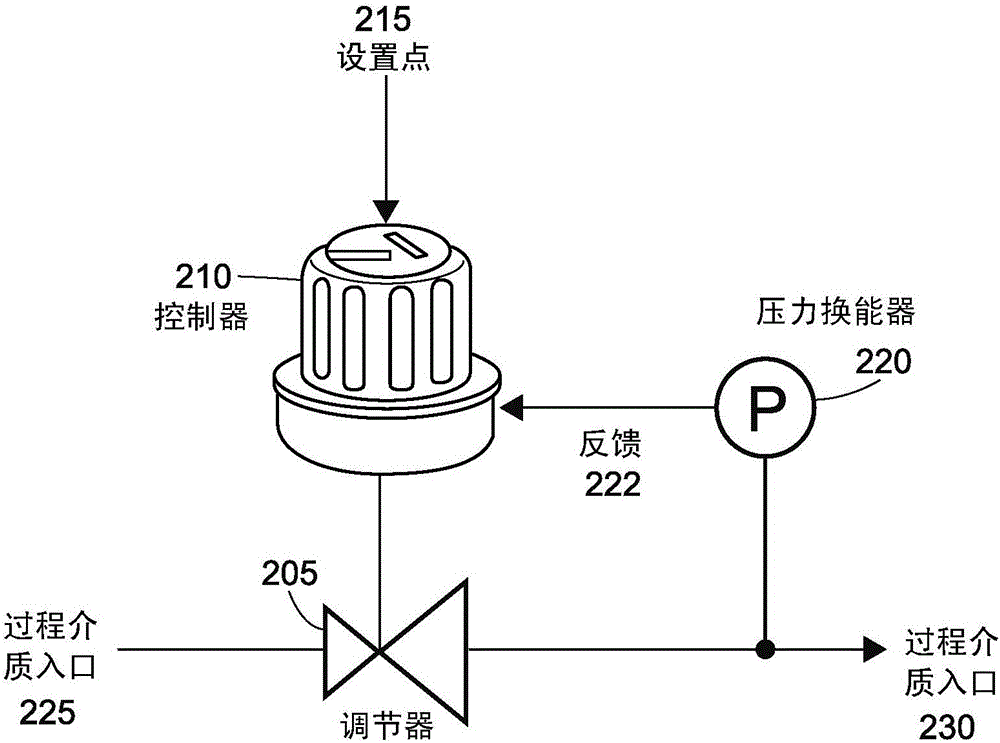

Methods and apparatus to couple an electro-pneumatic controller to a position transmitter in a process control system

InactiveCN102395932APneumatic programme controlElectric signal transmission systemsElectricityControl system

Example methods and apparatus to couple an electro-pneumatic controller to a position transmitter in a process control system are disclosed. A disclosed example apparatus includes a position transmitter having a first connection and having a second connection coupled to a power source, an electro-pneumatic controller including at least a first connection coupled to the first connection of the position transmitter, and a resistor coupled between the first connection and a second connection of the electro-pneumatic controller.

Owner:FISHER CONTROLS INT LLC

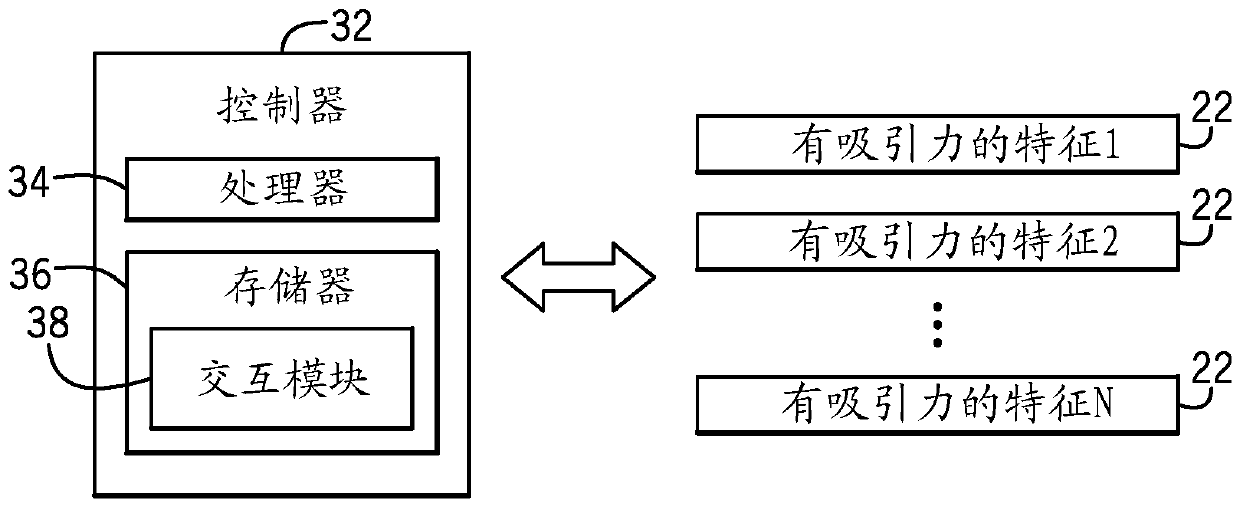

Soft robot system and method

ActiveUS20180272239A1Programme-controlled manipulatorPneumatic programme controlFluid controlActuator

An amusement park attraction includes an attraction feature. The attraction feature includes a fluid actuator having an inflatable mass, the inflatable mass being fluidly connected to a source of pressurized fluid to enable inflation of the inflatable mass. Fluid control devices are configured to adjust inflation of the inflatable mass, and sensors are configured to monitor state properties of the fluid actuator. A controller is communicatively coupled to the fluid control devices and the sensors. The controller is configured to controllably inflate the inflatable mass based at least on feedback from the sensors to cause the fluid actuator to impact an object. The controller is configured to control the inflation of the inflatable mass to adjust parameters of the fluid actuator to maintain a force exerted by the fluid actuator on the object to within a predetermined range.

Owner:UNIVERSAL CITY STUDIOS LLC

Mesa ball X-Y trace pneumatic controller

InactiveCN1811643AGood compressibilityReduce stiffnessPneumatic programme controlControl using feedbackData acquisitionControl theory

The present invention relates to a table ball X-Y path pneumatic control device, belonging to the field of machinery technology. Said invention includes data acquisition card, computer, platform support, platform, small ball, touch screen device, potentiometer and platform servo device. Besides, said invention also provides their connection mode, working principle of said table ball X-Y path pneumatic control device and its concrete application method.

Owner:SHANGHAI JIAO TONG UNIV

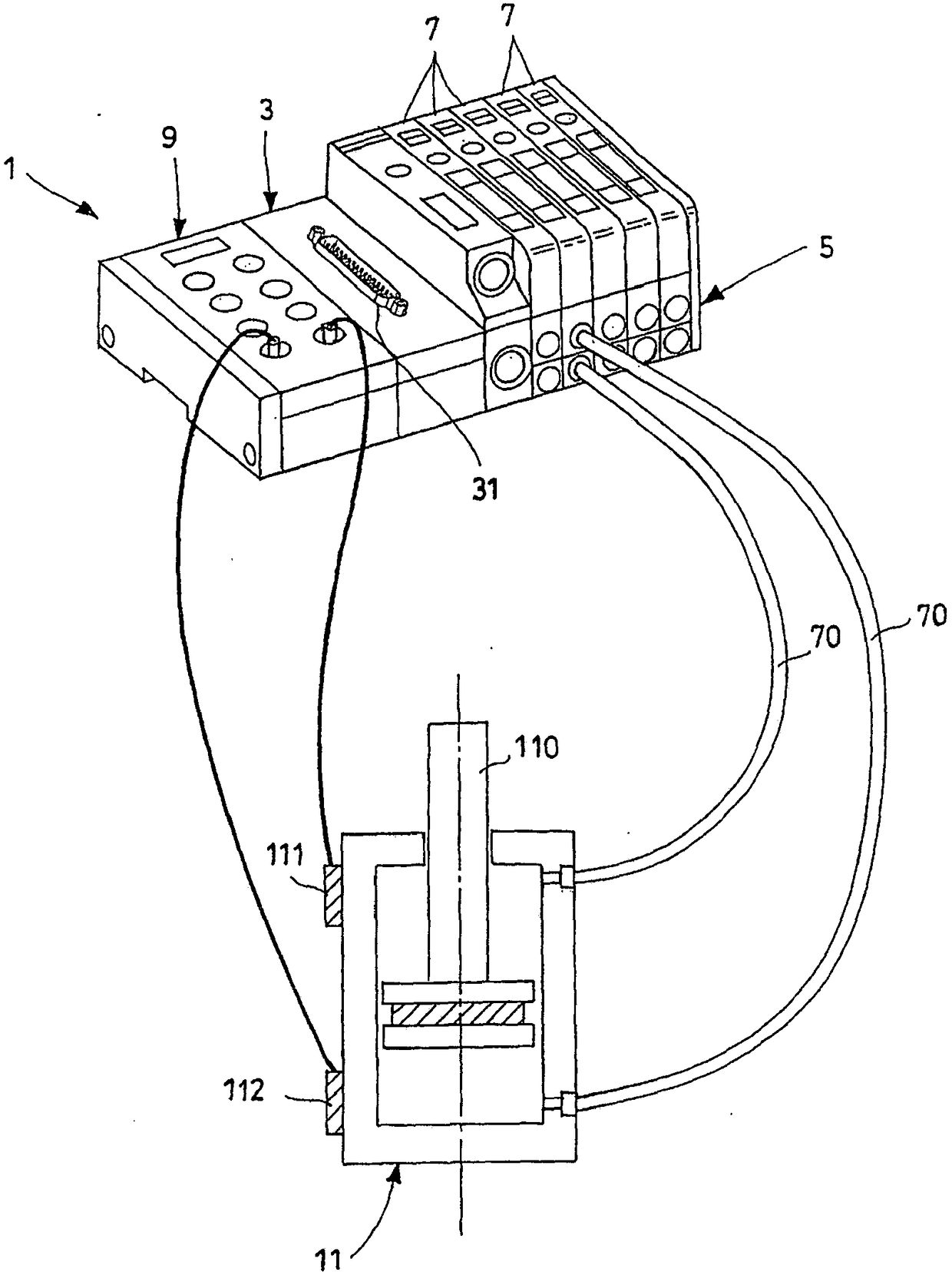

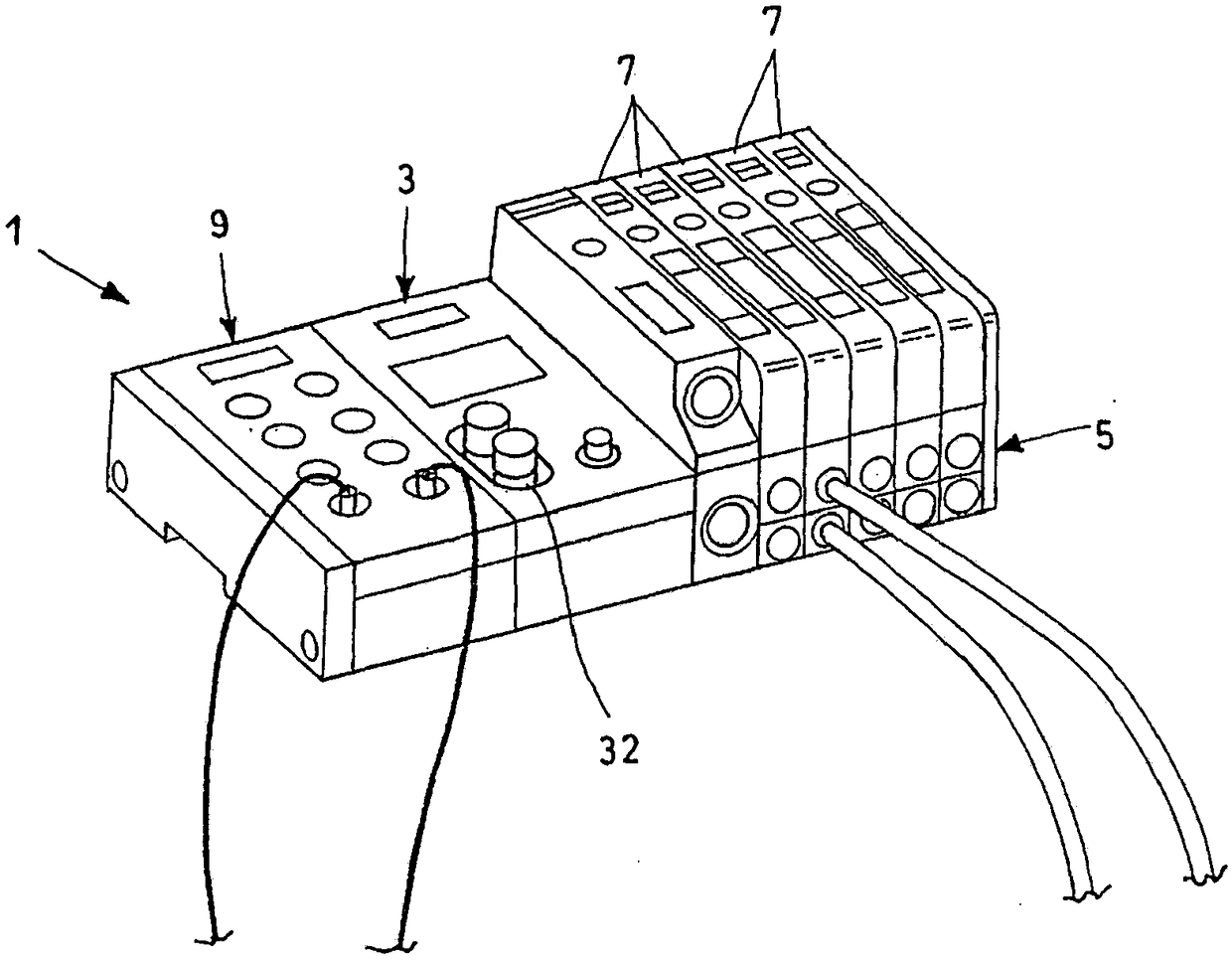

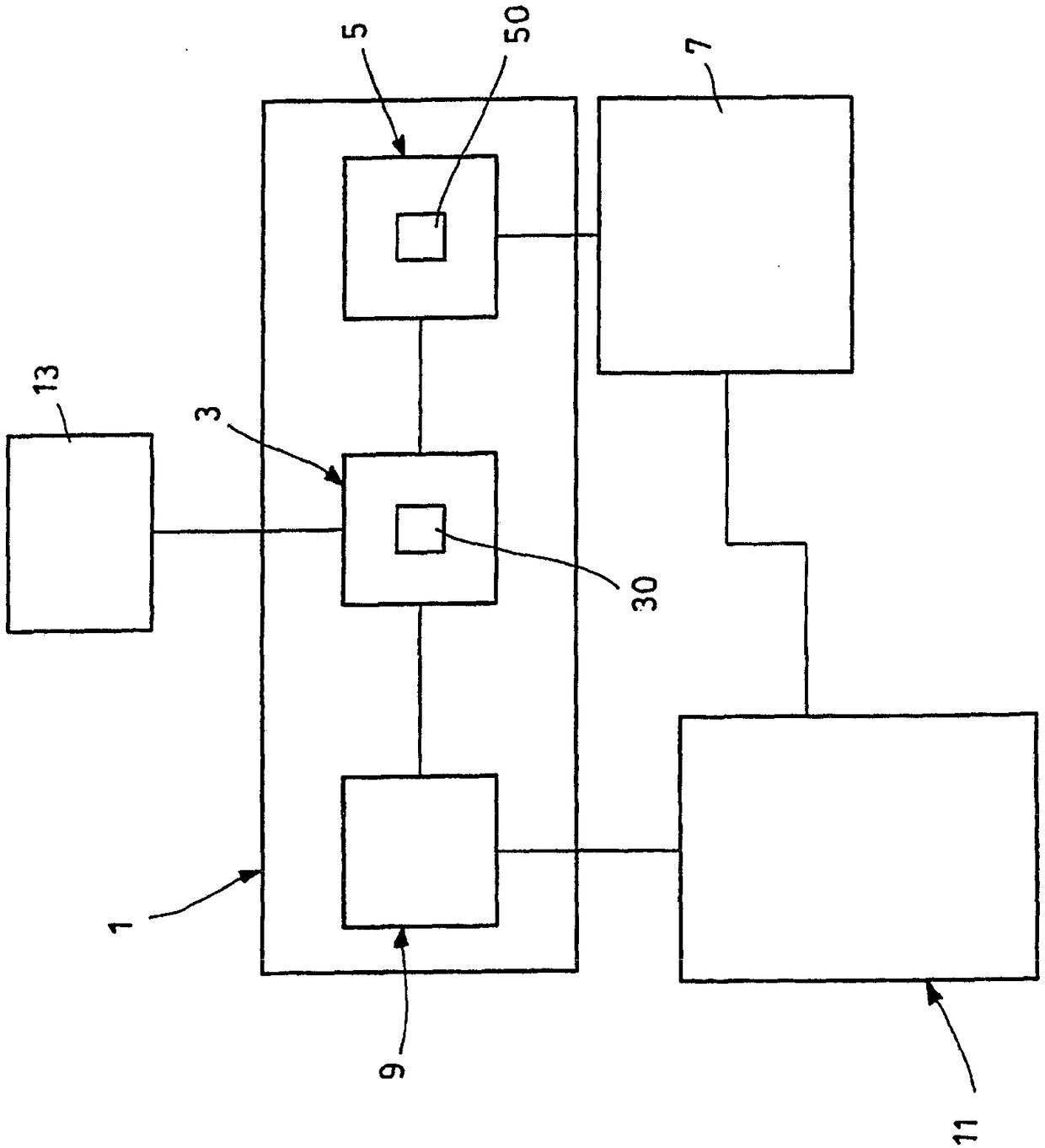

Modular control device for solenoid valve islands, particularly for the actuation of actuators

InactiveCN108694063AGuaranteed reliabilityEnsure safetyPneumatic programme controlFluid-pressure actuator testingSolenoid valveControl signal

A modular control device 1 for solenoid valve islands, particularly for the actuation of actuators is described in one aspect of the disclosure. The modular control device 1 includes at least one control module 5 for controlling at least one solenoid valve 7 adapted for actuating at least one actuator 11, a communication module 9 adapted to exchange information signals with such an actuator and anelectrical connection module 3 adapted to receive control signals from a user 13. The electrical connection module 3 transmits the control signals to the control module 5 and receives the informationsignals from the communication module 9. The electrical connection module 3 has a processing and control unit 30 configured to receive, store and process the information signals and the control signals.

Owner:METAL WORK S P A BRESCIA

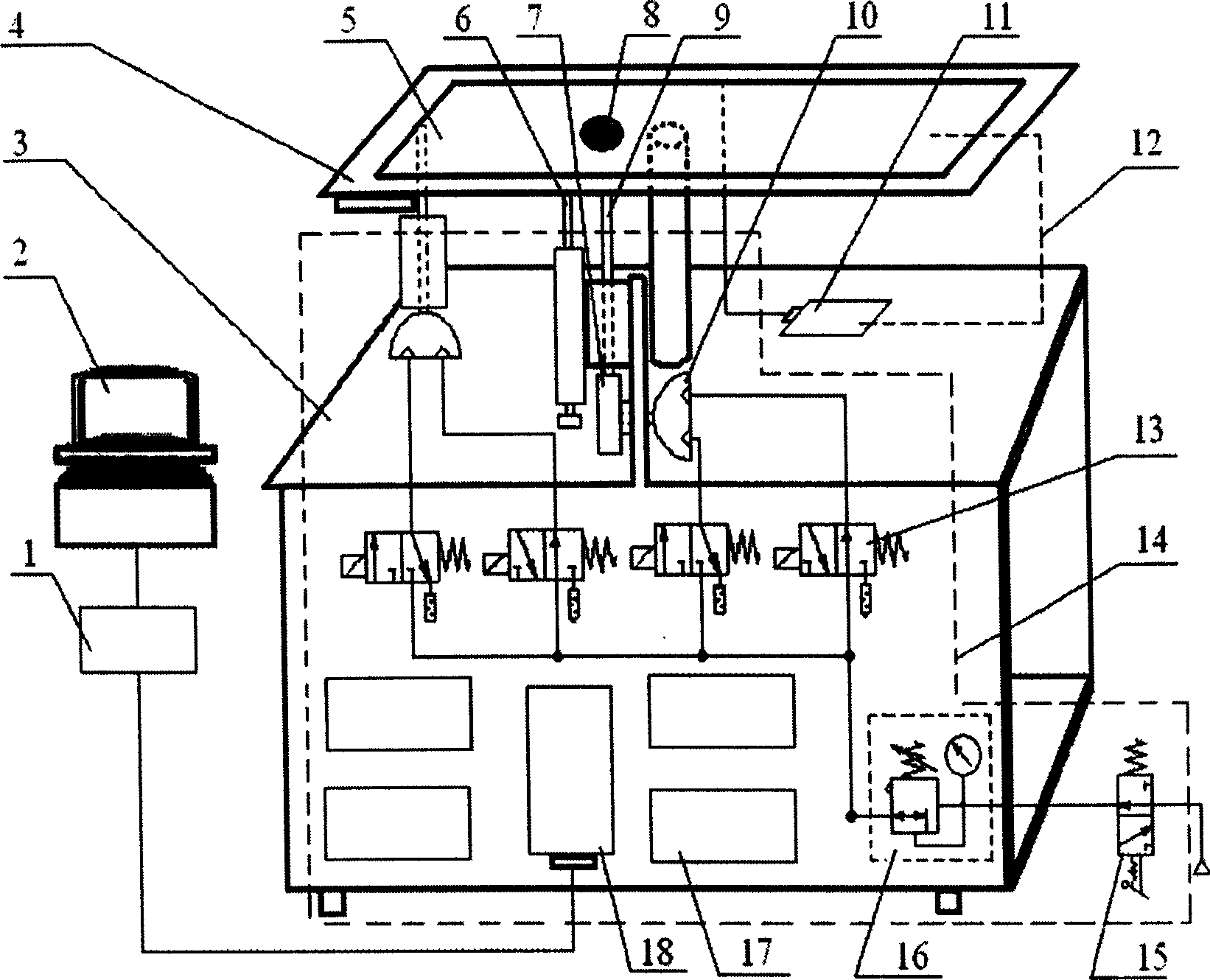

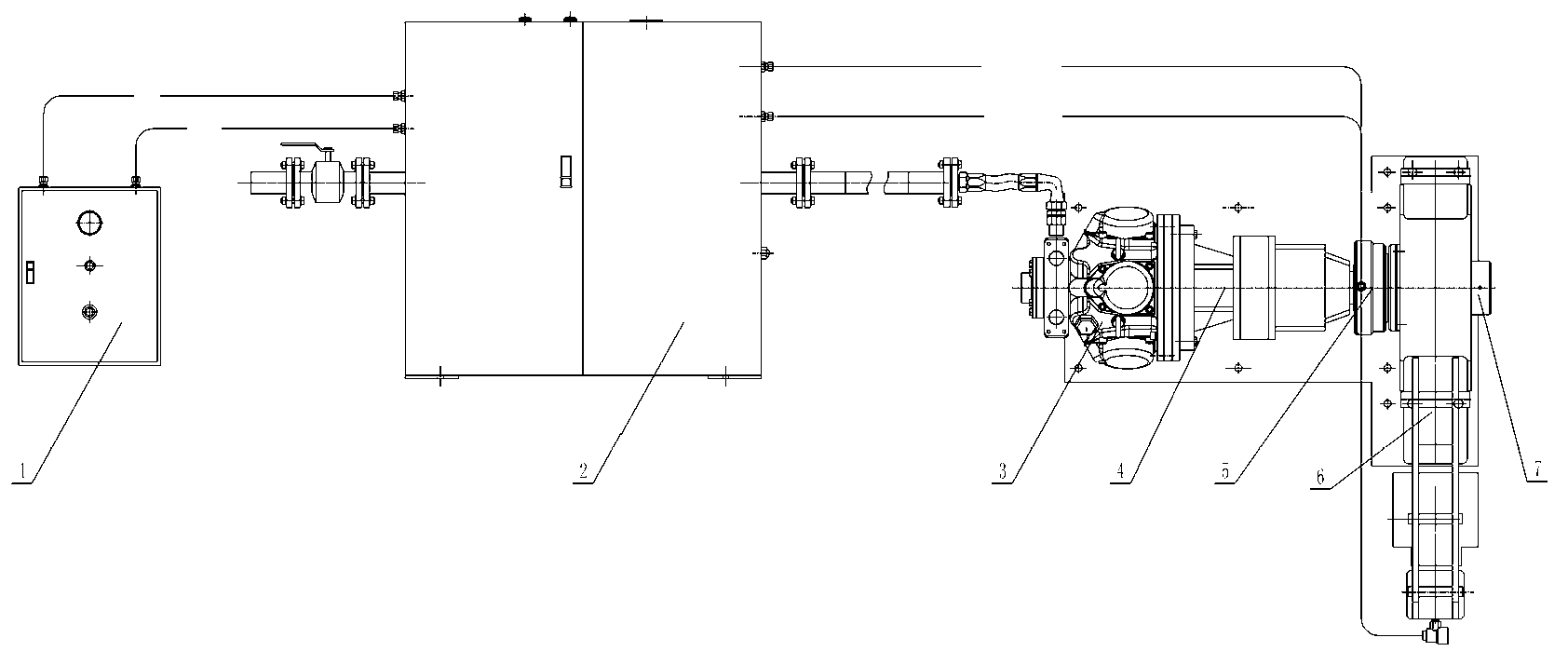

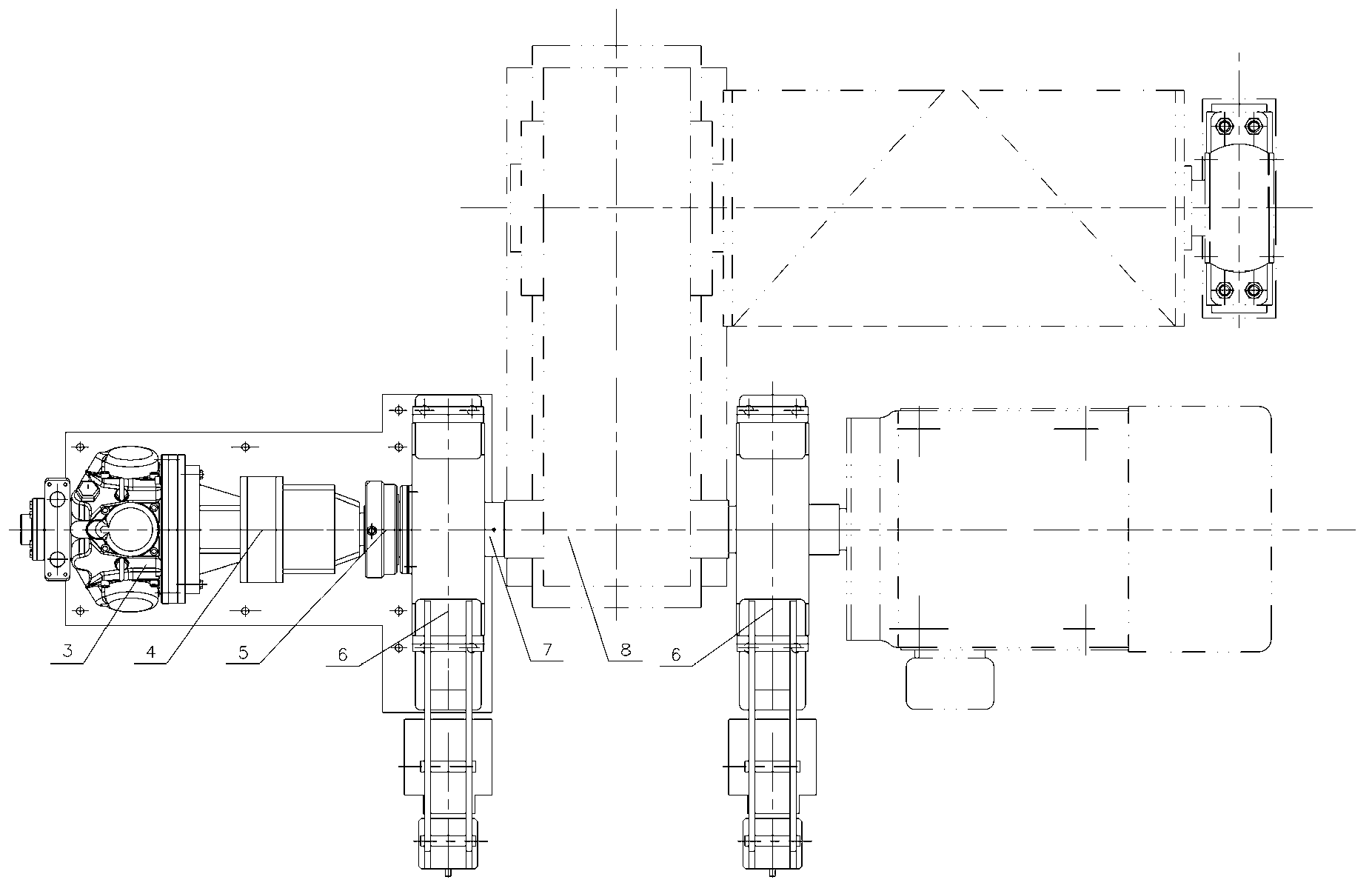

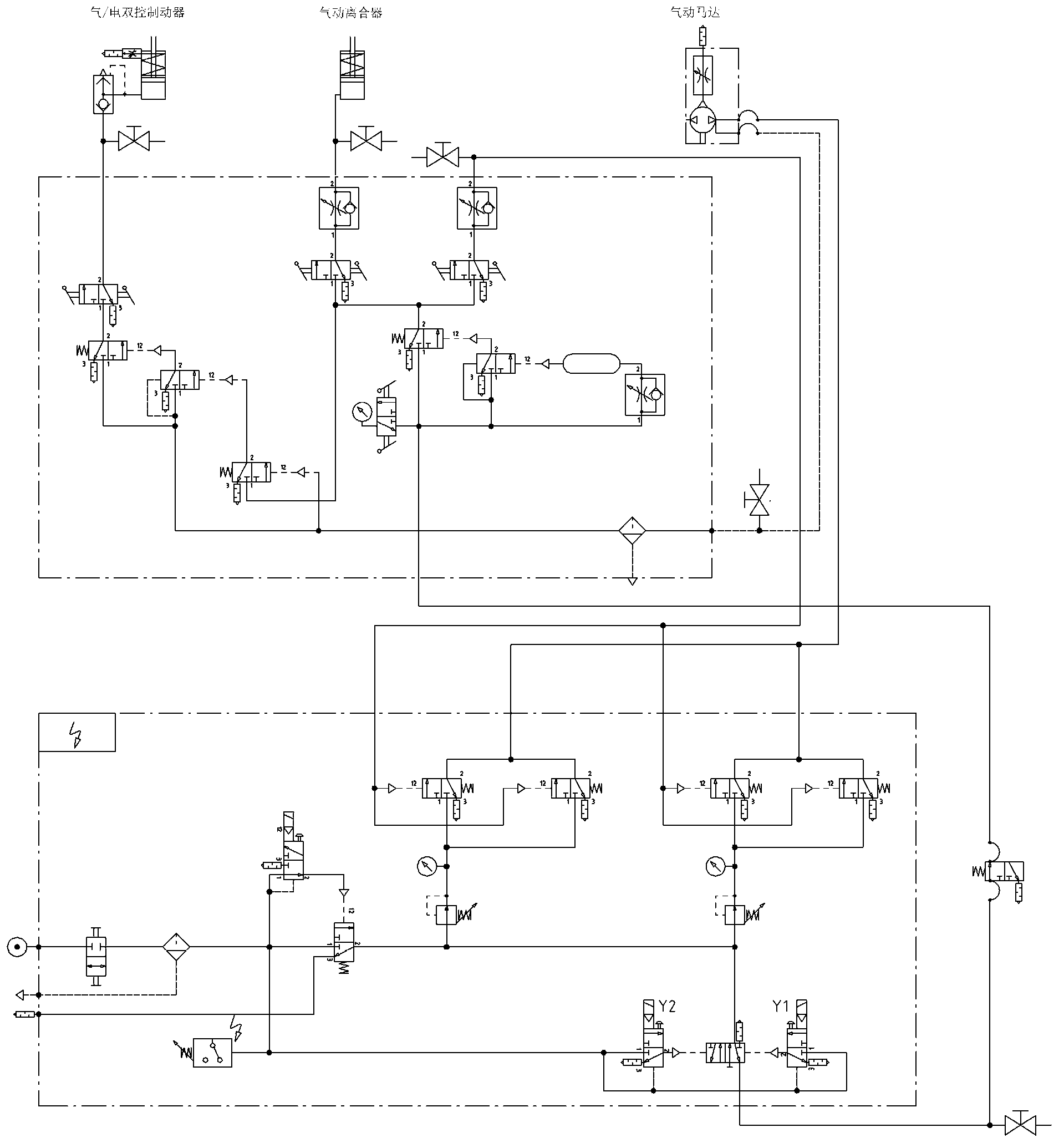

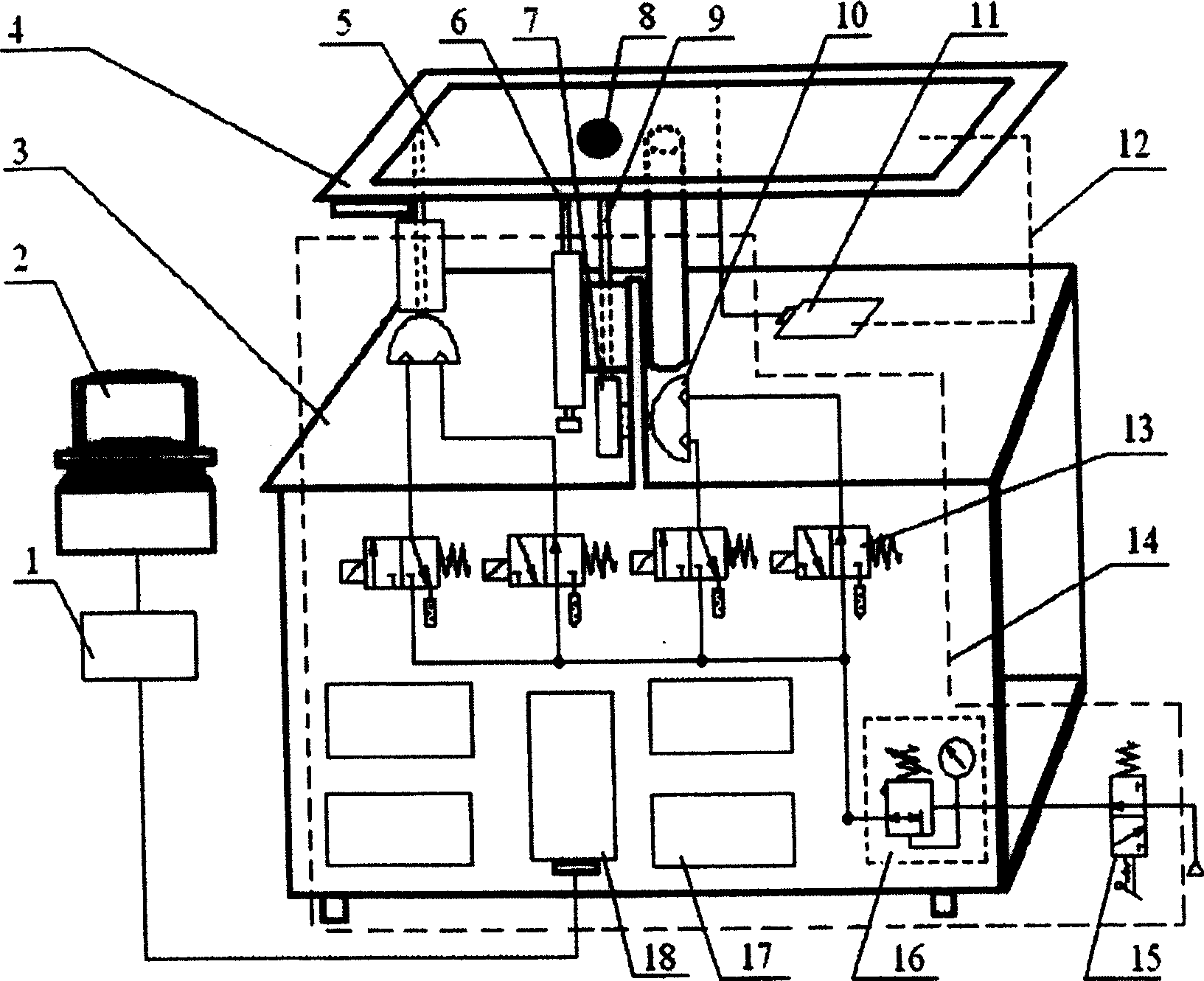

Full-pneumatic accident driving system for metallurgical production equipment

InactiveCN103306762AAccident Driven SafetyEasy to preparePneumatic programme controlSteam engine plantsEngineeringPneumatic motor

The invention discloses a full-pneumatic accident driving system for metallurgical production equipment, which is high in safety performance and convenient to control. The driving system comprises a pneumatic control cabinet, a power output mechanism connected with the former, and a power transmission mechanism connected with a power output end of the power output mechanism, wherein the control cabinet controls performance time sequences of all devices of the power transmission mechanism, and the power output device adopts a pneumatic motor. The driving system adopts a compressed air source as the sole power source; all pneumatic devices are reasonably and orderly controlled by the pneumatic cabinet, as a result, the reliability and safety of the system are improved at a lower cost.

Owner:HUATIAN ENG & TECH CORP MCC

Method for determining amplitude of stick-slip on a valve assembly and implementation thereof

ActiveUS20180142807A1Accurately distinguish cyclingPneumatic programme controlValve arrangementsRoot causeBiomedical engineering

A method for processing operating data (e.g., position, setpoint, and pressure) for a valve assembly. The method is configured to associate characteristics of operation for the valve assembly with a root cause and / or a contributing factor. In one embodiment, the method can assign a first amplitude with a value that quantifies movement or “jump” of the valve stem that results from stick-slip on the valve assembly. The method can also assign a second amplitude with a value that quantifies a change in the data for the setpoint. The method can further ascertain the relationship or “position” of the first amplitude relative to the second amplitude, or vice versa. The method can use the relationship between the first amplitude and the second amplitude to indicate the root cause of the operation of the valve assembly.

Owner:DRESSER LLC

Valve positioner and user interface for valve positioner

ActiveUS10698525B2Reduce crosstalkPneumatic programme controlOperating means/releasing devices for valvesDisplay deviceEngineering

Owner:NELES FINLAND OY

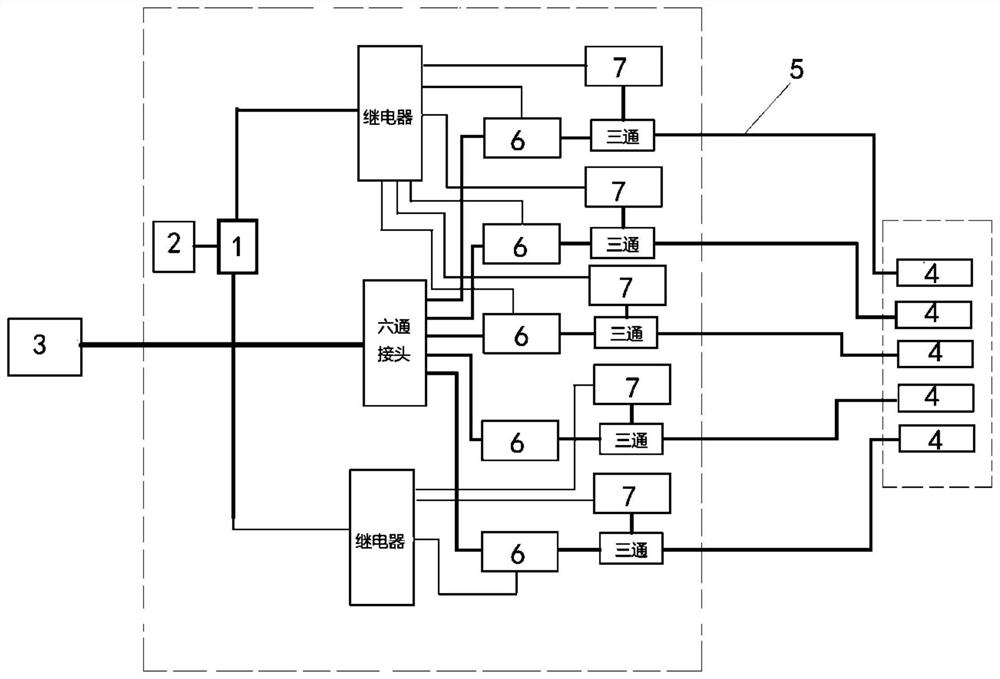

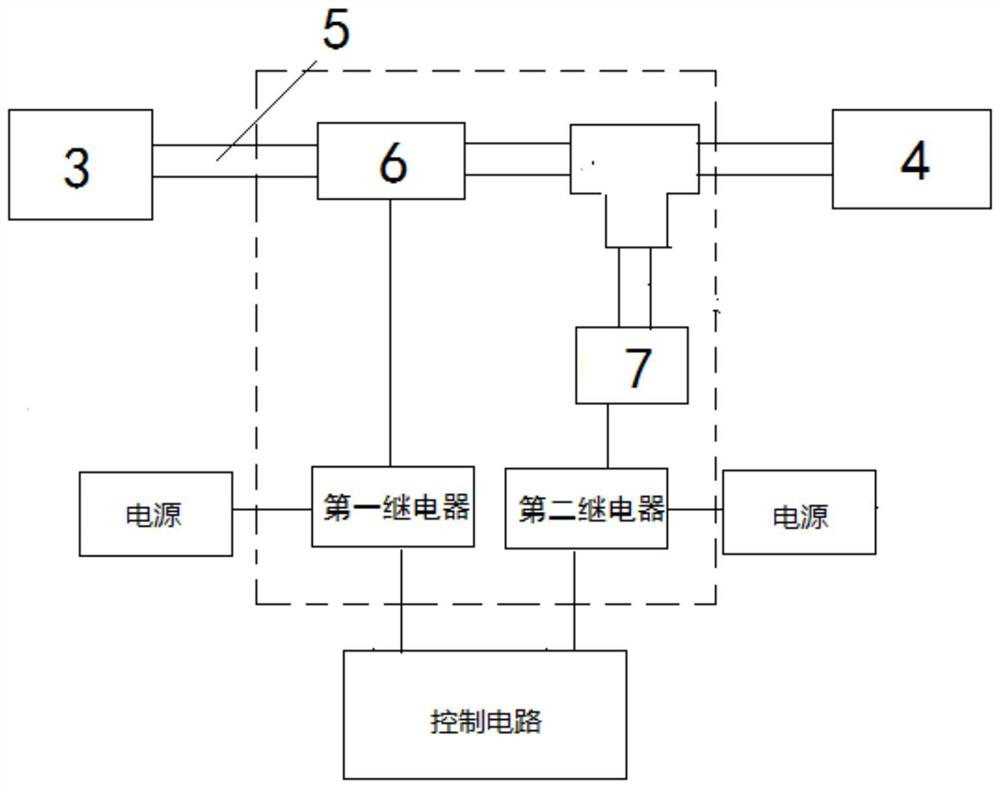

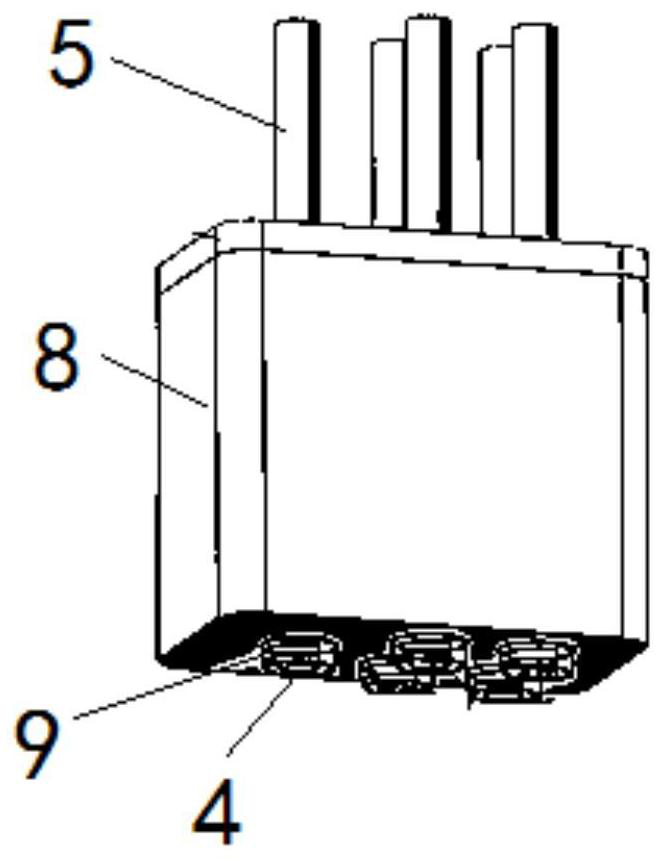

Low-reflection remote control system of myocardial minimally invasive rotary cutter

PendingCN112987600ASolve electromagnetic radiation emissionAddress effectivenessPneumatic programme controlExcision instrumentsRemote controlControl engineering

The invention discloses a low-reflection remote control system of a myocardial minimally invasive rotary cutter. The low-reflection remote control system comprises a controller, an instruction input module, an air source, a pneumatic control mechanism and a plurality of pneumatic keys; the pneumatic control mechanism is provided with an air inlet end and a plurality of air outlet ends, the number of the air outlet ends is equal to that of the pneumatic keys, the air outlet ends correspond to the pneumatic keys one to one, and the air inlet end of the pneumatic control mechanism is communicated with the air source. A plurality of air outlet ends of the pneumatic control mechanism are communicated with air inlets of the corresponding pneumatic keys respectively, the instruction input module and the pneumatic control mechanism are electrically connected with the controller, the instruction input module is used for sending instructions to the controller, and the controller controls the pneumatic control mechanism to inflate or deflate any pneumatic key, so that the pneumatic keys are pressed or loosened. According to the low-reflection remote control system disclosed by the invention, testers can remotely carry out key pressing operation on the myocardial minimally invasive rotary cutter, so that the testers are prevented from being damaged by radiation in a radiation emission and radiation immunity test process, and disturbance to a test field is avoided.

Owner:湖北省医疗器械质量监督检验研究院 +1

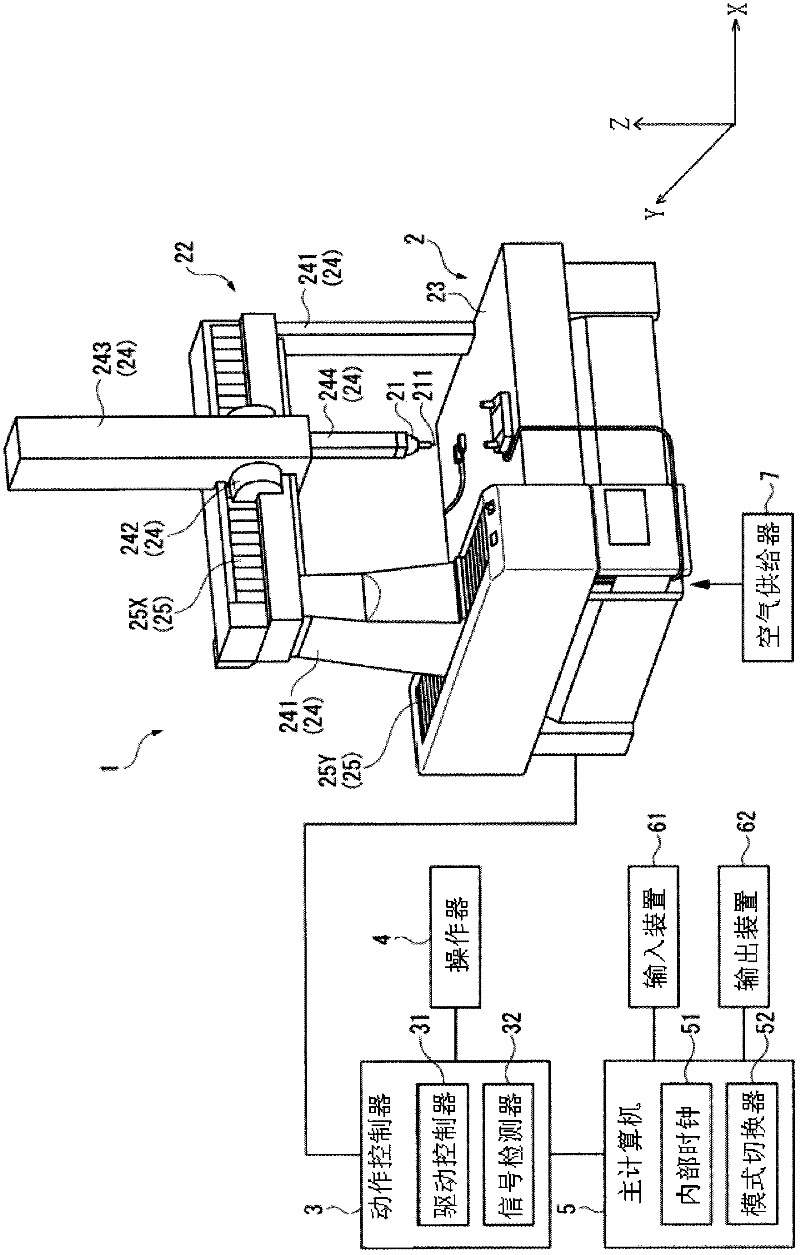

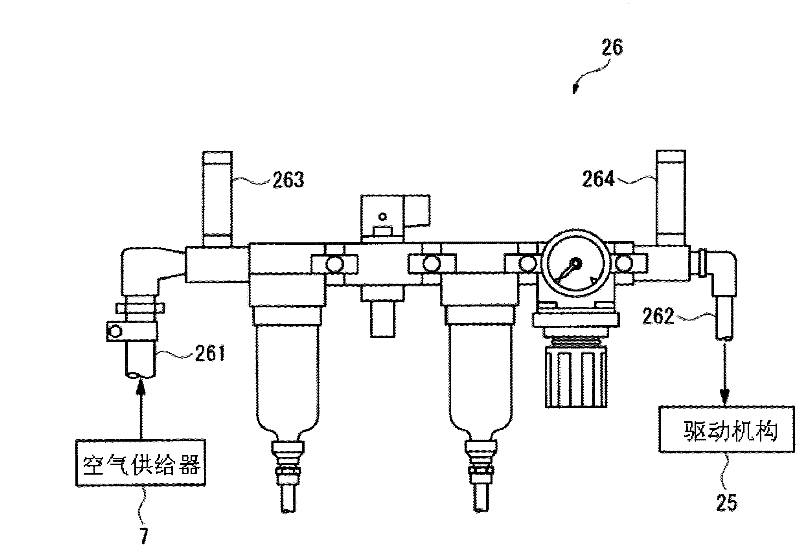

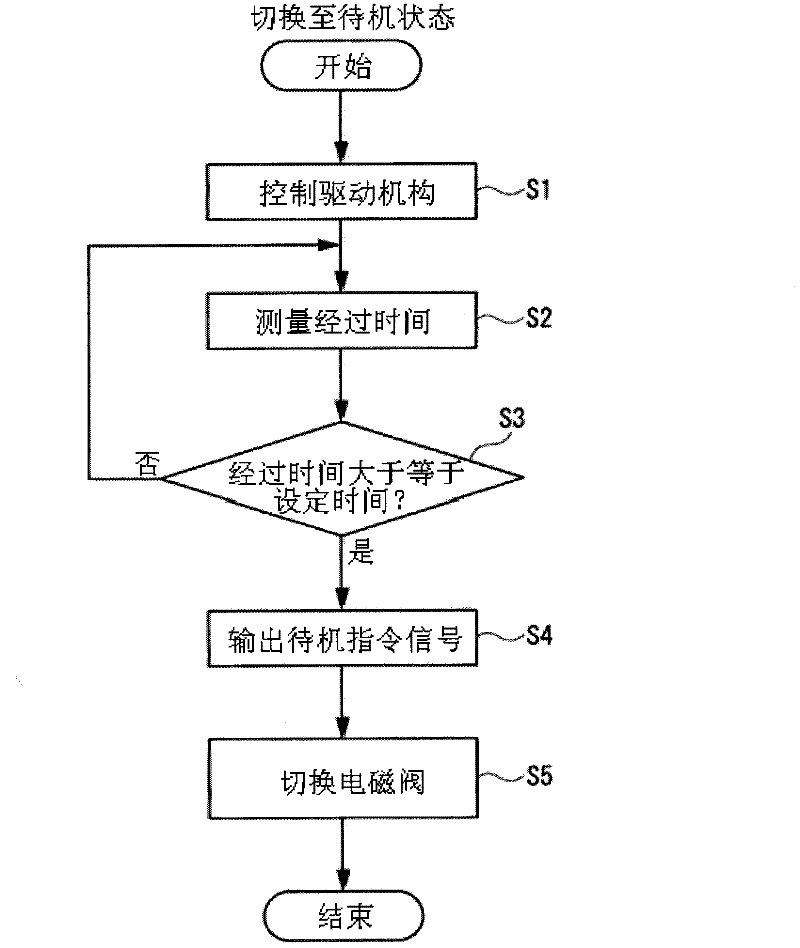

Industrial machine

ActiveCN102411316AAvoid waste releaseIncrease savingsPneumatic programme controlSafety arrangmentsIndustrial machineMotion controller

A three-dimensional measuring machine (industrial machine) includes an air supplier supplying air; a drive mechanism driven by the air supplied from the air supplier; an electromagnetic valve provided inside an air regulator set to open and close an air supply passage inside the air regulator set, the air regulator set introducing the air from the air supplier to the drive mechanism; and a motion controller controlling the electromagnetic valve to block the air supply passage when a time since the drive mechanism stopped operation reaches a preset time.

Owner:MITUTOYO CORP

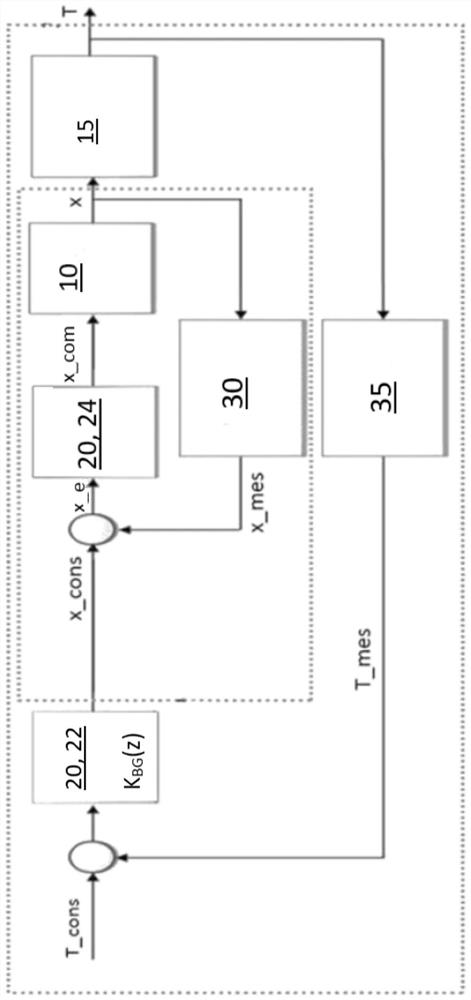

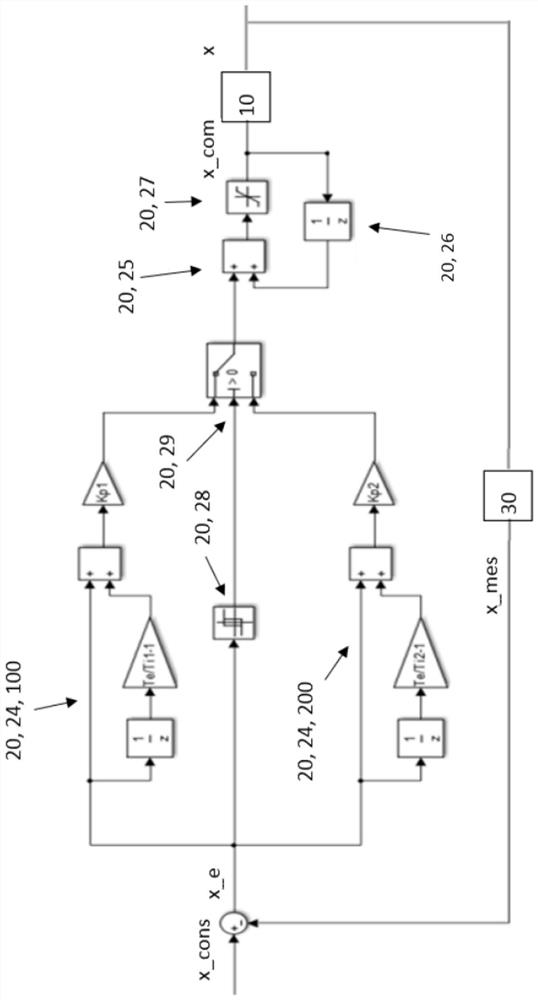

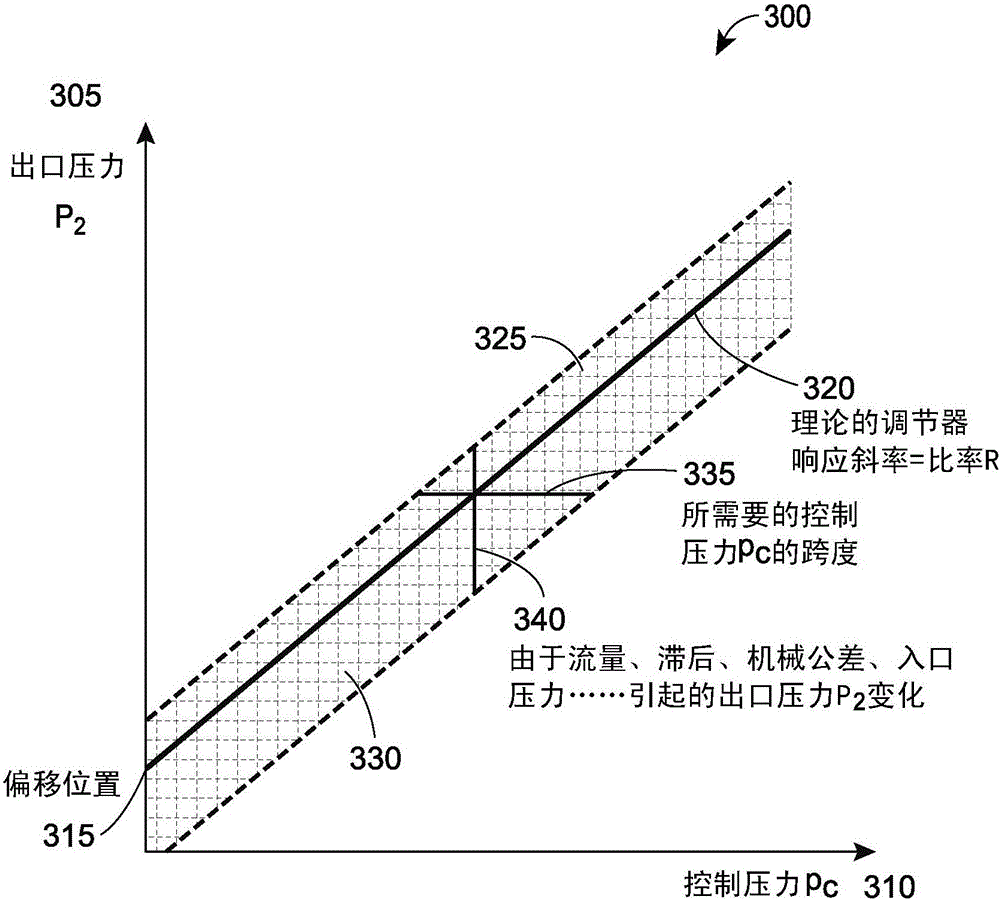

Double corrector for asymmetrical mechanism compensation

PendingCN113242938APneumatic programme controlServomotor componentsControl signalClassical mechanics

The invention concerns a method for controlling a mechanism (10) displaying asymmetrical behaviour, the mechanism (10) comprising a first operating direction (F+) and a second operating direction (F-), the control method making it possible to generate, using a control module (24) of a computer (20), a control signal (x_com) from a setpoint signal (x_cons), in which - when the setpoint signal (x_cons) indicates that the mechanism (10) should be operated in the first direction (F+), the control module (24) applies a first corrector (100) to the setpoint signal (x_cons) in order to generate a control signal (x_com), - when the setpoint signal (x_cons) indicates that the mechanism (10) should be operated in the second direction (F-), the control module (24) applies a second corrector (100) to the setpoint signal (x_cons) in order to generate a control signal (x_com), and in which the first and second correctors (100, 200) have different parameters (Kp1, Kp2, Ti1, Ti2), in order to compensate for the asymmetrical behaviour of the mechanism (10).

Owner:SAFRAN AIRCRAFT ENGINES SAS

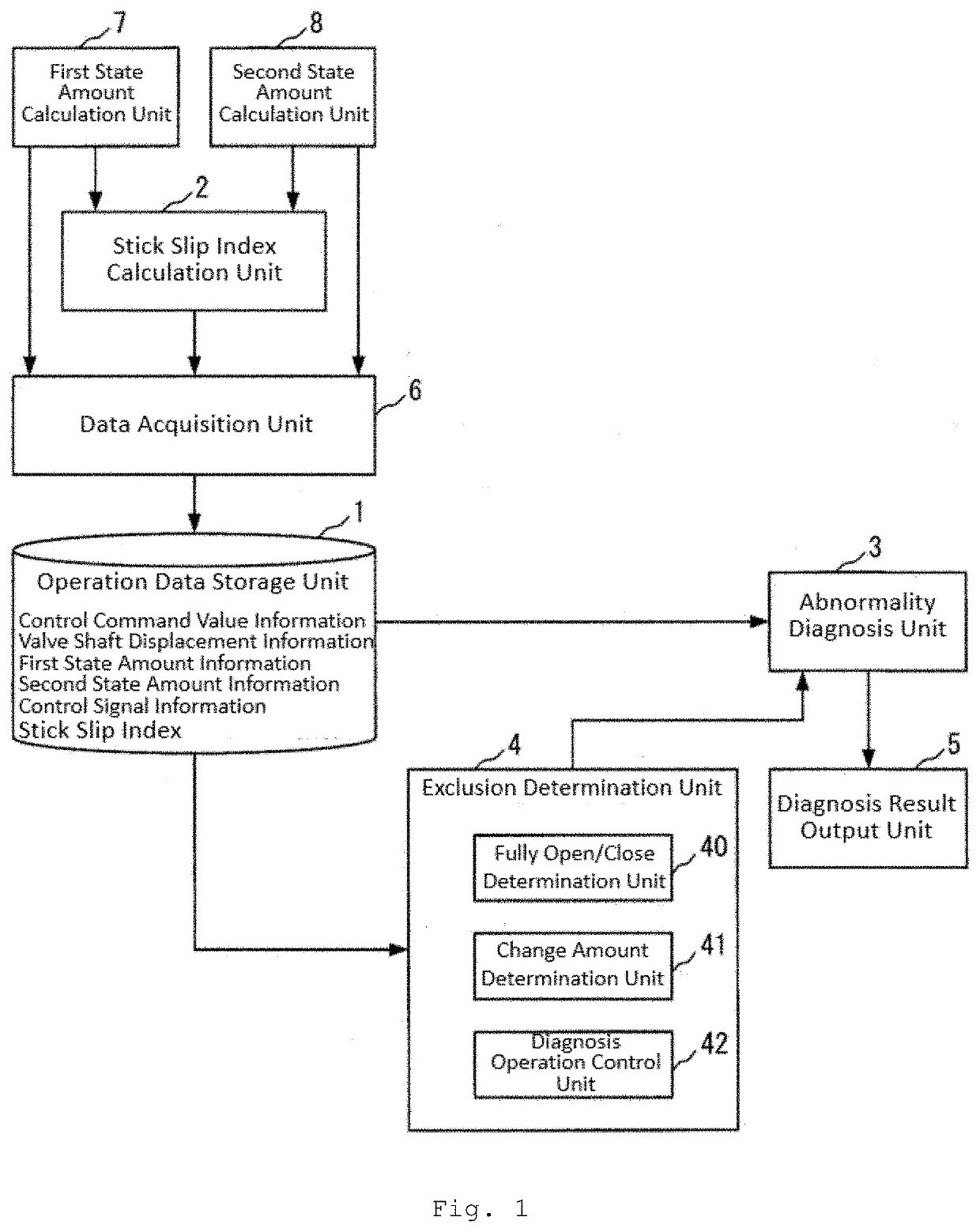

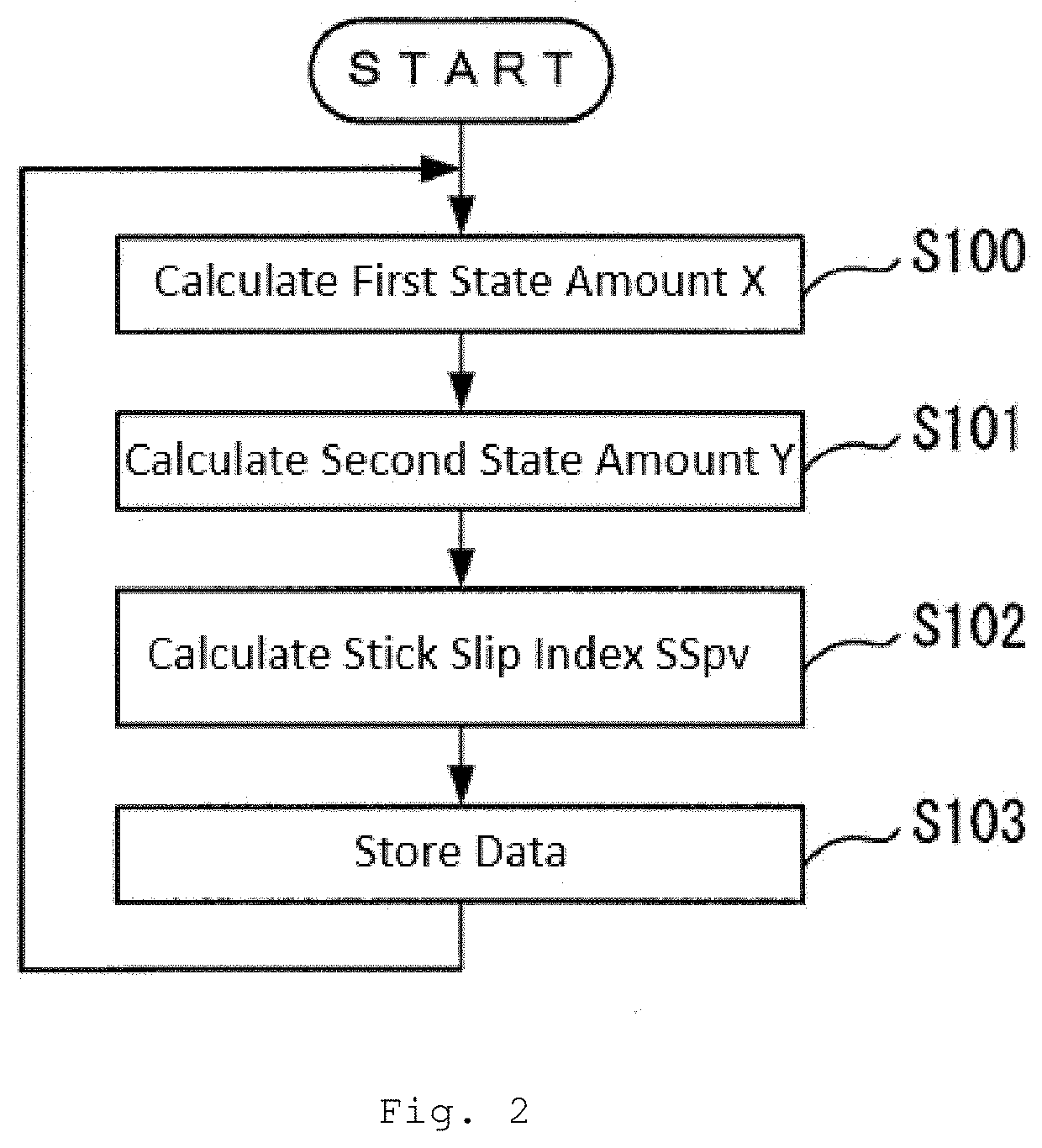

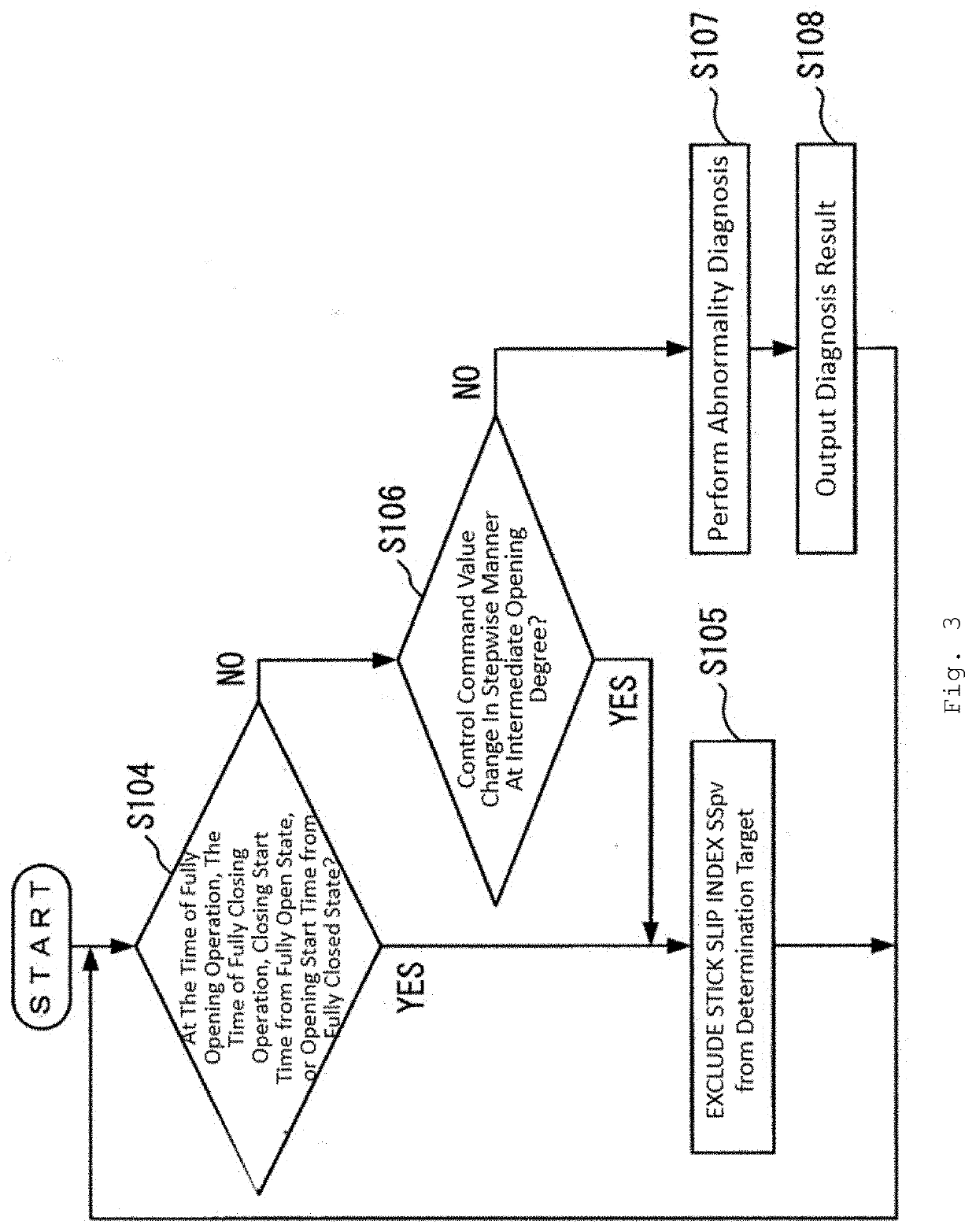

Stick slip detection system and method

PendingUS20220356962A1Easily reflecting knowledgePneumatic programme controlValve arrangementsEngineeringMechanical engineering

A stick slip detection system includes: an operation data storage unit configured to store a stick slip index, the stick slip index being a ratio of a first state amount based on a displacement of a valve shaft of a valve to be diagnosed to a second state amount based on the displacement; an abnormality diagnosis unit configured to determine whether a stick slip phenomenon occurs in the diagnosis target based on the stick slip index; and a diagnosis operation control unit configured to, when a stepwise change in a control command value in an intermediate opening degree of the valve to be diagnosed is detected, stop a determination operation of the abnormality diagnosis unit. The present disclosure makes it possible to easily reflect knowledge of an expert with respect to a diagnosis target such as a valve in the stick slip detection system and method.

Owner:YAMATAKE HONEYWELL CO LTD

Actuator control device

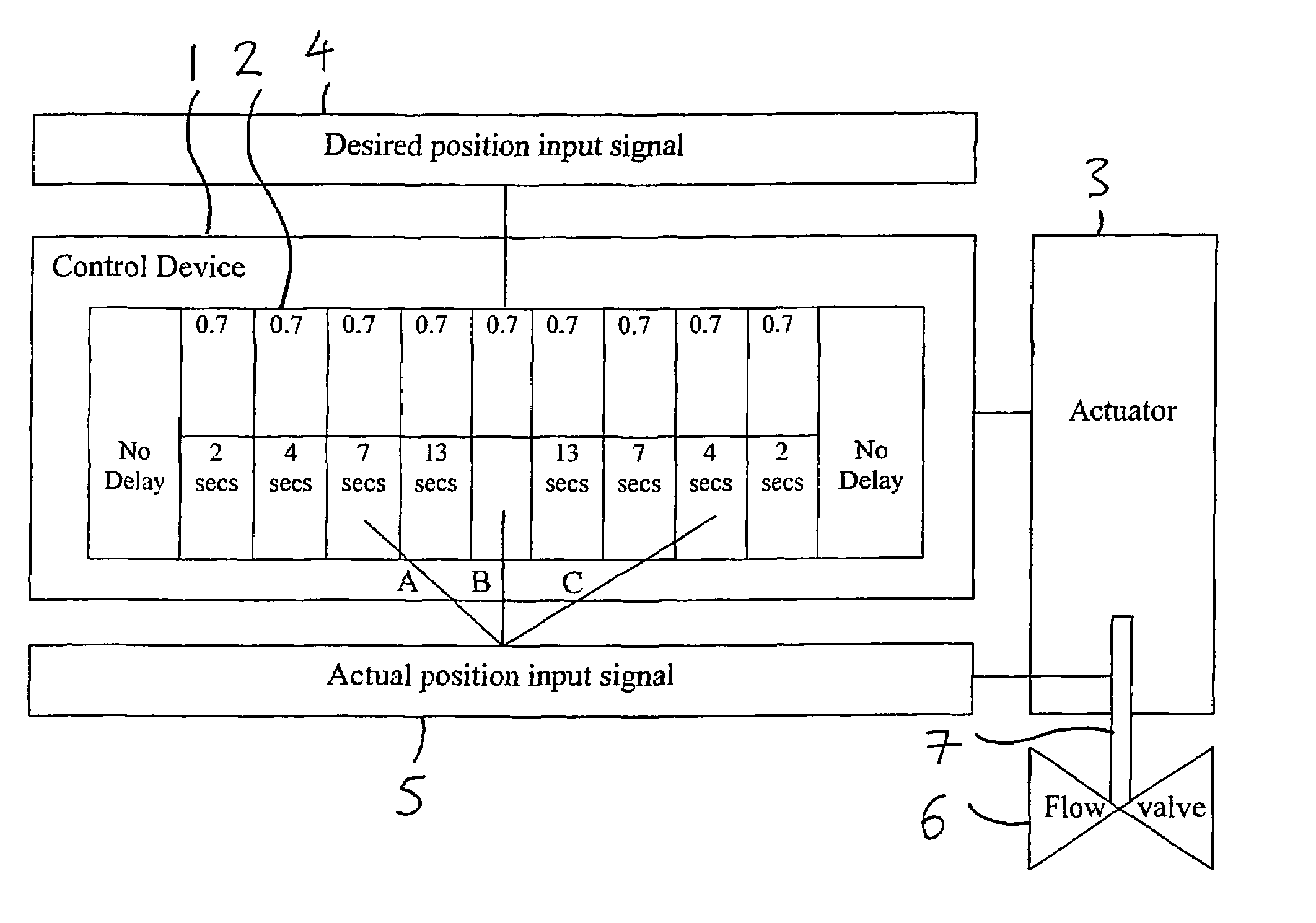

InactiveUS7131631B2Slow movementPneumatic programme controlOperating means/releasing devices for valvesValve actuatorSolenoid valve

A valve actuator control device adapted to control the position of a valve actuator by means of solenoid valves, in which if the actuator position deviates from a desired position, but remains within a predetermined distance from said desired position, the control device is adapted to only return the actuator to the desired position after a delay period, thereby to increase the life span of said solenoid valves.

Owner:FORAC LTD

Pneumatic solar tracking system for solar panels

The pneumatic solar tracking system for solar panels adjusts the angular orientation of a solar panel to maximize exposure of an upper surface of the solar panel to incident solar radiation from the sun as the sun moves across the sky. The pneumatic solar tracking system includes a base and a platform supported above the base. The platform has an opening formed therein. A plurality of pneumatic actuators are supported on the base beneath the opening formed in the platform. The solar panel is supported on an upper surface of the platform, and a plurality of pivotal connectors pivotally connect the lower surface of the solar panel to respective pistons of the plurality of pneumatic actuators. Each of the pivotal connectors pivots along at least two orthogonal axes. An optical sensor is provided for detecting and tracking the angular position of the sun.

Owner:UNITED ARAB EMIRATES UNIVERSITY +1

Gas path control system of vacuum adsorption platform

Owner:GUANGDONG HANS YUEMING LASER GRP CO LTD

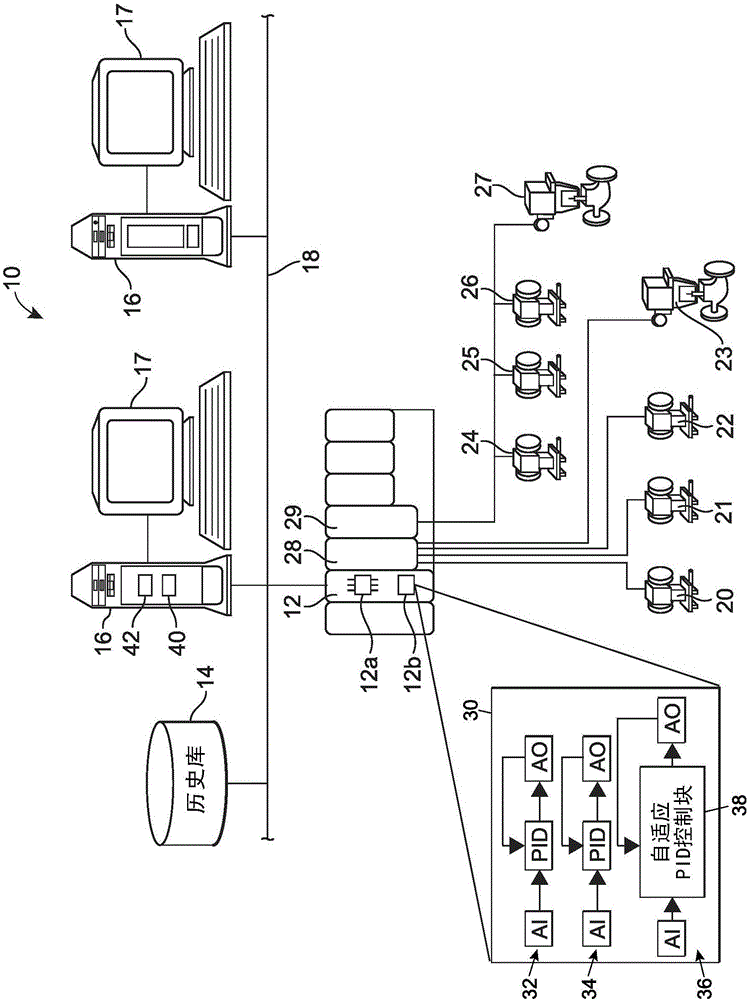

Methods, apparatuses and systems for controlling a valve based on a combination of a characteristic curve for the valve and a proportional, integral and derivative signal value

InactiveCN106292575APneumatic programme controlFluid pressure control using electric meansControl valvesBiomedical engineering

A process device control may use a combination of a characteristic curve for the device and a proportional, integral and derivative signal value. The characteristic curve for the device may define operational characteristics of the process device. The proportional, integral and derivative signal value may be representative of process device operational deviations from the characteristic curve.

Owner:TESCOM CORP

Soft robot system and method

ActiveCN110430926AProgramme-controlled manipulatorPneumatic programme controlRobotic systemsFluid control

An amusement park attraction includes an attraction feature. The attraction feature includes a fluid actuator having an inflatable mass, the inflatable mass being fluidly connected to a source of pressurized fluid to enable inflation of the inflatable mass. Fluid control devices are configured to adjust inflation of the inflatable mass, and sensors are configured to monitor state properties of thefluid actuator. A controller is communicatively coupled to the fluid control devices and the sensors. The controller is configured to controllably inflate the inflatable mass based at least on feedback from the sensors to cause the fluid actuator to impact an object. The controller is configured to control the inflation of the inflatable mass to adjust parameters of the fluid actuator to maintaina force exerted by the fluid actuator on the object to within a predetermined range.

Owner:UNIVERSAL CITY STUDIOS LLC

Valve manifold serially mounted to distributed control system assembly

ActiveCN108141984APneumatic programme controlPLC for automation/industrial process controlTelecommunicationsSolenoid valve

A control system has an I / O bank with a communication module controlling a plurality of Input / Output modules operably connected to its communication backplane and a valve manifold having a communication module serially connected to the backplane of the I / O bank. The I / O bank with a plurality of Input / Output modules is constructed to be connected to a plurality of field sensors or loads. The valvemanifold with a plurality of solenoid valves is constructed to be pneumatically connected to a plurality of field devices.

Owner:NUMATICS INCORPORTED

Mesa ball X-Y trace pneumatic controller

InactiveCN100462883CGood compressibilityReduce stiffnessPneumatic programme controlControl using feedbackData acquisitionEngineering

The present invention relates to a table ball X-Y path pneumatic control device, belonging to the field of machinery technology. Said invention includes data acquisition card, computer, platform support, platform, small ball, touch screen device, potentiometer and platform servo device. Besides, said invention also provides their connection mode, working principle of said table ball X-Y path pneumatic control device and its concrete application method.

Owner:SHANGHAI JIAO TONG UNIV

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com