Jet type torsional impact drilling tool

A percussion drilling and jet-type technology, applied in percussion drilling, drilling equipment, reciprocating drilling rigs, etc., can solve problems affecting tool life and reliability, complicated ratchet structure and easy wear, and affecting downhole working life. It is beneficial to popularization and use, weakens the stick-slip phenomenon, and basically stabilizes the jet flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

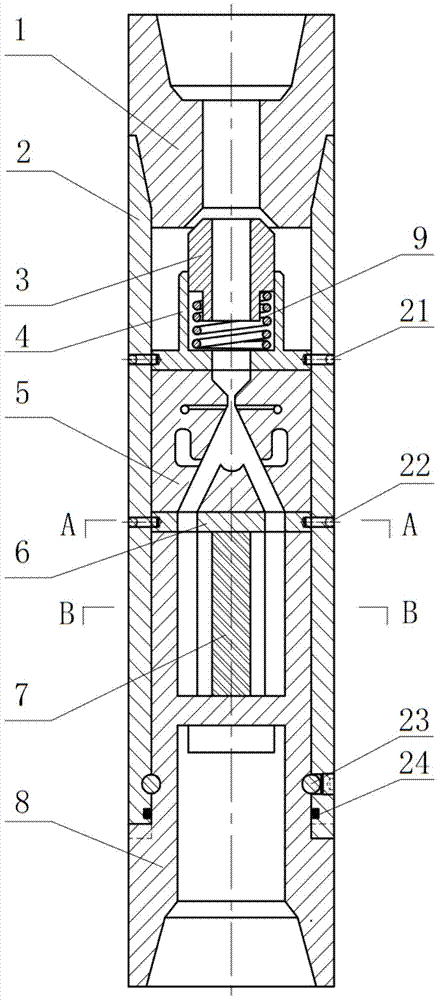

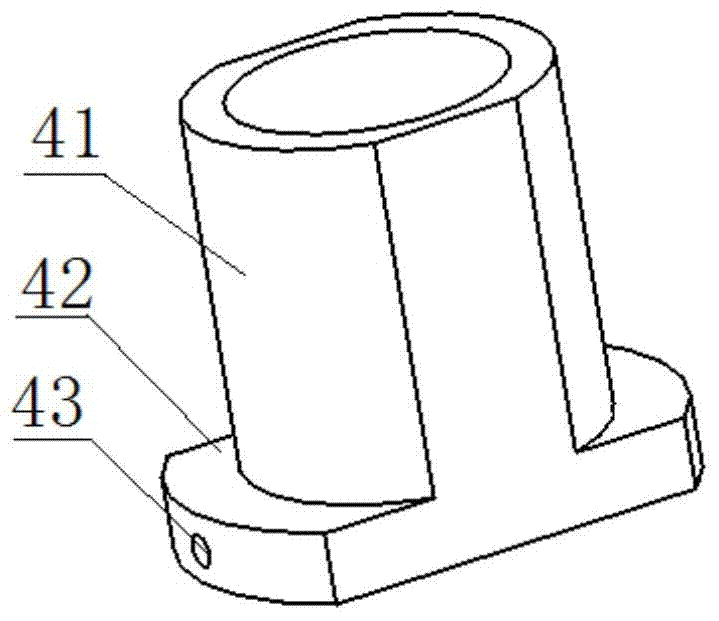

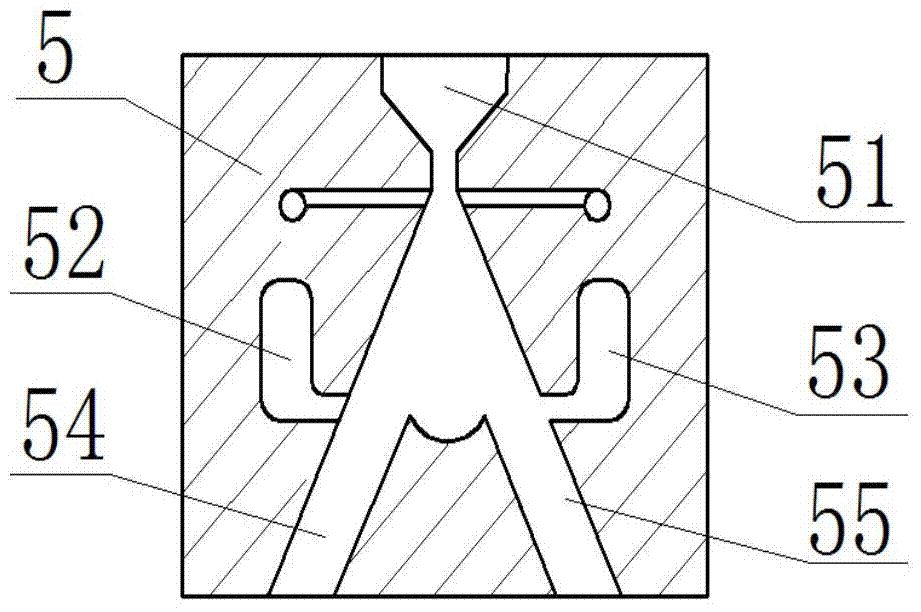

[0023] like figure 1 As shown, the jet-type torsional impact drilling tool includes: upper joint 1, outer shell 2, float valve 3, valve seat diverter plate 4, jet element 5, jet diverter plate 6, hammer 7, impact transmission cylinder 8, spring 9 . The upper joint 1 is fixedly connected with the outer shell 2, the surgical body 2 is fixed with the impact transmission cylinder 8, the float valve 3, the valve seat diverter plate 4, the jet element 5, the jet diverter plate 6, and the spring 9 are located in the outer shell 2, and the impact hammer 7 Set in the impact transmission cylinder 8; the upper joint 1, the outer shell 2, and the impact transmission cylinder 8 transmit the conventional drilling pressure and torque and protect the internal components; the float valve 3, the spring 9 and the valve seat diverter plate 4 The flow is automatically divided to ensure that the flow rate participating in the jet flow and impact process is basically unchanged; the jet element 5 ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com