Double corrector for asymmetrical mechanism compensation

A corrector, asymmetric technology, applied in the direction of controllers, instruments, machinery, etc. with specific characteristics, which can solve the requirements of meeting overflow, cannot allow slow behavior, rapidity, servo control solutions cannot allow meeting specifications, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] Now, a specific implementation of this solution will be described. The solution is again explained in conjunction with the three-way valve described in the introduction. The "Situational Modeling" context described in section is considered.

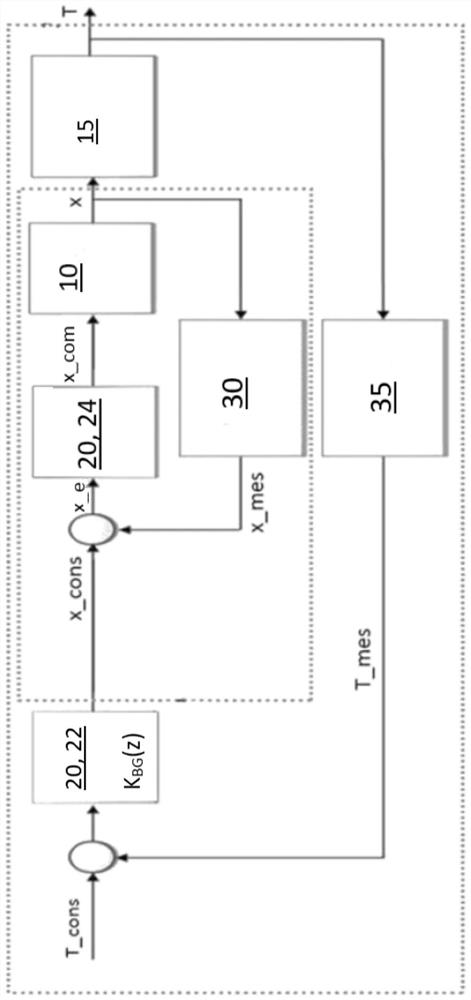

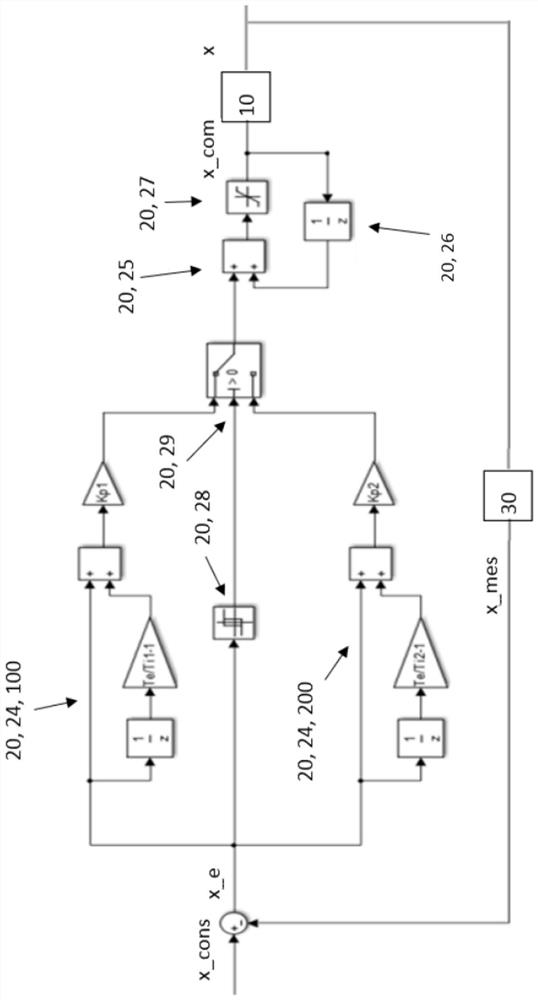

[0051] will refer to figure 1 and figure 2 The control system 1 and the control method are described.

[0052] The control system includes a valve 10 such as a three-way valve (channel one, channel two and channel three) and a calculator 20 . Advantageously, a sensor 30 is provided to measure the position of the valve 10 . Define three positions P1, P2 and P3 for the three-way valve 10:

[0053] - In position P1 (called stop position), channel three (exit channel) is connected to channel one (oil from the exchanger),

[0054] - In position P2 (also called stop position), channel three is connected to channel two (uncooled oil),

[0055] - In position P3, channel three is connected to the other two channels (this position ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com