Patents

Literature

65 results about "Stick-slip phenomenon" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

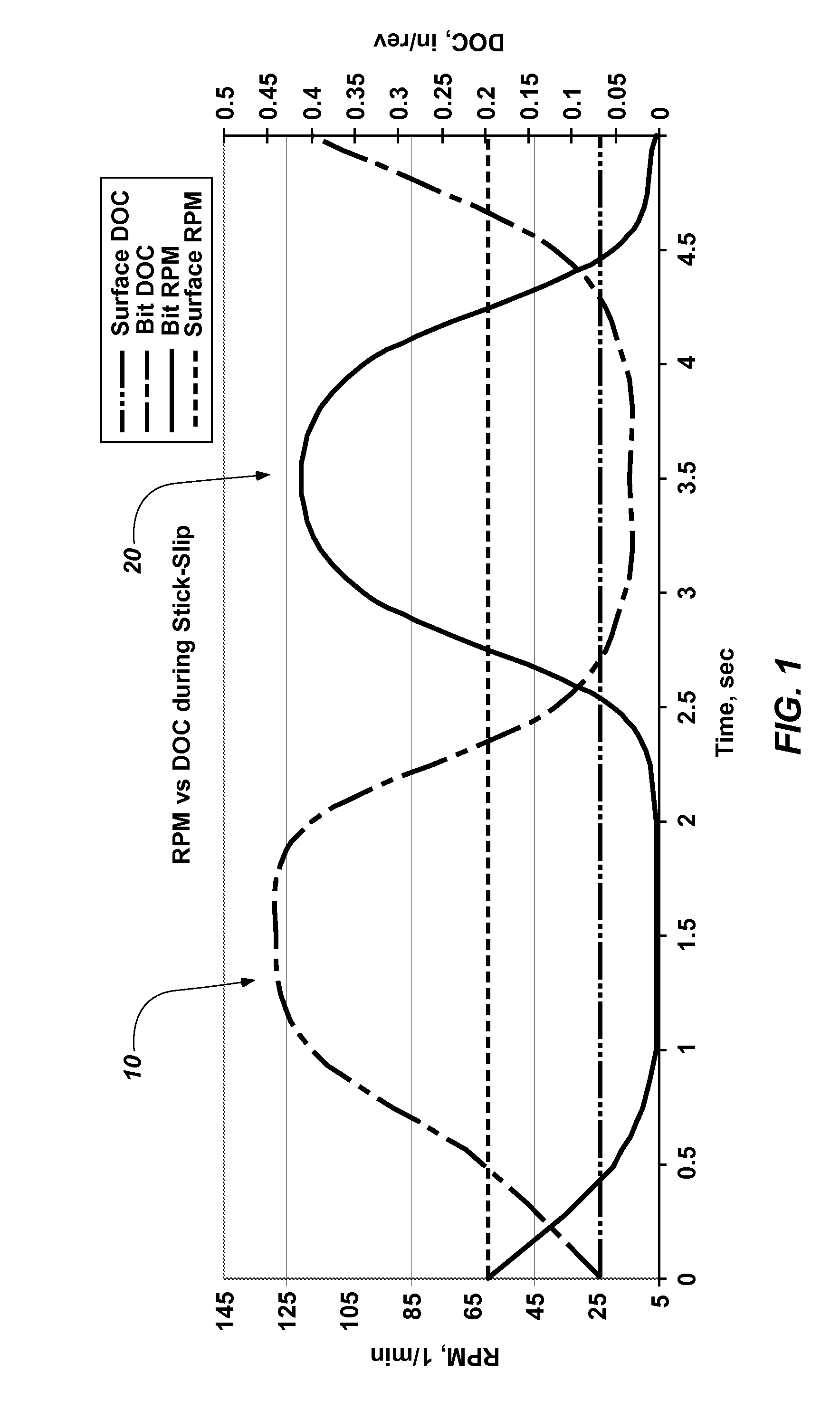

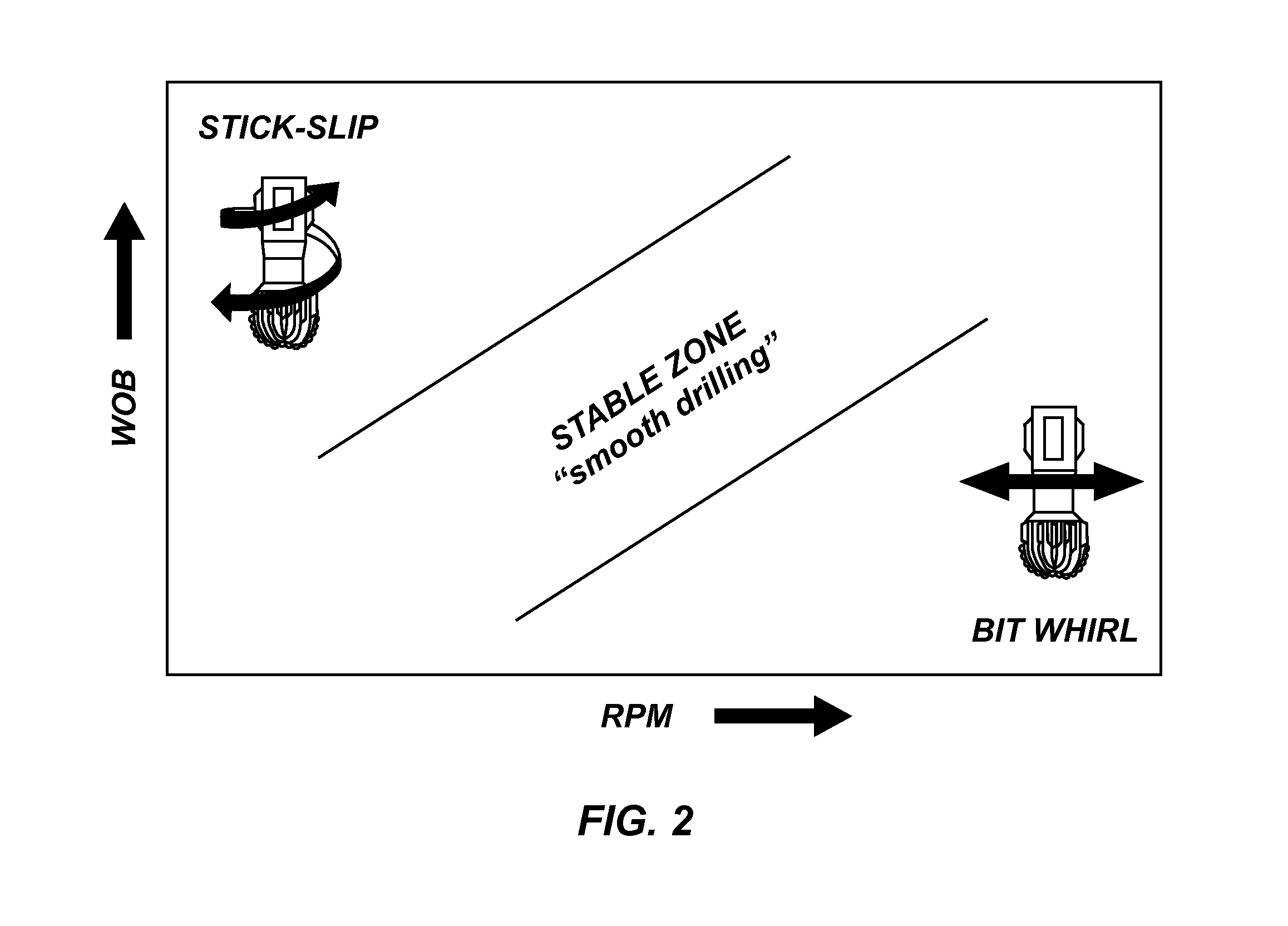

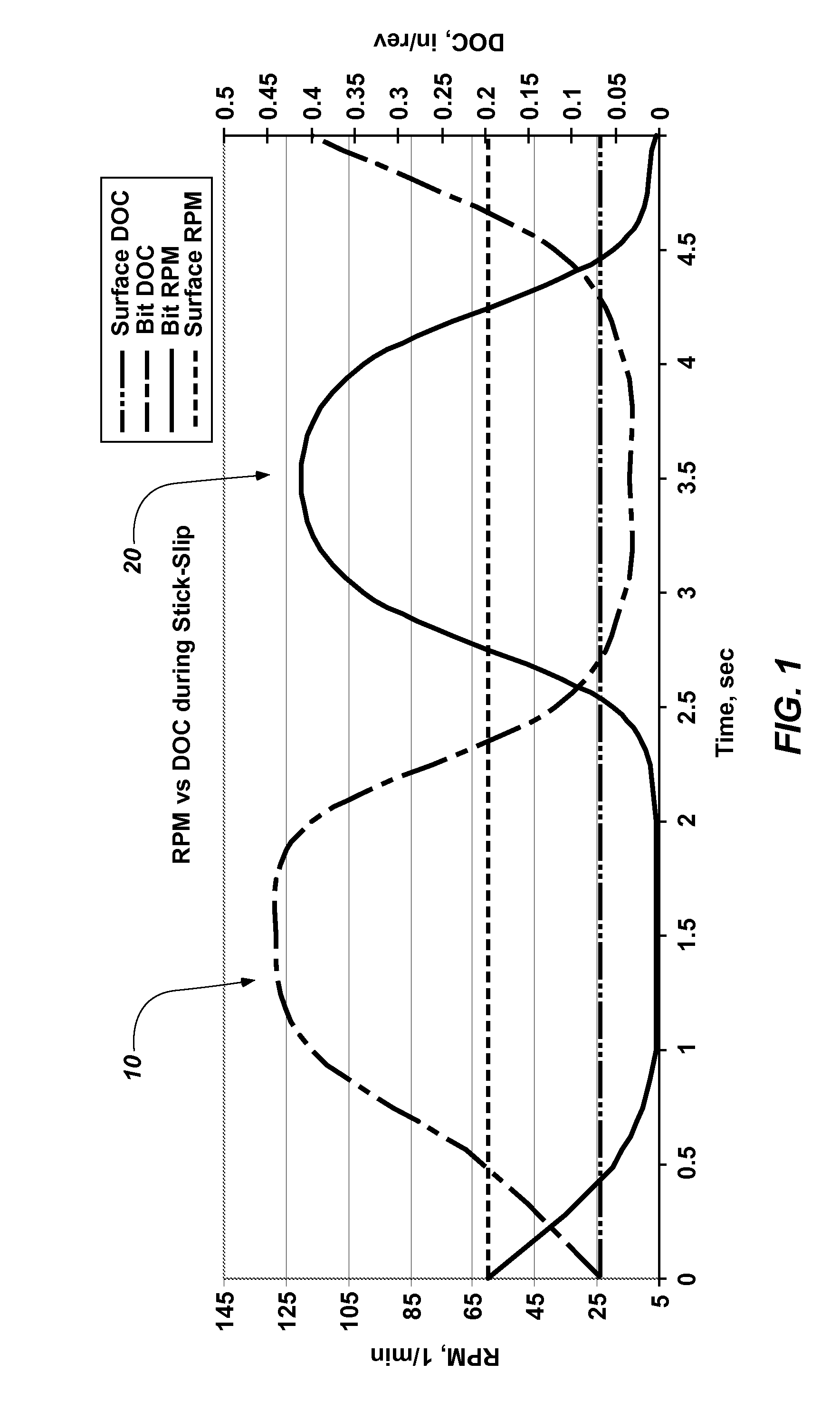

The stick-slip phenomenon, also known as the slip-stick phenomenon or simply stick-slip, is the spontaneous jerking motion that can occur while two objects are sliding over each other.

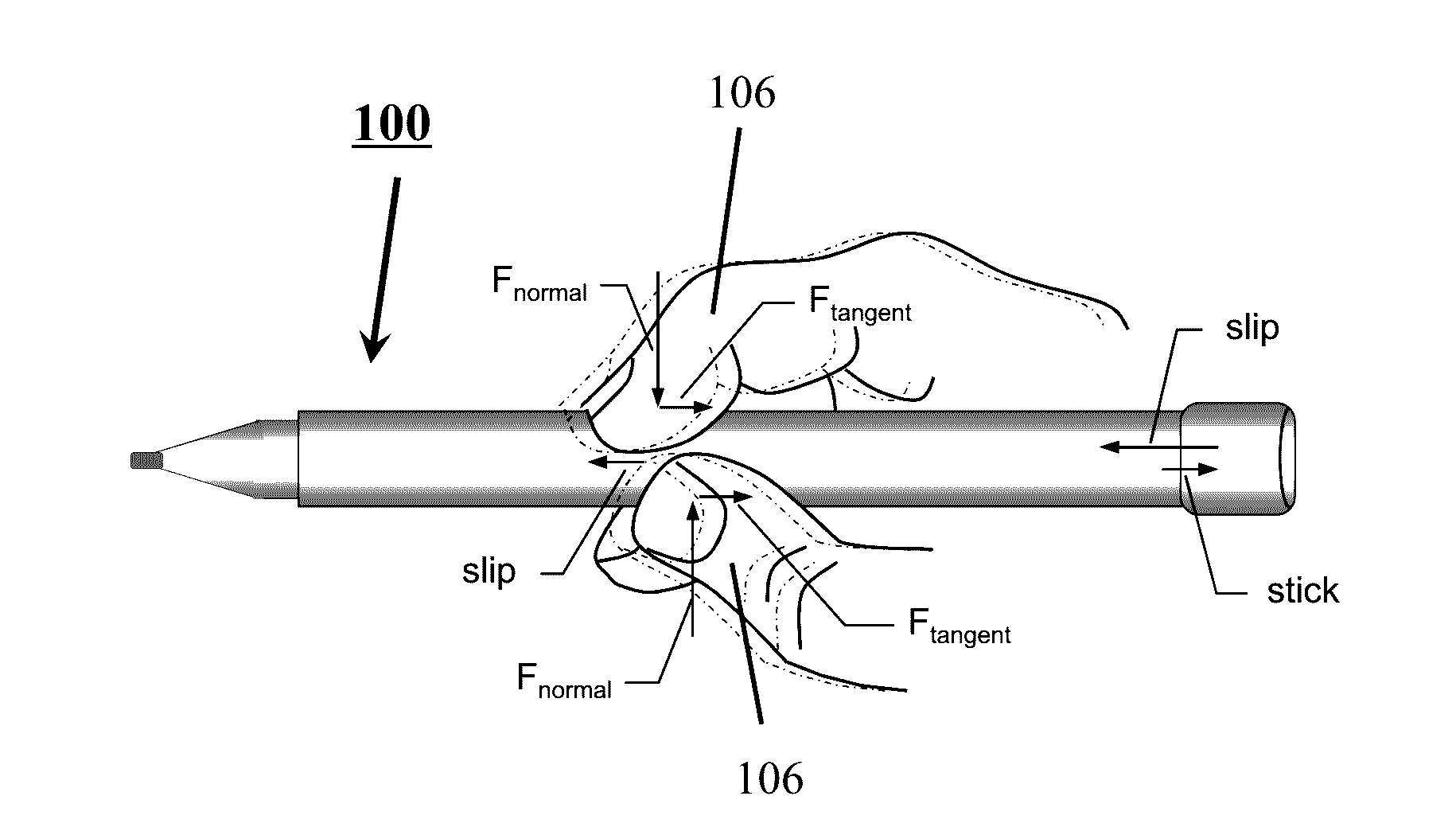

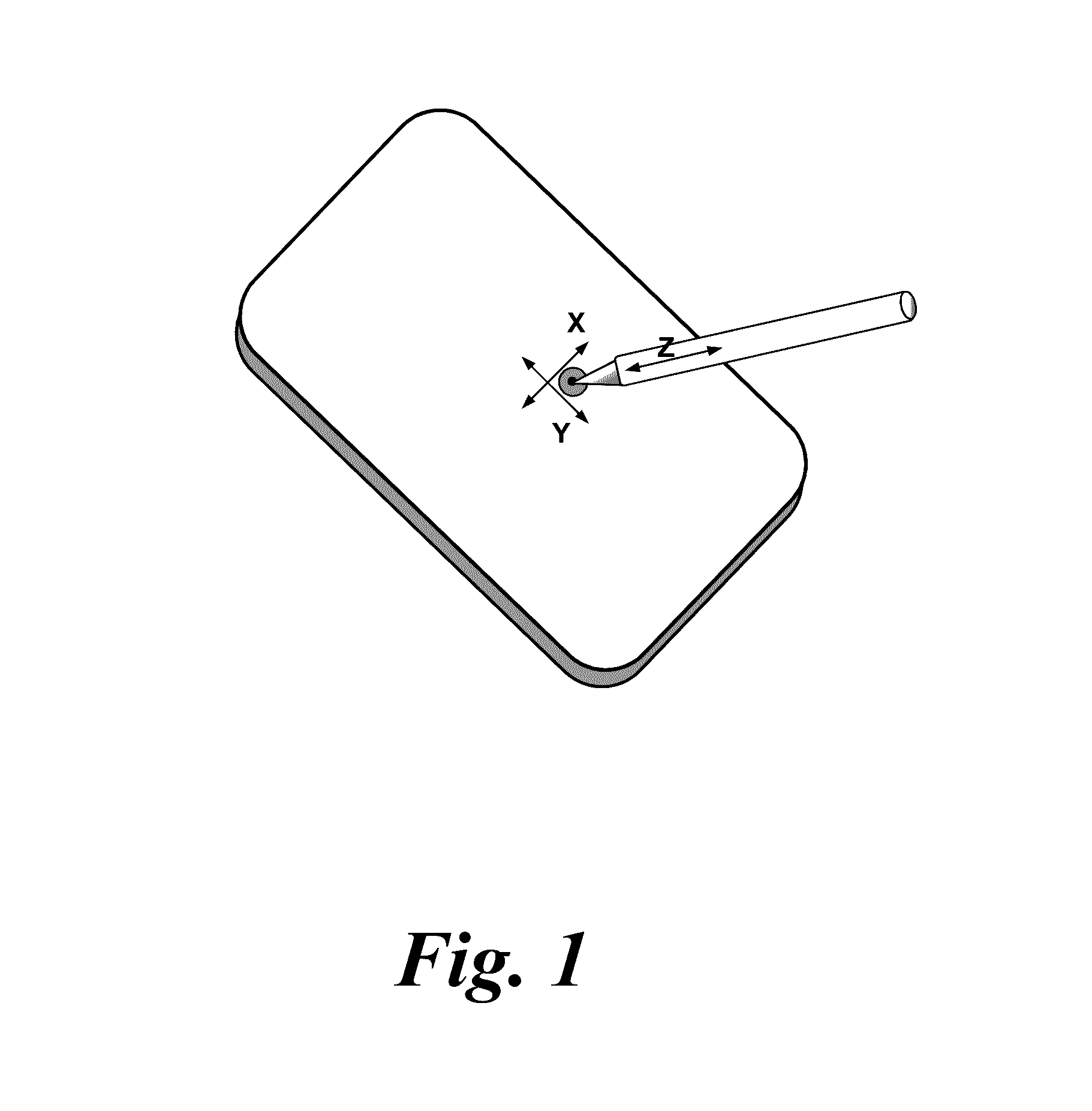

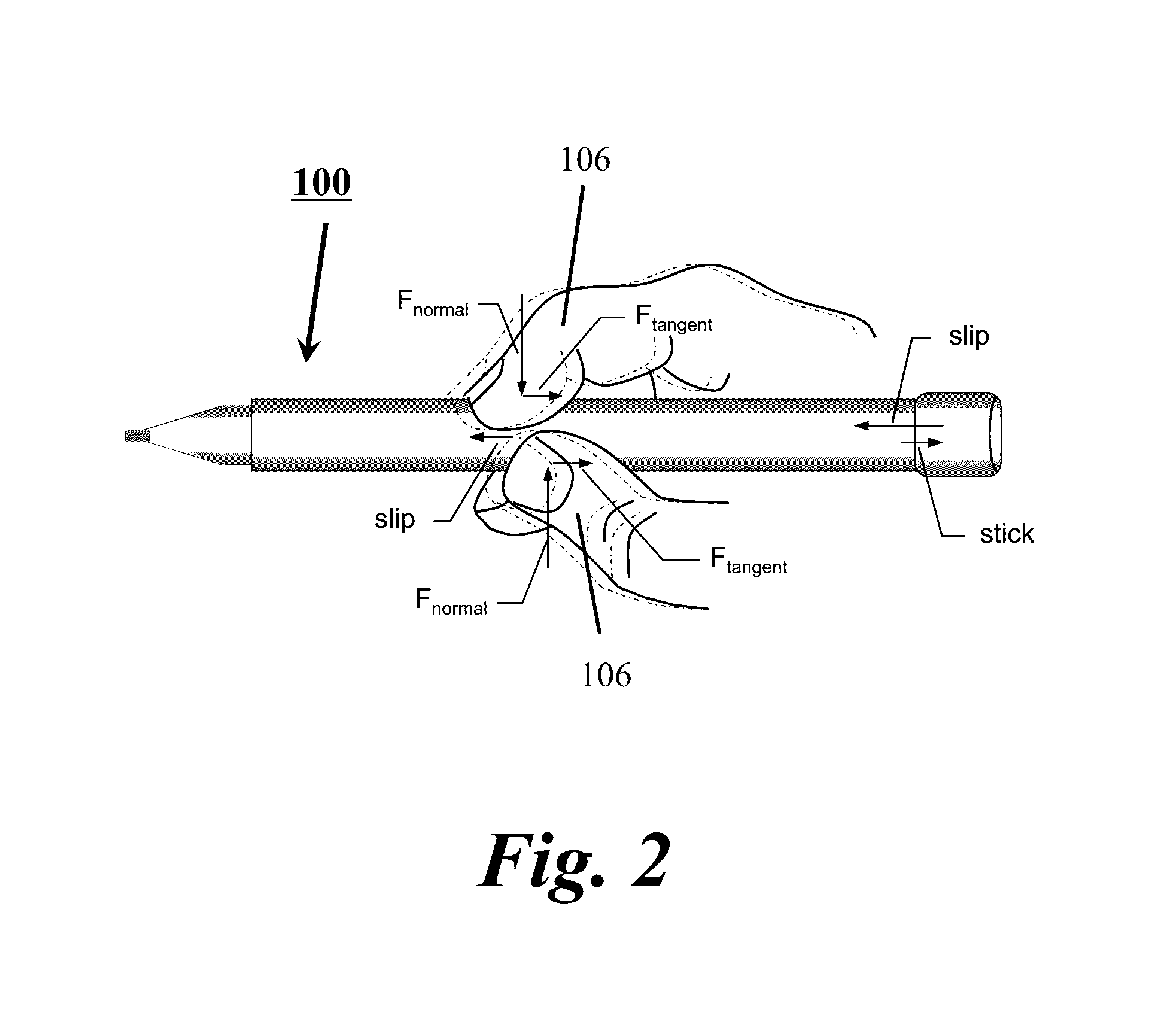

Haptic stylus

InactiveUS20160282970A1Input/output for user-computer interactionGraph readingEngineeringTouchscreen

One embodiment relates to a haptic stylus includes: a stylus housing; a stylus tip attached to one end of the stylus housing, so as to be in contact with an interaction surface, such as a touchscreen; a stylus covering attached to a circumference of the stylus housing, so as to be movable with respect to the stylus housing along a longitudinal direction of the haptic stylus and so as to be gripped / held by user's fingers; and a first actuator configured to activate the stylus housing to thereby cause a stick-slip phenomenon between the stylus covering and the user's fingers gripping / holding the stylus covering thereby allowing the user's fingers to grip / hold the stylus covering while moving along the longitudinal direction of the haptic stylus.

Owner:UNIVERSITY OF TAMPERE +1

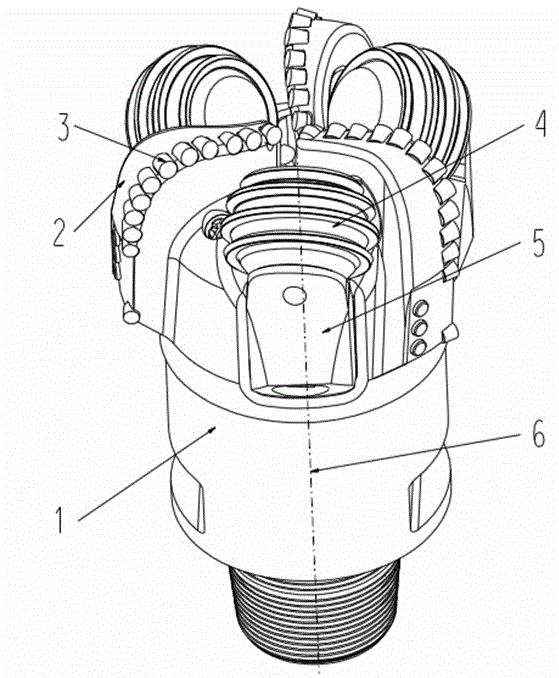

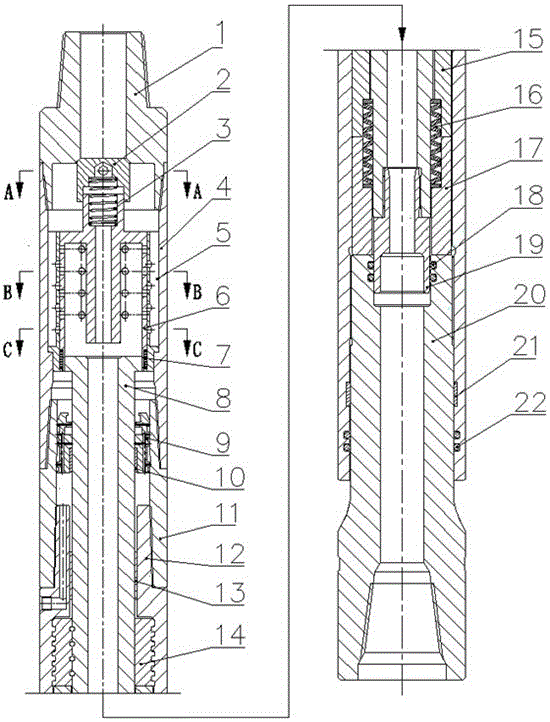

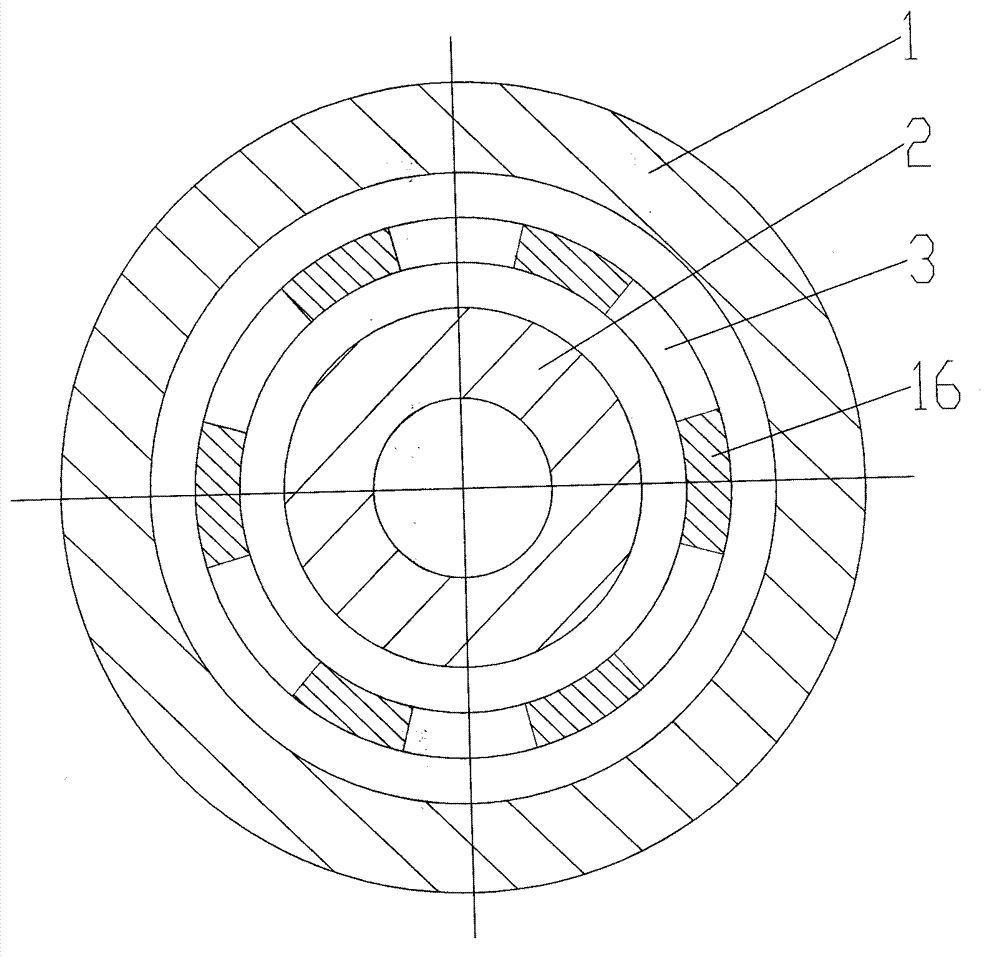

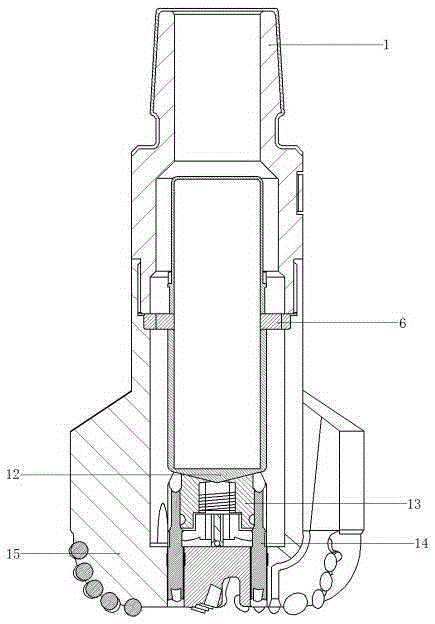

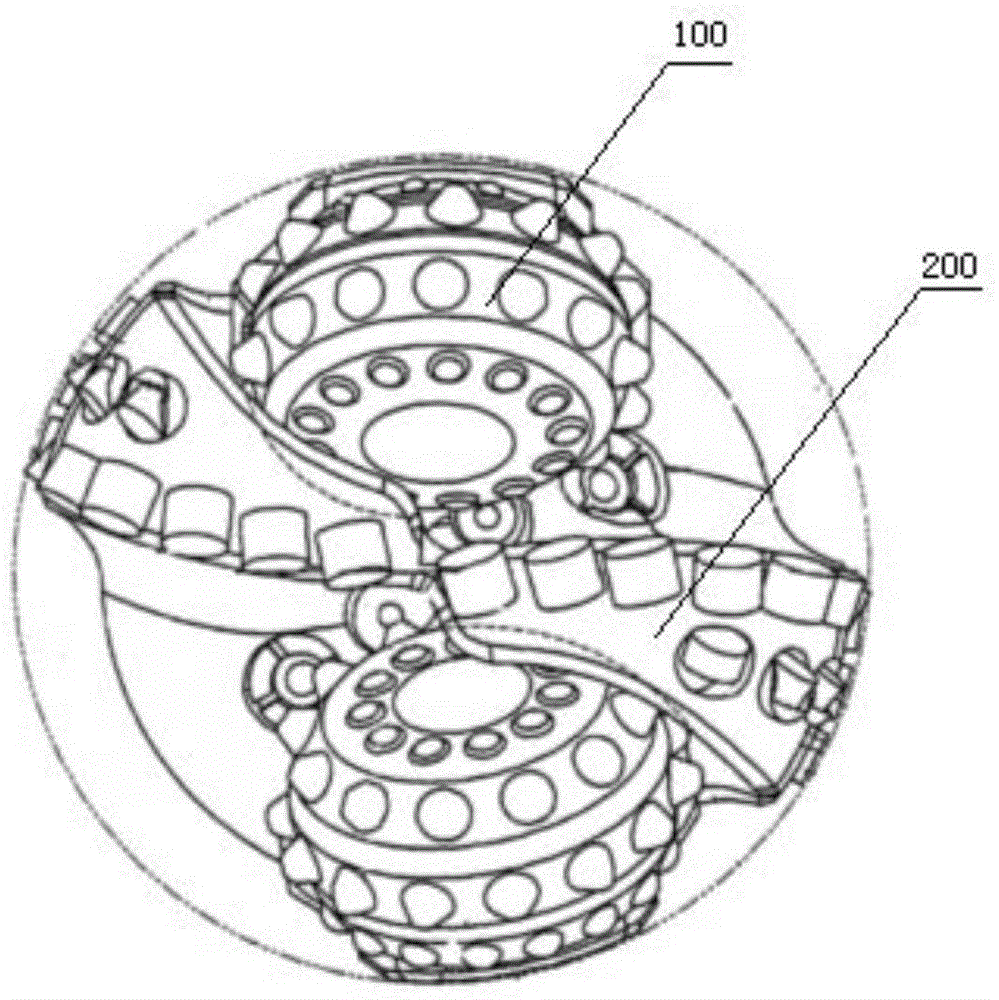

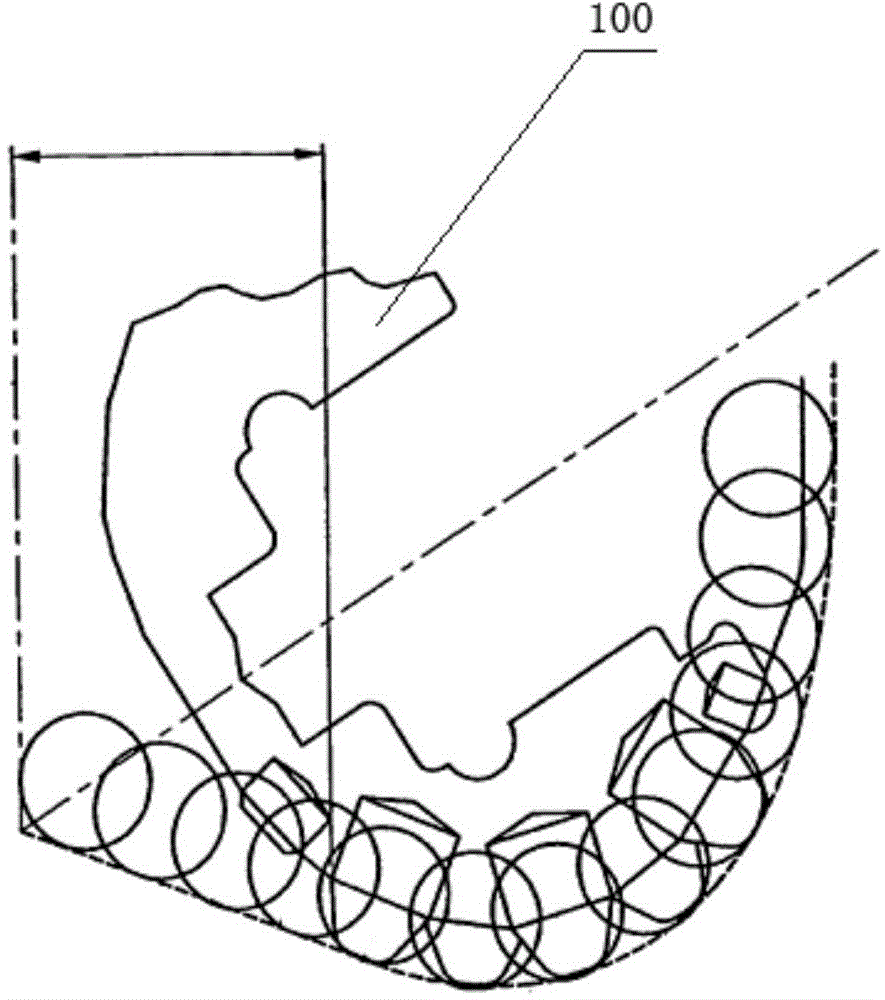

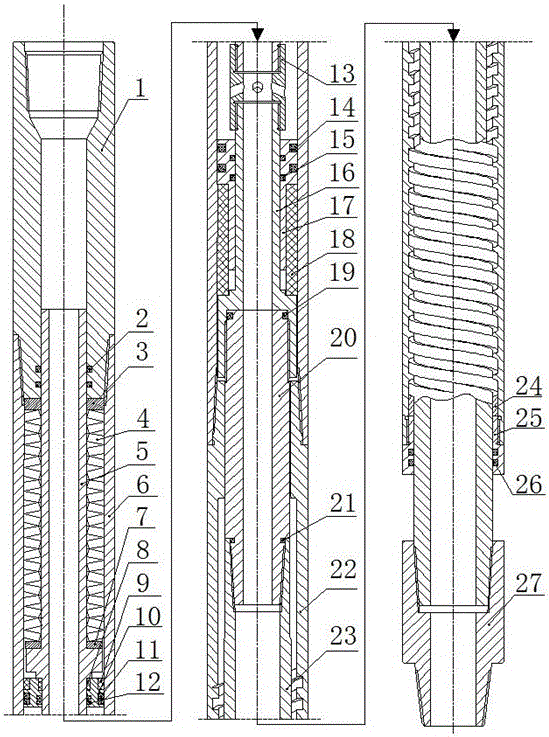

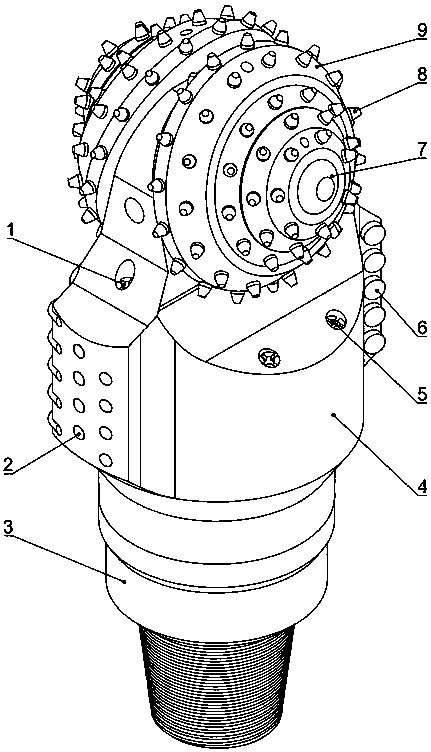

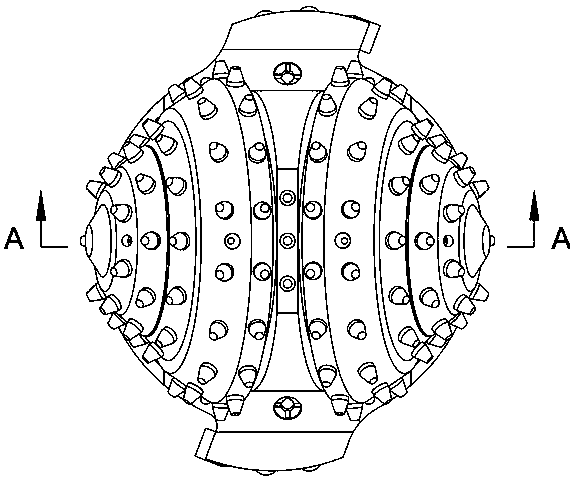

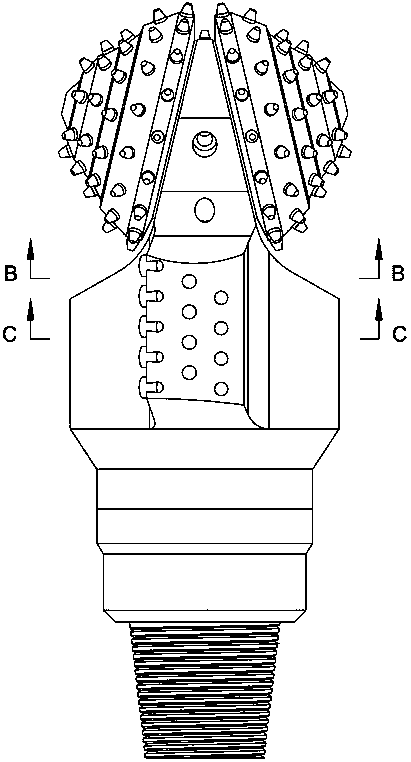

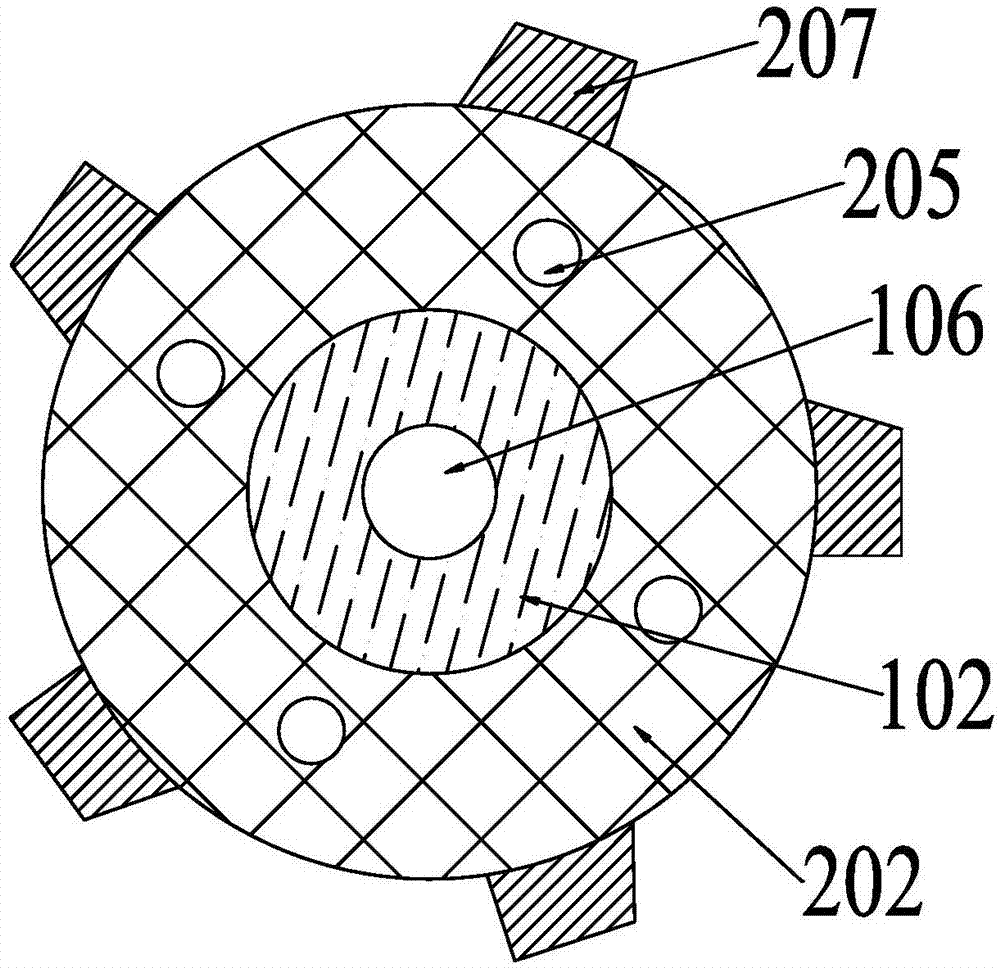

Hybrid drill bit

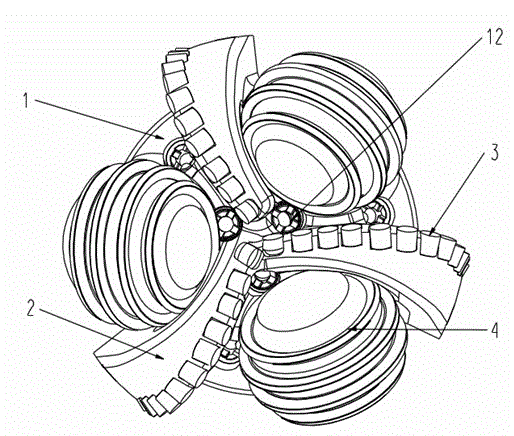

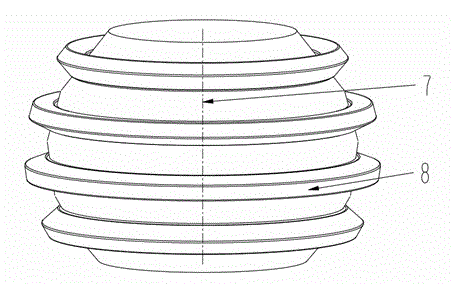

InactiveCN102747960AEliminate stick-slipImprove cutting efficiencyDrill bitsDiamond cuttingWell drilling

The invention relates to a hybrid drill bit for petroleum, natural gas and geological drilling. The hybrid drill bit comprises a drill bit body, wherein a cutter wing and a roller cone are arranged on the drill bit body, cutting teeth are arranged on the cutter wing, the roller cone is connected with the drill bit body through a cone leg, and the hybrid drill bit is characterized in that the roller cone is a disk type roller cone. A cutting element on the disk type roller cone is shaped like a disk cutter or an intermittent disk cutter. The patent disclosed by the invention has the beneficial effects that, 1) the scraping motion of a diamond drill bit and the rolling motion of a disk type roller cone drill bit are combined for realizing precrushing at the bottom of a well, thereby ensuring that the diamond cutting teeth can effectively bite rock, eliminating the stick-slip phenomenon of the drill bit in some special formations and the probability of impact disrepair of a polycrystalline diamond compact (PDC) and improving the cutting efficiency and the mechanical drilling speed of the drill bit; and 2) the disk type roller cone can realize the precrushing of a rock layer at the bottom of the well more steadily, reduce the impact on the PDC, enhance the stability in drilling of the drill bit and enable the drill bit to realize faster and more stable drilling.

Owner:SINOPEC OILFIELD EQUIP CORP

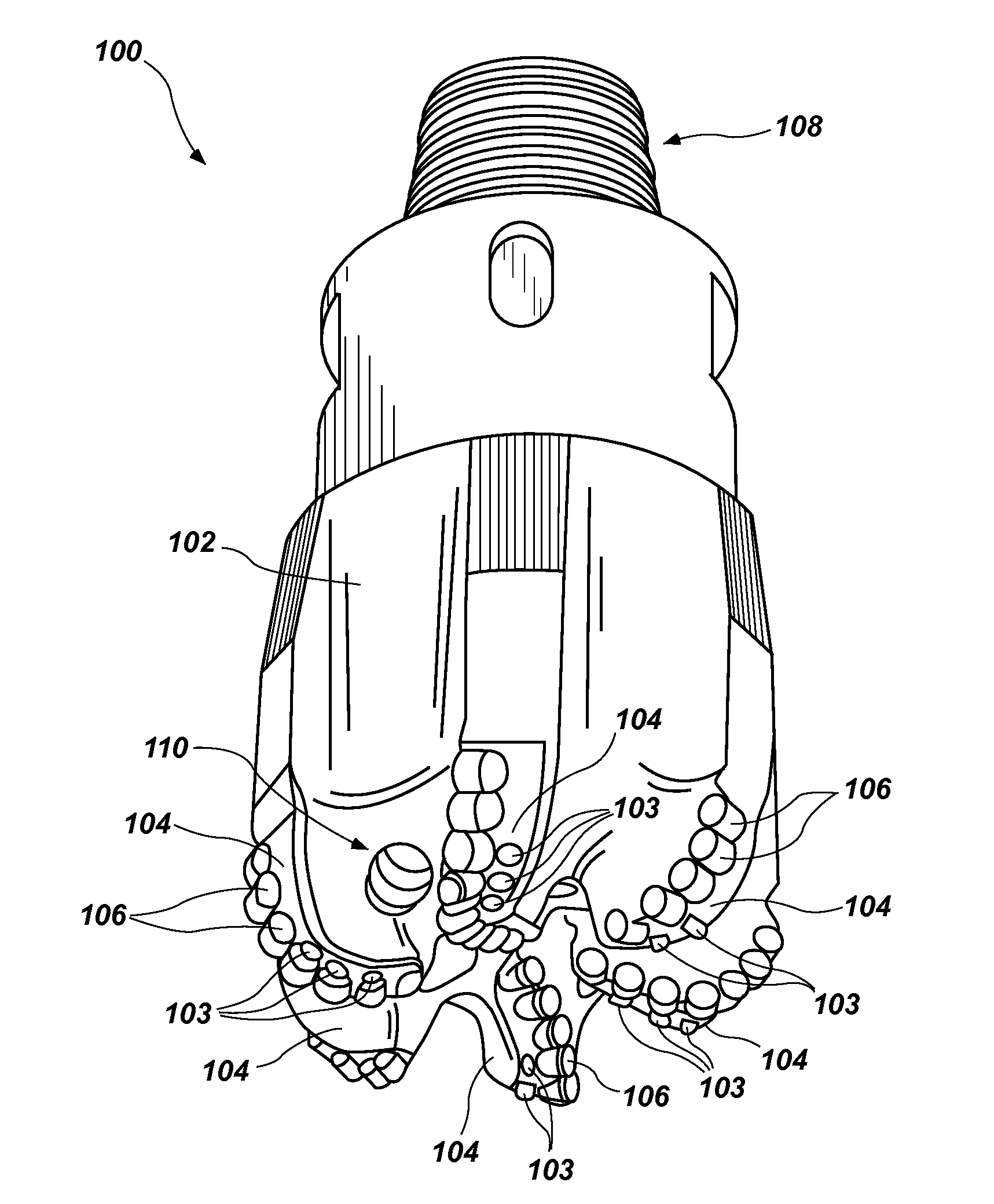

Drill bit design for mitigation of stick slip

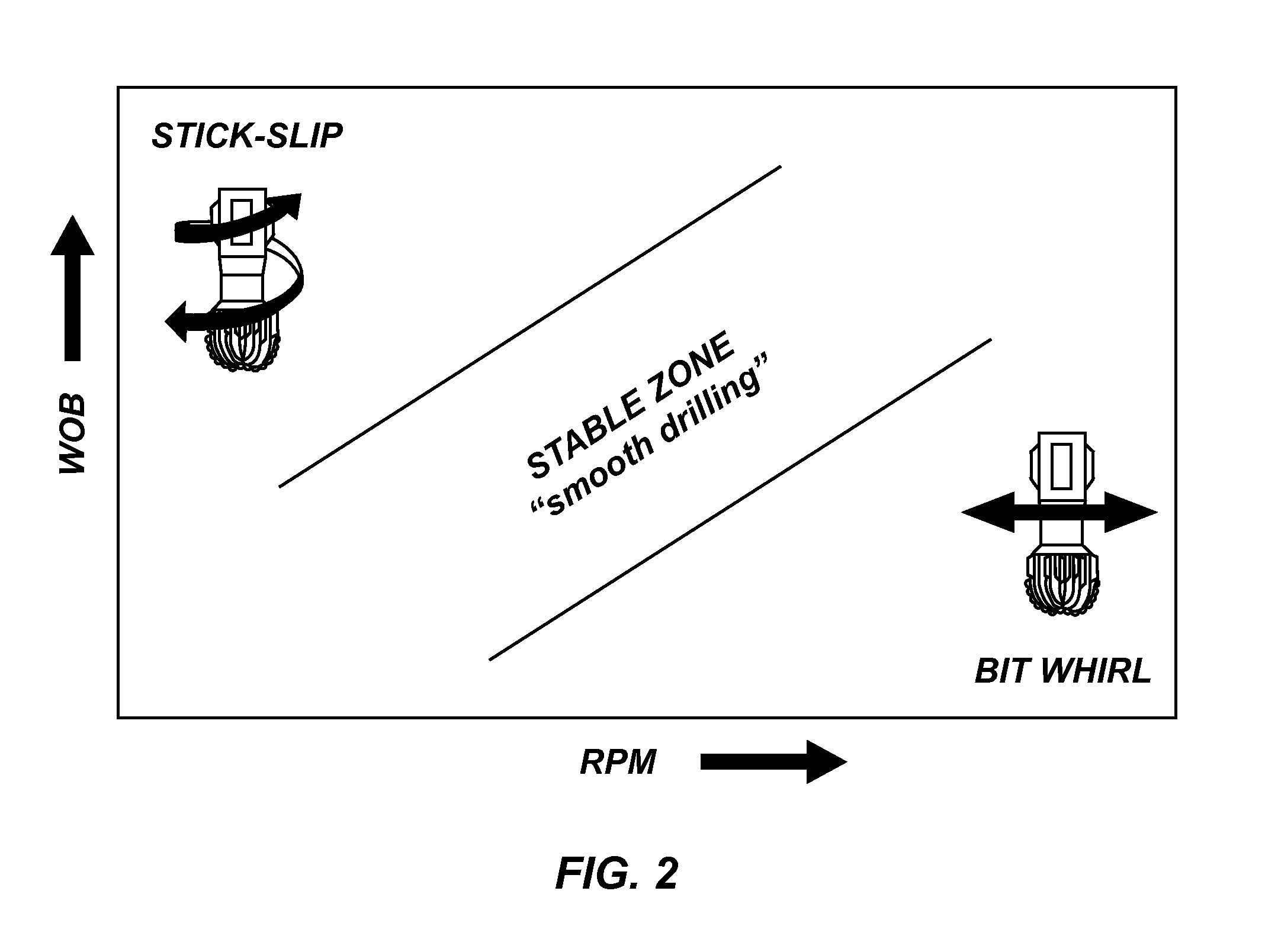

A method of designing an earth-boring rotary drill bit includes designing a bit body and cutting elements of the drill bit such that features of the drill bit other than cutting elements engage and rub against the subterranean formation being drilled by the drill bit at depths-of-cut beyond, but close to, an intended median depth-of-cut, and such that the amount of rubbing area between such features and the formation increases at a relatively rapid rate as the depth-of-cut increases beyond the intended median depth-of-cut. Such methods may be employed to mitigate the occurrence of the stick-slip phenomenon during drilling. A method of fabricating a drill bit includes configuring a bit body and cutting elements in accordance with such a design. Earth-boring drill bits include a bit body and cutting elements so configured.

Owner:BAKER HUGHES INC

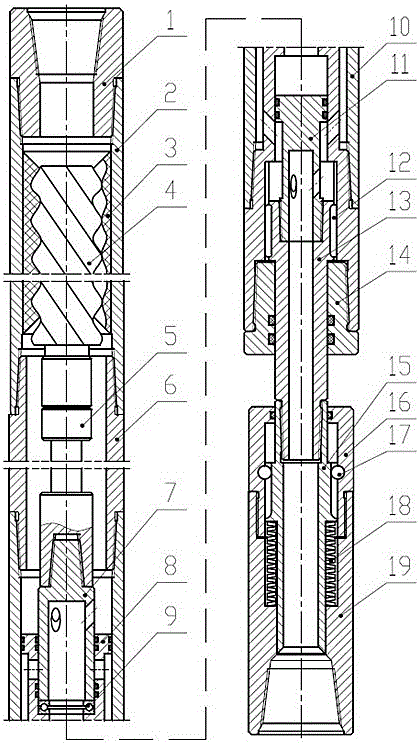

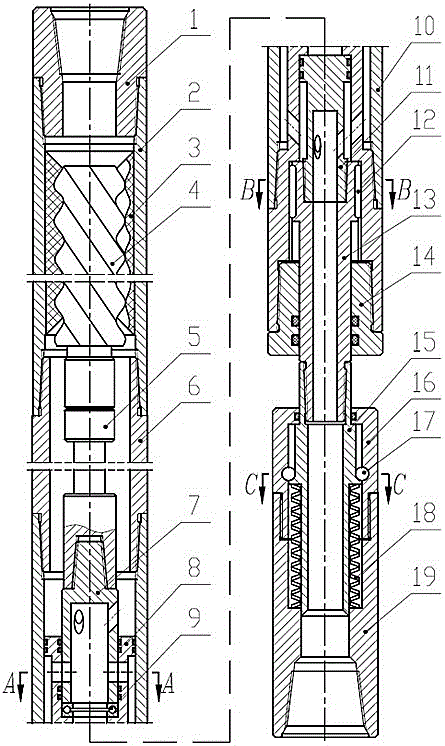

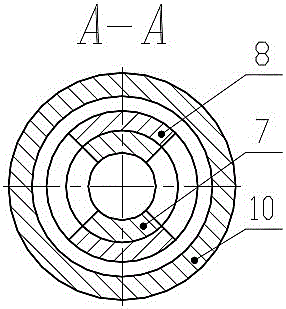

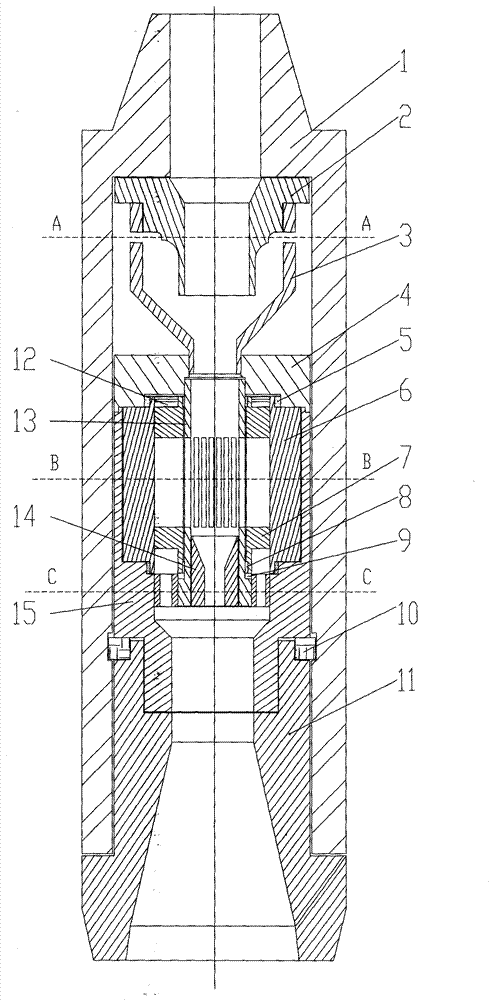

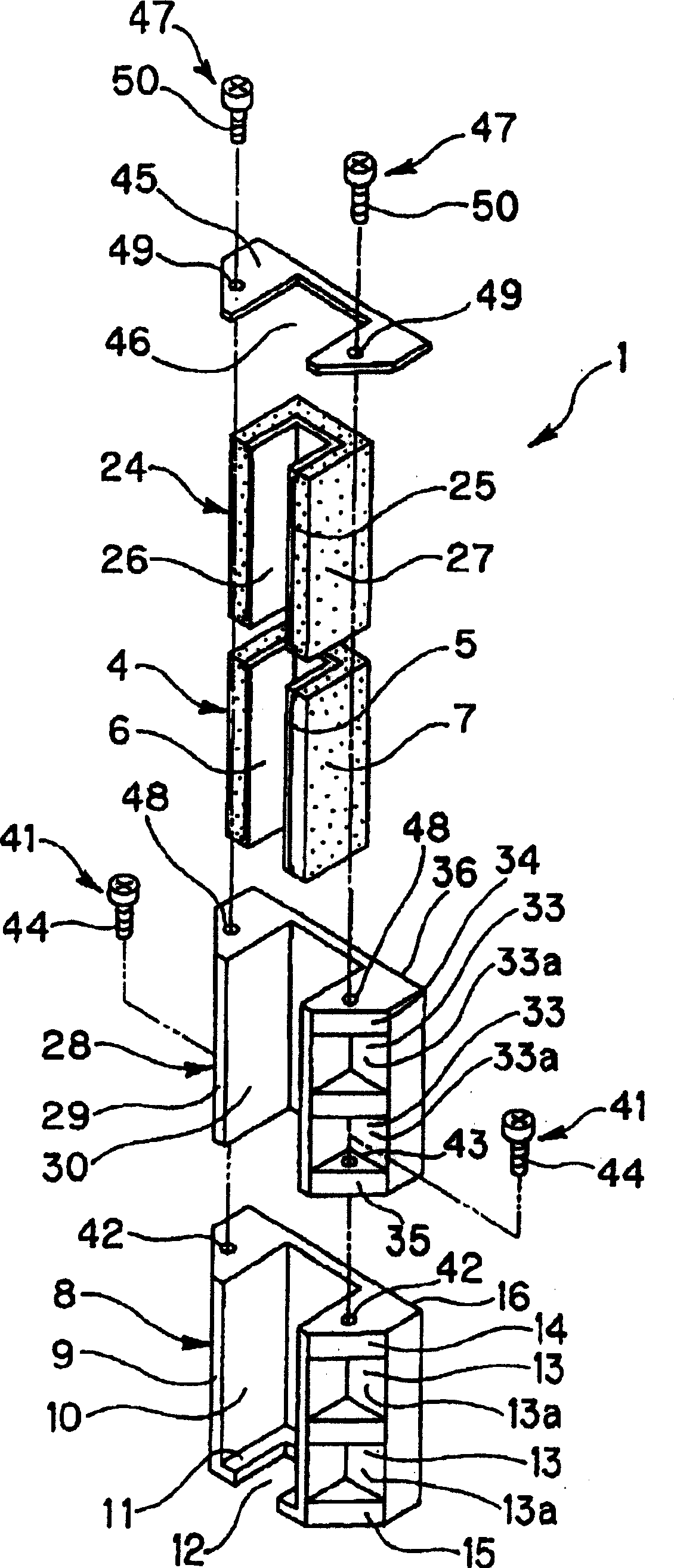

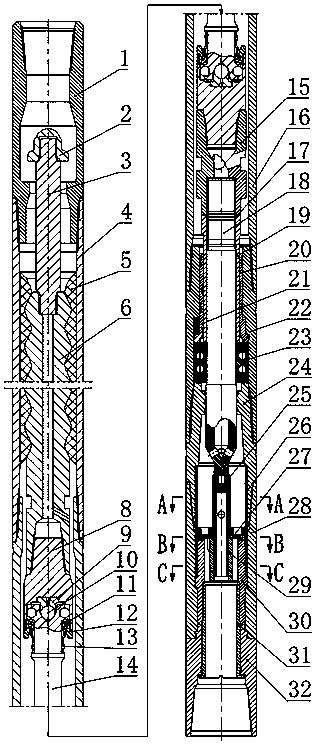

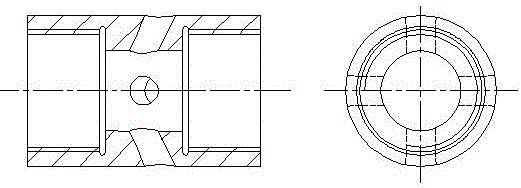

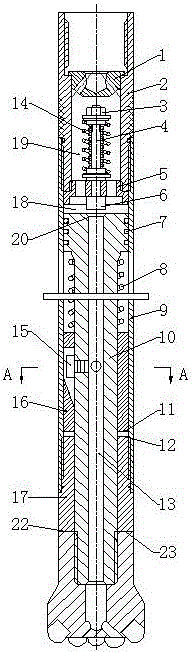

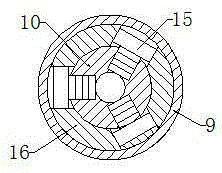

Jet type torsional impact drilling tool

ActiveCN103774983AIncreased torque averageReduce stick-slipReciprocating drilling machinesConstructionsWorking lifeWell drilling

The invention relates to a jet type torsional impact drilling tool. The jet type torsional impact drilling tool comprises an upper connector, an outer shell, a float valve, a valve seat spreader plate, a jet element, a jet spreader plate, a punch hammer, an impact transmission cylinder and a spring. The upper connector is fixedly connected with the outer shell, the outer shell is fixedly connected with the impact transmission cylinder, the float valve, the valve seat spreader plate, the jet element, the jet spreader plate and the spring are located in the outer shell, and the punch hammer is arranged in the transmission cylinder. According to the jet type torsional impact drilling tool, the attachment jet element generates alternating jet to drive the punch hammer to swing left and right, and the punch hammer collides with and impacts on the transmission cylinder to make underground torque greatly fluctuate; compared with a conventional drilling mode, the mean value of the torque of an underground drill bit is increased, the torque of the underground drilling tool is made to greatly fluctuate at high frequency in the drilling process, the stick slip phenomenon of the drill bit is alleviated, the probability of bit bouncing is reduced, and drilling efficiency is improved. The drilling tool is fewer in movable parts and quick-wear parts, long in normal work life, and high in safe reliability.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

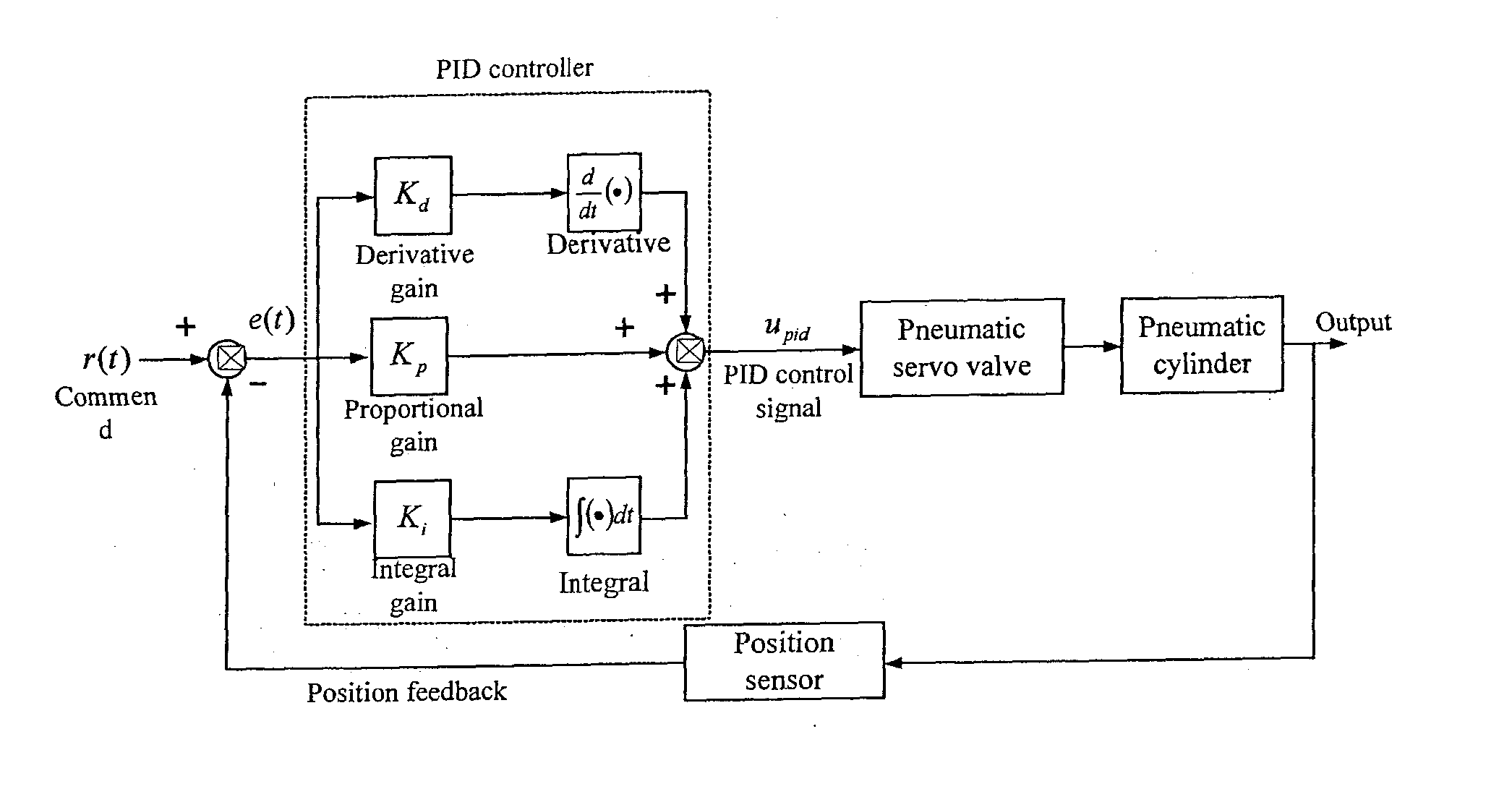

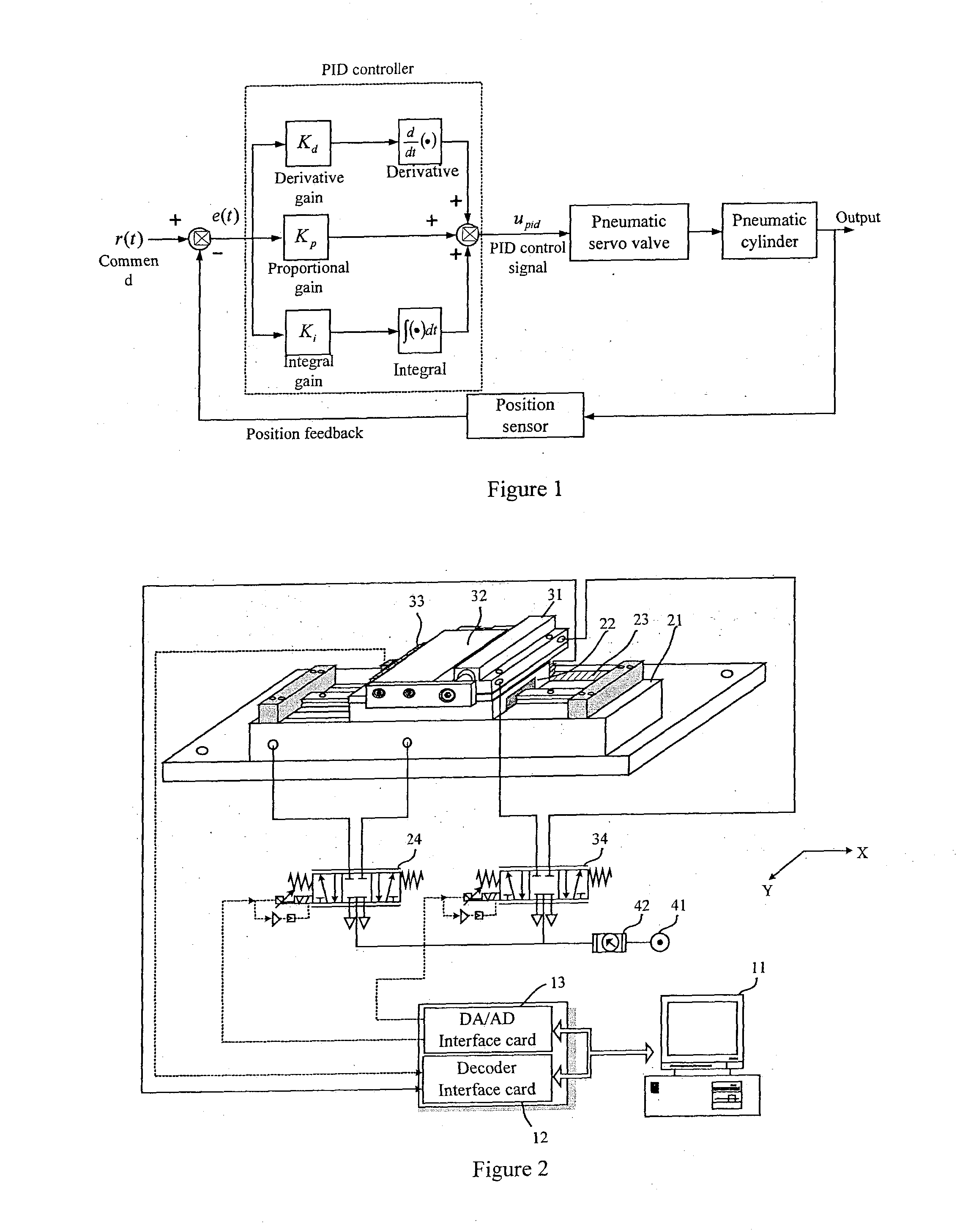

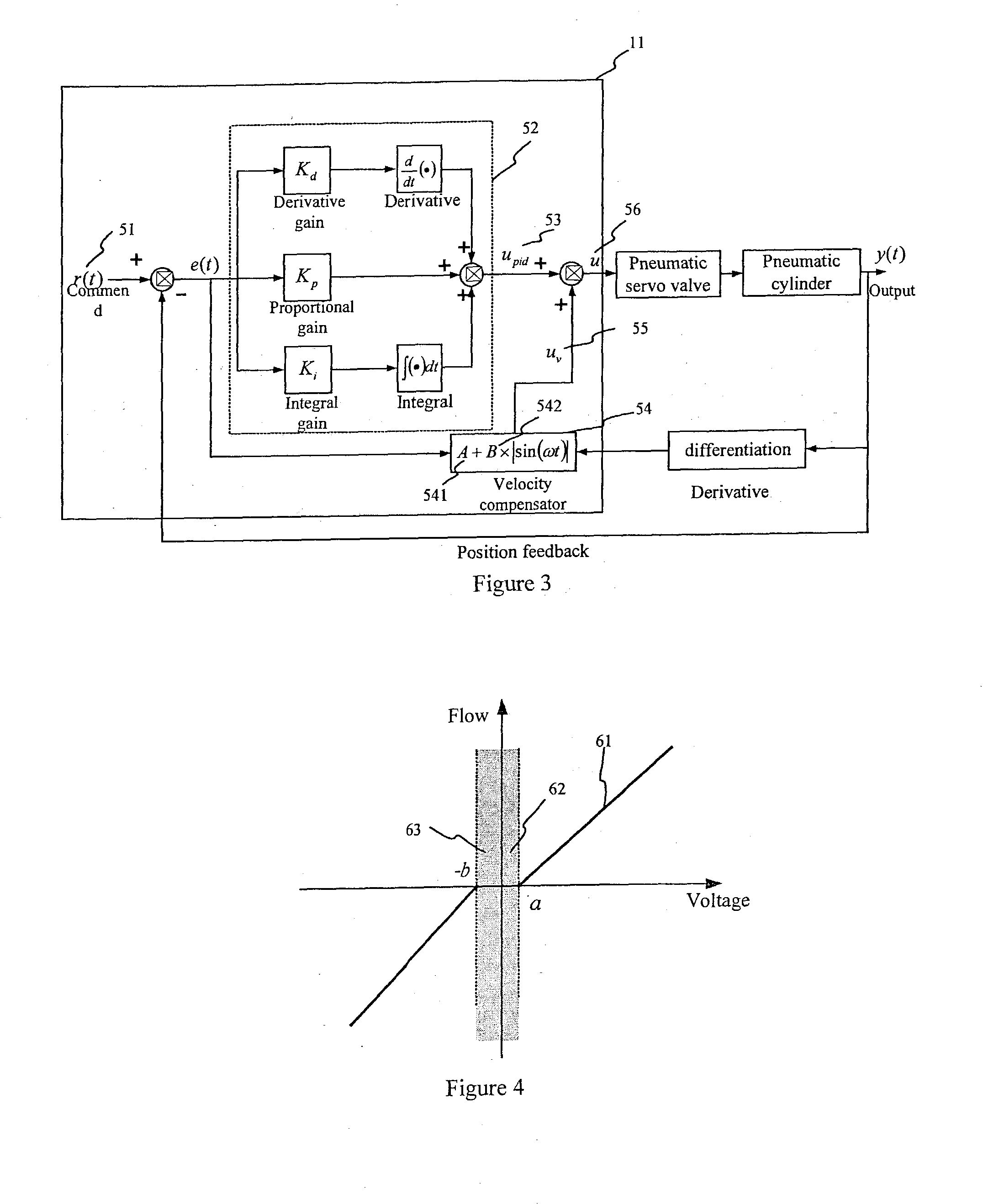

Design and control method of a micro-nanometer precision servo pneumatic X-Y positioning table

InactiveUS20050004689A1Precise positioningComputer controlSimulator controlControl signalFriction force

A micro-nanometer precision servo pneumatic X-Y positioning table comprises by two slide air cylinders and drives the two slide air cylinders by the servo control rule to make the pneumatic table to get the purpose of X-Y two degrees of freedom precision positioning. However, the pneumatic servo system is a high time-variant and nonlinear system and the nonlinear friction force; causes the stick-slip phenomenon of the servo pneumatic system. Therefore the. micro-nanometer precision servo pneumatic X-Y positioning table in accordance with the present invention has a new velocity feedback compensation method to overcome the nonlinear friction force and the stick-slip phenomenon. The new method is to add a velocity compensation signal, which periodic frequency is larger than the system's natural frequency into the control signals. The method is to put the velocity compensation signal directly into the servo valve control signals. By this method; it is able to avoid the complex control rules and the calculation of the feedback compensation and to get higher precision positioning. The positioning precision of the micro-nanometer servo pneumatic X-Y positioning table is about the resolution of the linear scale (ex. in this case 20 nanometer, is the resolution of the used optical linear scale; if the resolution is 10 nanometer the precision can be also 10 nanometer) not only for long stroke but also for micro-step command.

Owner:SHIH MING CHANG +1

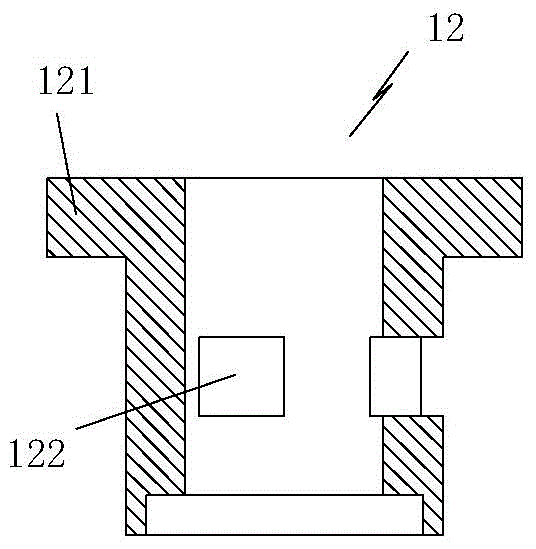

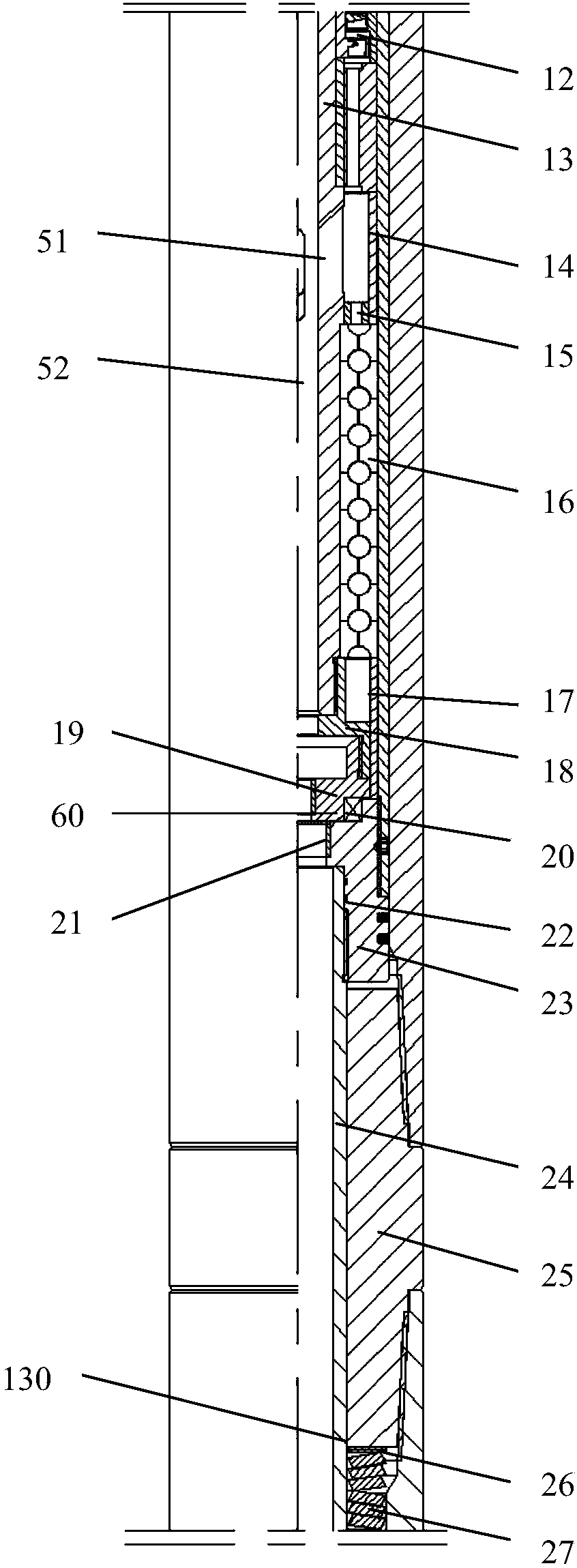

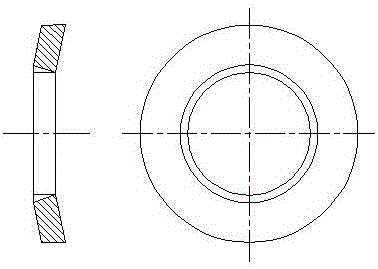

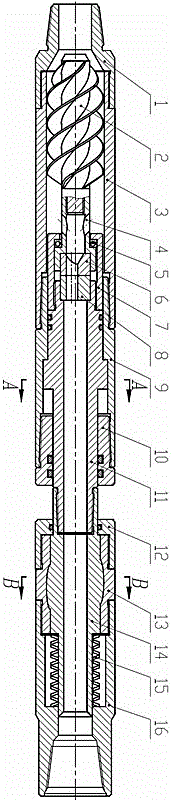

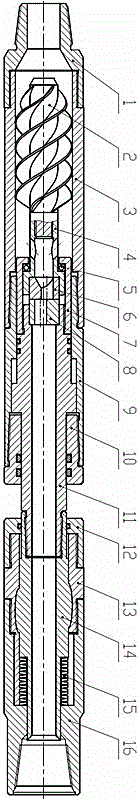

Spiral double-stage compounding impacting device for drilling well speed raising and effect enhancing

InactiveCN105909166AReduce supplyImprove rock breaking efficiencyReciprocating drilling machinesConstructionsUpper jointSpray nozzle

The invention relates to a spiral double-stage compounding impacting device for drilling well speed raising and effect enhancing in the fields of oil drilling, geological drilling and the like. The pressure of slurry can be converted into spiral impact of a center pipe. The spiral double-stage compounding impacting device has the technical scheme that an upper joint, an upper casing, a middle joint, a lower casing and a lower joint are sequentially matched through screw threads; a cavity is formed after the fixation; a valve body, a valve body spring, a driving hammer, a center pipe, a disc spring and an impact spray nozzle are sequentially arranged in the cavity from top to bottom; the driving hammer and an inner tube realize the axial positioning through an inner tube spring; through holes are uniformly formed in the peripheral direction; and a spiral bearing groove is formed in the outer surface of the center pipe. According to the tool, the driving hammer is driven to move in the axial direction through slurry pressure; the center pipe is subjected to axial impact; under the joint effects of the driving hammer, the disc spring and a spiral bearing, the center pipe drives the impact spray nozzle to generate the periodic spiral impact on the lower joint, and the impact acts on a lower part drilling tool; the rock breaking efficiency of a drill bit can be effectively improved; the drilling cost is reduced; and meanwhile, the occurrence of a stick-slip phenomenon is reduced.

Owner:SOUTHWEST PETROLEUM UNIV

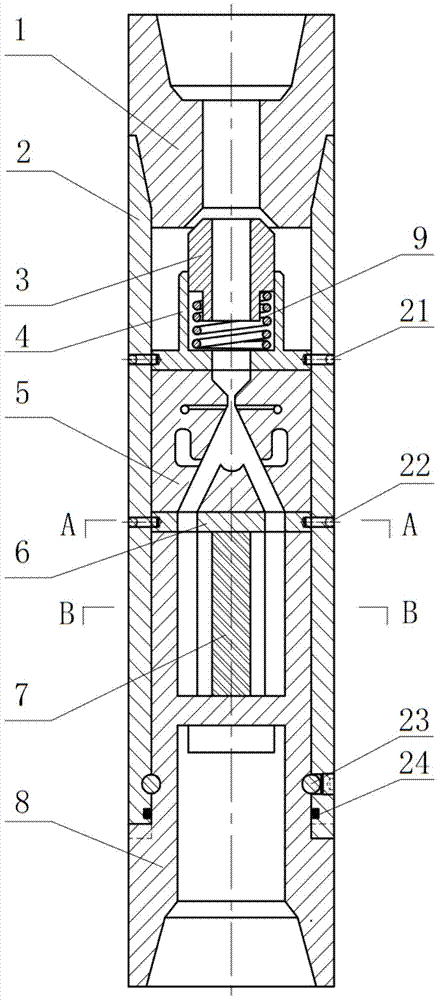

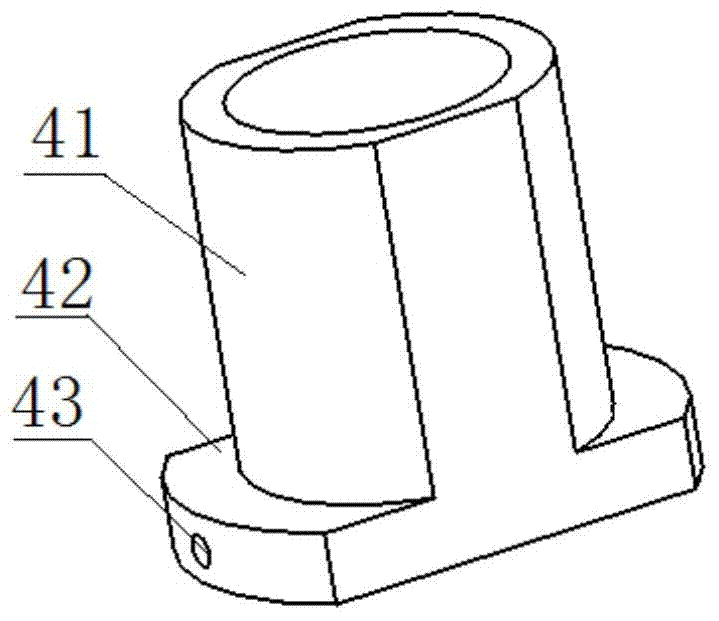

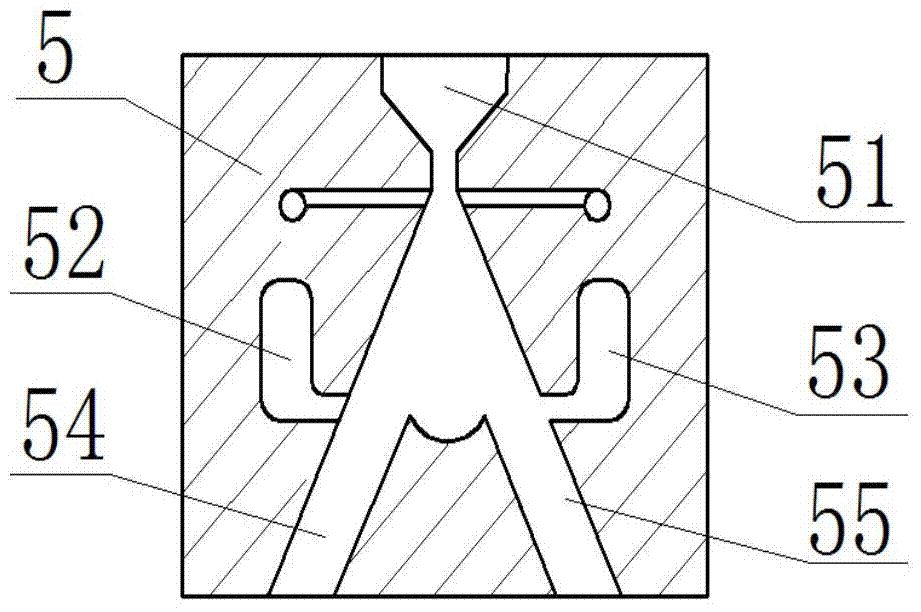

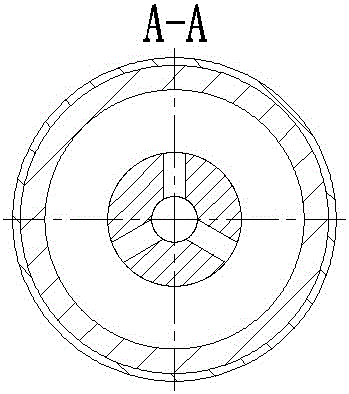

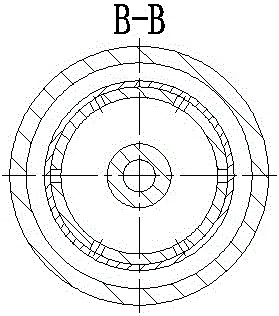

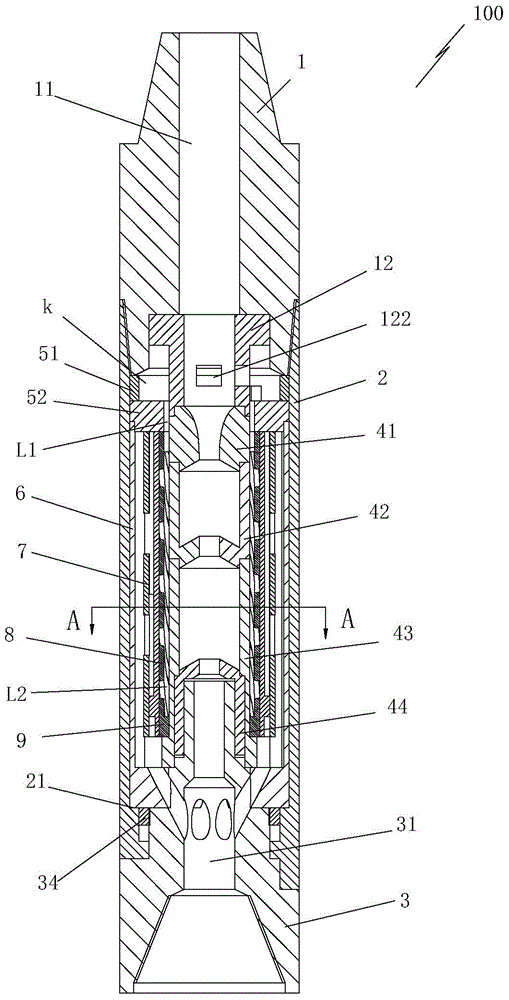

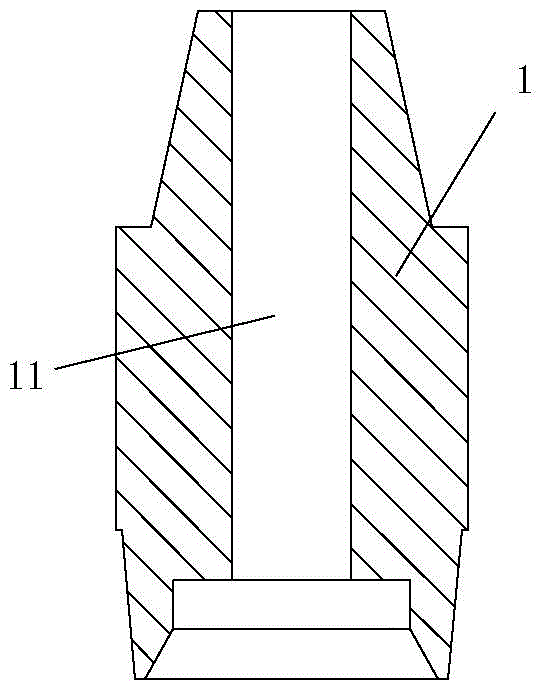

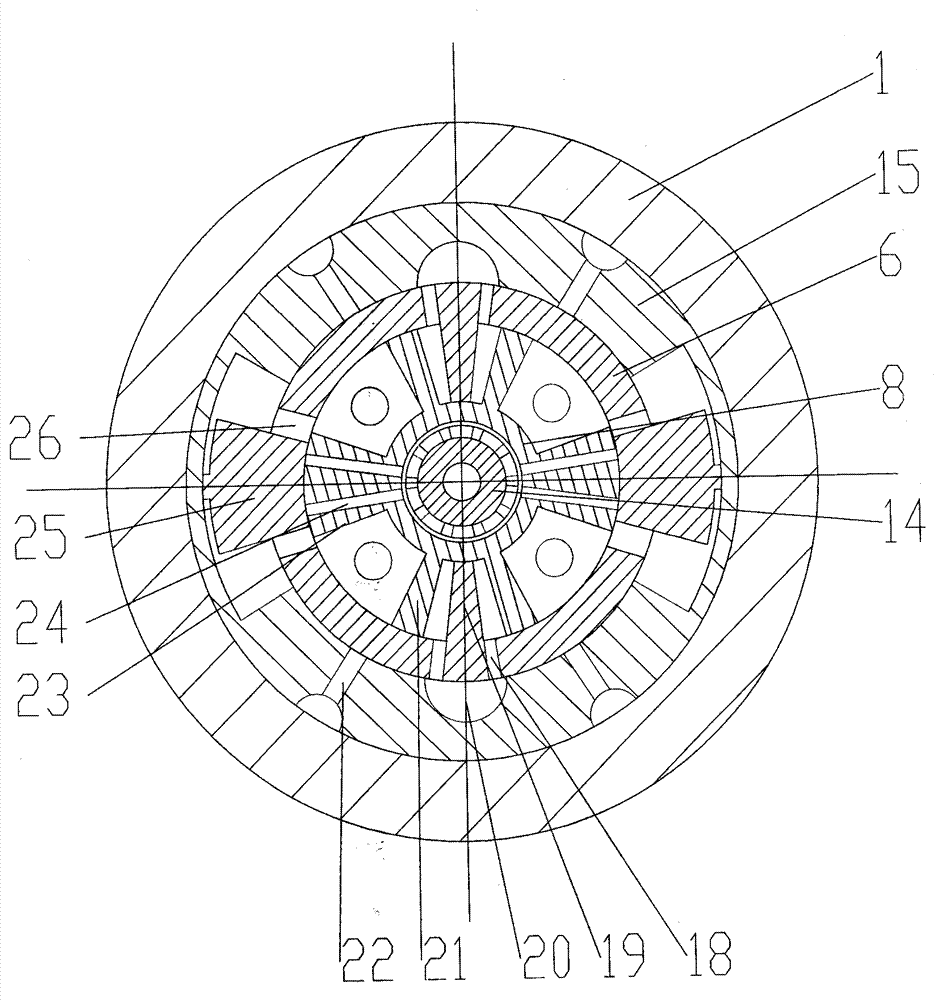

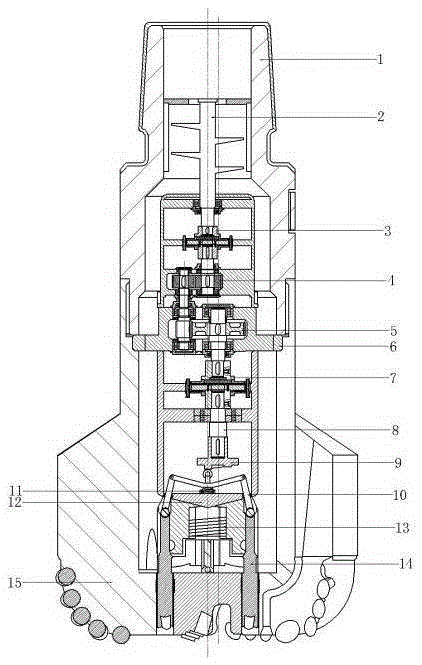

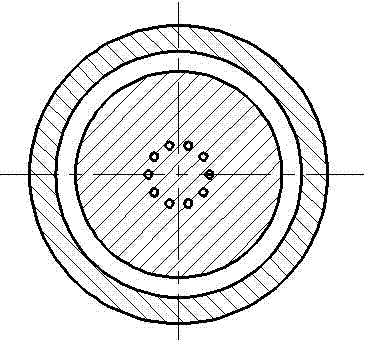

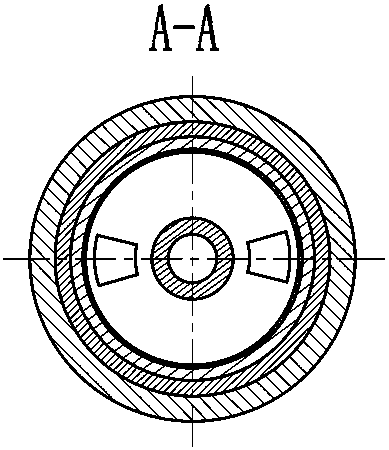

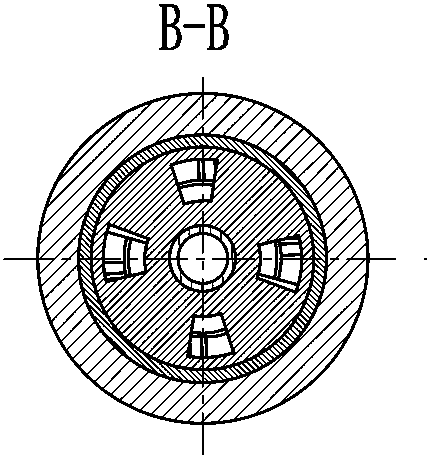

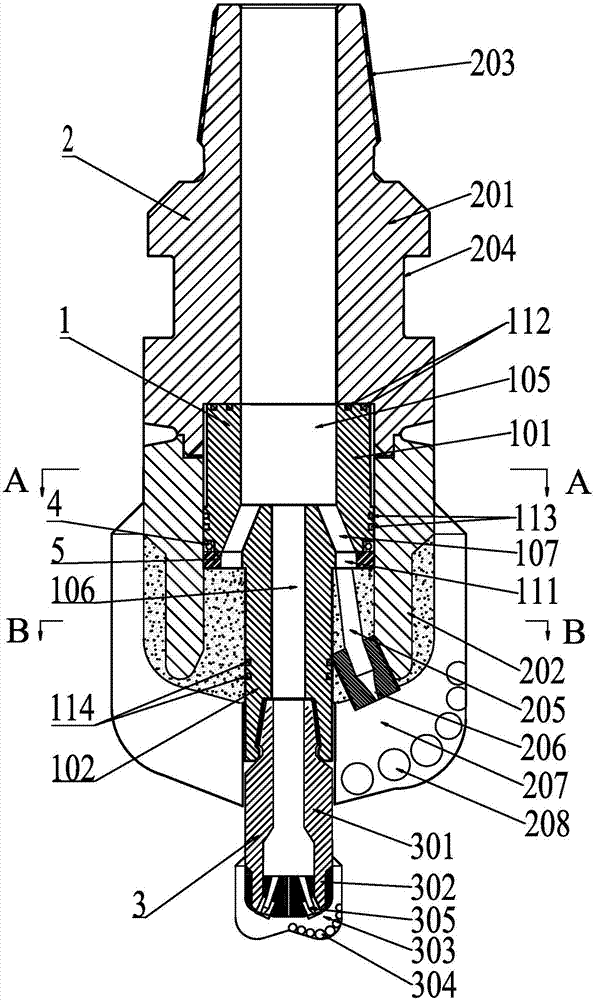

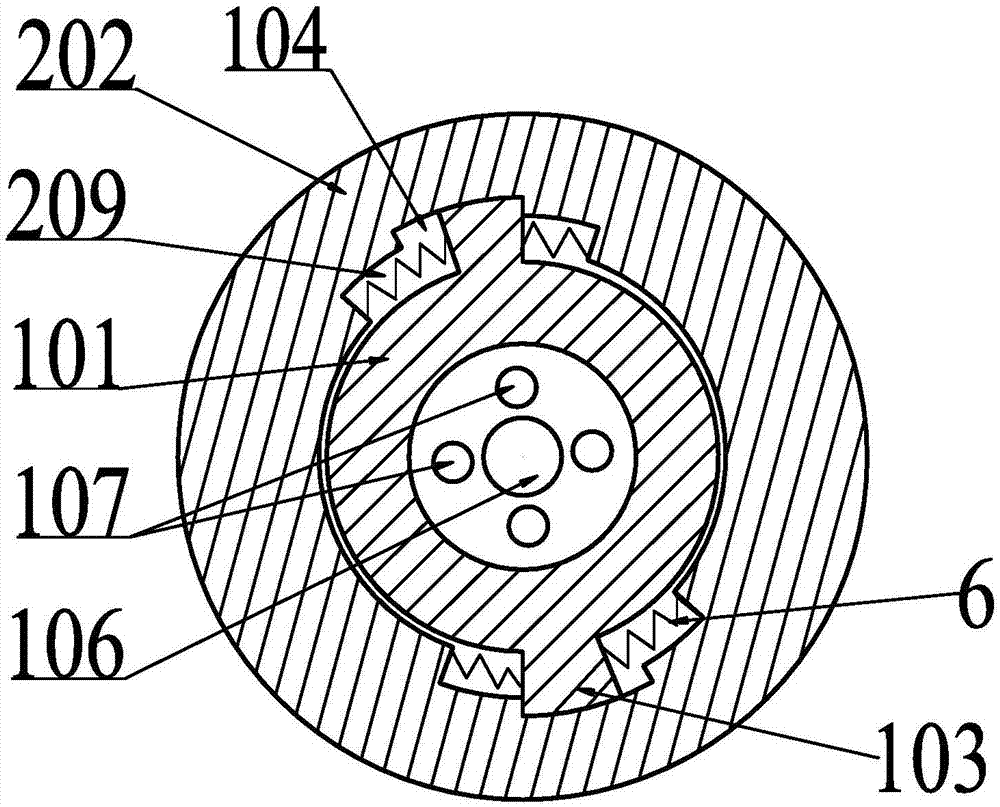

Composite impact well drilling tool

ActiveCN104563862AImprove stabilityExtended service lifeDrilling drivesBorehole drivesWell drillingFlow divider

The invention relates to a composite impact well drilling tool, which comprises an upper pup joint and a middle outer casing in fixed connection, wherein the bottom of the middle outer casing is provided with a drill bit seat in a hanging way, the lower end of the inner side of the upper pup joint is provided with a flow divider, the side wall of the flow divider is provided with a flow dividing passage, the lower end of the flow divider is sequentially and fixedly connected with an upper spray nozzle, an upper cavity and a lower cavity, the upper part of the drill bit seat is provided with a lower spray nozzle in a sleeving way, the lower spray nozzle is glidingly arranged in the lower cavity, a sleeve, an end cover and an impact tube which are fixed in the axial direction and the circumferential direction are sequentially arranged at the inner side of the middle outer casing and are positioned under the upper pup joint from top to bottom, and a pendulum bob and a reversing tube are coaxially arranged inside the impact tube. The well drilling tool has the advantages that high-frequency axial impact loads generated through the upper spray nozzle, the upper cavity, the lower cavity and the lower spray nozzle exert on rock, so that a drill bit can easily cut into the rock, the rock breaking efficiency is improved, meanwhile, the high-frequency circumferential impact loads are generated through continuous reciprocating swinging of the pendulum bob, and the drill bit is prevented from generating a stick slip phenomenon when the cutting-in depth is greater.

Owner:CHINA UNIV OF PETROLEUM (BEIJING) +1

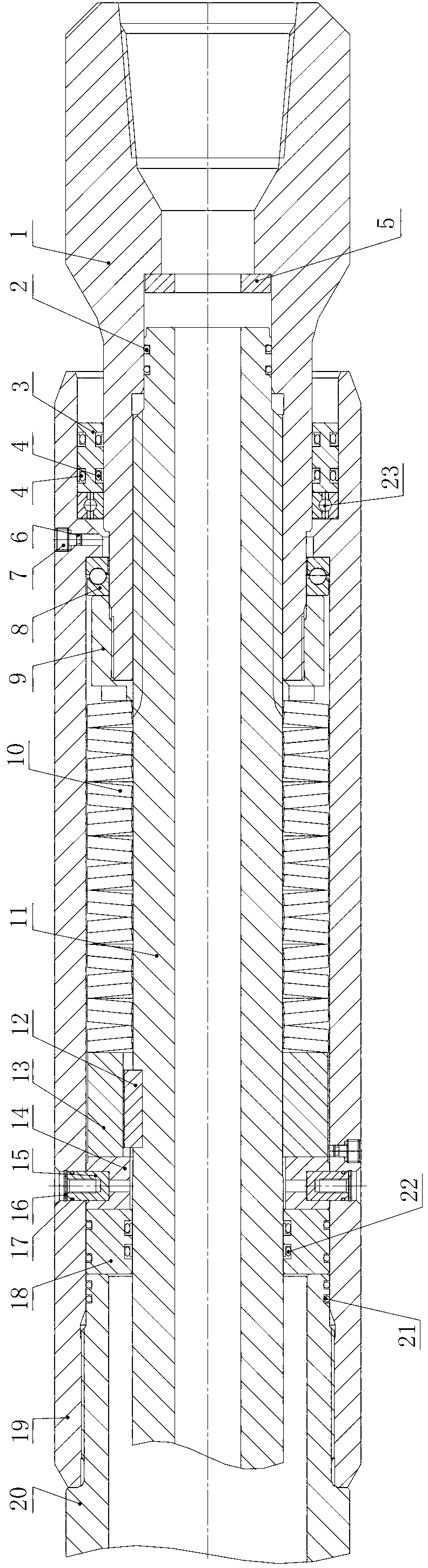

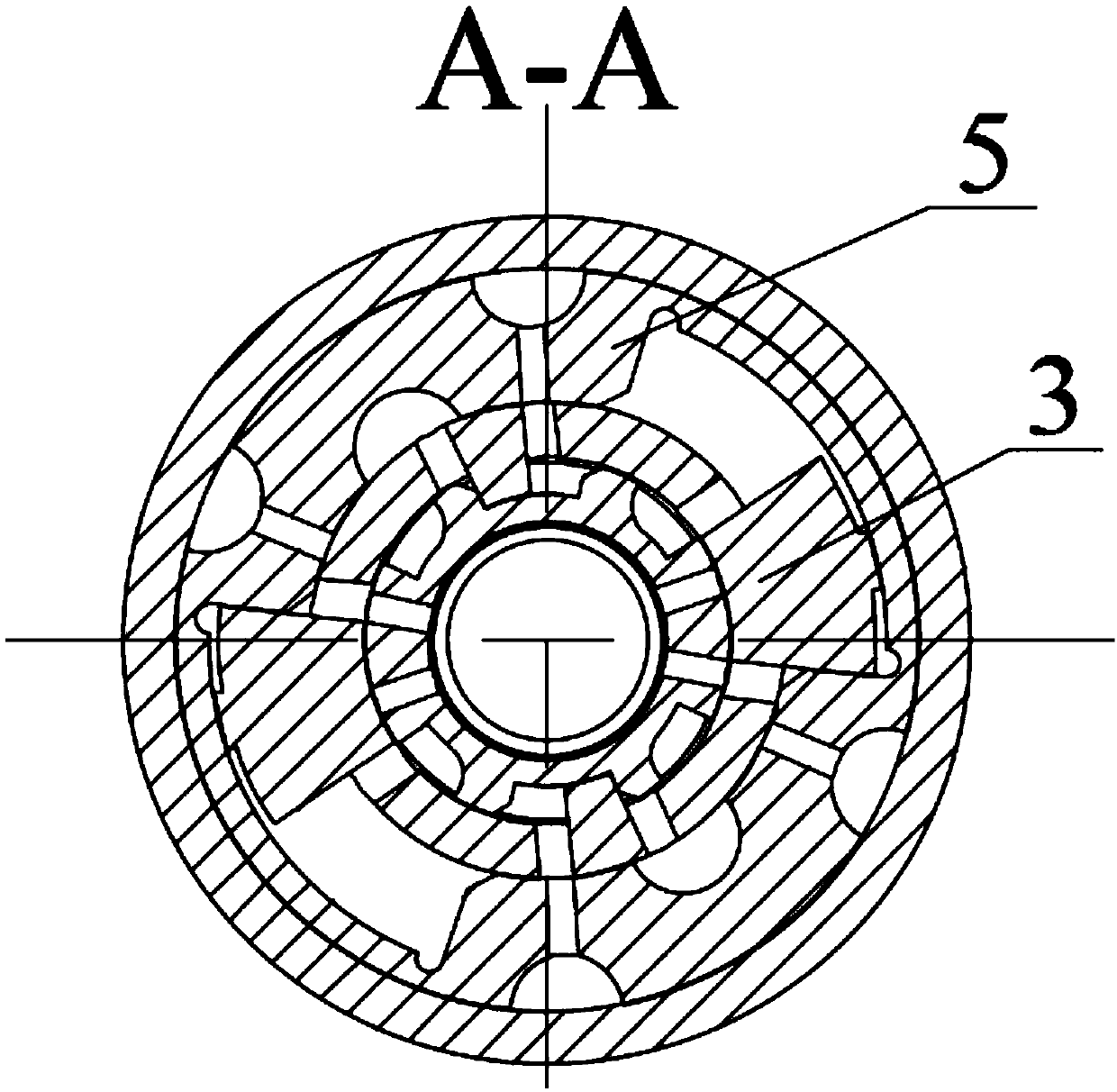

High-frequency torsion impact drilling tool

InactiveCN106089018AImprove rock breaking efficiencyImprove mechanical propertiesReciprocating drilling machinesConstructionsThrust bearingSteel ball

The invention relates to a high-frequency torsion impact drilling tool used for drilling engineering in petroleum and gas industries. The problems that hard formation drilling of a deep well and an extra-deep well is difficult, the drilling speed of machinery is low, and well body quality is poor are solved. According to the technical scheme, the upper end of a cardan shaft and the lower end of a screw rotor are connected in a threaded mode, and the lower end of the cardan shaft and the upper end of a rotary valve element are connected in a threaded mode; a thrust bearing is installed on a protruding step of the upper portion of a valve seat inner cavity, and the outer circle of the lower portion of the rotary valve element are in clearance fit; the upper end of a valve shell and the lower end of a cardan shaft shell are connected in a threaded mode, and the lower end of the valve sheel and the middle of a valve seat are connected in a threaded mode; six steel balls are installed in six semi-spherical grooves in the middle of a transmission shell inner cavity and six spiral grooves of a protruding outer circle of the middle of a spiral shaft correspondingly; and the upper end of a lower shaft body and the lower end of a transmission shell are connected in a threaded mode. The high-frequency torsion impact drilling tool can generate high-frequency axial impact vibration, and improves the rock breaking efficiency and mechanical drilling speed of a drill bit. The lower shaft body generates high-frequency micro-amplitude circumferential reciprocating swinging, and can effectively prevent a stick-slip phenomenon.

Owner:SOUTHWEST PETROLEUM UNIV

Near-bit circumferential resonance impacter

The invention relates to a near-bit circumferential resonance impacter. The near-bit circumferential resonance impacter comprises a housing pup joint, a guide part, the resonance impacter and a transmission pup joint, wherein the lower part of the housing pup joint is connected with the transmission pup joint; the guide part and the resonance impacter are mounted between the housing pup joint and the transmission pup joint; the guide part comprises a T-shaped inner lining pipe and a V-shaped outer sleeve pipe; the T-shaped inner lining pipe is arranged on the V-shaped outer sleeve pipe; a distribution hole is formed in the upper end of the V-shaped outer sleeve pipe; the lower end port of the V-shaped outer sleeve pipe is communicated with an inlet of the resonance impacter; an outlet of the resonance impacter is communicated with the transmission pup joint; the resonance impacter is provided with a hydraulic hammer; a hammer anvil on the outer surface of the hydraulic hammer is positioned in an impacting groove of a hammer housing; an impacting flow channel comprises the impacting groove; a positioning key on the inner surface of the hydraulic hammer extends into a positioning groove of a starter; and a pressure relief flow channel comprises the positioning groove. According to the near-bit circumferential resonance impacter, the stick slip phenomenon and the intermittent tool jamming phenomenon of a drill bit can be eliminated, the drill bit is guaranteed to stably break a rock, and the mechanical drilling speed is increased.

Owner:大庆东油普润石油科技有限公司

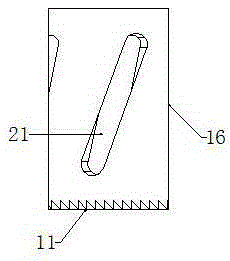

Guide boot

InactiveCN1660687AImprove development efficiencyIncrease productivityElevatorsGlass fiberEngineering

The guide shoe comprises a guide shoe assembly having a shoe assembly with a shoe to be slid along the guide rail comprising a compound of ultrahigh molecular weight polyethylene and glass fiber reinforced nylon and a housing for holding the shoe assembly to be fixed to a mobile body, and a connection guide shoe assembly having a connection shoe assembly to be slid along the guide rail and a connection housing holding the connection shoe assembly. The connection guide shoe assembly can be connected to the guide shoe assembly, and the length in sliding directions of the shoes is adjustable. To provide a guide shoe capable of improving development / production efficiency and consequently reducing development / production costs, wherein a problem of a stick slip phenomenon is solved.

Owner:HITACHI LTD +1

Novel PDC drill bit for improving rock-breaking efficiency based on impact effect

ActiveCN105275405AChange the depth of cutConvenient power sourceEarth drilling toolsDrill bitsReduction driveCam

The invention relates to a novel PDC drill bit for improving the rock-breaking efficiency based on the impact effect and belongs to the fields of oil and gas drilling engineering, mine exploiting, geological drilling, tunnel engineering, tunnel engineering, tunnel shield, non-excavation and the like. According to the invention, the balling-up phenomenon or the stick-slip phenomenon generated during the drilling process of the hard and soft staggered formations in the prior art can be avoided, and the defects of low breaking rate, short service life and the like are overcome. According to the technical scheme of the invention, a blade shaft is arranged at the end port of a drill bit, and the lower end of the blade shaft enters a shell to be connected with a driver of the same transmission ratio via a shaft coupling. The driver of the same transmission ratio is then connected with a speed reducer. The output end of the driver is connected with a drive shaft via a magnetic coupler. The drive shaft is connected with a cam disk by a flat key. A connecting rod mechanism is connected with the cam disk and the lower end thereof is connected with a centre pinion via a spherical hinge. According to the invention, the longitudinal displacement of the centre pinion is realized, so that the intake amount of a core part is changed. Meanwhile, the breaking rate of the drill bit in soft and hard formations is increased, and the phenomena of balling-up, stick-slip and the like are reduced. Therefore, the well drilling cost is lowered.

Owner:四川川石金刚石钻头有限公司

Torsion generator for providing one-way impact

InactiveCN104120971AImprove rock breaking efficiencyPrevent stick-slipBorehole drivesDrive shaftWell drilling

The invention discloses a torsion generator for providing one-way impact, wherein the torsion generator is used for petroleum and gas well drilling and can convert pressure of mud into circumferential one-way impact of a driving shaft. According to the technical scheme, the torsion generator is mainly composed of an upper connector, an outer cylinder, a central shaft, a lower connector, a drill bit connector and the like; the upper connector, the outer cylinder, the lower connector and the drill bit connector are matched through threads and form a cavity inside after being fixed, and the cavity is sequentially provided with an anti-disengaging assembly, an inner cylinder, the central shaft, the driving shaft, a mass block, a universal shaft upper connector, a locking check ring, a universal shaft and a universal shaft lower connector from top to bottom; blades are arranged on the outer wall of the inner cylinder, and a screw stator is arranged on the inner wall of the inner cylinder; a screw rotor is arranged on the outer wall of the upper end of the central shaft, and an inner spline is arranged at the lower end of the central shaft; an outer spline is arranged at the upper end of the driving shaft, and the universal shaft upper connector is arranged at the lower end of the driving shaft. According to the torsion generator, the driving shaft is driven through drilling fluid to rotate so as to generate periodic circumferential one-way impact, and rock breaking efficiency of a drill bit is improved; stable circumferential vibration is generated, and the phenomenon that the drill bit is stuck and the stick slip phenomenon are effectively avoided.

Owner:SOUTHWEST PETROLEUM UNIV

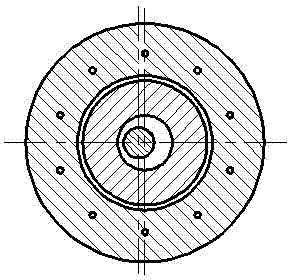

Downhole auxiliary hole drilling tool

ActiveCN110410000AGood stable torque functionSolve the problem of holding back and jumpingDrilling rodsBorehole drivesWell drillingAxial vibration

The invention discloses a downhole auxiliary hole drilling tool. An impacting energy generator is included, and can be used for converting energy of well drilling liquid so that axial impacting energycan be generated. An impacting energy allocator is included, and can be used for allocating the axial impacting energy generated by the impacting energy generator again, an axial impacting force is converted into a composite impacting force, and therefore the impacting force changing at a high frequency in the composite direction is provided for a drill bit, and the rock breaking efficiency of the drilling tool is greatly improved and the mechanical drilling speed of the drilling tool is greatly increased. The downhole auxiliary hole drilling tool further comprises a shock absorbing twistingstabilizing device arranged between the impacting energy generator and the impacting energy allocator, the shock absorbing twisting stabilizing device can be used for lowering the axial vibration of the well drilling tool, the stick-slip phenomenon is reduced, impacting on the drill bit is reduced, and the service life of the drill bit is effectively prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

Cam type high-frequency percussion well drilling tool

InactiveCN103321569AExtended service lifeEliminate axial runoutBorehole drivesThrust bearingEngineering

The invention relates to a cam type high-frequency percussion well drilling tool which is characterized by comprising a screw assembly and an axial vibration assembly. The screw assembly comprises a sealed chamber, a mandrel and a lower connector, the axial vibration assembly comprises an upper cam, a lower cam, a disc spring, a suspension nut and a thrust bearing, the disc spring, the suspension nut and the thrust bearing are sleeved on the outside of the mandrel, the suspension nut is connected with the lower connector in a threaded manner, and an upper sealing sleeve is arranged between the sealed chamber and the mandrel; a floating piston is sleeved between the sealed chamber and the lower connector, the floating piston, the upper sealing sleeve, the mandrel, a first sealing sleeve and the sealed chamber form a closed cavity, and hydraulic oil can be filled in the closed cavity. The cam type high-frequency percussion well drilling tool has the advantages that high-frequency, uniform and stable mechanical percussion energy can be generated by the tool in a well drilling procedure, so that a drill bit can constantly keep continuously cutting a well bottom at a high frequency, the shearing efficiency is improved, and one or a plurality of types of possible harmful vibration and a possible stick-slip phenomenon are prevented when the drill bit moves; axial runout, transverse vertex motion and the stick-slip phenomenon in the well drilling procedure can be prevented, the well drilling mechanical rotation speed further can be increased, and the service life of the well drilling tool is prolonged.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Mixed type downhole drilling bit

InactiveCN106194033AImprove cutting efficiencyImprove mechanical propertiesDrill bitsWell drillingStick-slip phenomenon

The invention discloses a mixed type downhole drilling bit. The mixed type downhole drilling bit comprises a drilling bit body, blades, heads and cones, wherein the blades and the heads are fixedly connected with the upper end of the drilling bit body; the lower ends of the heads are fixedly connected with the side wall of the drilling bit body; the cones are rotationally connected with the upper ends of the heads through shaft journals; an included angle is formed between a central axis of each cone and a central axis of the drilling bit body; multiple conical teeth or / and wafer cutting teeth are arranged on the blades; multiple chisel-point teeth and flat teeth are arranged on the cones. By the combination of impact crushing of a cone drilling bit and ploughing motion and shearing motion of a blade structure drilling bit capable of realizing mixed tooth distribution, downhole primary crushing is realized, fixed cutting teeth are effectively drilled into rock, the stick-slip phenomenon of the drilling bit in some specific strata is eliminated, impact load of the fixed cutting teeth is reduced, the probability of impact damage of the fixed cutting teeth is reduced, and the cutting efficiency and the mechanical drilling rate are increased.

Owner:CHENGDU BEST DIAMOND BIT

Threaded rod type double-acting acceleration tool

The invention provides a threaded rod type double-acting acceleration tool. The threaded rod type double-acting acceleration tool comprises a power assembly, a universal shaft assembly, a transmissionassembly and an impact assembly, wherein the power assembly converts liquid energy into rotary mechanical energy through a screw rod; so that a rotating valve of the impact assembly is driven by theuniversal shaft assembly and the transmission assembly to rotate; because holes are formed in the rotating valve and a valve cover, drilling fluid periodically enters into a hammer head and a cylindercavity of a hammer body, and the hammer head periodically impacts the hammer body cylinder under the pushing of liquid so as to generate circumferential shocking; meanwhile, axial holes of the rotating valve and the valve cover are periodically staggered to ensure that liquid pressure is changed, and high-frequency axial shocking is produced; axial and circumferential impact force is transmittedto a drilling head through a lower joint, so that the stick-slip phenomenon is eliminated and a drilling bit is protected, thereby improving the rock breaking efficiency of the drilling bit. Accordingto the threaded rod type double-acting acceleration tool disclosed by the invention, axial impact and circumferential impact are produced under the driving of the drilling fluid, so that the well drilling efficiency can be effectively improved.

Owner:SOUTHWEST PETROLEUM UNIV +2

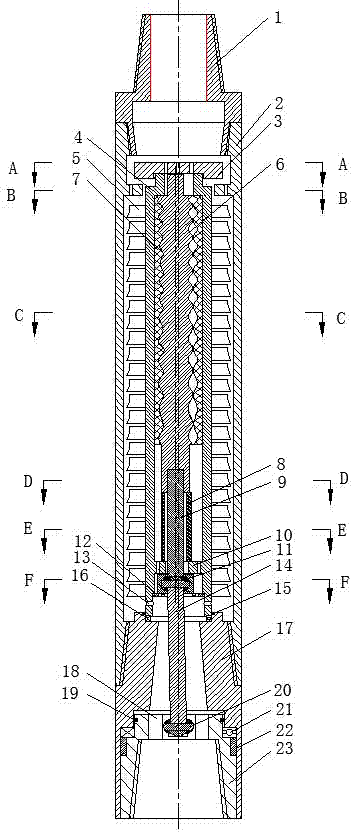

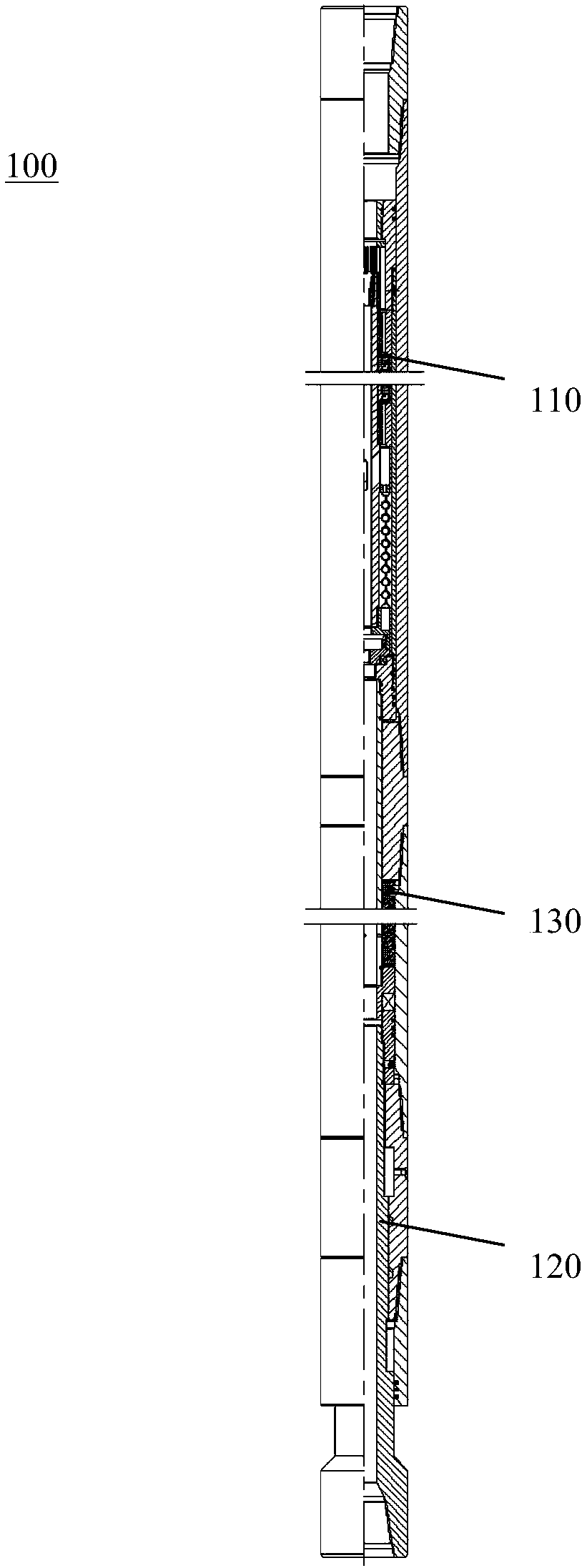

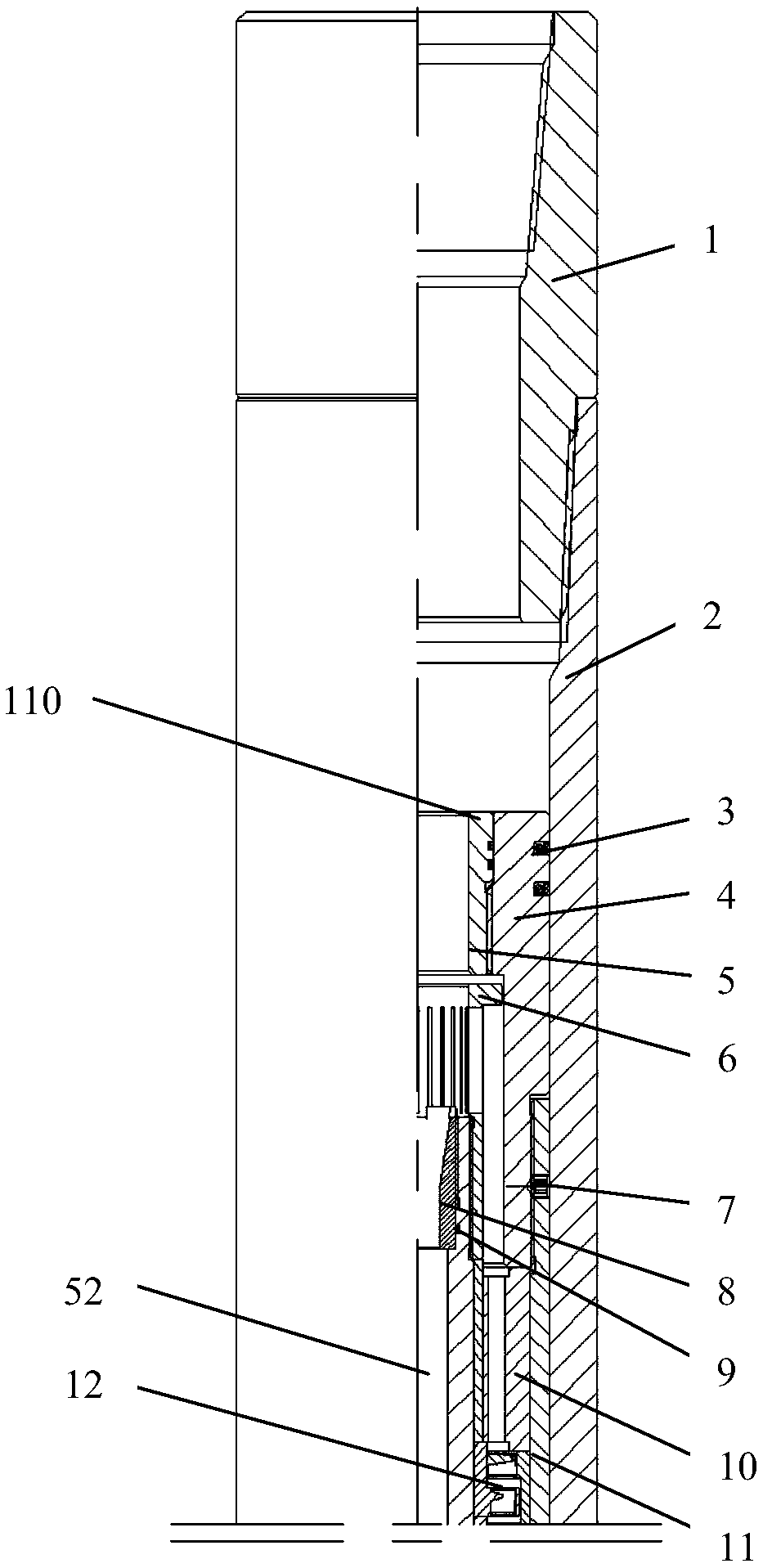

Stagnation-prevention drilling tool capable of reducing stick slip phenomenon through multi-head helical pair

ActiveCN106050160AIncreased versatilityRealize reciprocating motionDrilling rodsDrilling casingsSmall amplitudeDrive shaft

The invention relates to a stagnation-prevention drilling tool capable of reducing a stick slip phenomenon through a multi-head helical pair. The stagnation-prevention drilling tool is installed on the upper portion of a drill bit in a thread connection mode and comprises an upper assembly, a vibration absorption assembly and a lower assembly. The rear end of the vibration absorption assembly is provided with an upper connector assembly, and the front end of the vibration absorption assembly is provided with the lower assembly. Vibration generated in the work process of the tool is absorbed through disc springs connected in series, a pressure cavity and a rubber spring. Through matching of a spiral outer shell and a spiral transmission shaft, the multi-head helical pair is formed. When the reaction torque acting on the drill bit is increased and a stick slip or clamping phenomenon occurs, the spiral transmission shaft rotates backwards relative to the spiral outer shell, and therefore small-amplitude reverse rotation is applied to the drill bit. The reaction force of the ground to the drill bit is lowered, stress of the drill bit reaches balance again, and therefore efficient rock breaking with the drill bit is realized. According to the stagnation-prevention drilling tool capable of reducing the stick slip phenomenon through the multi-head helical pair, the vibration generated during rock breaking with the drill bit can be absorbed, the stick slip phenomenon is reduced, and continuous drilling of the drill bit is guaranteed.

Owner:沛县东宝机电设备有限公司

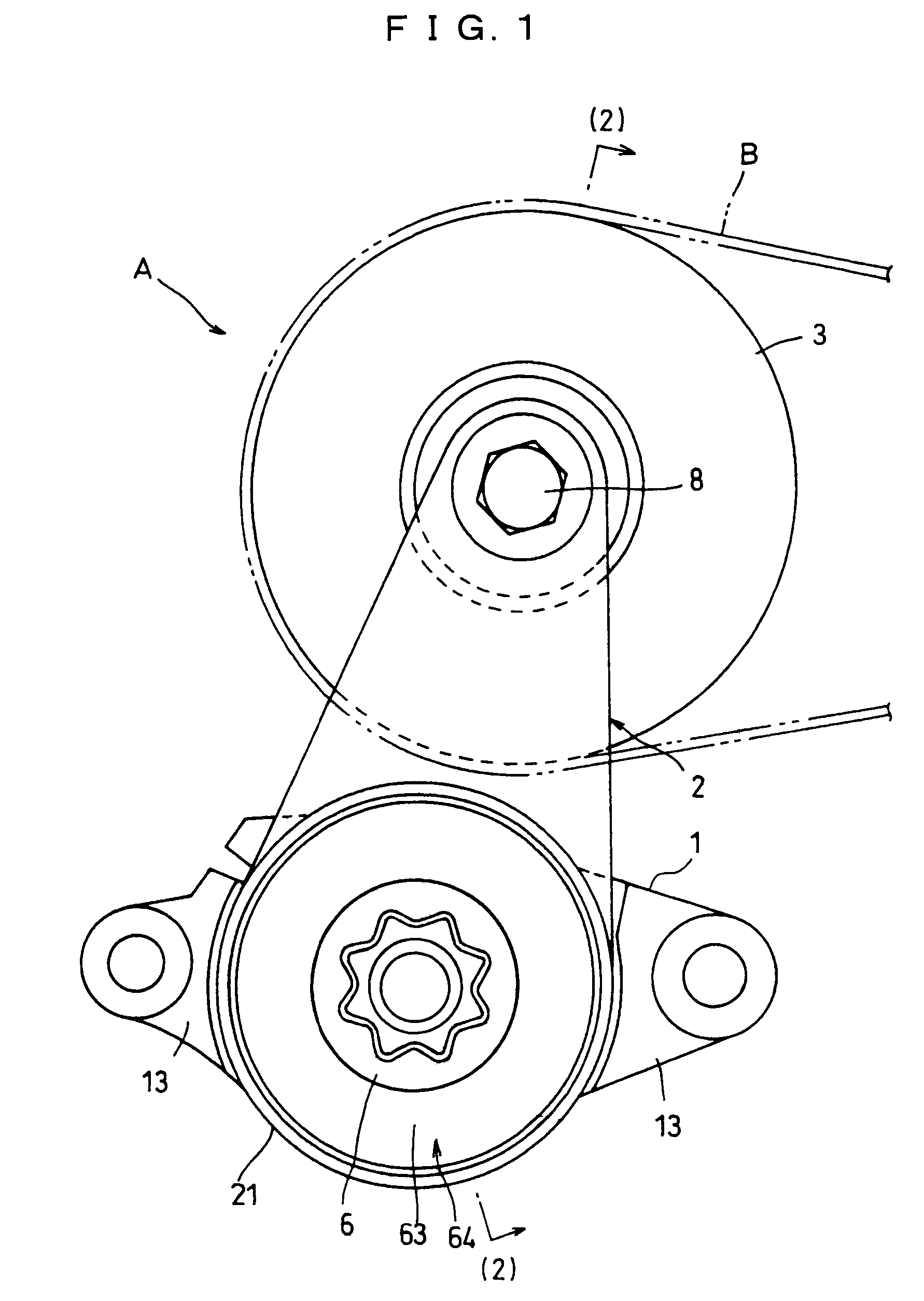

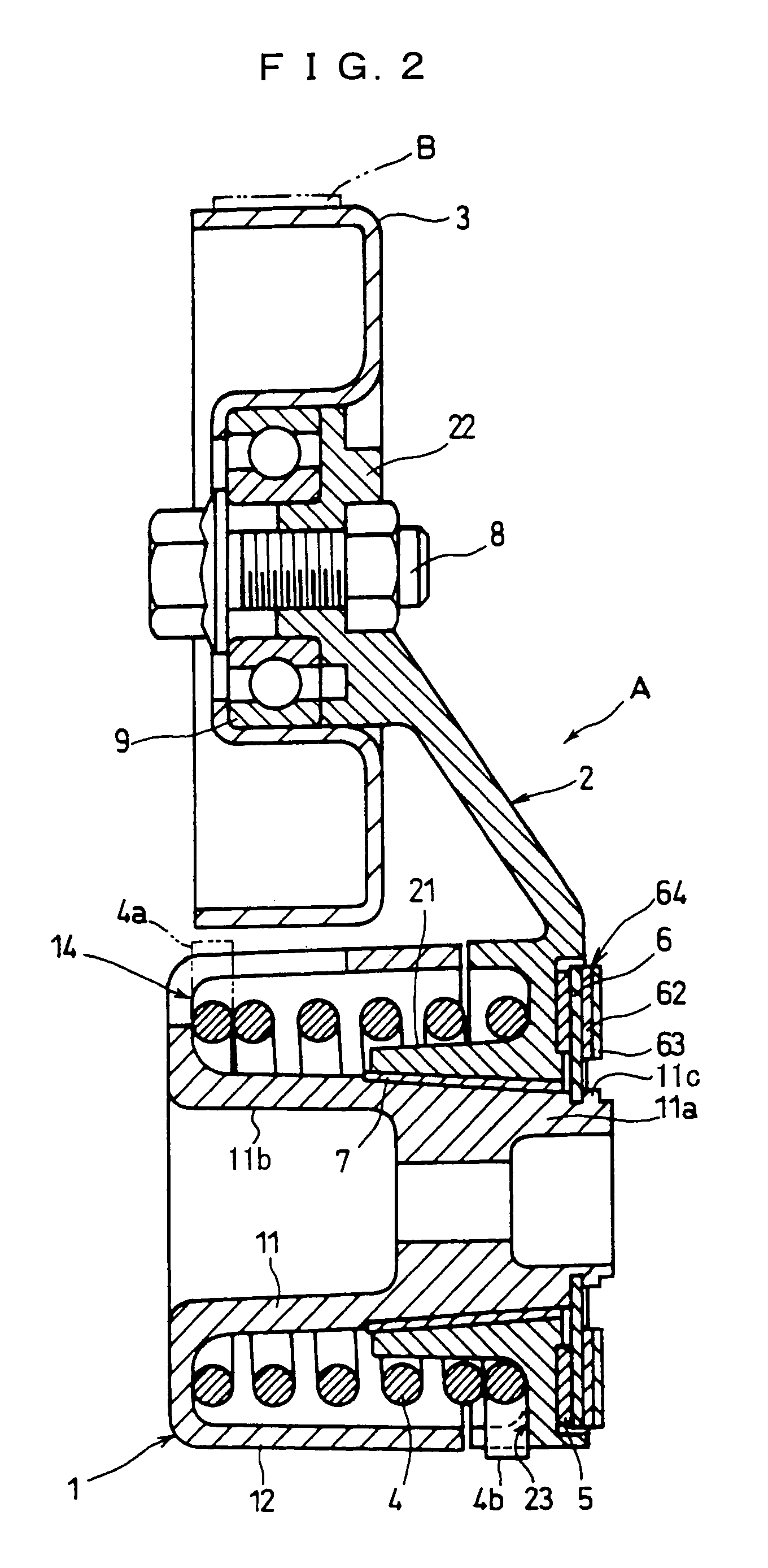

Auto tensioner

Owner:JTEKT CORP

Grease composition

InactiveUS20150024980A1Reduce coefficient of frictionFully dispersedOrganic chemistryBase-materialsBase oilLubricant

Provided is a grease composition that improves the dispersibility of a solid lubricant, that provides a sufficiently low friction coefficient in steel-resin sliding parts, and that prevents a stick-slip phenomenon.The grease composition comprising a lubricant base oil having a density of 0.75 to 0.95 g / cm3 at 15° C., an amide compound, a solid lubricant, and a metal soap-based thickener, wherein the solid lubricant is preferably a layered compound or a fluororesin, and wherein the amide compound is preferably a monoamide or a bisamide.

Owner:JX NIPPON OIL & ENERGY CORP

Drilling tool with spinning coupling function and operating method of drilling tool

InactiveCN105257212ASimple structureShorten the lengthDrilling drivesDrilling machines and methodsCouplingWell drilling

The invention relates to a drilling tool with a spinning coupling function in the drilling process and an operating method of the drilling tool, and aims to improve the drilling efficiency and the penetration rate and reduce the drilling cost. The technical scheme is that an overflow valve is mounted in an upper connector; a control valve at the lower part of the upper connector is in threaded connection with an inner hole of the upper connector; the control valve, a casing and the upper end surface of a core shaft form a volume variable cavity; a fluid passage is formed in the middle of the core shaft; a sealing part is arranged between the outer wall of the upper end of the core shaft and the inner wall of the casing; a thread in the lower part of the core shaft is used for being connected with a drilling bit; a spiral hole is formed in a spinning sleeve; followers of the spinning sleeve are mounted on the core shaft; one-way lower ratchets are arranged at the bottom of the spinning sleeve, and are matched with upper ratchets at the upper part of a lower connector. The drilling tool is simple in structure, is suitable for the well repairing and drilling operations, and can provide torque and impact power at the same time, weaken the stick-slip phenomenon of the drilling bit, increase the penetration rate, improve the drilling efficiency and reduce the drilling cost.

Owner:SOUTHWEST PETROLEUM UNIV

Split type drill bit with torsion impact function

Owner:SOUTHWEST PETROLEUM UNIV +2

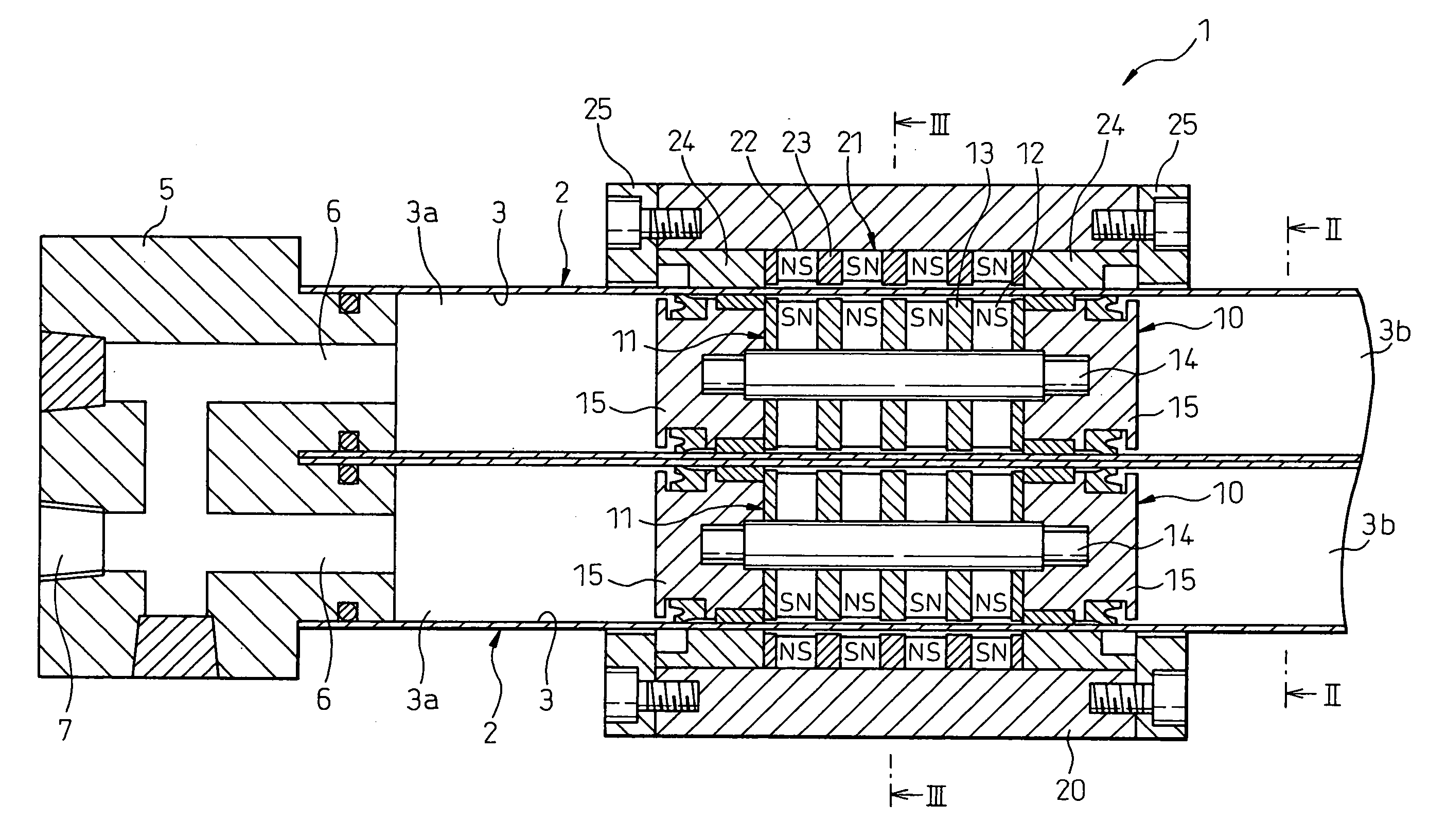

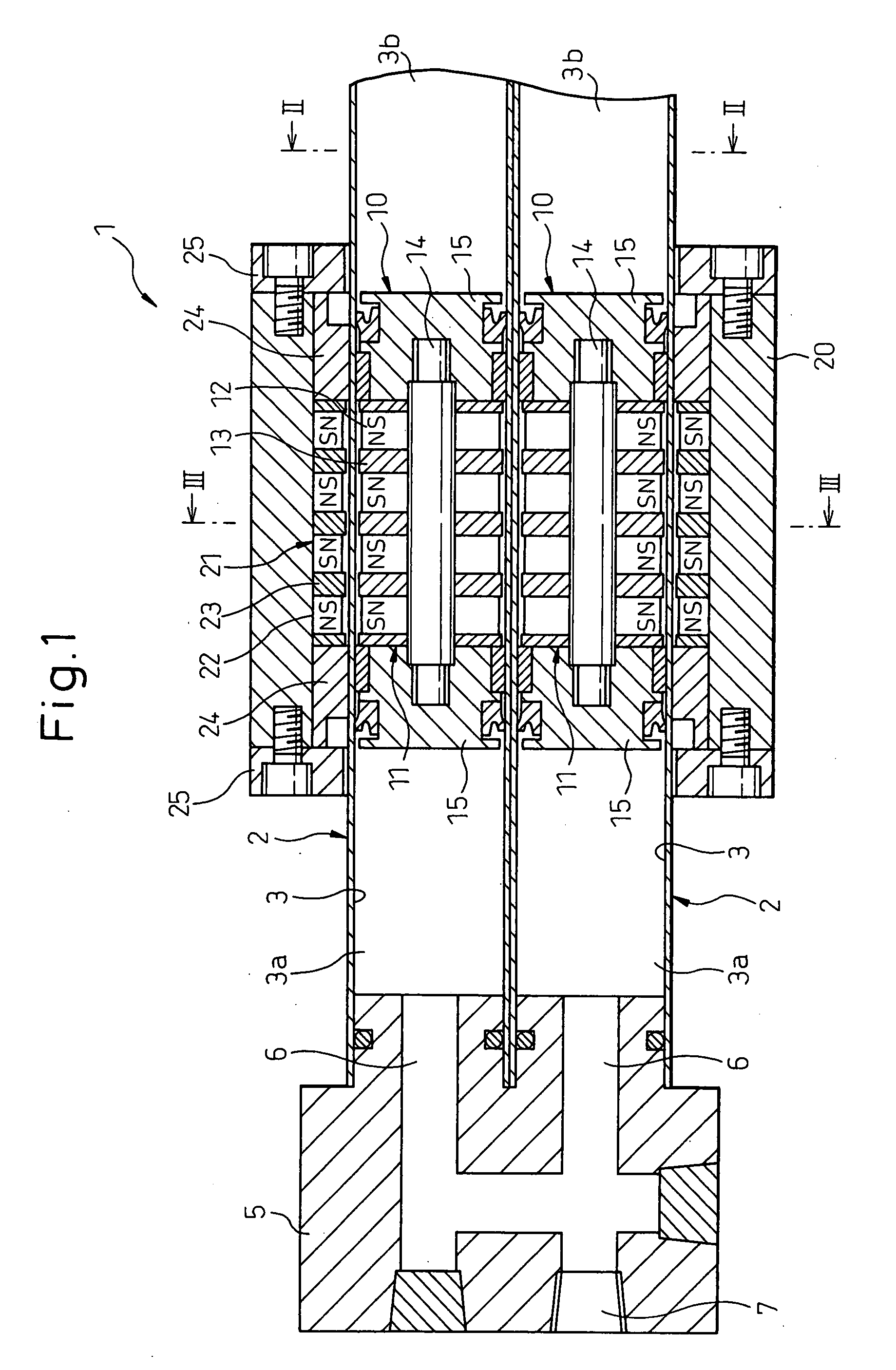

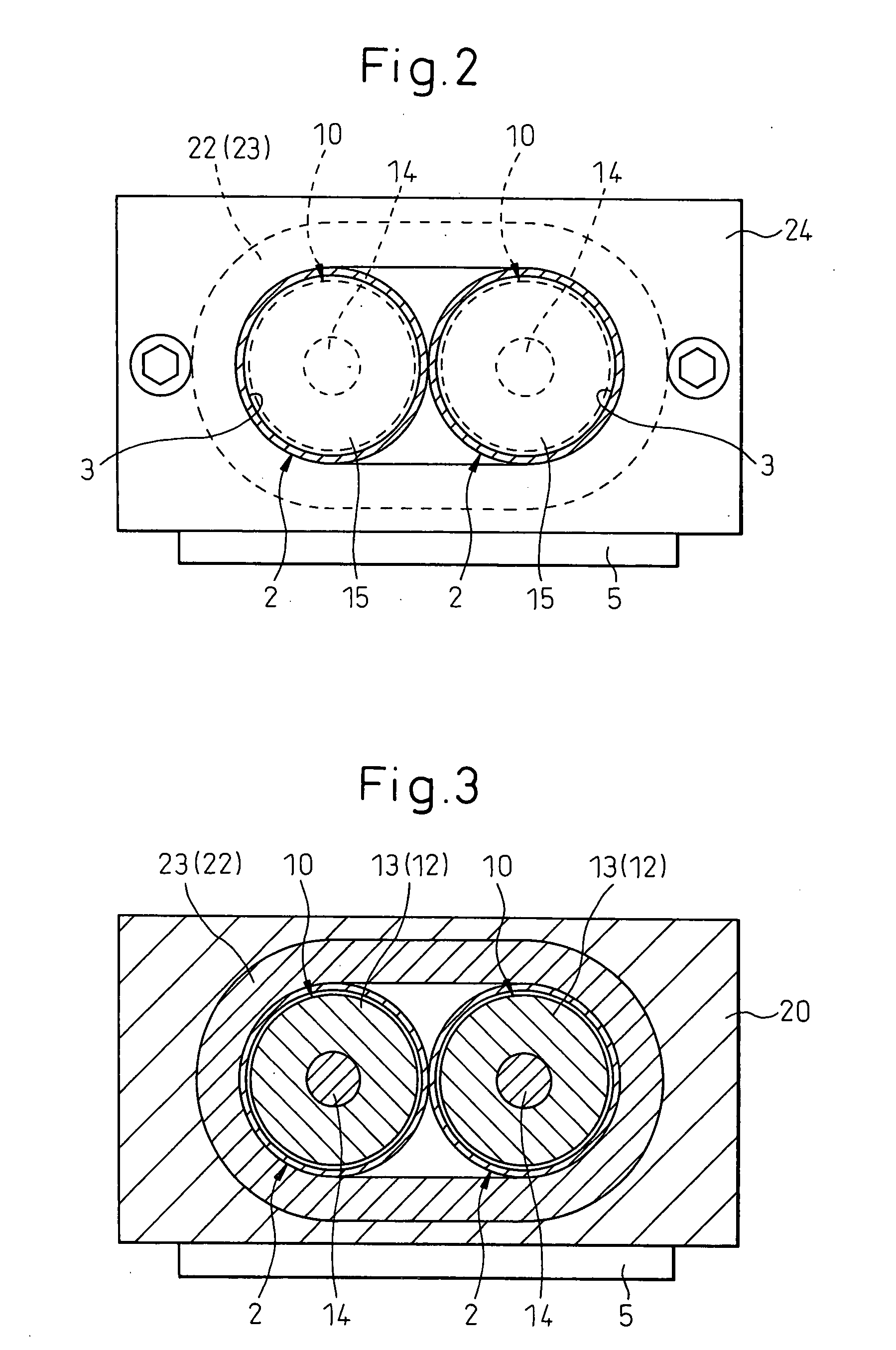

Magnet Type Rodless Cylinder

ActiveUS20080115664A1Smooth movementReduce the overall heightCylindersFluid-pressure actuatorsMagnetic tension forceState of art

Repulsive magnetic forces in the axial direction of cylinder tubes act between the rows 11 of inner magnets of pistons 10, 10 accommodated in two cylinder tubes 2, 2, and the inner magnets 12 of the pistons 10 come to a halt being slightly deviated relative to the outer magnets 22 in the axial direction of the tube. Due to this deviation, a magnetic holding force Fc is produced between the inner and outer magnets 12, 22. Since the magnetic holding force Fc is produced in a static state, a smooth movement can be attained from a static state suppressing the occurrence of a stick slip phenomenon at the start of movement as compared to the prior art, which does not produce the magnetic holding force in a static state.

Owner:HOWA MASCH LTD +1

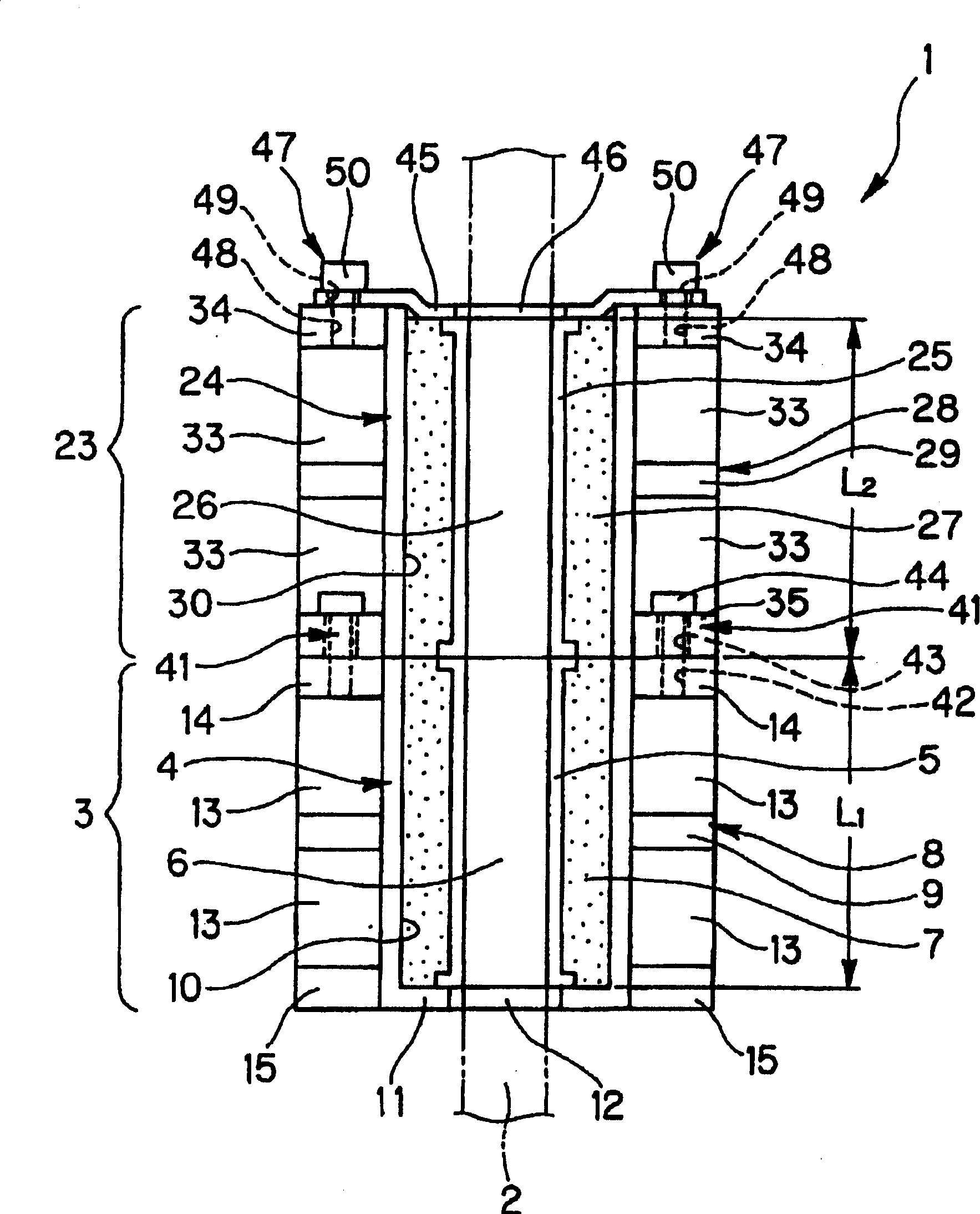

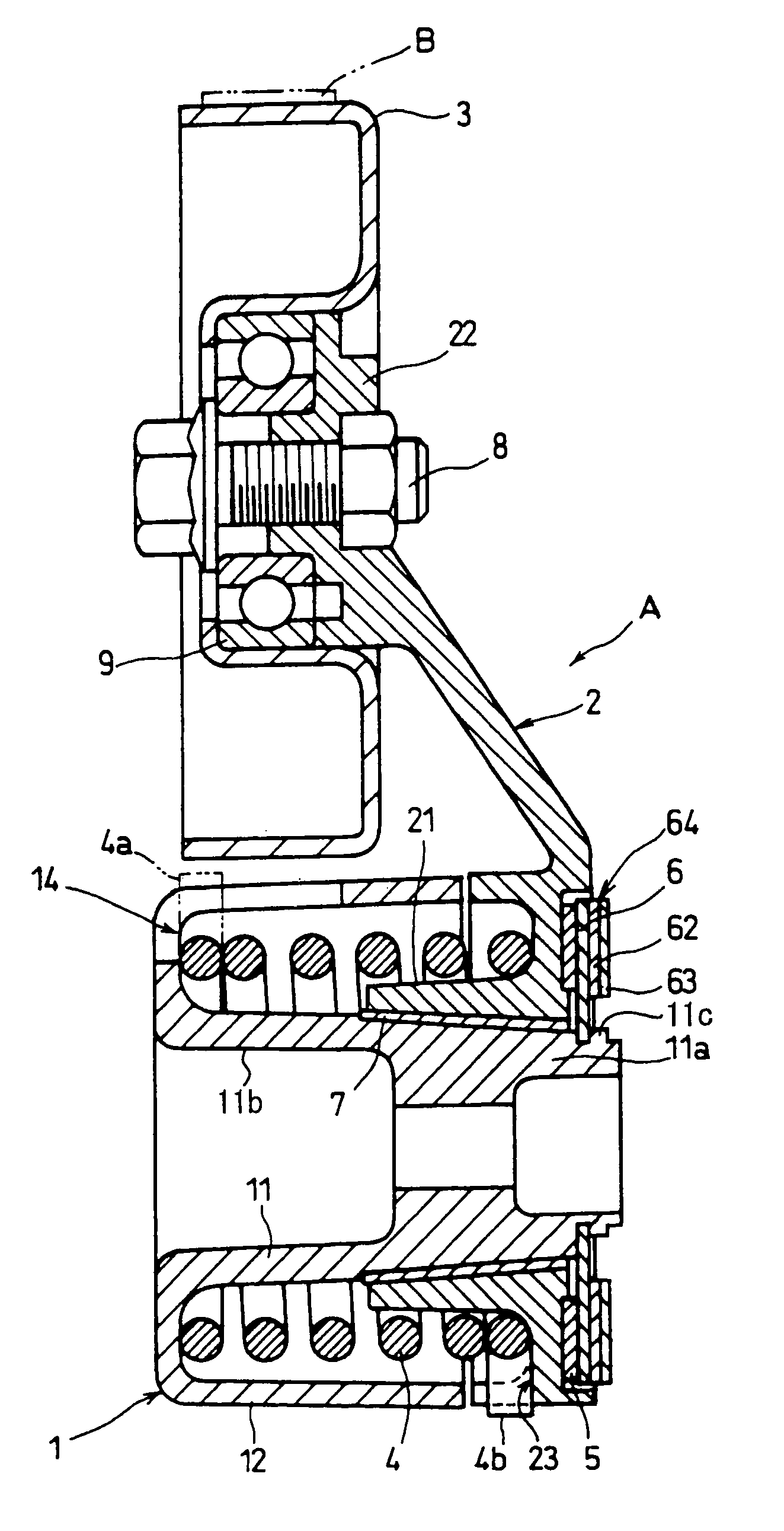

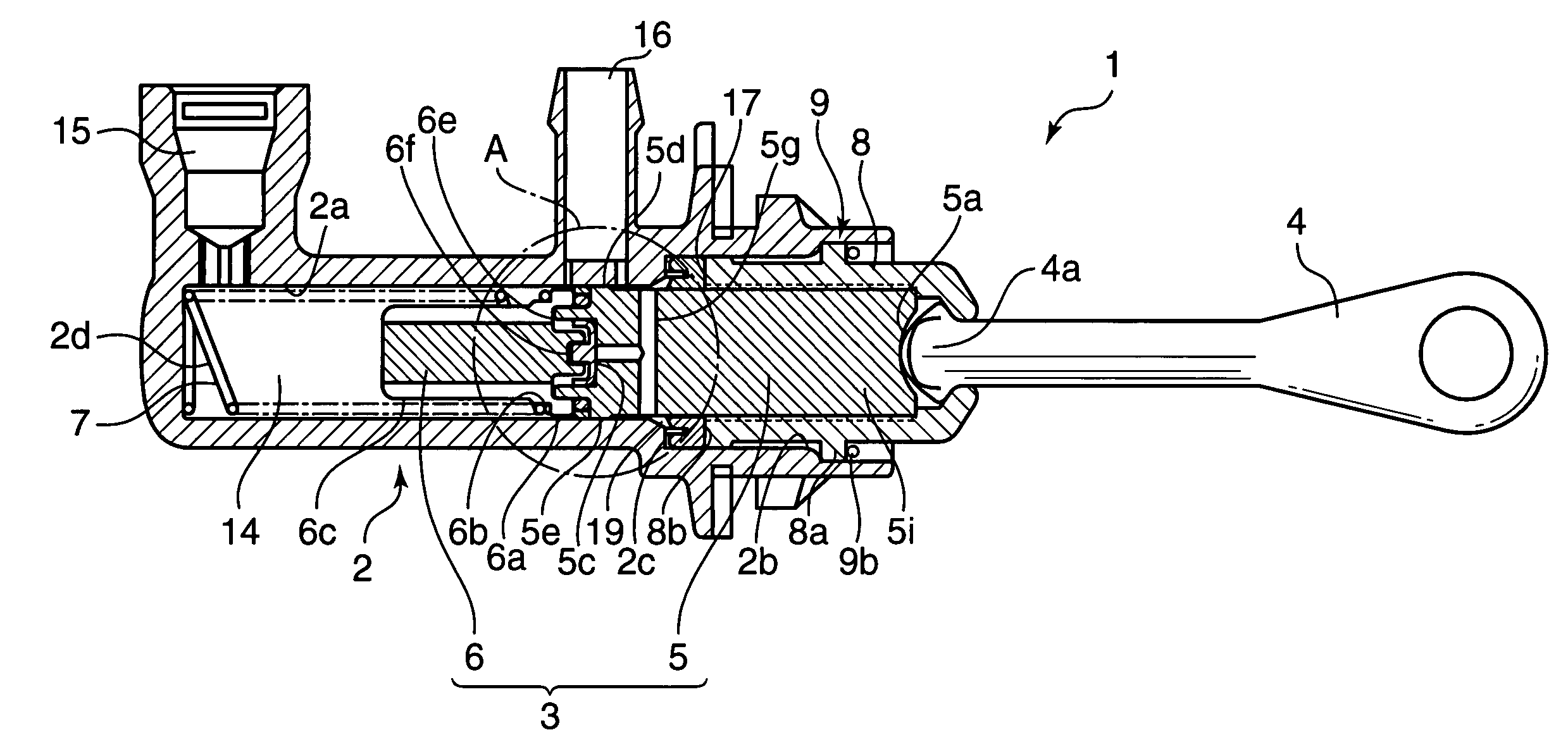

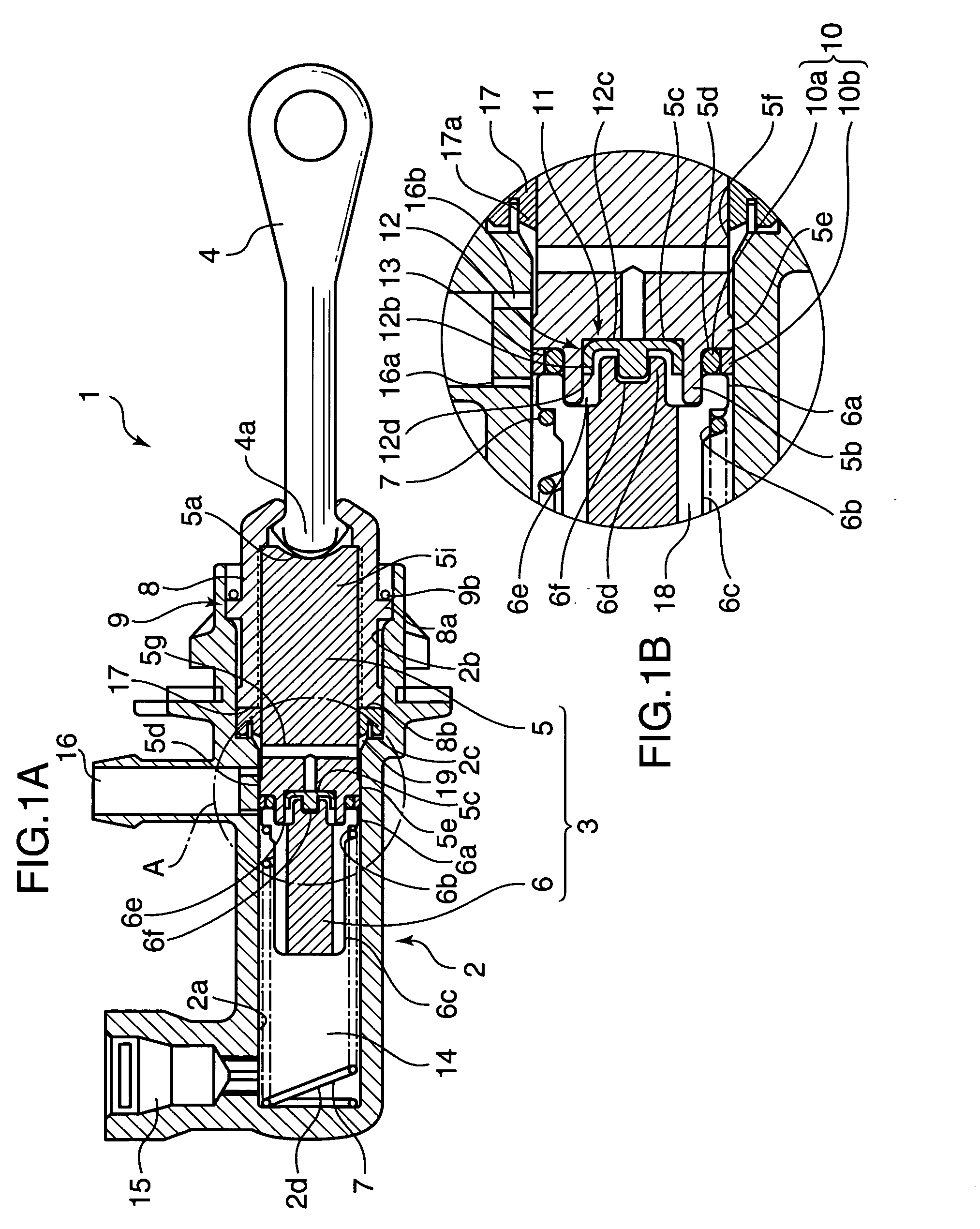

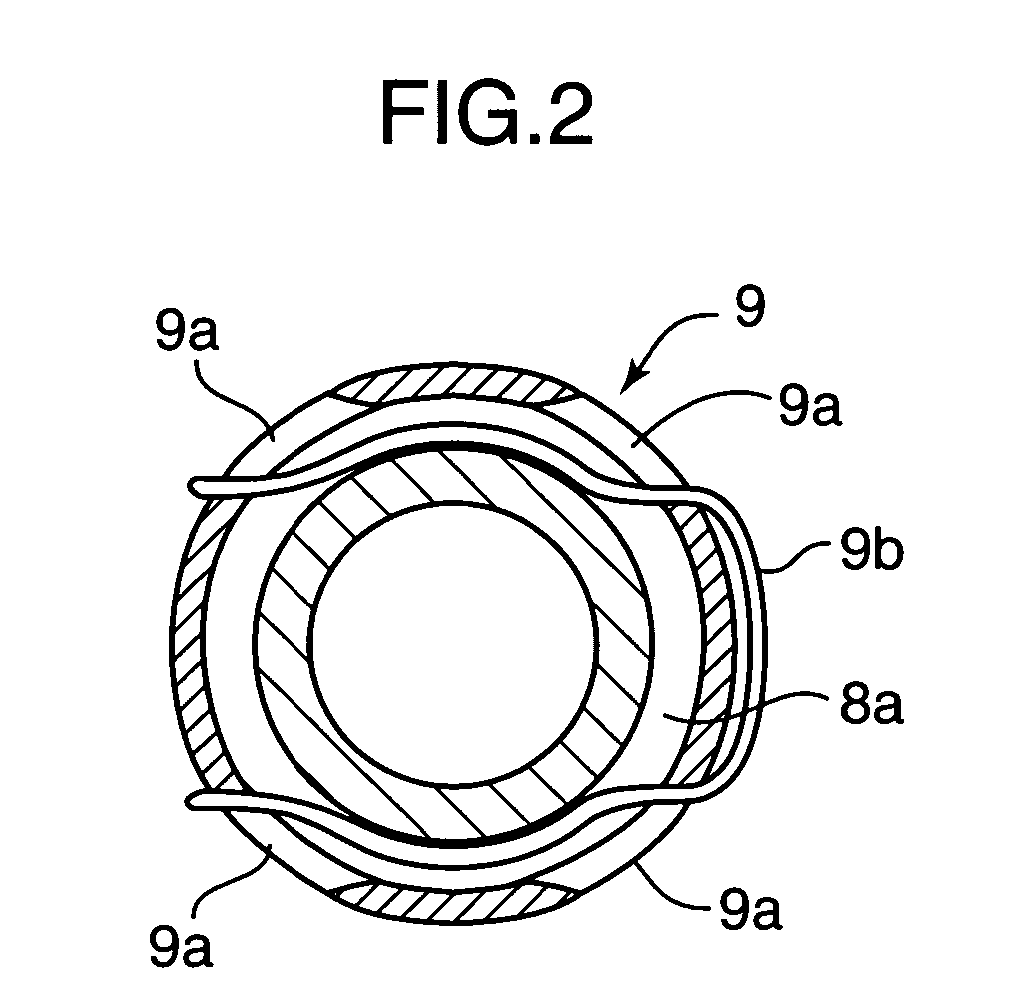

Master cylinder

A master cylinder has a resin cylinder main body formed with a step at a boundary between a cylinder hole and a mount hole. A piston cooperates with the inner circumferential surface of the cylinder hole to define a hydraulic chamber. A guide sleeve is locked in the cylinder main body and guides a base end of the piston. A first annular sealer, which has an inner seal member made of a soft material and an outer seal member made of a hard material, is held on the outer circumferential surface of a leading end of the piston. A second annular sealer is squeezed between the step and a leading end of the guide sleeve. At least a portion of the outer circumferential surface of the piston is made of a metal. The master cylinder is inexpensive and suppresses squeaks and rattles caused by the stick-slip phenomenon.

Owner:NABLESCO CORP

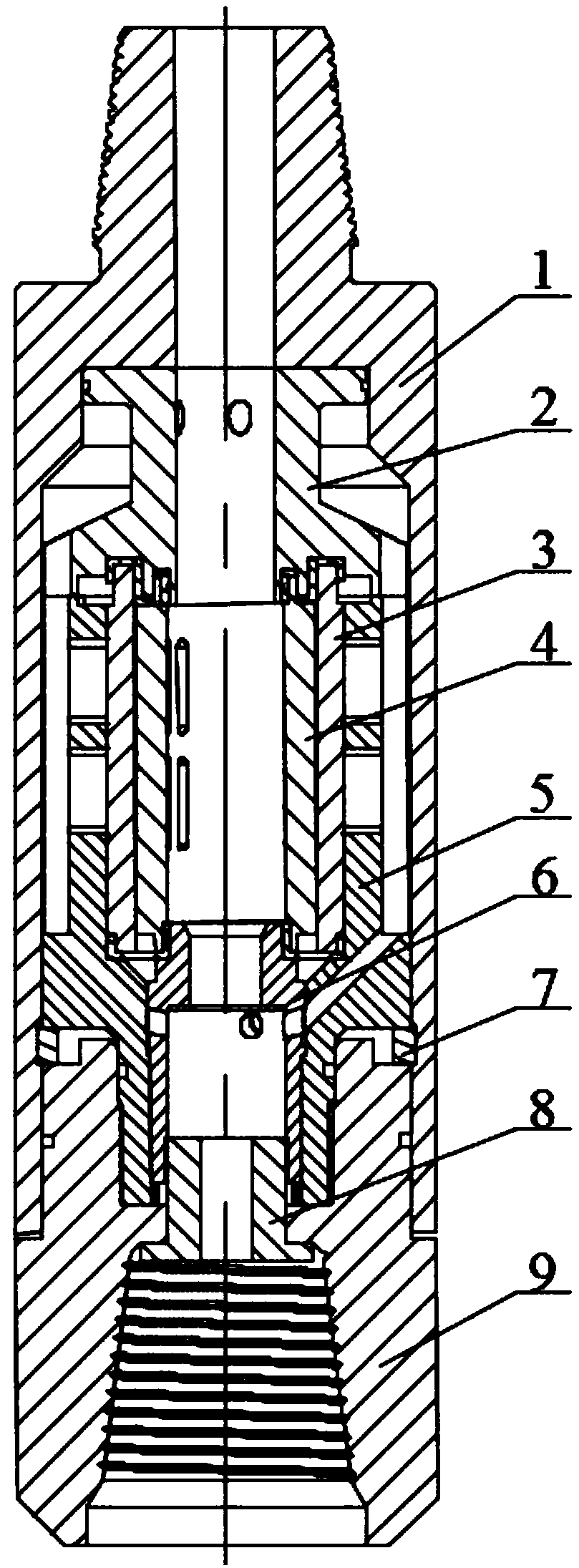

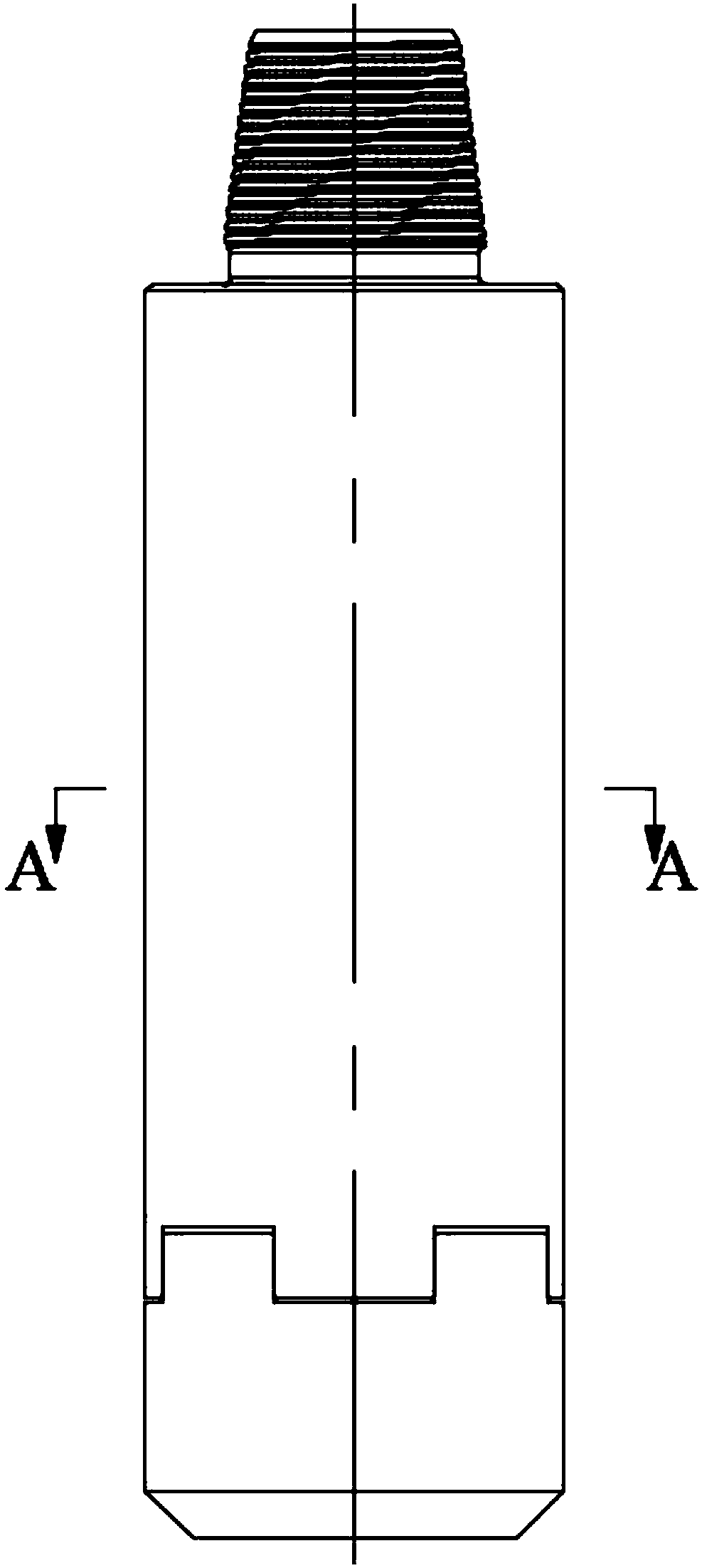

Stick slip prevention torsion impact drilling tool

InactiveCN106050177AChange flow areaIncrease drilling speedVibration devicesInterference fitDrive shaft

The invention relates to a stick slip prevention torsion impact drilling tool which is used for improving the penetration rate and well quality in the field of drilling engineering. By the adoption of the stick slip prevention torsion impact drilling tool, the problem that a drilling tool and a well body are severely damaged by the stick slip phenomenon in the drilling process. According to the technical scheme, the lower end of an output shaft is connected with a screw thread of a drill bit; the upper end of an outer shell is connected with a screw thread at the lower end of an upper connector; the lower end of the outer shell is connected with a screw thread at the upper end of a transmission shell; the outer circle of a movable valve ring is in interference fit with a stepped hole in the lower portion of an inner cavity of a movable valve seat; the outer circle of a static valve is in interference fit with a stepped hole in the upper portion of an inner cavity of a transmission shaft; the lower end of a spiral rotor is connected with a screw thread at the upper end of the movable valve seat; the transmission shaft is arranged in an inner cavity of the transmission shell; the external octagon shape in the middle of the transmission shaft is in clearance fit with the internal octagon shape in the middle of the inner cavity of the transmission shell; the lower end of a spiral shell is connected with a screw thread at the upper end of the output shaft; and the upper end of a spiral shaft is connected with a screw thread at the lower end of the transmission shaft, and a spline of the spiral shaft is in clearance fit with a spline of the spiral shell. The stick slip prevention torsion impact drilling tool generates high-frequency micro-amplitude circumferential reciprocating swing, the stick slip phenomenon can be prevented, and the penetration rate is increased.

Owner:SOUTHWEST PETROLEUM UNIV

High-frequency torsional vibration viscosity reducing tool

ActiveCN109667536AImprove reliabilityAlleviate or eliminate stick-slip phenomenonBorehole drivesMechanical energyEngineering

The invention relates to a high-frequency torsional vibration viscosity reducing tool, which is mainly composed of an upper connector shell, a flow splitting sleeve, an impact hammer, a reversing shifting fork, an impact valve body, a retainer, a positioning clamping ring, a jet nozzle and an adapter substitute. When the high-frequency torsional vibration viscosity reducing tool works, hydraulic energy of drilling fluid is converted into mechanical energy of the tool, after the drilling fluid enters the tool through the upper connector shell, most of the drilling fluid flows out through a central flow passage, a part of the fluid is split through small holes in the flow splitting sleeve, the part of the drilling fluid flowing through the central flow passage is split through the reversingshifting fork, reciprocating movement of the reversing shifting fork and the impact hammer is realized through flow passage conversion inside the tool, the impact hammer collides with the impact valvebody back and forth to generate a circumferential reciprocating impact load, and finally the circumferential load is transmitted downwards through the adapter substitute. According to the high-frequency torsional vibration viscosity reducing tool, the stick-slip phenomenon of a drill string can be relieved or eliminated, rock breaking of a drill bit is accelerated, the drilling efficiency is improved, and the drilling cost is saved.

Owner:SOUTHWEST PETROLEUM UNIV

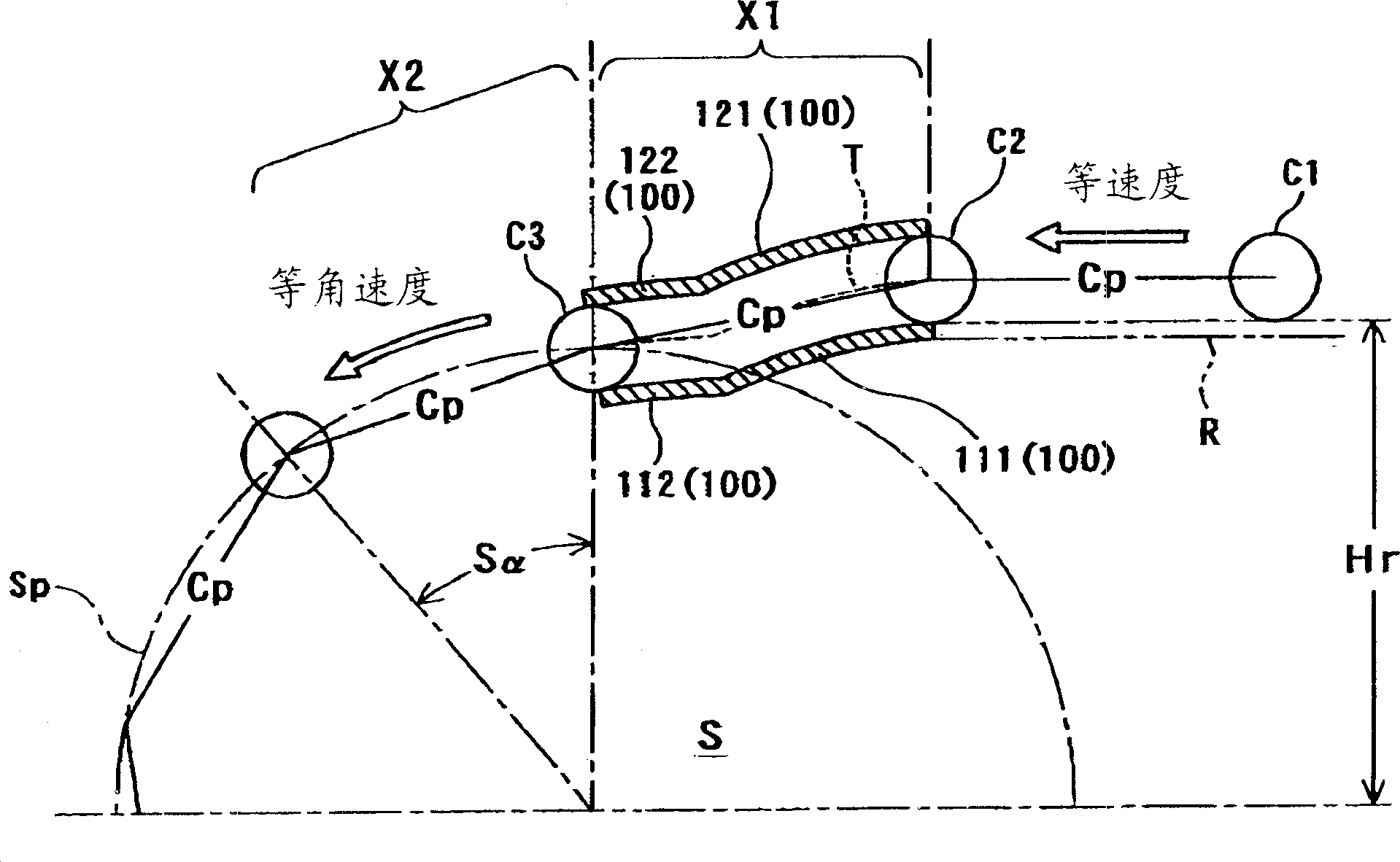

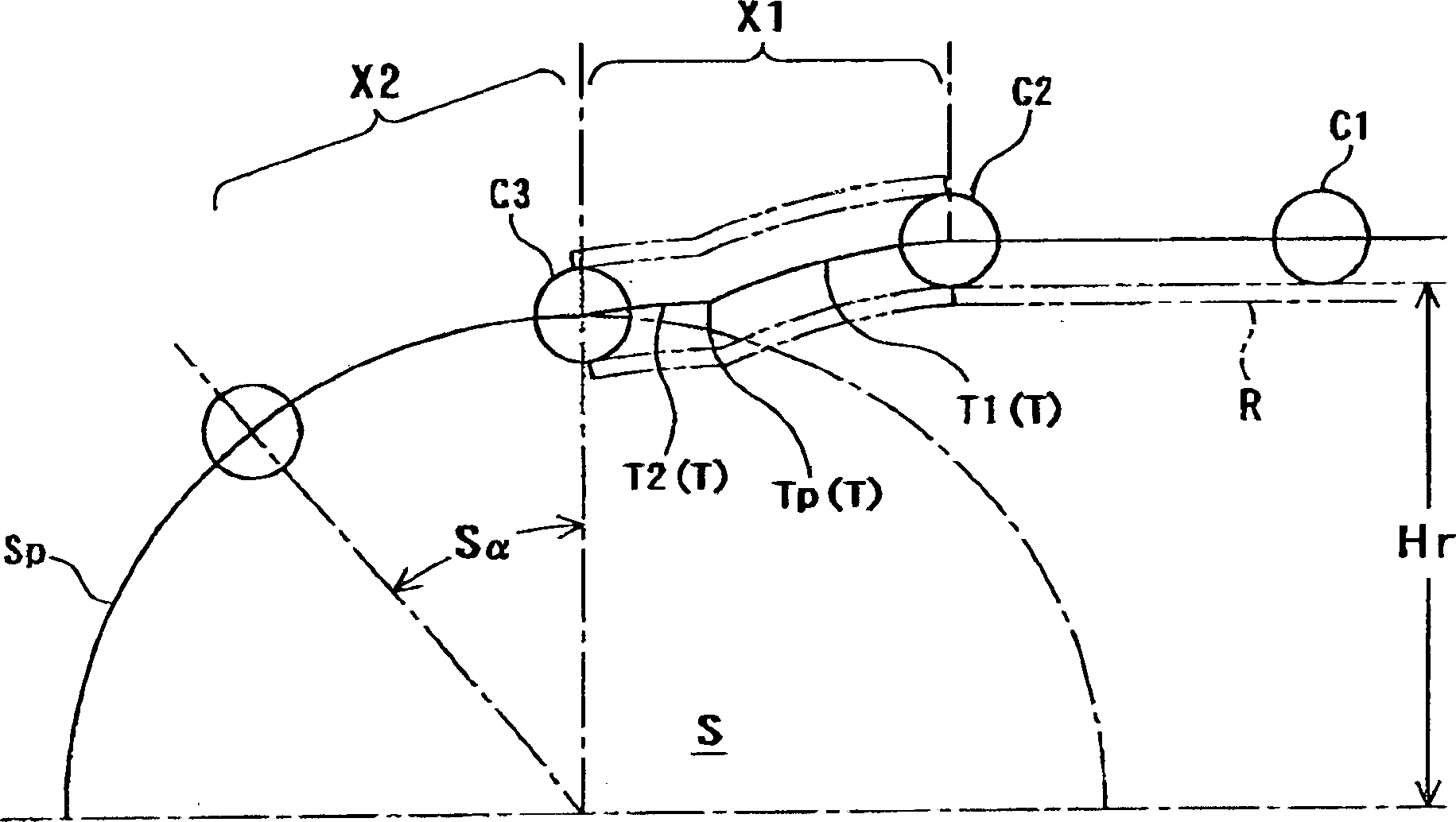

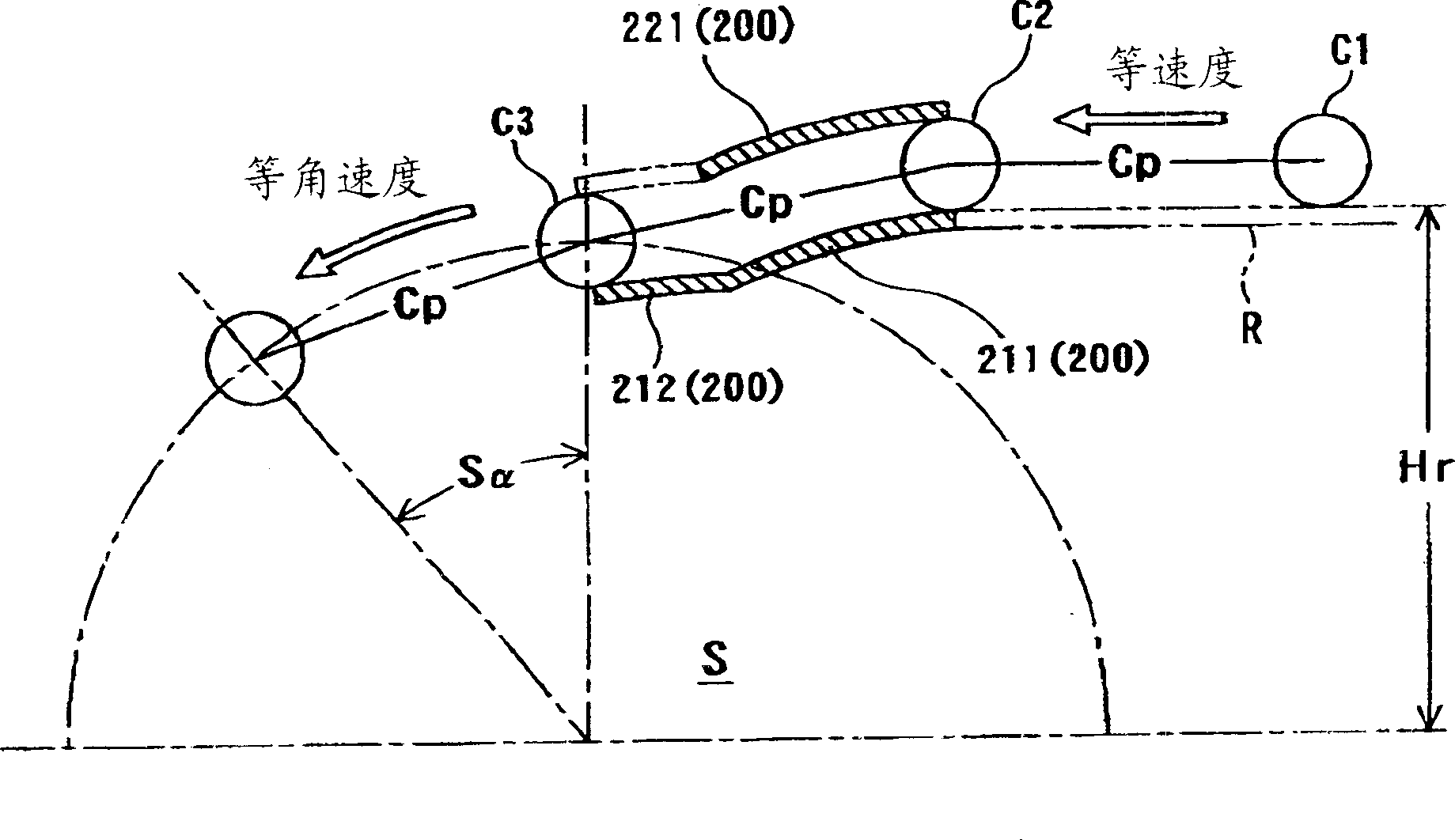

Guidance device for moving chain

A conveying chain guide, in which the stick slip phenomenon of a conveying chain, which meshes with a driving sprocket, and a seasickness phenomenon are removed whereby stable conveying of articles can be smoothly realized and the driving force and vibration noise of a conveying chain can be remarkably reduced. When continuous three rollers C1, C2, C3 in the conveying chain C is to be meshed with the sprocket while gradually descending from the linear rail R for supporting the conveying surface toward the driving sprocket S, in such an arrangement traveling state that always corresponds to the linear rail R for supporting the conveying surface, a transfer position X1 and a meshing position X2, the guide track T is defined along an movement passage of the roller C2 in the transfer position X1.

Owner:TSUBAKIMOTO CHAIN CO

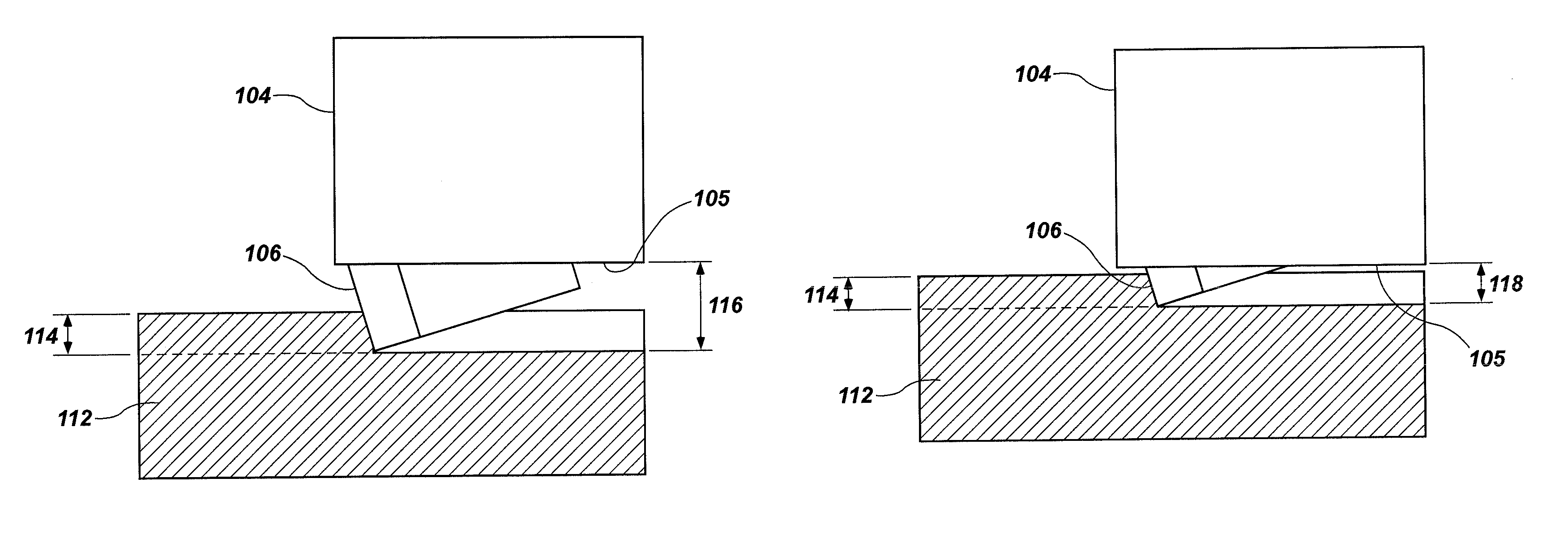

Drill bit design for mitigation of stick slip

A method of designing an earth-boring rotary drill bit includes designing a bit body and cutting elements of the drill bit such that features of the drill bit other than cutting elements engage and rub against a subterranean formation being drilled by the drill bit at depths-of-cut beyond, but close to, an intended median depth-of-cut, and such that the amount of rubbing area between such features and the formation increases at a relatively rapid rate as the depth-of-cut increases beyond the intended median depth-of-cut. Such methods may be employed to mitigate the occurrence of the “stick-slip” phenomenon during drilling. A method of fabricating a drill bit includes configuring a bit body and cutting elements in accordance with such a design. Earth-boring drill bits include a bit body and cutting elements so configured.

Owner:BAKER HUGHES INC

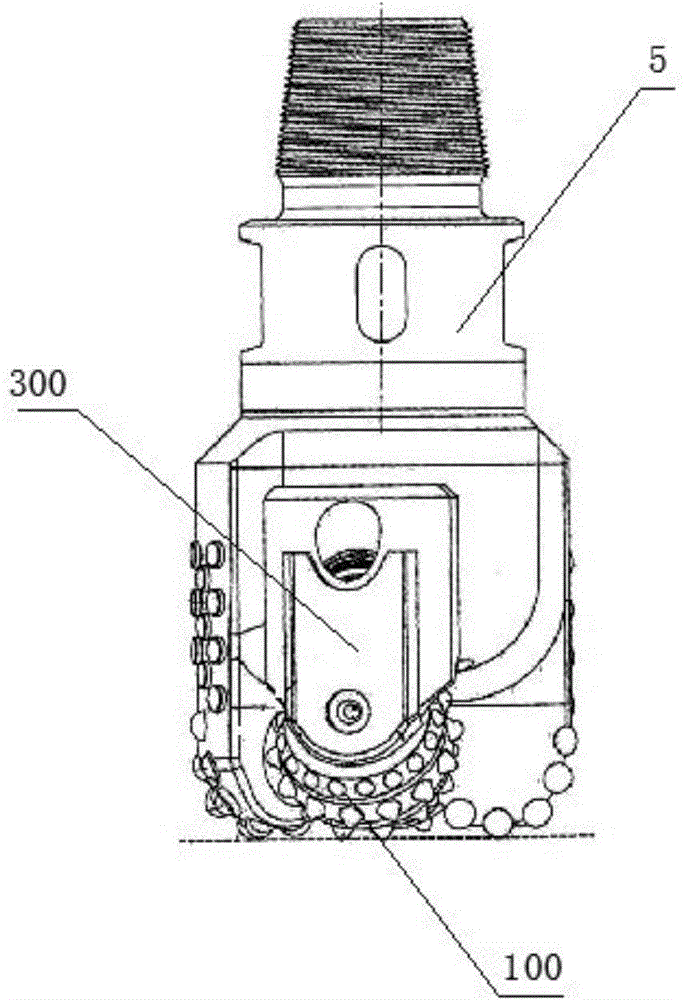

Self-adaption torque balance drill bit

ActiveCN107288548ASlow down or even avoid torsional shock vibrationsProtected from impact damageEarth drilling toolsDrill bitsTorque transmissionEngineering

The invention relates to a self-adaption torque balance drill bit comprising a hole reaming drill bit body and a hole piloting drill bit body. The hole reaming drill bit body comprises a hole reaming drill bit connector and a hole reaming drill bit crown. The hole piloting drill bit body is mounted in the hole reaming drill bit crown and protrudes out of the hole reaming drill bit crown, and a torque transmission device is mounted in an inner cavity formed by connecting the hole reaming drill bit connector and the hole reaming drill bit crown. The torque transmission device comprises a rotating piece and a transmission piece fixedly connected with the rotating piece, the transmission piece is connected with the hole piloting drill bit body, and at least one retainer is arranged on the rotating piece. The torque transmission device further comprises limiting pieces matched with the retainers, and the limiting pieces are arranged on the hole reaming drill bit crown. Elastic pieces matched with the retainers for using and used for transmitting partial hole piloting drill bit rock breaking torque and buffering torque fluctuation are arranged between the retainers and the hole reaming drill bit crown. According to the self-adaption torque balance drill bit, drill bit torque fluctuation in the drilling process can be controlled in a self-adaption mode, and torsion impact vibration generated by the stick-slip phenomenon in the drilling process is slowed down and even avoided.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

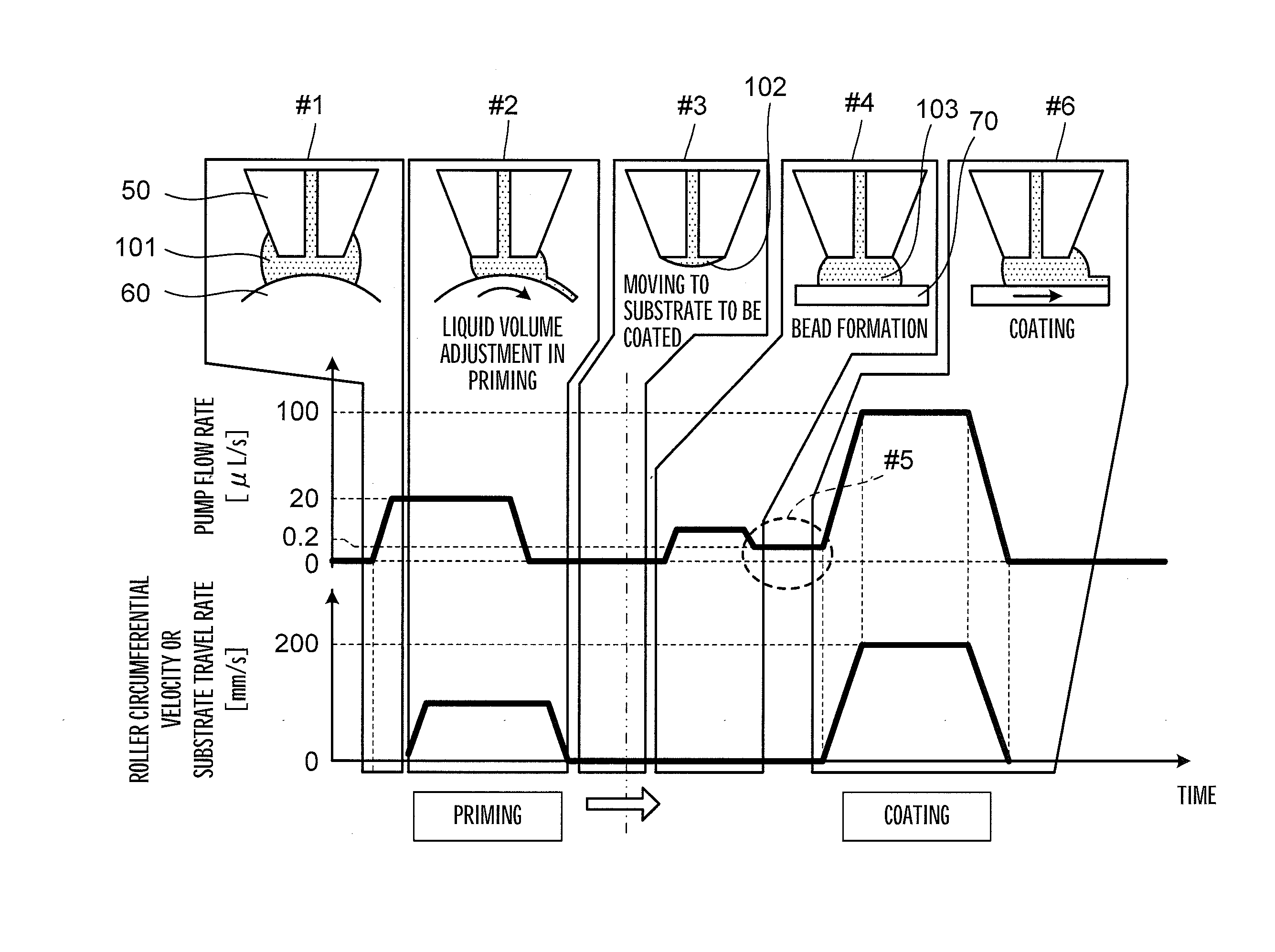

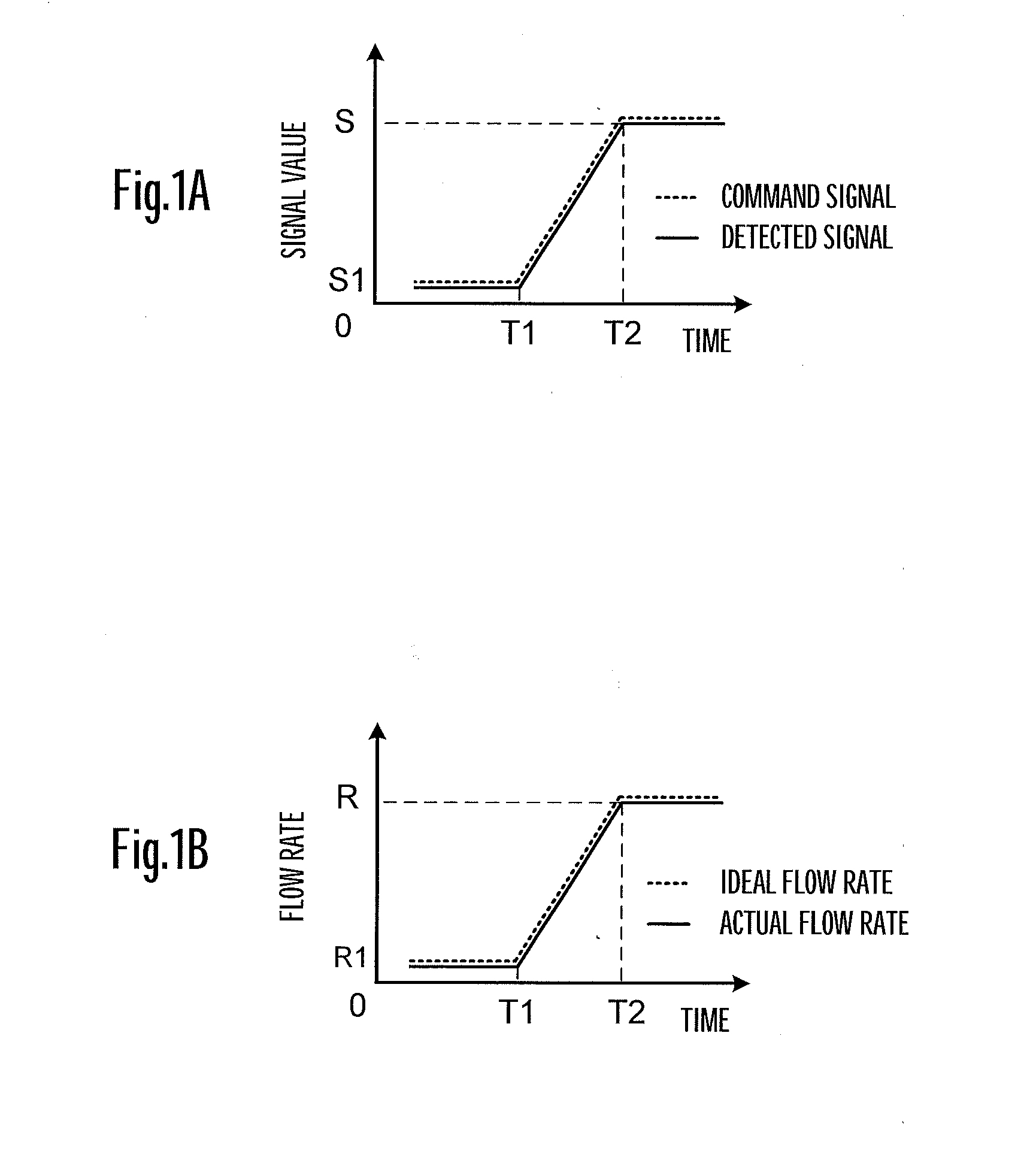

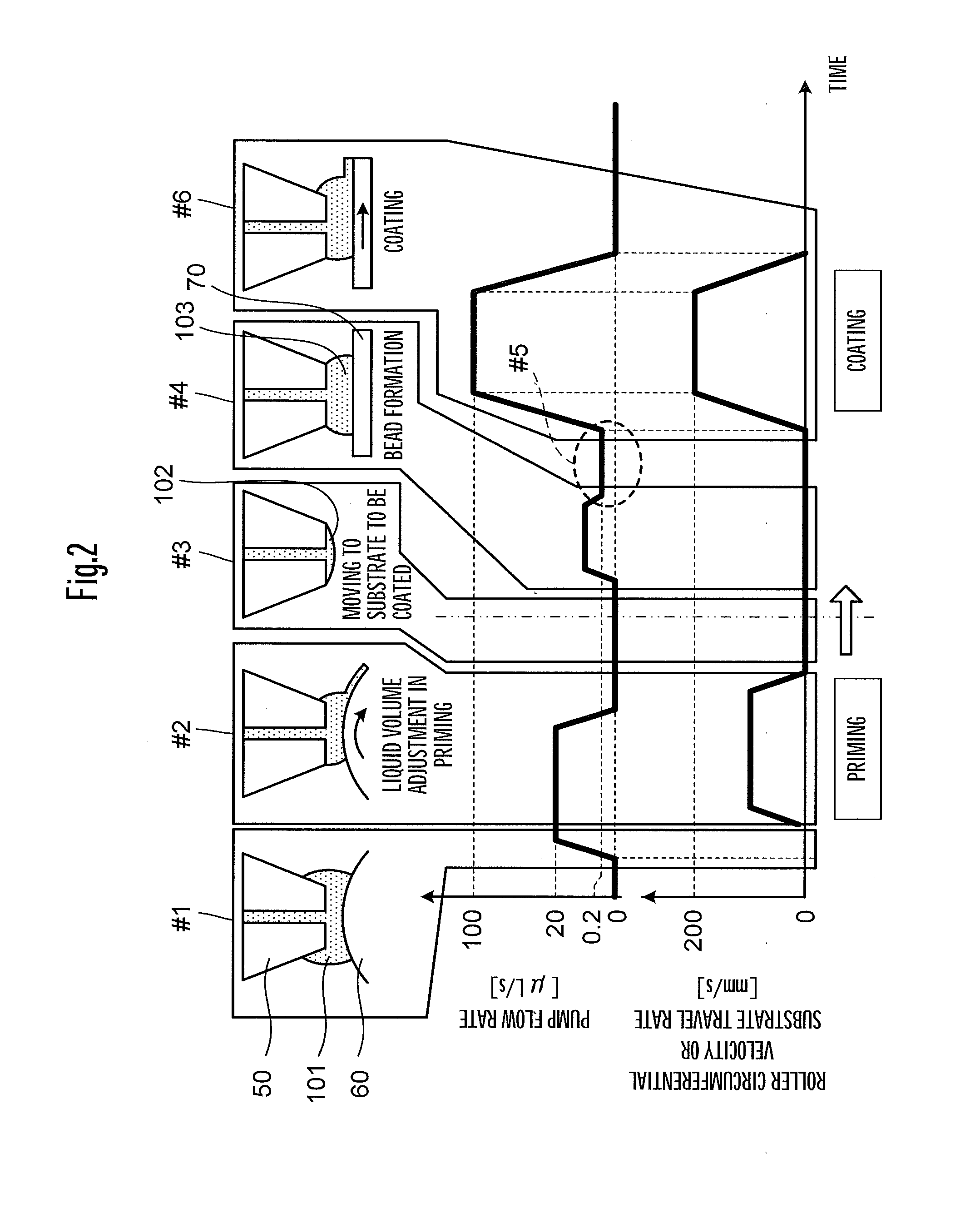

Method for controlling a flow rate of a pump and method for forming a coated film

InactiveUS20140186537A1Stable flow rateFlexible member pumpsFlow control using electric meansStatic frictionEngineering

A method for controlling a flow rate of a pump (10) transporting a liquid being driven by a drive system having a sliding portion, wherein a flow rate is maintained at a minute first flow rate (R1) at an early stage of operation of the pump (10); and subsequently the flow rate is increased to a steady second flow rate (R). With the method, at the early stage of operation of the pump (10), a state is established beforehand in which the pump (10) is kept stable at the minute first flow rate in order for the stick-slip phenomenon not to occur; and because the flow rate of the pump is increased from the state, transition from static friction to kinetic friction does not occur; and thus a disorderly flow rate of the pump (10) due to the stick-slip phenomenon of a motor (12) is suppressed.This makes it possible to attain a stable control of the flow rate at the early stage of operation of the pump (10).

Owner:TATSUMO KK

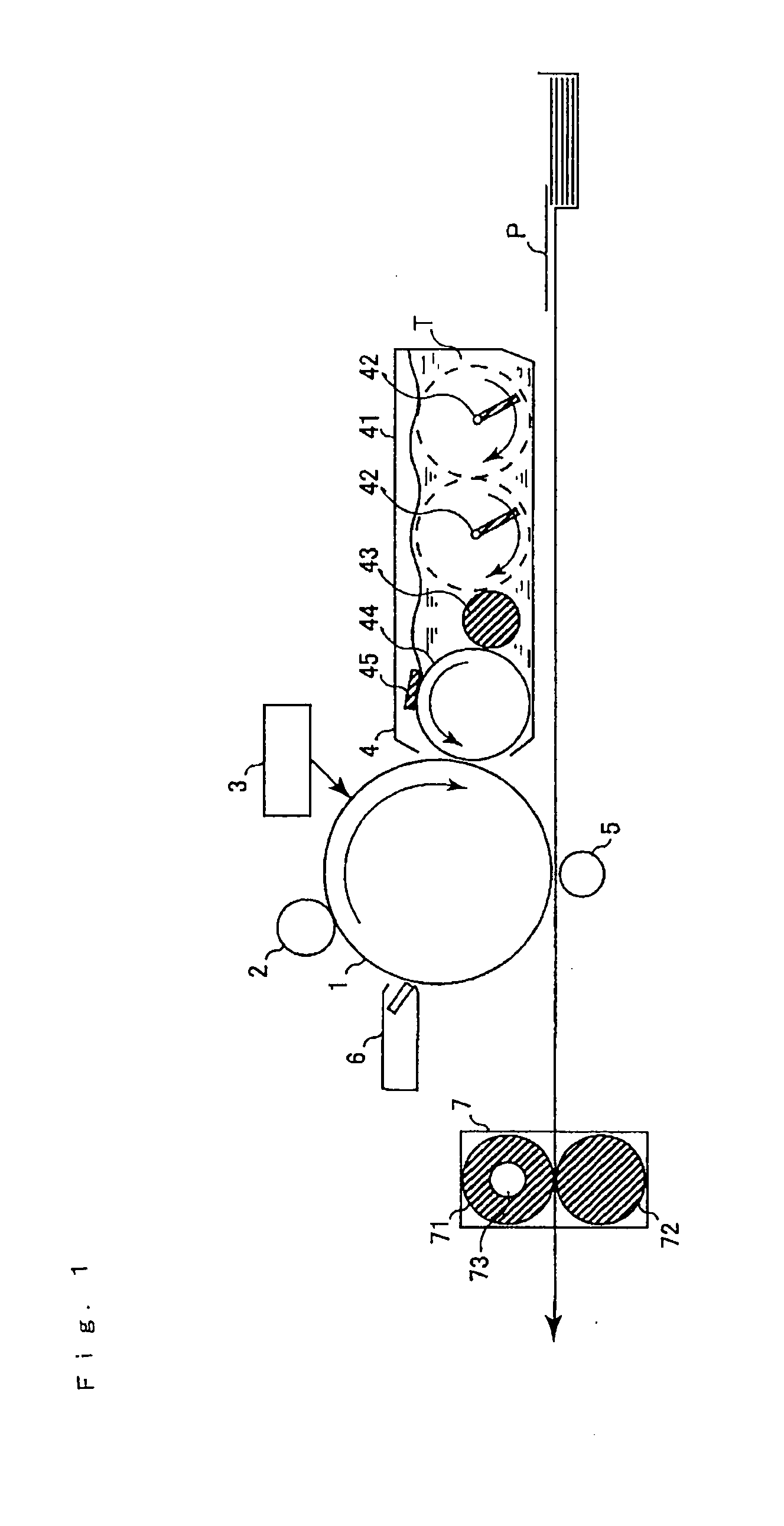

Electrophotographic photoreceptor, image-forming apparatus, and electrophotographic cartridge

ActiveUS20110294053A1Reduce the impactImpair electrical propertyElectrographic process apparatusNoise generationEngineering

When an abutting pressure of the cleaning blade on a photoreceptor is increased, a chattering occurs due to the so-called a stick-slip phenomenon that the blade repeatedly undergoes sticking to the outermost surface of the photoreceptor and slipping thereon. As a result, a possibility of noise generation becomes higher and there is a possibility that toner particles might pass through during slipping to cause a cleaning failure, resulting in a streaky image defect. There is also a higher possibility that the so-called a filming phenomenon might occur, in which a component of the toner sticks to the photoreceptor surface by the action of the blade pressure and becomes difficult to remove, so as to lead to persistent image defects. Furthermore, since the photoreceptor is rotated with toners in the state of being strongly pressed thereagainst, the image defects are apt to be caused due to peripheral-direction scratches. An electrophotographic photoreceptor is provided in which the outermost layer of the photoreceptor contains a specific charge-transporting material and a specific binder resin.

Owner:MITSUBISHI CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com