Patents

Literature

131results about How to "Drilling smoothly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

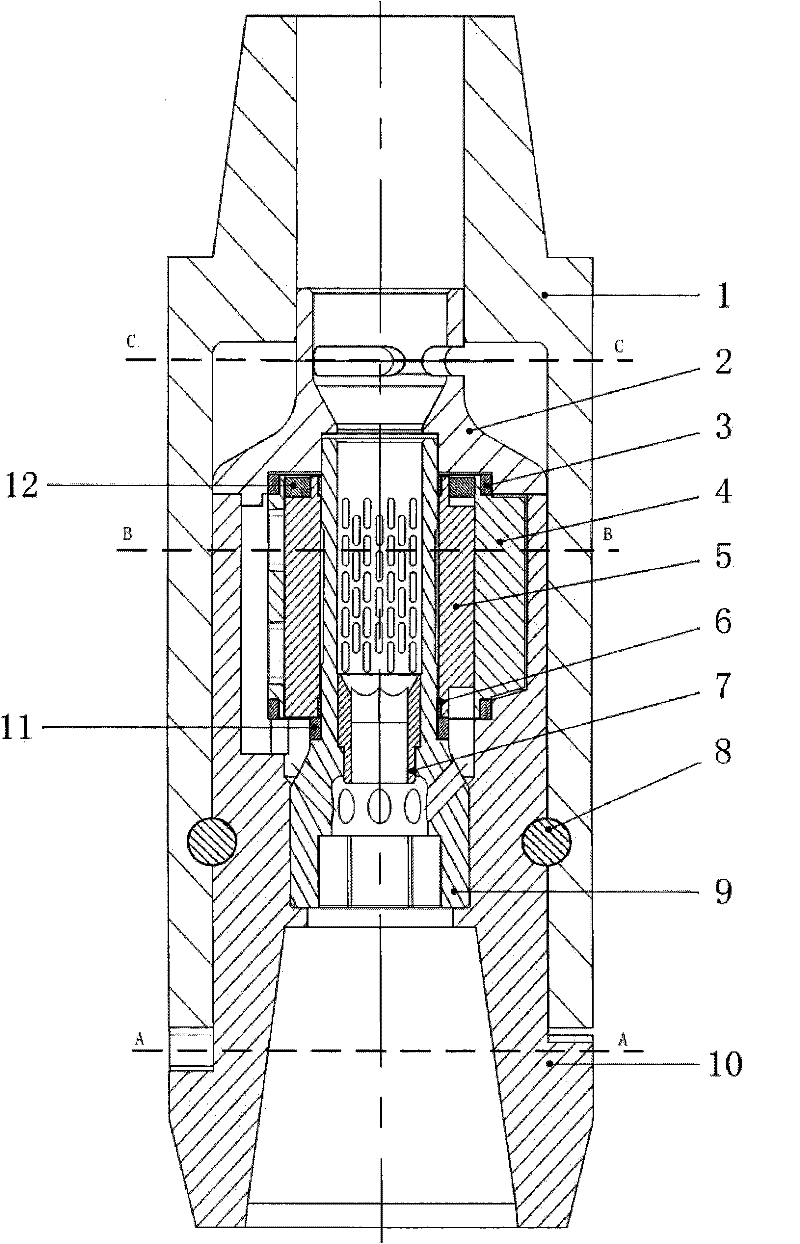

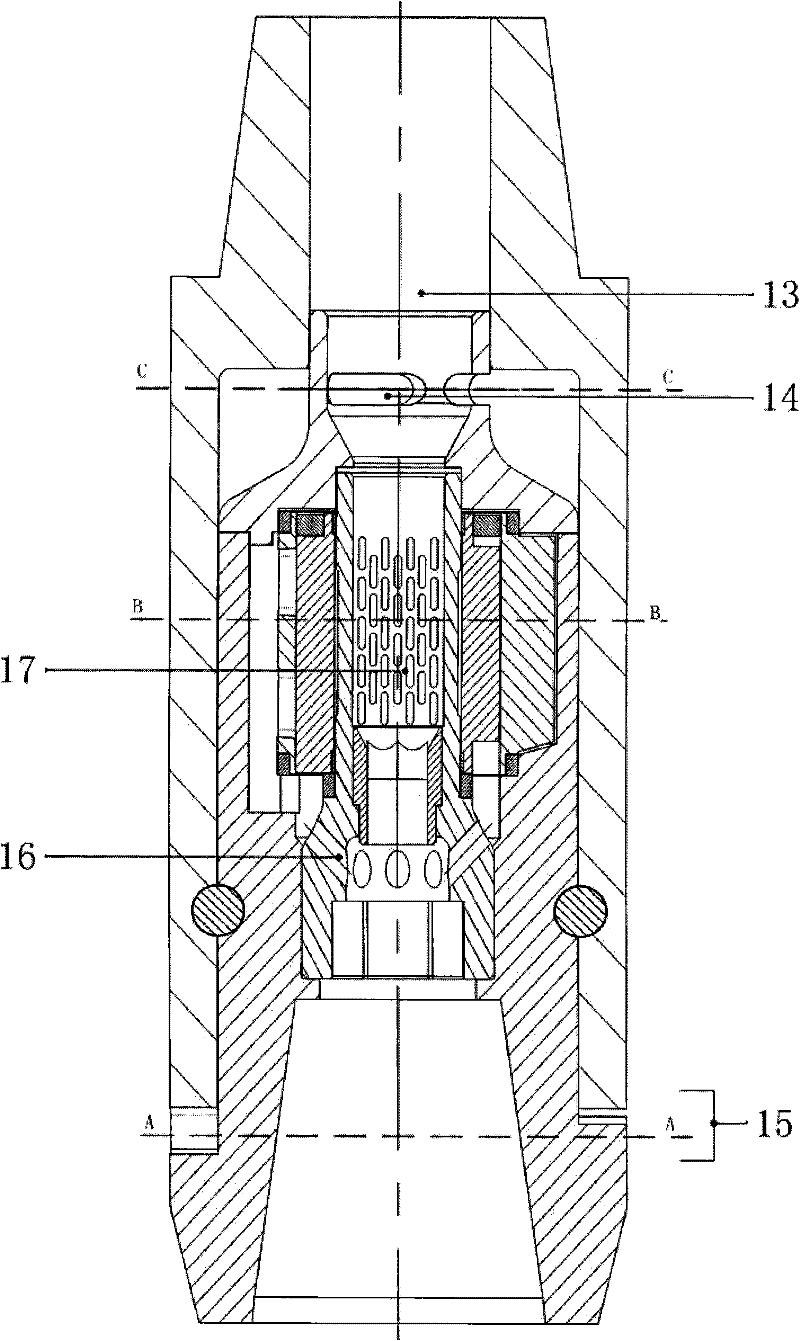

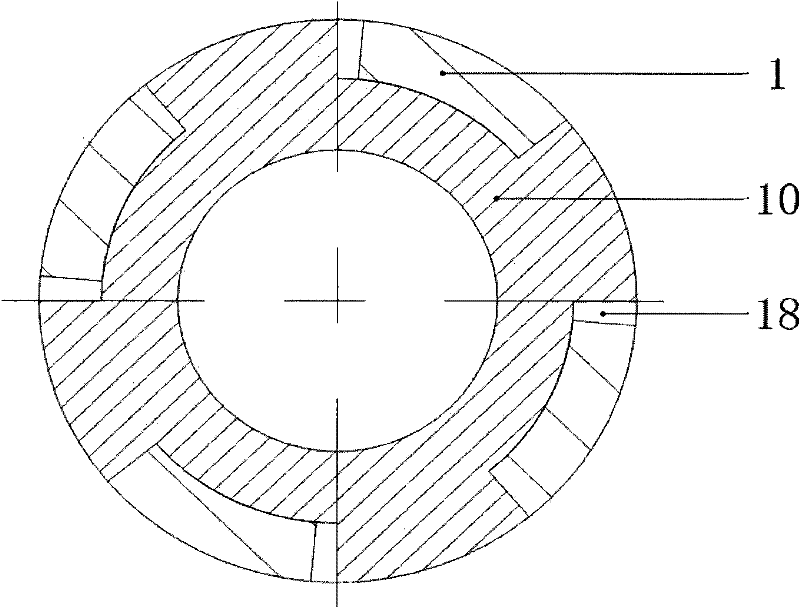

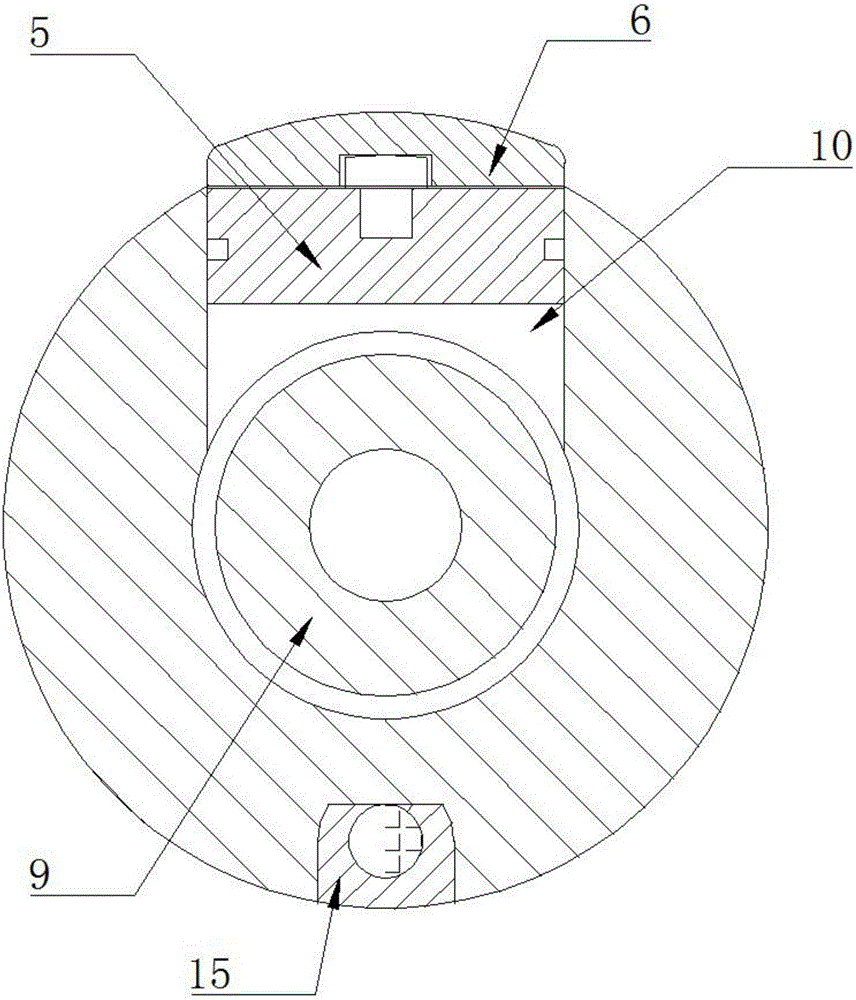

Torsional impact drilling tool

ActiveCN102454364ATorque stability and balanceReduce torsional oscillationsVibration drillingImpact hammerPetroleum engineering

The invention discloses a torsional impact drilling tool which can apply high-frequency torsion impact to a drilling bit in the drilling engineering. The technical scheme of the torsional impact drilling tool is as follows: the torsional impact drilling tool mainly comprises a short section of a drill collar, a torsional impact generator and a connecting body, wherein the short section of the drill collar and the torsional impact generator are in clearance connection through the connecting body and are located by splines; a diversion cover is fixed on a hammer seat; a cavity is formed inside the diversion cover; a closure nozzle, a sieve tube, a locating sleeve and an impact hammer are sequentially arranged in the cavity from inside to outside; the sieve tube is fixed with the hammer seat; the impact hammer, the locating sleeve, the sieve tube and the hammer seat are provided with through holes in the circumferential direction; and an impact hammer head and a starting hammer head are processed on the impact hammer. The torsional impact drilling tool is arranged between the drill collar and the drilling bit; and the drilling bit receives the high-frequency torsional impact generated by the impact hammer under the driving of fluids while receiving the rotational torsion of a drill column. Compared with other drilling tools, the torsional impact drilling tool disclosed by the invention has the advantages that the high-frequency torsional impact can be generated, the sticking-sliding phenomenon of the drilling bit is eliminated, the mechanical drilling rate of harder or abrasive formation is increased, the service life of matched components, such as the drilling bit and the like of the drill column is prolonged, the drilling efficiency is improved and the drilling cost is reduced.

Owner:CHINA PETROCHEMICAL CORP +3

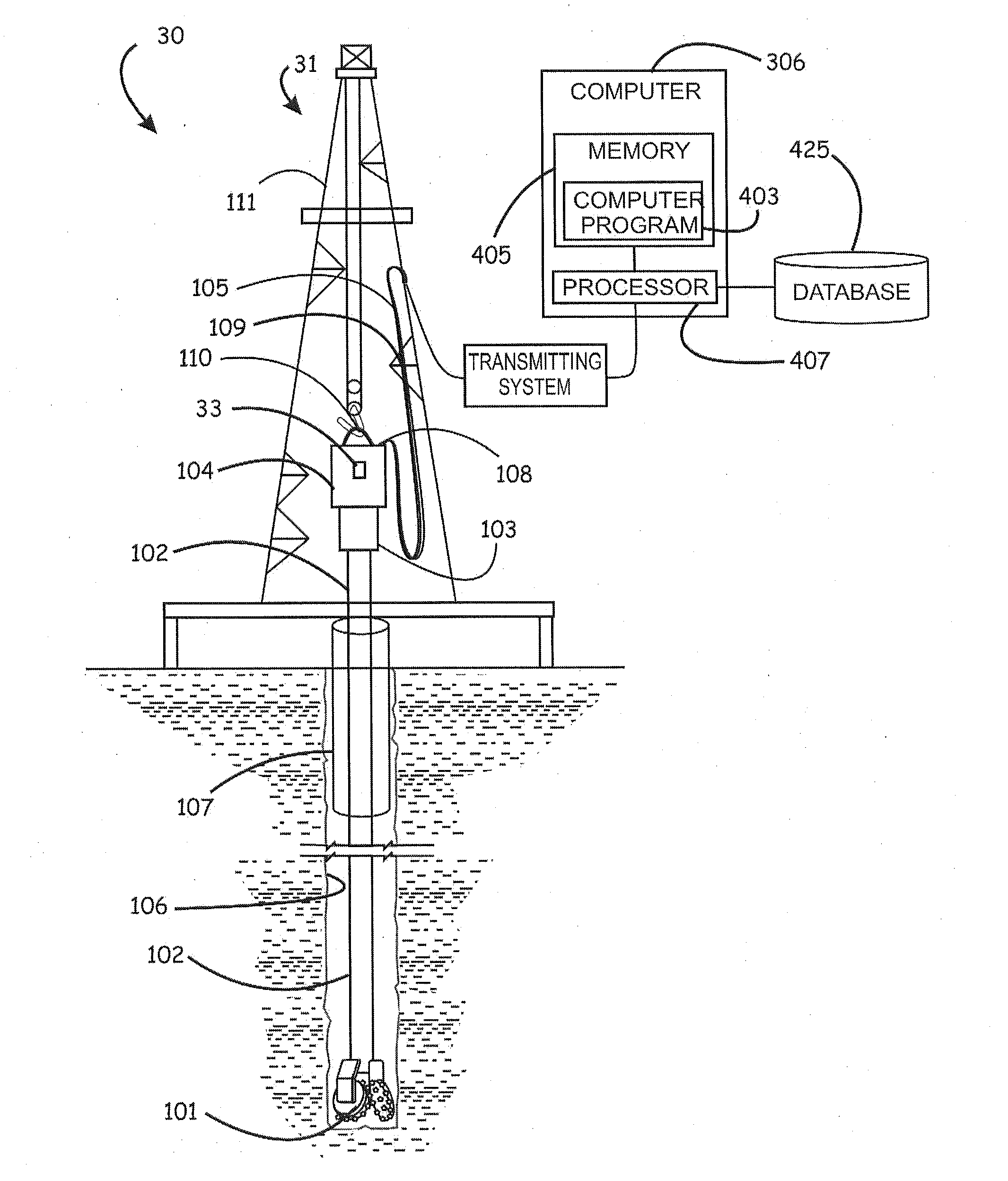

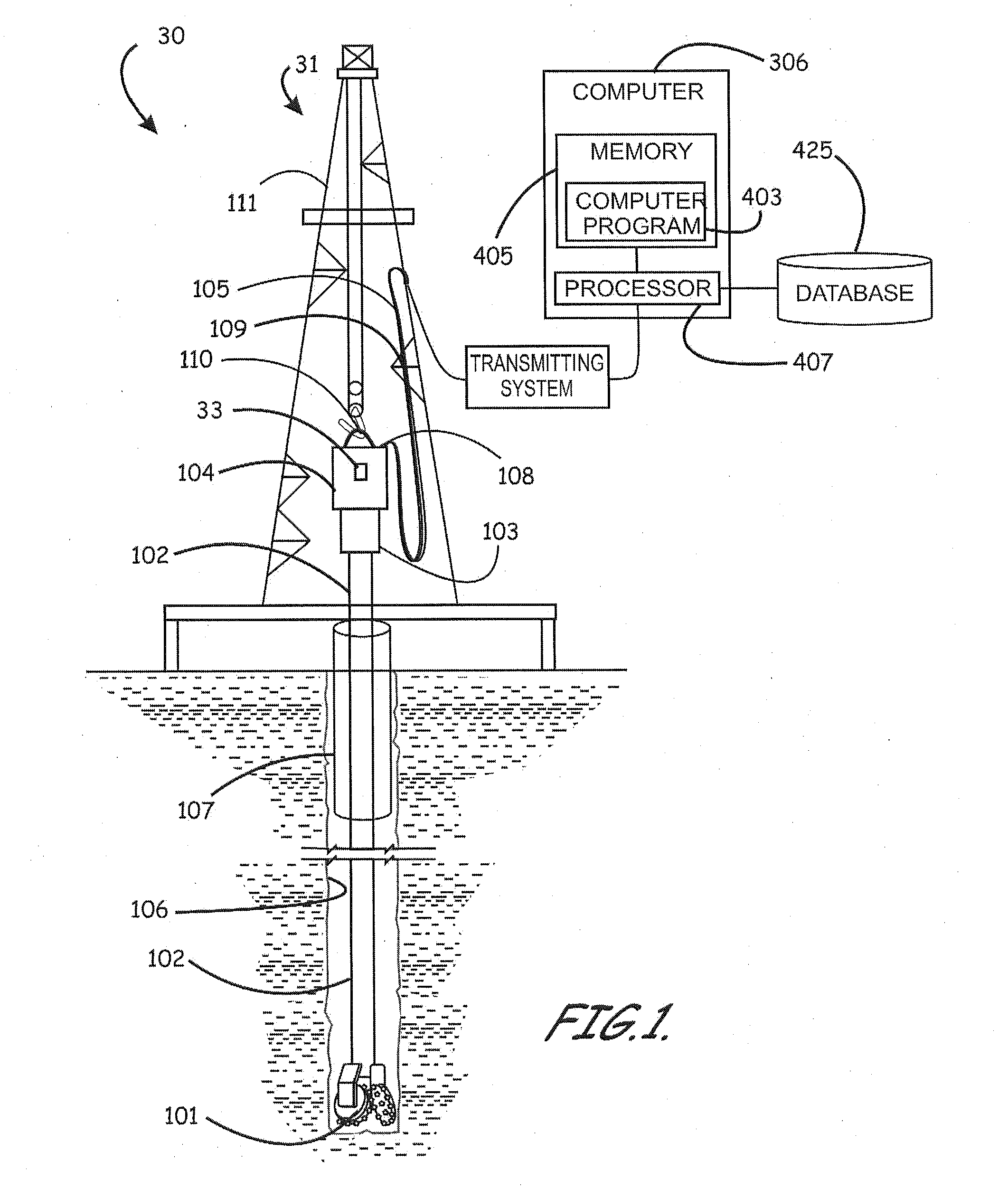

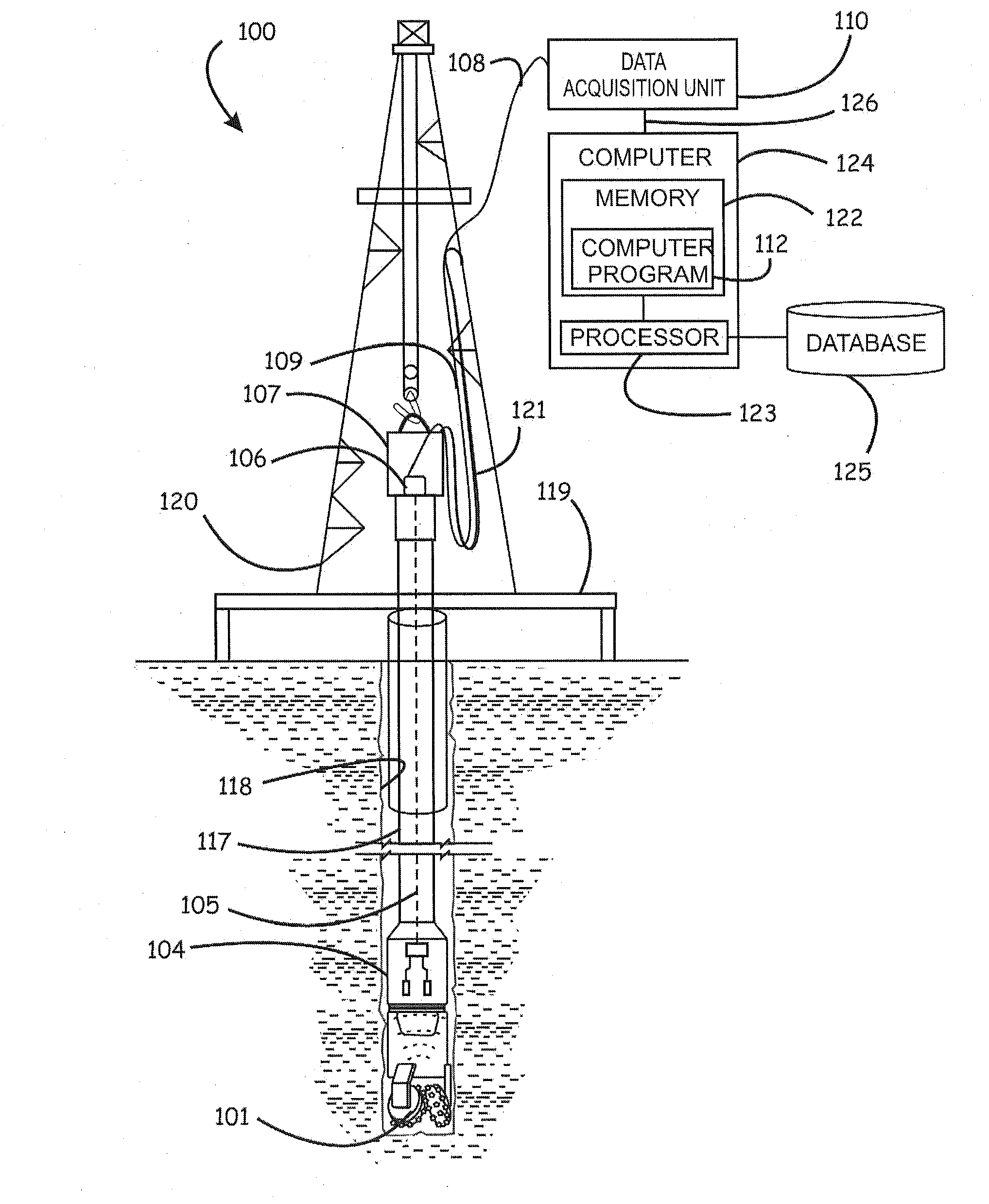

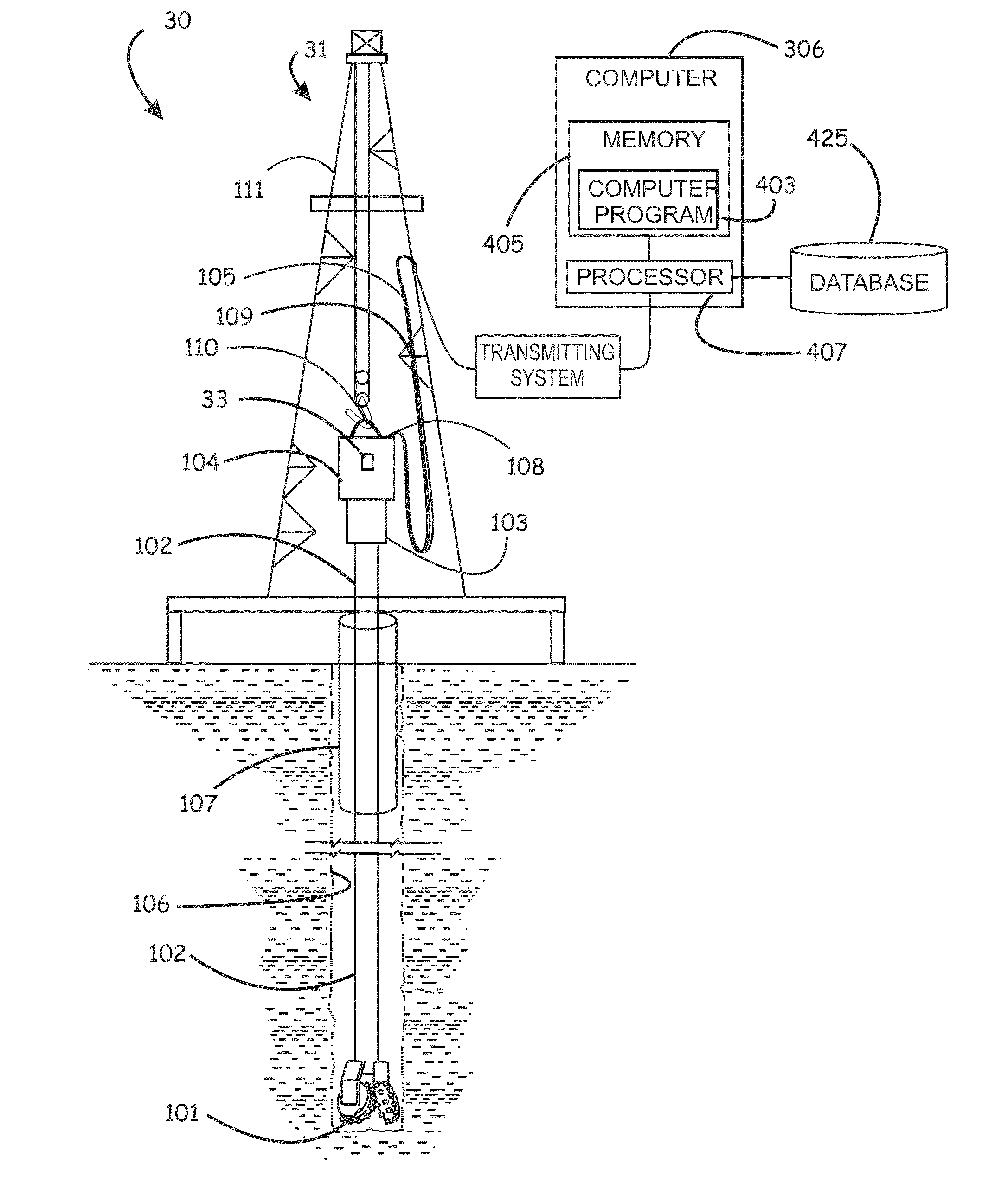

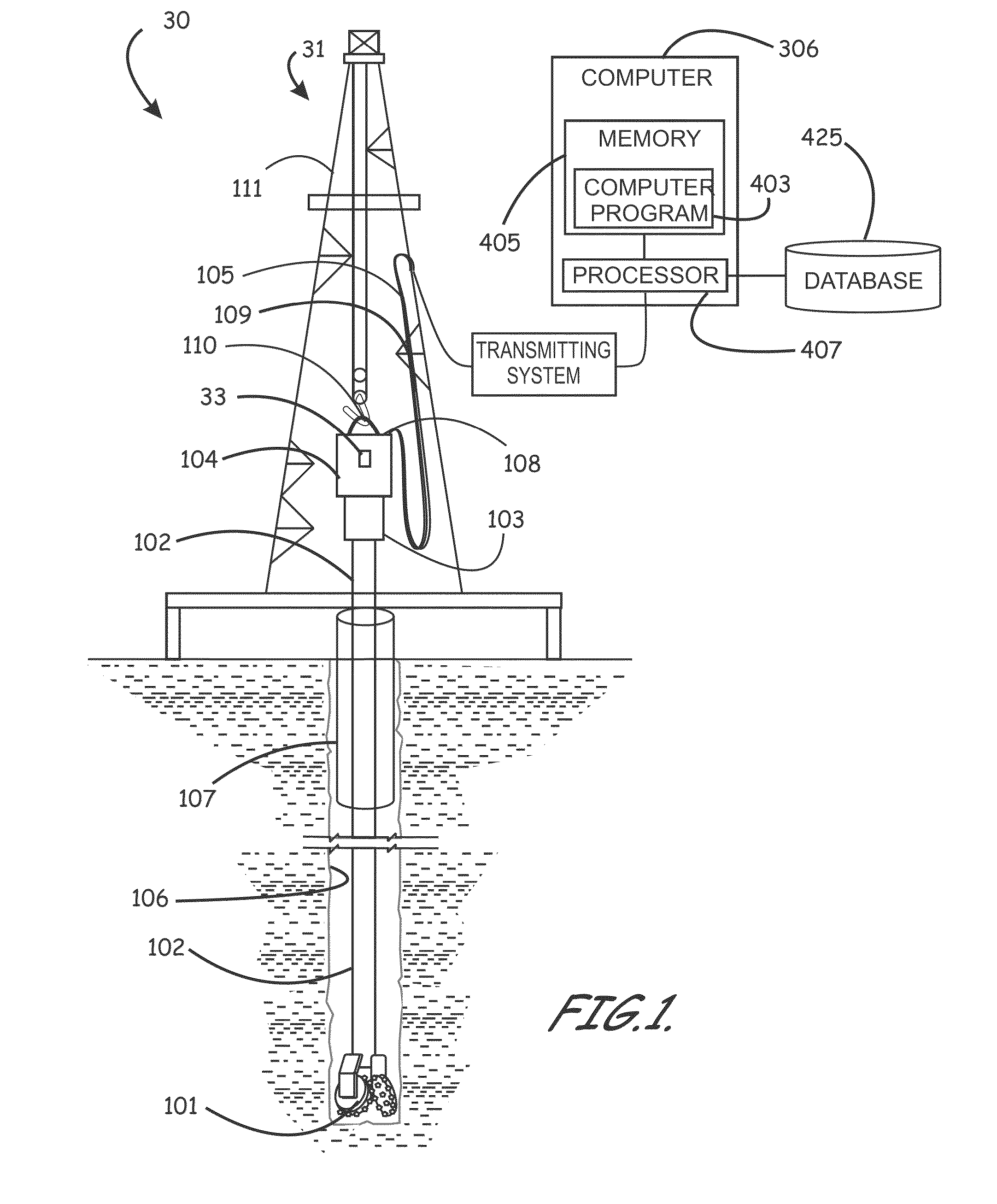

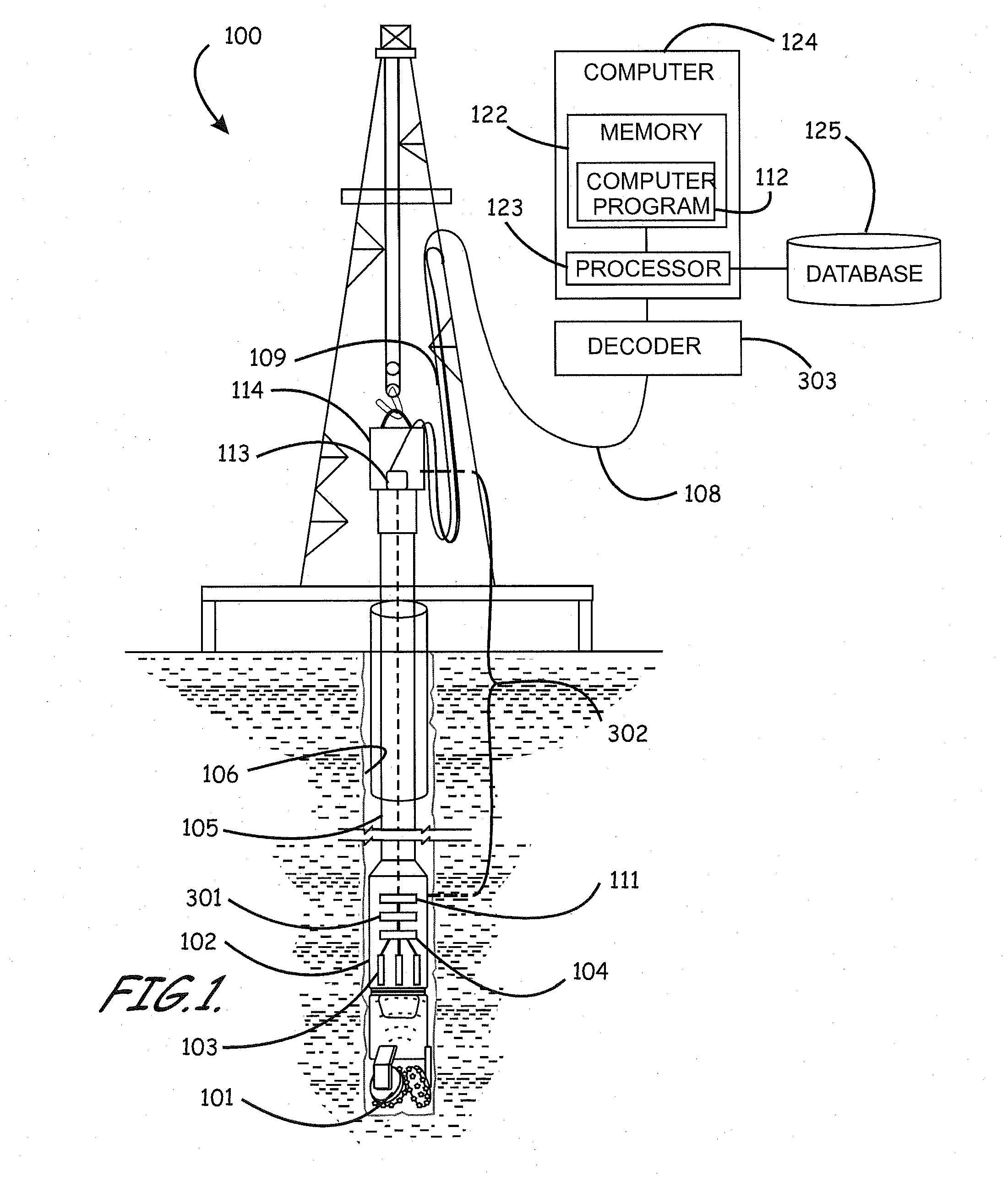

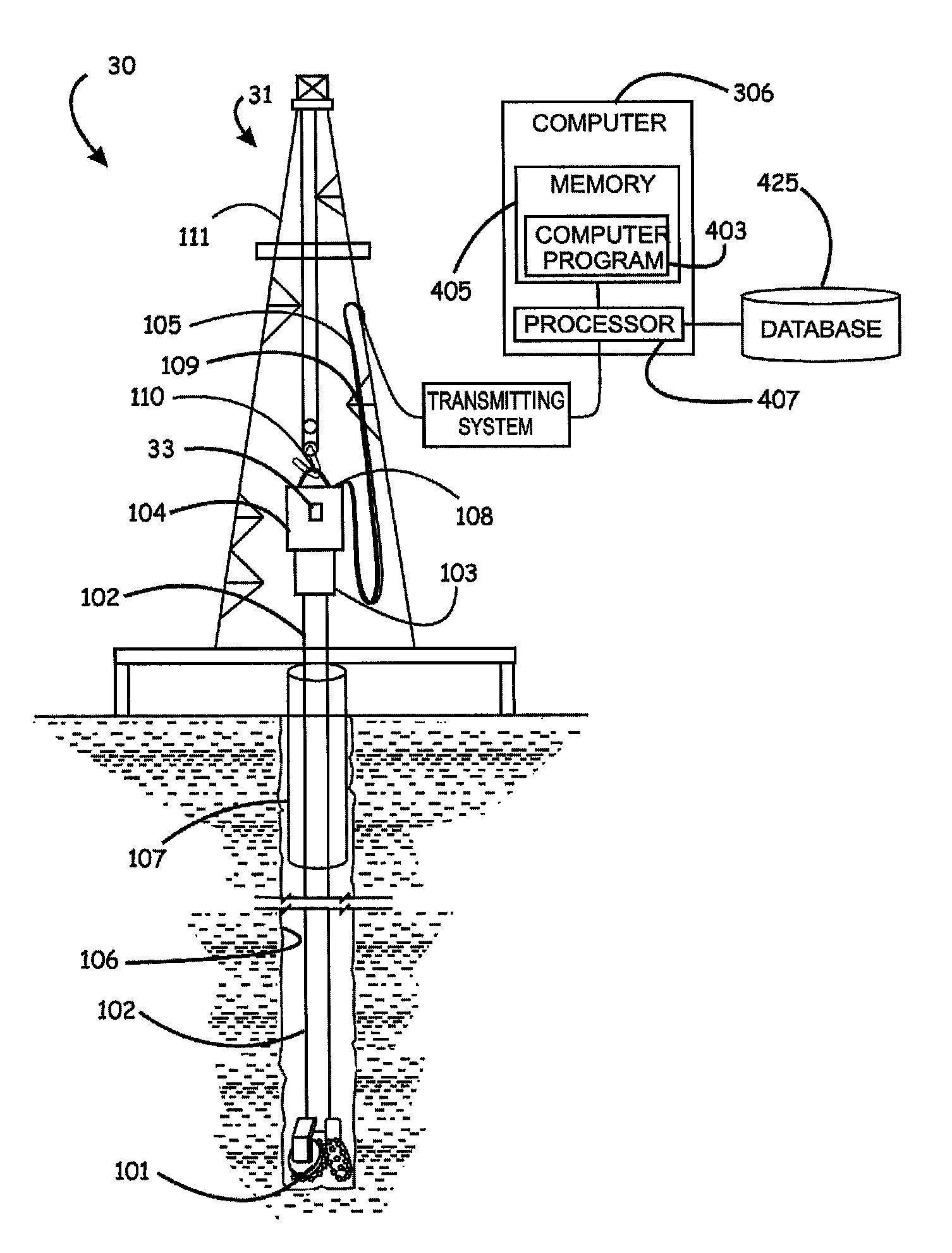

Apparatus for evaluating rock properties while drilling using drilling rig-mounted acoustic sensors

ActiveUS20130080060A1Drilling steeringEasy to produceElectric/magnetic detection for well-loggingSurveyLithologySystems analysis

Apparatus for identifying rock properties in real-time during drilling, are provided. An example of an embodiment of such an apparatus includes one or more acoustic sensors positioned to detect drill sounds emanating from the drill bit and the rock encountered during drilling operations, connected to select components of a drilling rig to maximally pick up the drill sounds of the drill bit engaging rock during drilling operations. The apparatus also includes an inductive telemetry, wireless telemetry, or wired transmitting system. The apparatus also includes a computer to analyze the acoustic signals received from the acoustic sensors through the respective transmitting system for lithology type and petrophysical properties.

Owner:SAUDI ARABIAN OIL CO

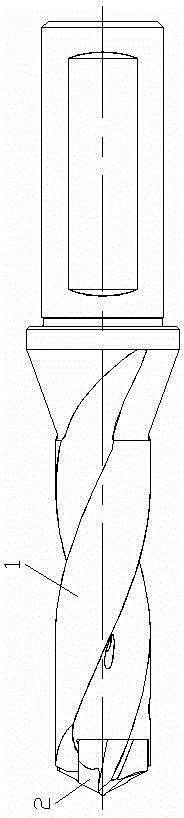

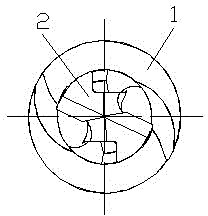

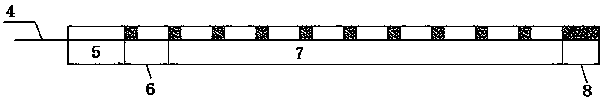

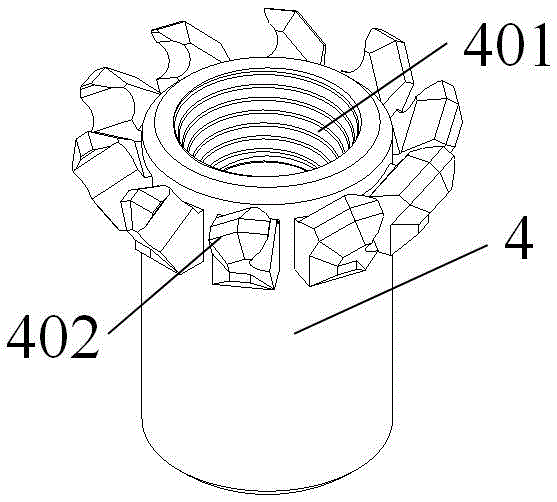

Drill bit of replaceable cutter head type structure

ActiveCN104907612AImprove installation accuracyGuaranteed stabilityTransportation and packagingCutting insertsEngineeringDrill bit

The invention discloses a drill bit of a replaceable cutter head type structure. Currently, a drill bit of a replaceable cutter head type structure high in machining accuracy, high in mounting accuracy and stable in rotating does not exist. The drill bit comprises a cutter rod, a cutter head and a fixing screw. The cutter rod comprises a cutter rod body. The drill bit is characterized in that a cutter head locating groove is formed in the front end of the cutter rod body, two supporting planes are arranged on the cutter head locating groove, after one supporting plane rotate around the axis of the cutter rod by 180 degrees, the supporting plane and the other supporting plane are overlapped, a locking groove is formed in a fixing column, the fixing column is arranged in a cutter head locating hole in a sleeved mode, a cutter head body is placed in the cutter head locating groove, the two supporting faces on the cutter head are tightly attached to the two supporting planes on the cutter rod respectively, the locating bottom face on the cutter head is tightly attached to the bottom of the cutter head locating groove, the fixing screw is in thread connection into a cutter head fixing hole, and the front end of the fixing screw abuts against the locking groove in the cutter head. The drill bit is high in machining accuracy, high in mounting accuracy, stable in rotating and stable in cutting, the cutter head can be abandoned, and service life is long.

Owner:ZHEJIANG XINXING TOOLS CO LTD

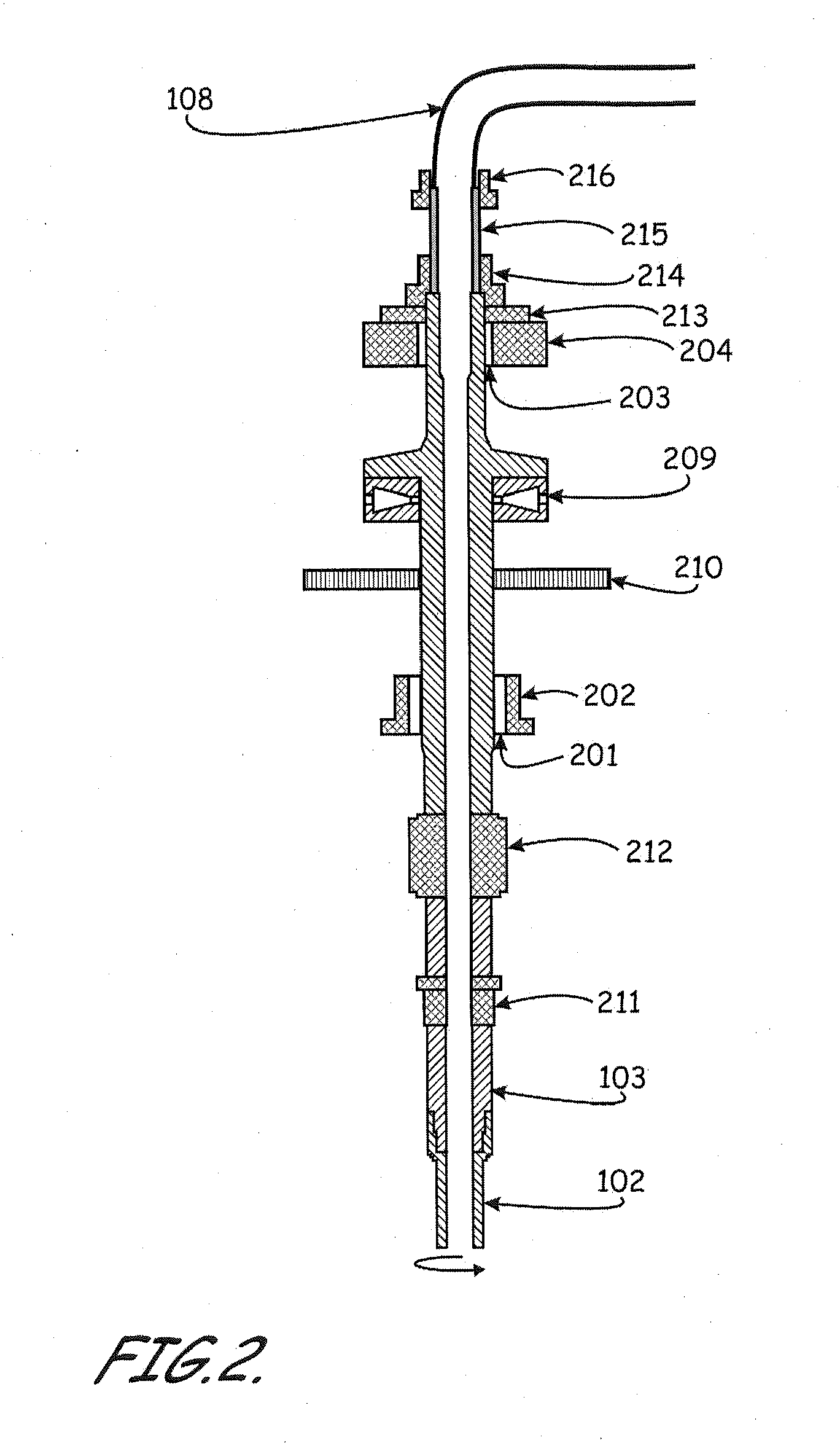

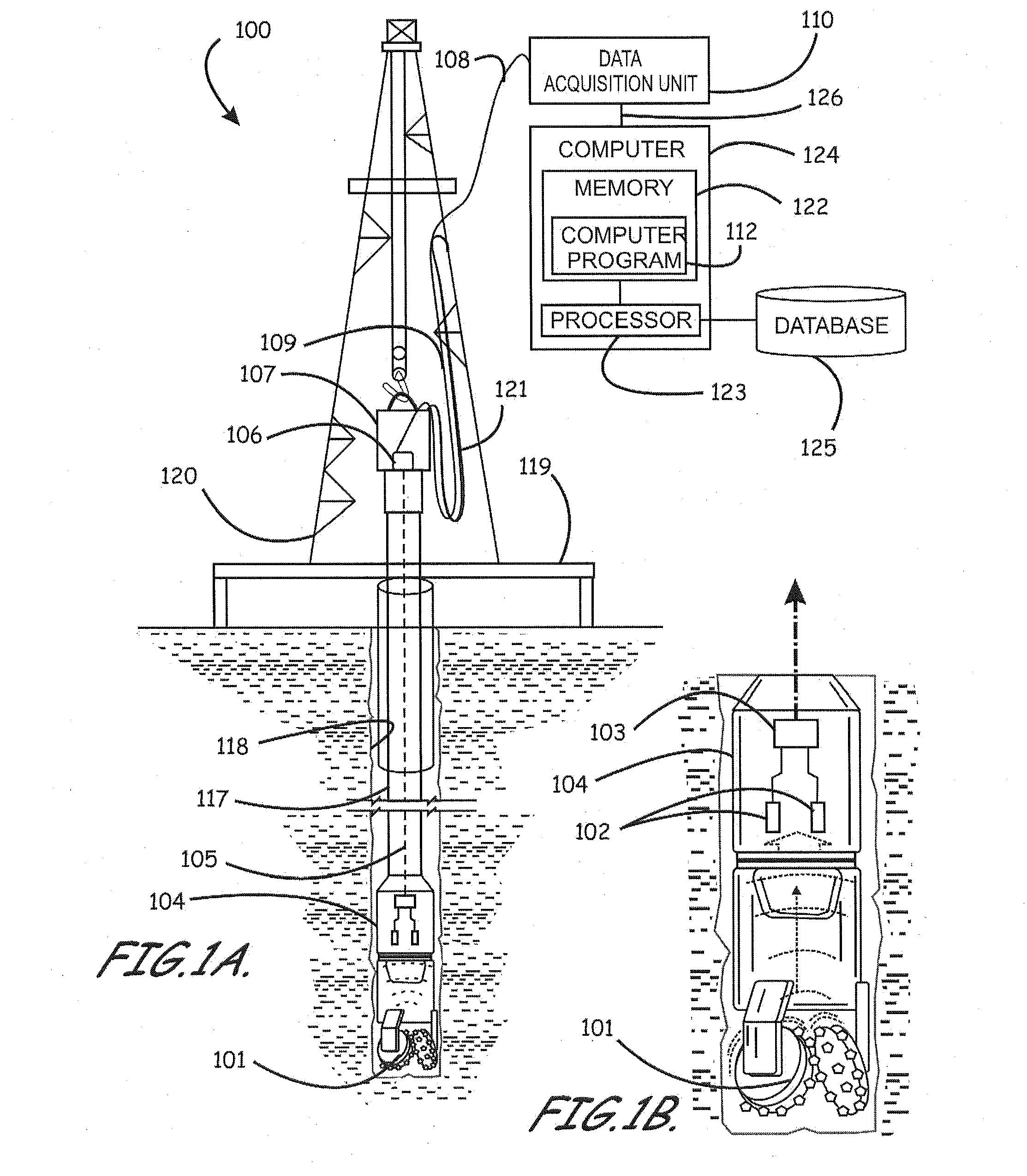

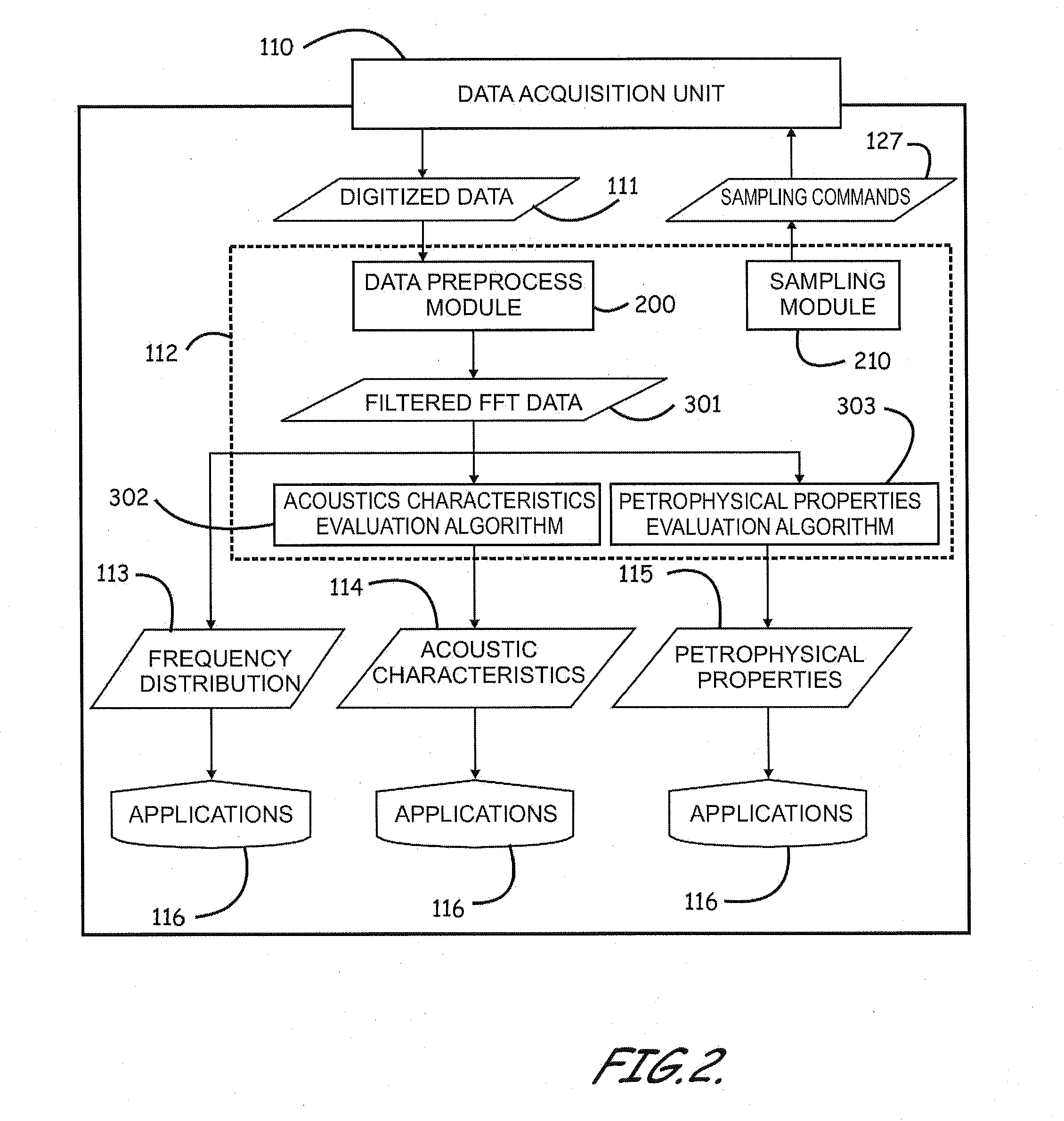

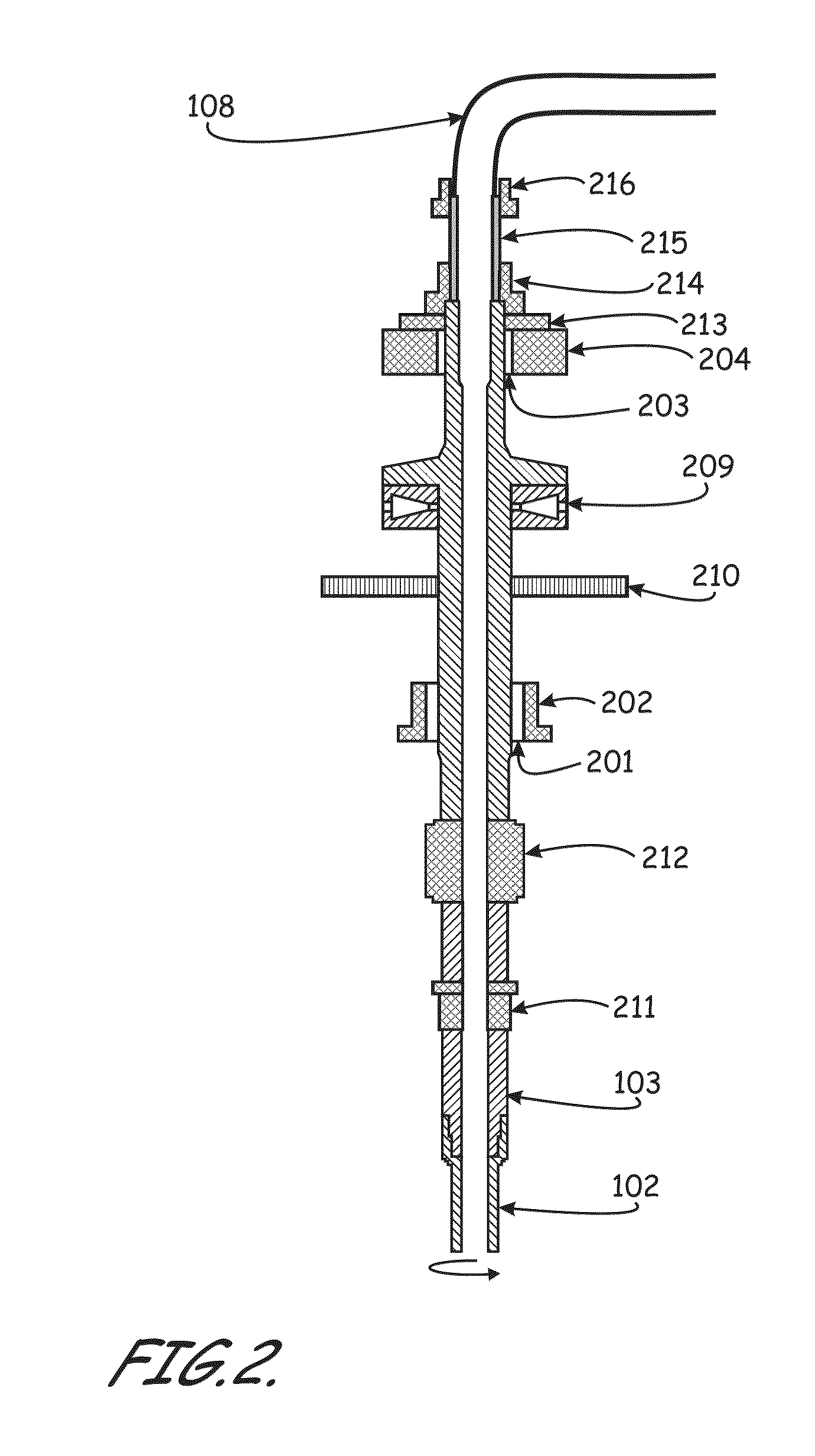

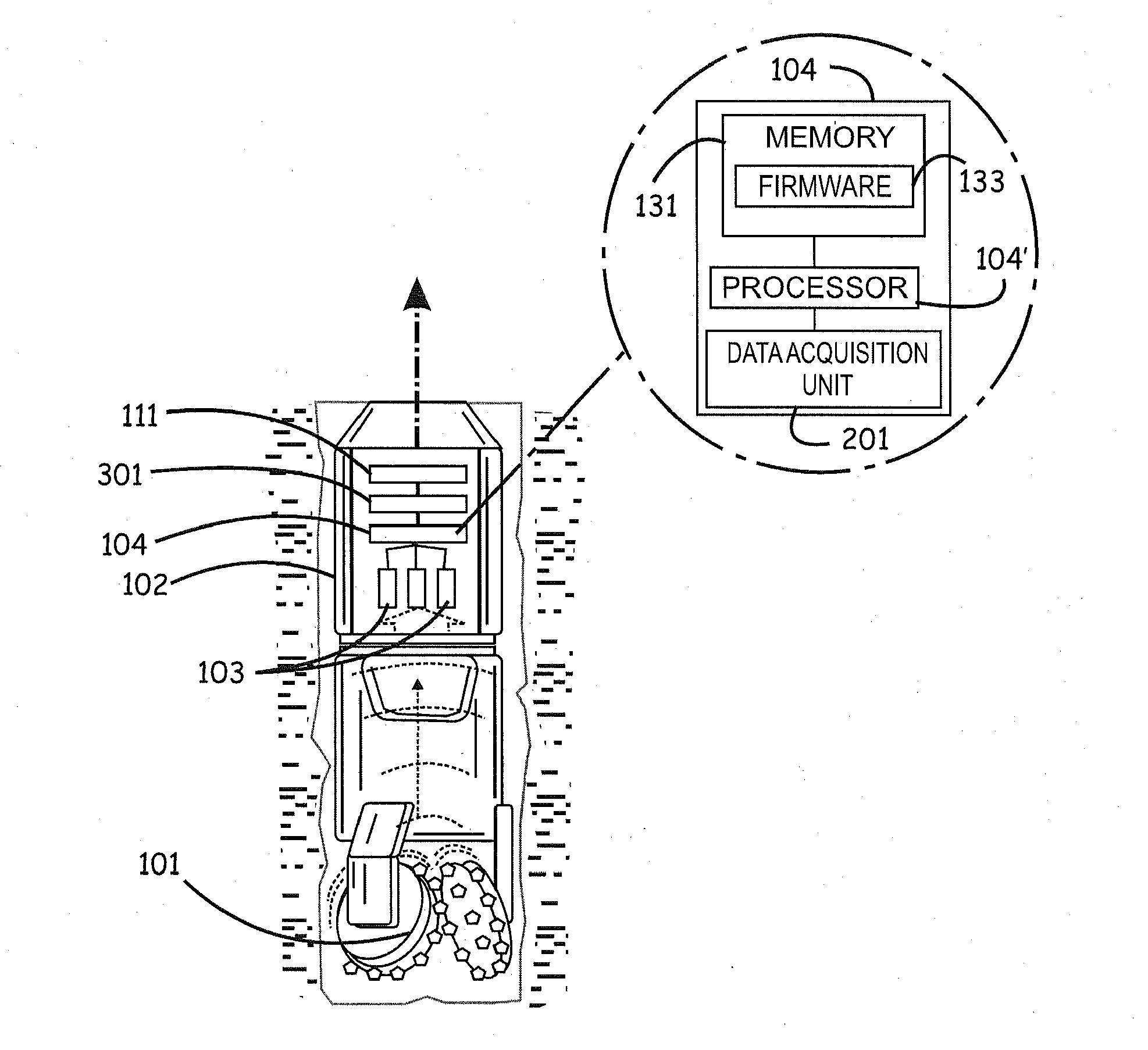

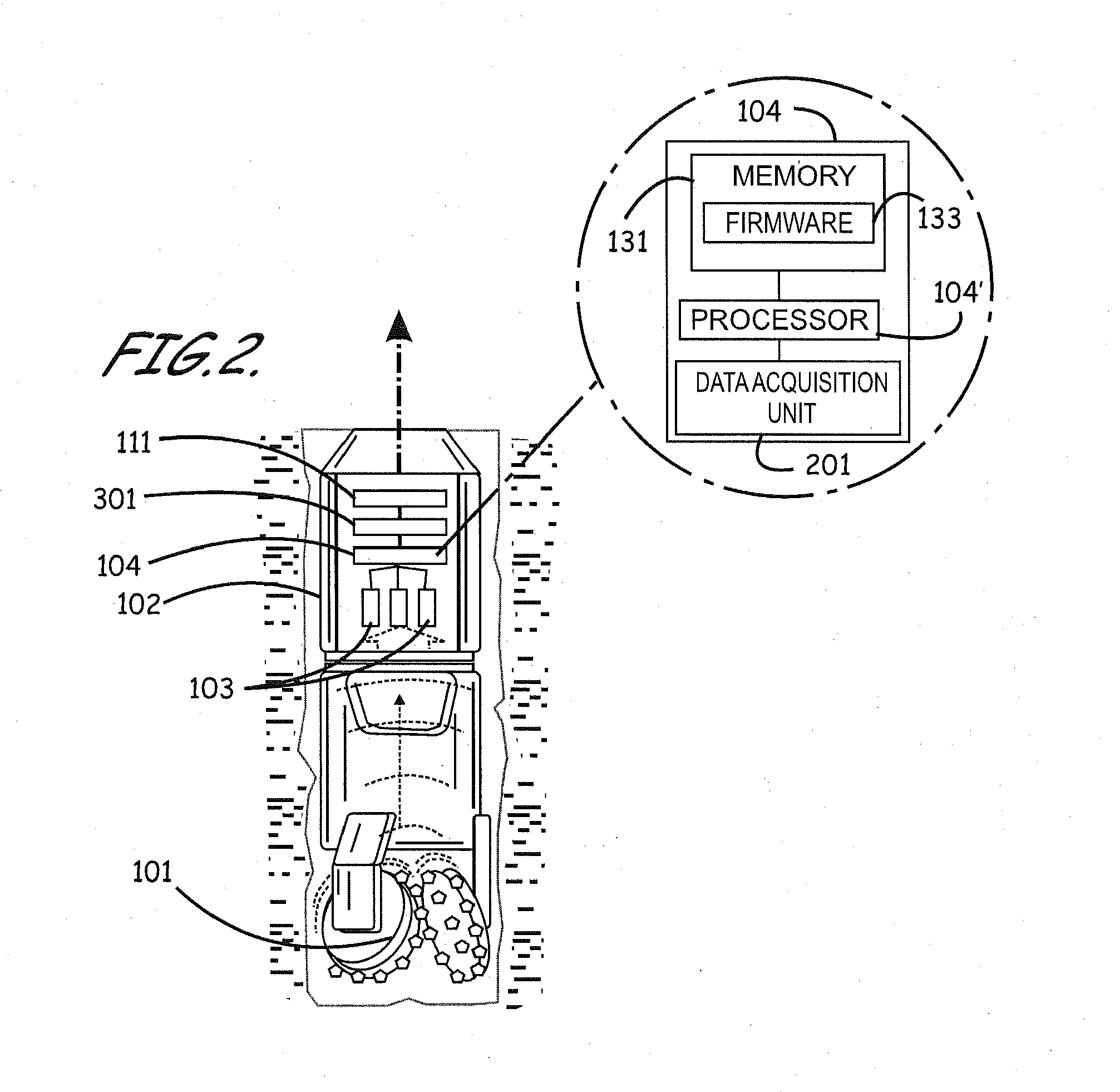

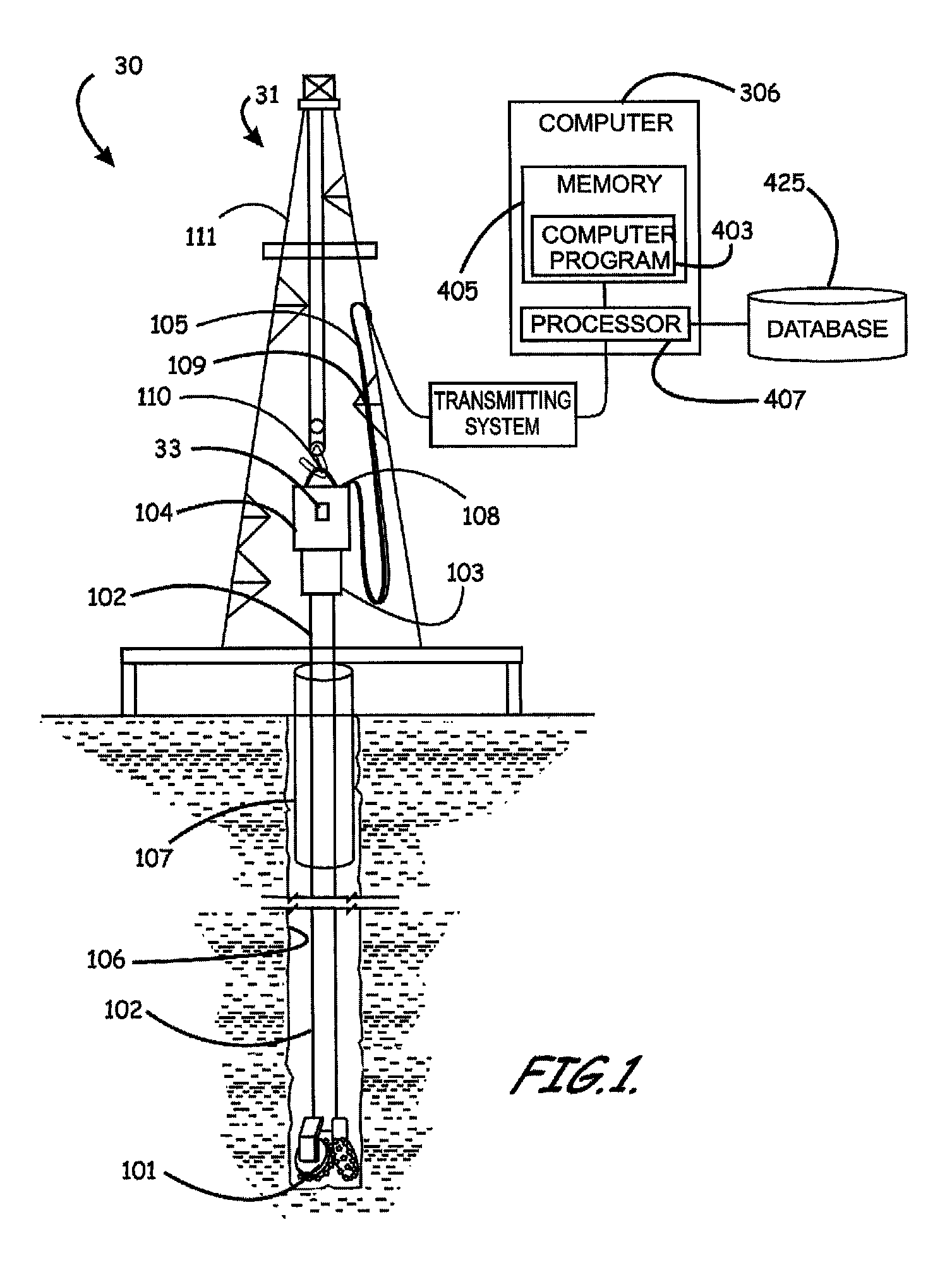

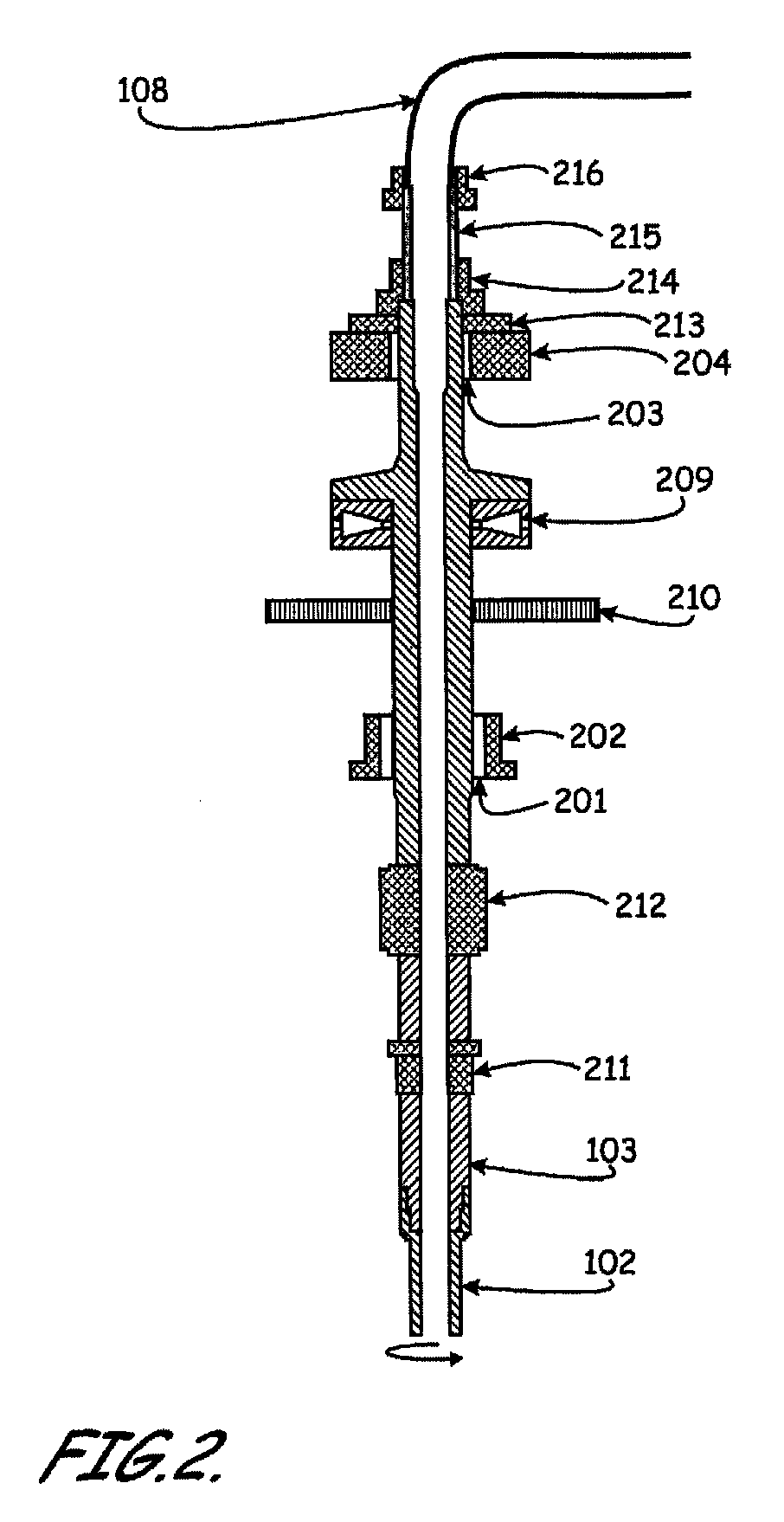

Apparatus, program product, and methods of evaluating rock properties while drilling using downhole acoustic sensors and a downhole broadband transmitting system

ActiveUS20130075160A1Improve steering performanceBetter drilling steeringSurveyDirectional drillingTransport systemWell drilling

Apparatus, computer readable medium, and program code for identifying rock properties in real-time during drilling, are provided. An example of an embodiment of such an apparatus includes a downhole sensor subassembly connected between a drill bit and a drill string, acoustic sensors operably coupled to a downhole data interface, and a surface computer operably coupled to the downhole data interface. The computer can include a petrophysical properties analyzing program configured or otherwise adapted to perform various operations including receiving raw acoustic sensor data generated real-time as a result of rotational contact of the drill bit with rock during drilling, transforming the raw acoustic sensor data into the frequency domain, filtering the transformed data, deriving a plurality of acoustic characteristics from the filtered data and deriving petrophysical properties from the filtered data utilizing a petrophysical properties evaluation algorithm employable to predict one or more petrophysical properties of rock undergoing drilling.

Owner:SAUDI ARABIAN OIL CO

Methods for evaluating rock properties while drilling using drilling rig-mounted acoustic sensors

ActiveUS20130075157A1Follow exactlyDrilling smoothlySurveyConstructionsWell drillingTelemetry Equipment

Methods for identifying rock properties in real-time during drilling, are provided. An example of an embodiment of such a method includes positioning one or more acoustic sensors to detect drill sounds emanating from the drill bit and the rock encountered during drilling operations, connecting the sensors to select components of a drilling rig to maximally pick up the drill sounds of the drill bit engaging rock during drilling operations. The method also includes providing and deploying an inductive telemetry, wireless telemetry, or wired transmitting system. The method also includes providing and configuring a computer to analyze the “raw” acoustic signals received from the acoustic sensors through the respective transmitting system.

Owner:SAUDI ARABIAN OIL CO

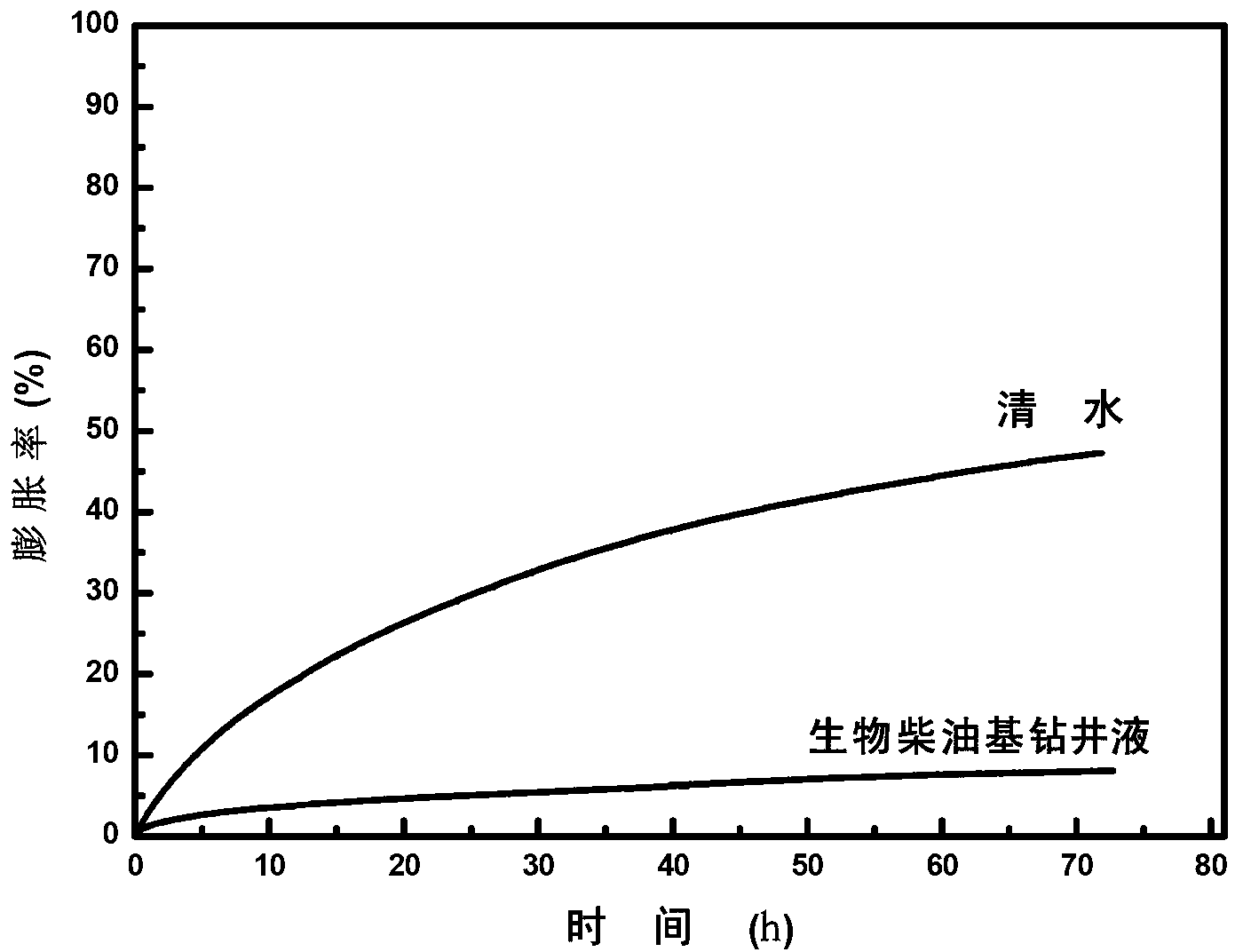

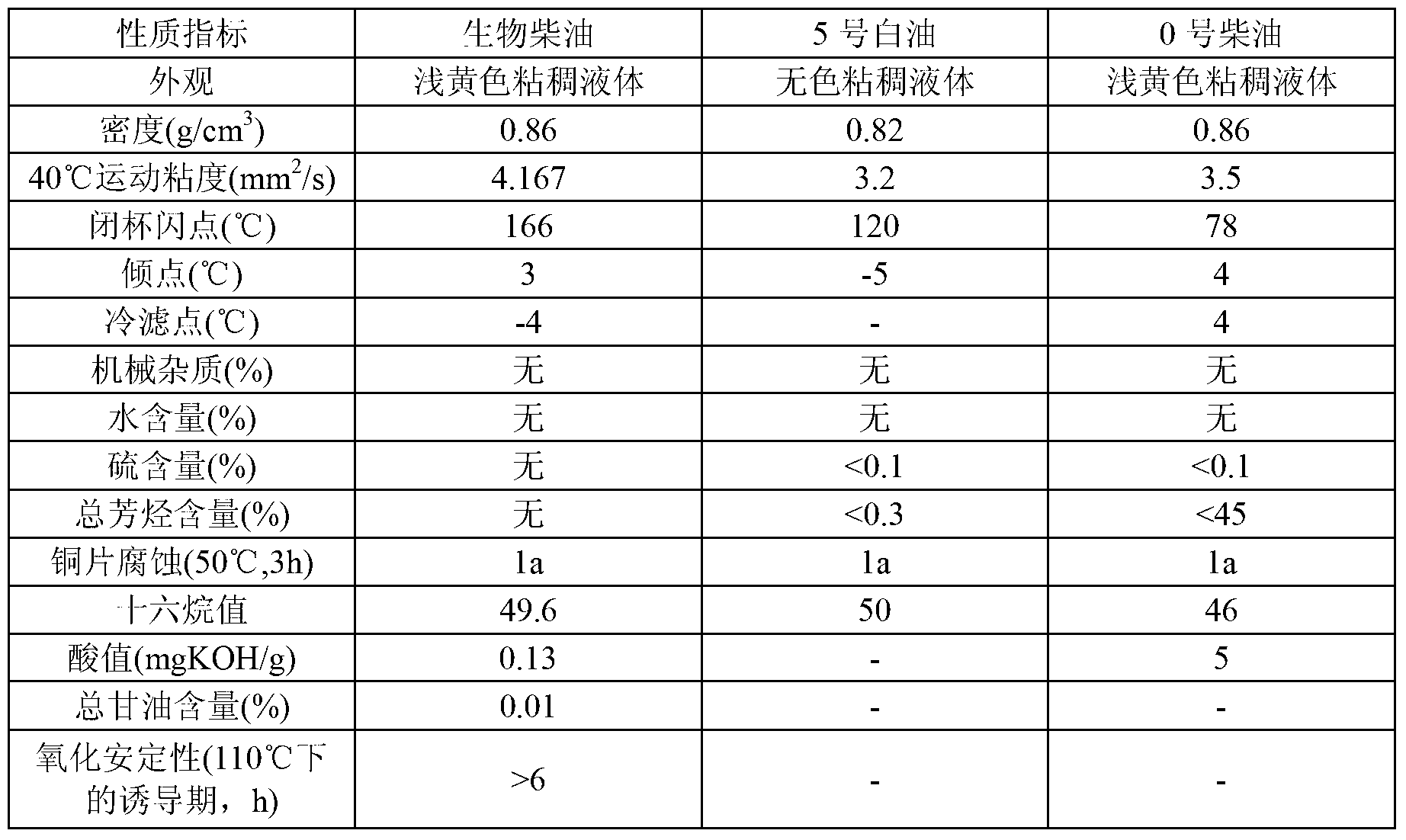

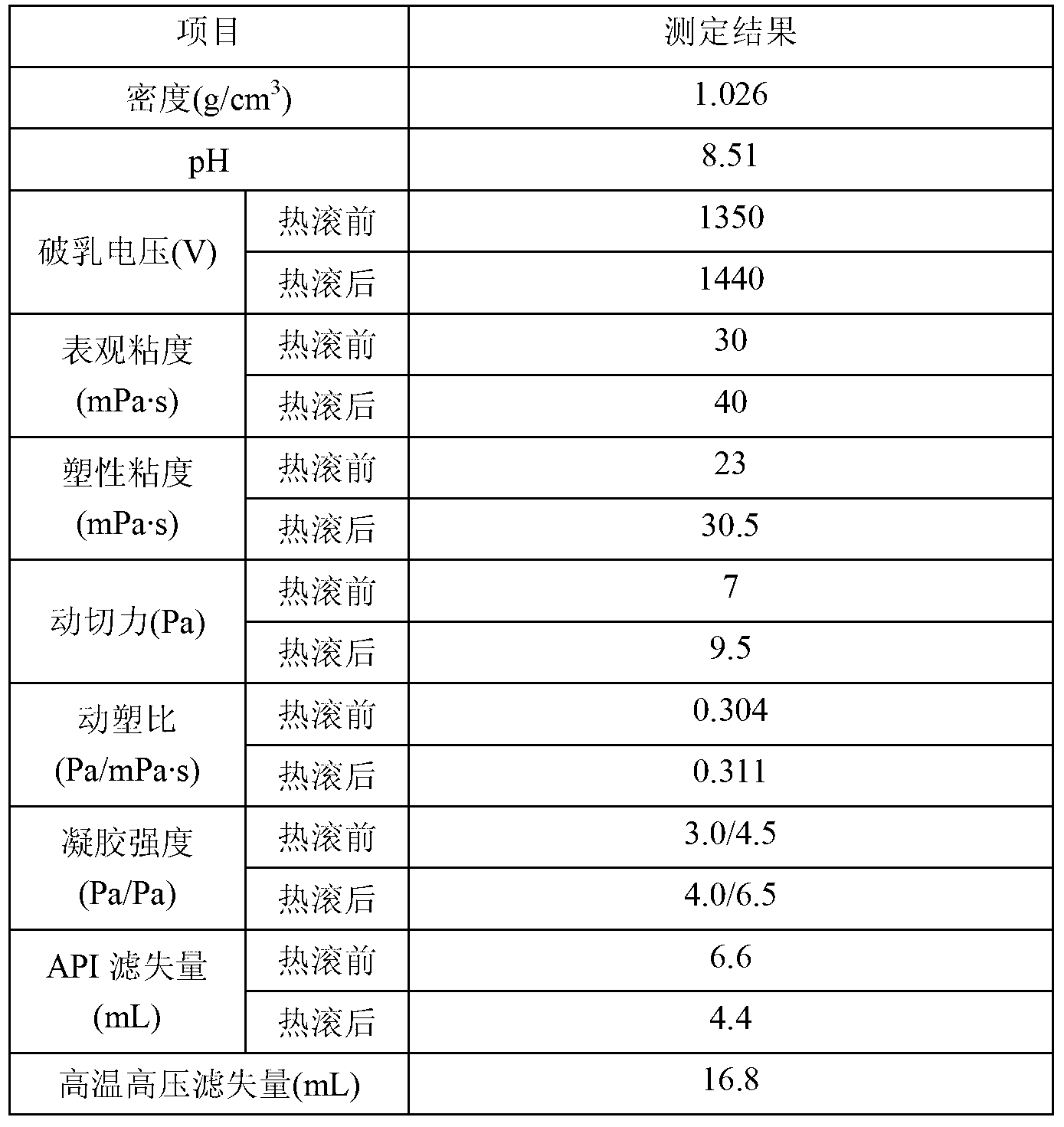

Water-in-oil-type biodiesel-based drilling fluid and preparation method thereof

ActiveCN103320104ASource requirements relaxedInhibit migrationDrilling compositionOil and greaseBiodiesel

The invention discloses a water-in-oil-type biodiesel-based drilling fluid and a preparation method thereof. The drilling fluid comprises the following components in parts by volume: 70 to 90 parts of biodiesel prepared by taking waste oils as a raw material, and 10 to 30 parts of calcium chloride aqueous solution. Based on the total volume of the biodiesel and the calcium chloride aqueous solution, the drilling fluid further comprises the following components in mass-volume ratio: 2% to 6% of calcium oxide, 1% to 6% of organic soil, 2% to 8% of emulsifier, 2% to 8% of wetting agent, 2% to 6% of filtrate reducer and 0% to 200% of weighting material. The drilling fluid disclosed by the invention has the characteristics of good operating performance, low cost, strong collapse-resisting inhibiting performance, excellent lubricating performance and excellent biological degradability.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

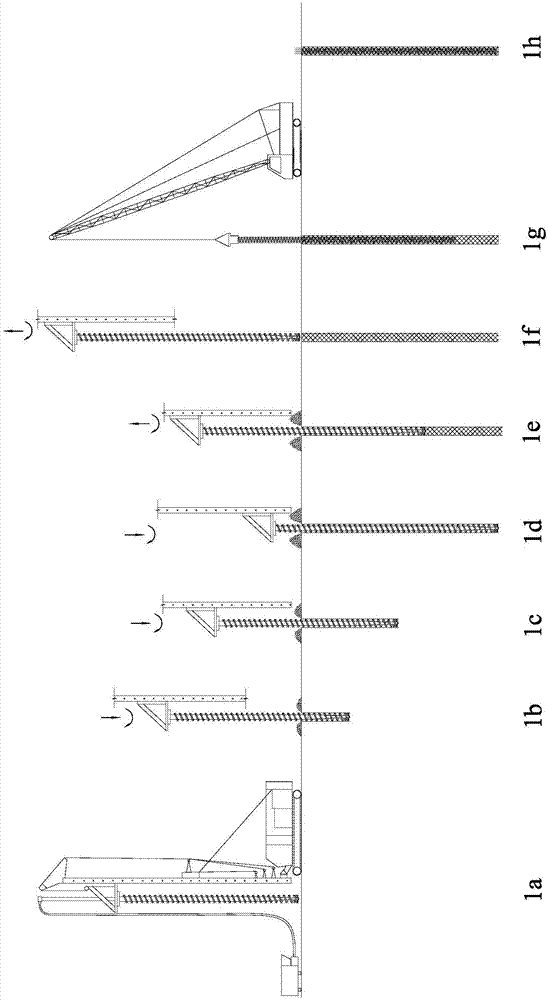

Method for machining slotted holes on carbon fiber laminated boards

The invention discloses a method for machining slotted holes on carbon fiber laminated boards, which belongs to a machining method for nonmetallic materials, solves the problem that by the existing milling and drilling methods, carbon fiber laminated boards are easy to laminate, split and burn, and aims at improving the machining precision of carbon fiber composite products and reducing the surface roughness of carbon fiber composite products. The method disclosed by the invention comprises a clamping step, a machining step and a post-processing step, wherein the machining step is one or two of a milling machining step and a drilling machining step. According to the invention, in the machining process, a non-deformed clamping mode is used, and through selecting reasonable cutting tool materials, geometric parameters of cutting tools, and milling and drilling machining parameters, the appearance allowances in machining are reasonably arranged, thereby solving the quality problems of laminating, splitting and burning and the like existing in the process of opening or drilling carbon fiber thin-wall revolution bodies and carbon fiber laminated boards by using the traditional methods, so that the qualified rate of carbon fiber parts is increased from 50% to more than 99%.

Owner:HUBEI SANJIANG AEROSPACE GRP HONGYANG ELECTROMECHANICAL

Apparatus, computer readable medium, and program code for evaluating rock properties while drilling using downhole acoustic sensors and telemetry system

ActiveUS20130080065A1Improve steering performanceFollow exactlyElectric/magnetic detection for well-loggingSurveyEngineeringAcoustic property

Apparatus, computer readable medium, and program code for identifying rock properties in real-time during drilling, are provided. An example of an embodiment of such an apparatus includes a downhole sensor subassembly connected between a drill bit and a drill string, acoustic sensors operably coupled to a downhole processor, a borehole telemetry system, downhole and surface data transmitting interfaces, and a surface computer operably coupled to the downhole data transmitting interface. The downhole processor is adapted to perform operations including receiving raw acoustic sensor data resulting from rotational contact of the drill bit with rock, transforming the raw acoustic sensor data into the frequency domain, filtering the transformed data, and deriving acoustic characteristics from the filtered data. The surface computer is adapted to perform operations including deriving petrophysical properties from the acoustic characteristics directly or by utilizing a petrophysical properties evaluation algorithm.

Owner:SAUDI ARABIAN OIL CO

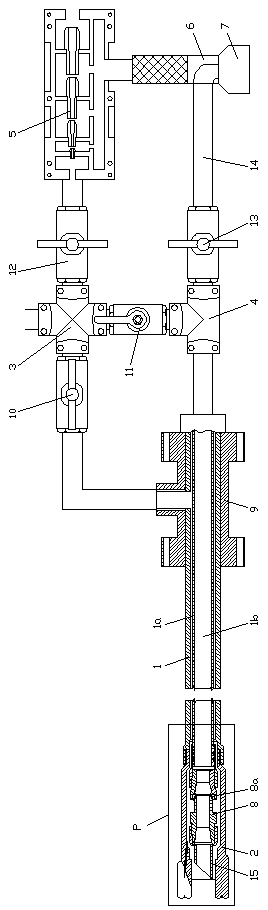

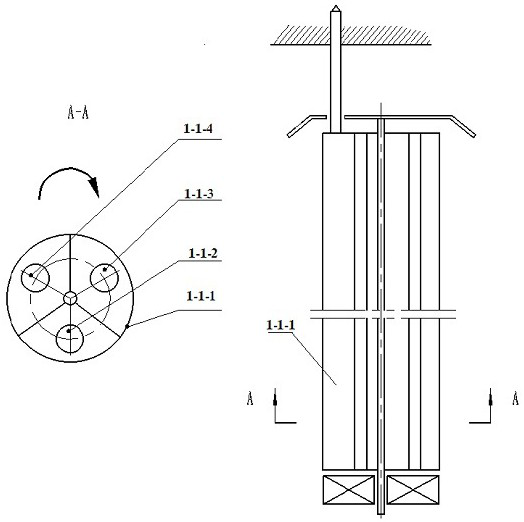

Positive and negative pressure combined plug flow fixed-point sampling device

ActiveCN102798548AMove fastDrilling smoothlyWithdrawing sample devicesPreparing sample for investigationGas solidDouble wall

The invention discloses a positive and negative pressure combined plug flow fixed-point sampling device, which includes a double-wall drill rod, a drill bit, a four-way connector, a three-way connector, a negative pressure generator, a gas-solid gravity separator and a sample collection tank, as well as an annular nozzle ejector disposed in the drill bit. The rear end of the double-wall drill rod is sleeved with a two-channel faucet on the outside. The first channel of the two-channel faucet is connected to a first interface of the four-way connector, and the second channel of the two-channel faucet is connected to a first interface of the three-way connector. The second interface of the four-way connector is communicated with the second interface of the three-way connector. The third interface of the four-way connector is connected to the first air inlet of the negative pressure generator. During sampling, a material plug with a section of a sample and a section of compressed air is formed in a double-wall drill rod in-inner wall channel, and has small motion resistance in the double-wall drill rod in-inner wall channel. Driven by a negative pressure, the sample moves fast, and the sampling work has high efficiency. No plugging or drilling is needed in a sampling process, and the process is simple. Sampling can be performed at any drilling point, thus realizing fixed-point sampling.

Owner:CHINA COAL TECH & ENG GRP CHONGQING RES INST CO LTD

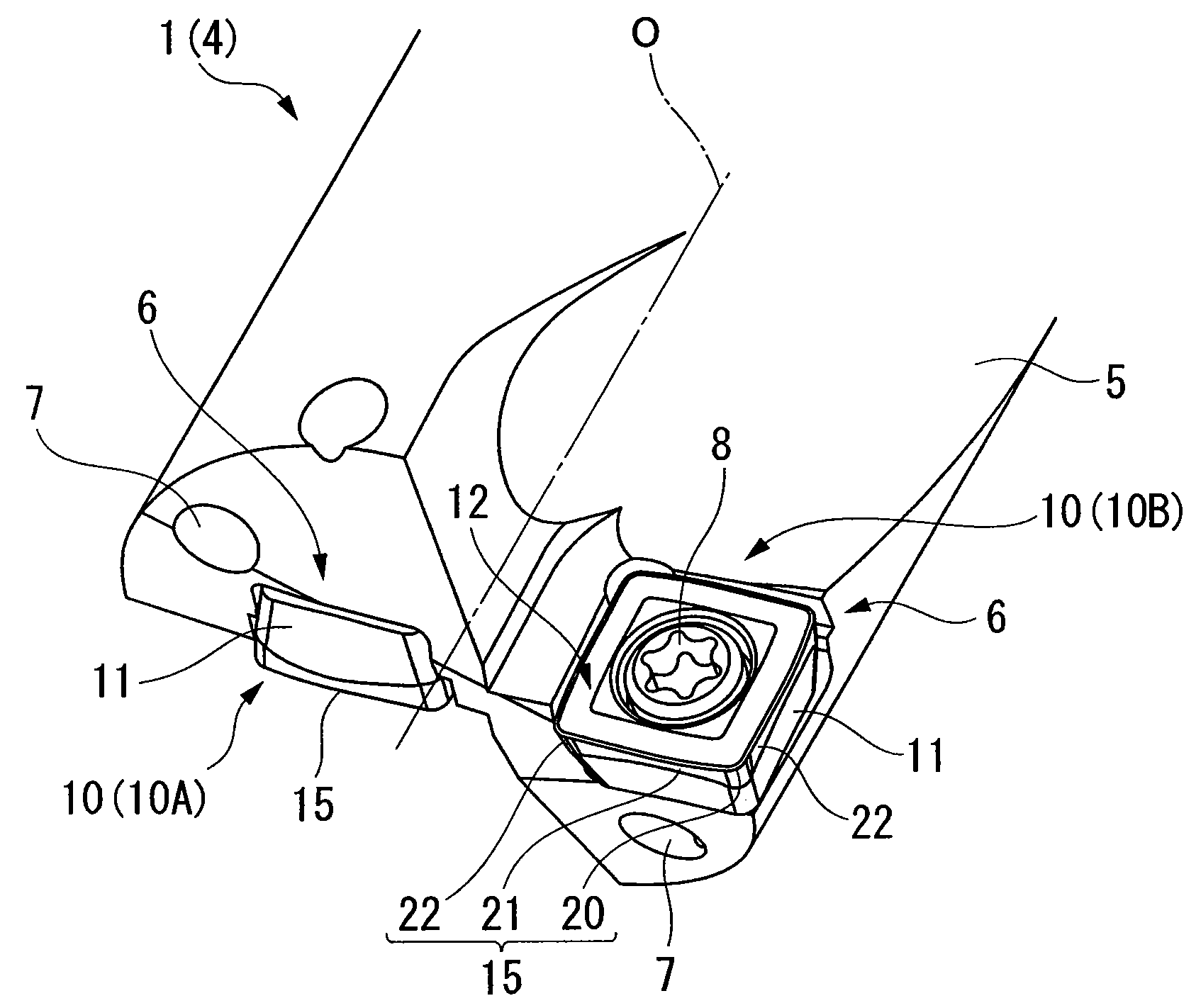

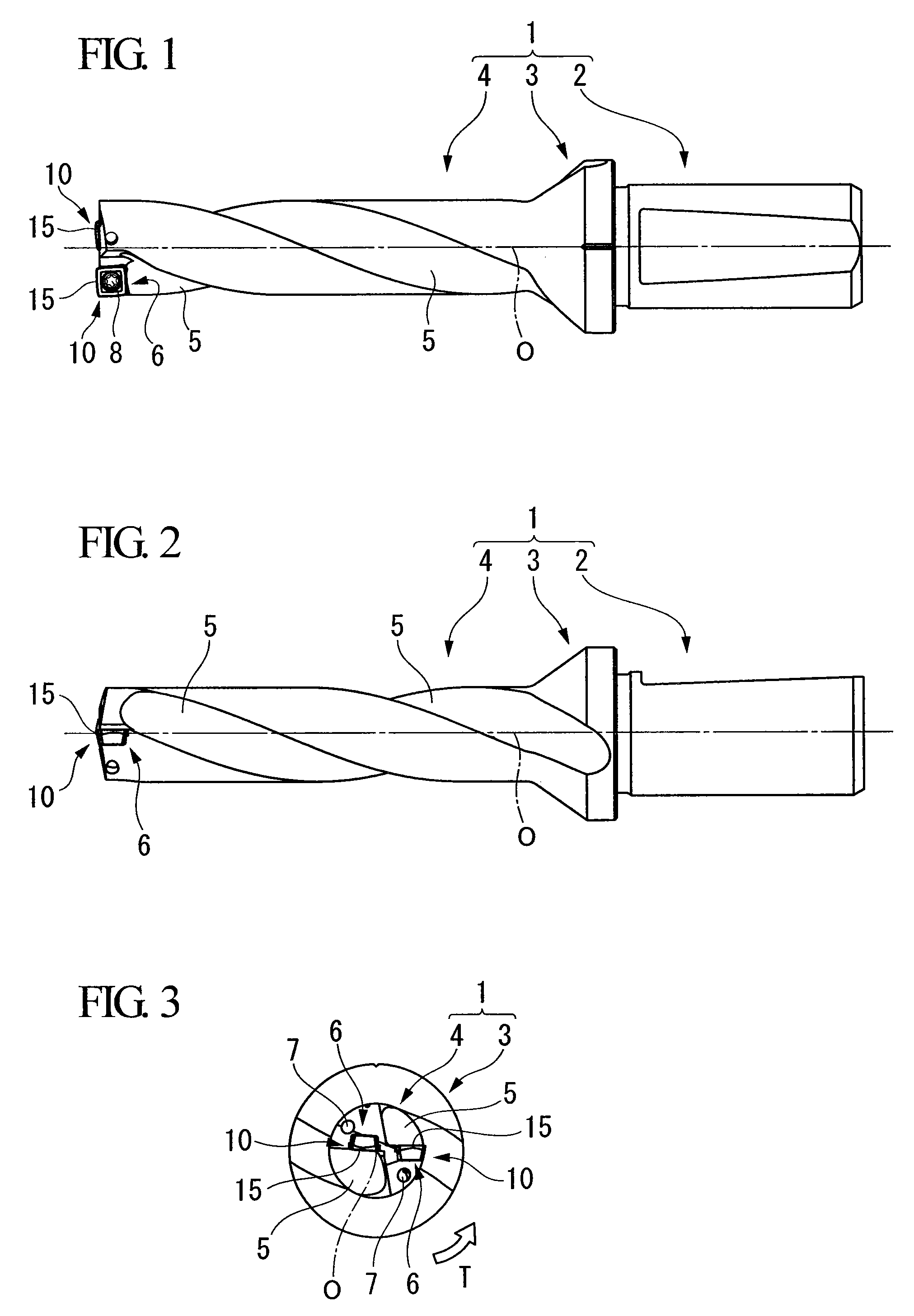

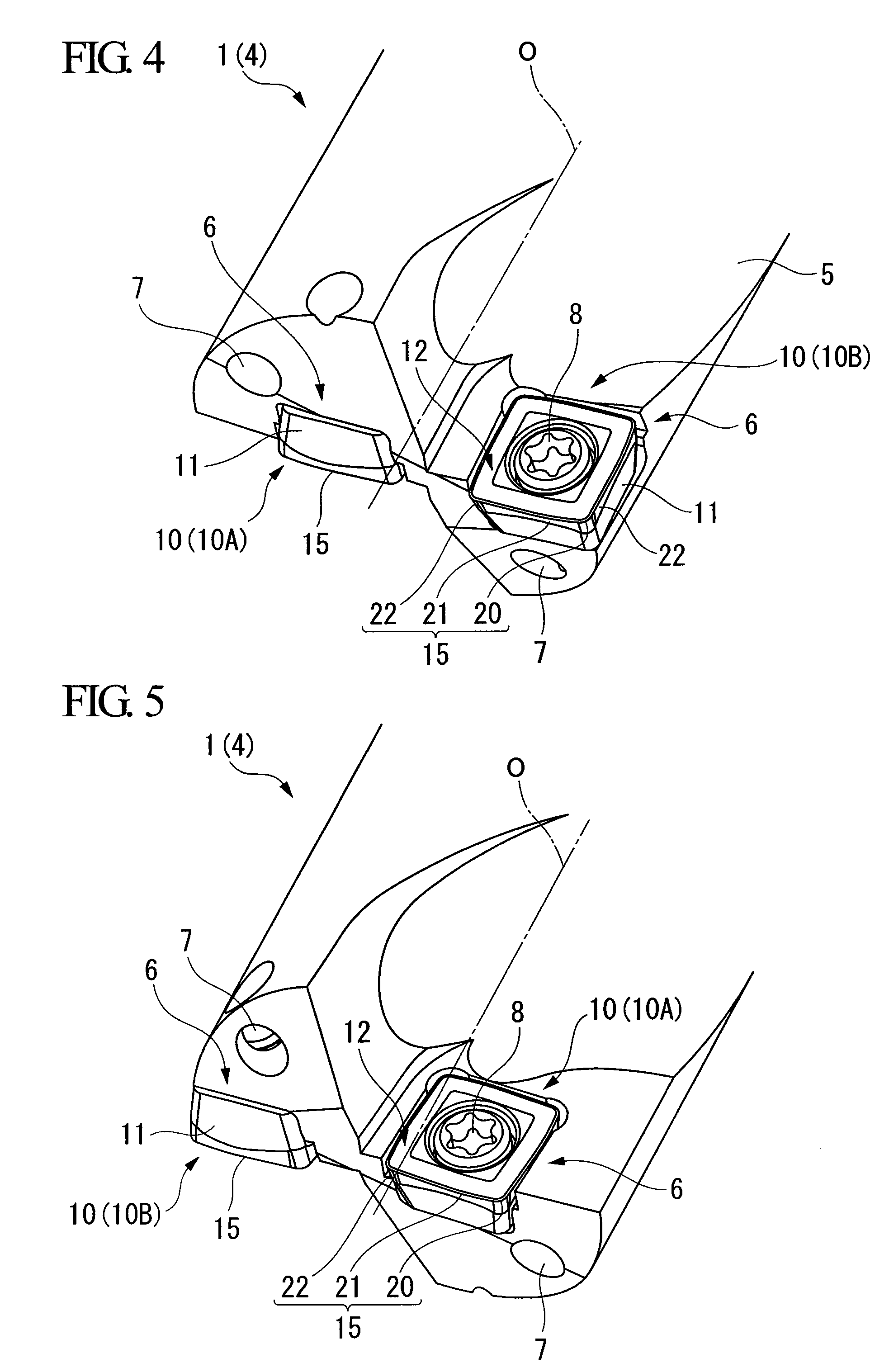

Insert for drill and indexable insert drill

ActiveUS20090245949A1Improve surface qualityHigh concentricityTransportation and packagingCutting insertsCurve shapeEngineering

An insert for a drill in which one of the cutting edges respectively formed at four side ridge portions of a rake face of a square flat plate-shaped insert body is made to protrude toward the tip of the drill body of the indexable insert drill while being detachably attached is provided. Each of the cutting edges has a corner cutting edge located at a corner of the rake face, and a major cutting edge and a wiper edge which extend substantially toward one peripheral direction of the rake face from a corner cutting edge. The major cutting edge has a first major cutting edge portion which has a convexly curved shape and extends from the corner cutting edge, and a second major cutting edge portion which smoothly touches the first major cutting edge portion and extends linearly, as seen from a direction facing the rake face. The wiper edge has a straight shape intersecting the second major cutting edge portion at an obtuse angle.

Owner:MITSUBISHI MATERIALS CORP

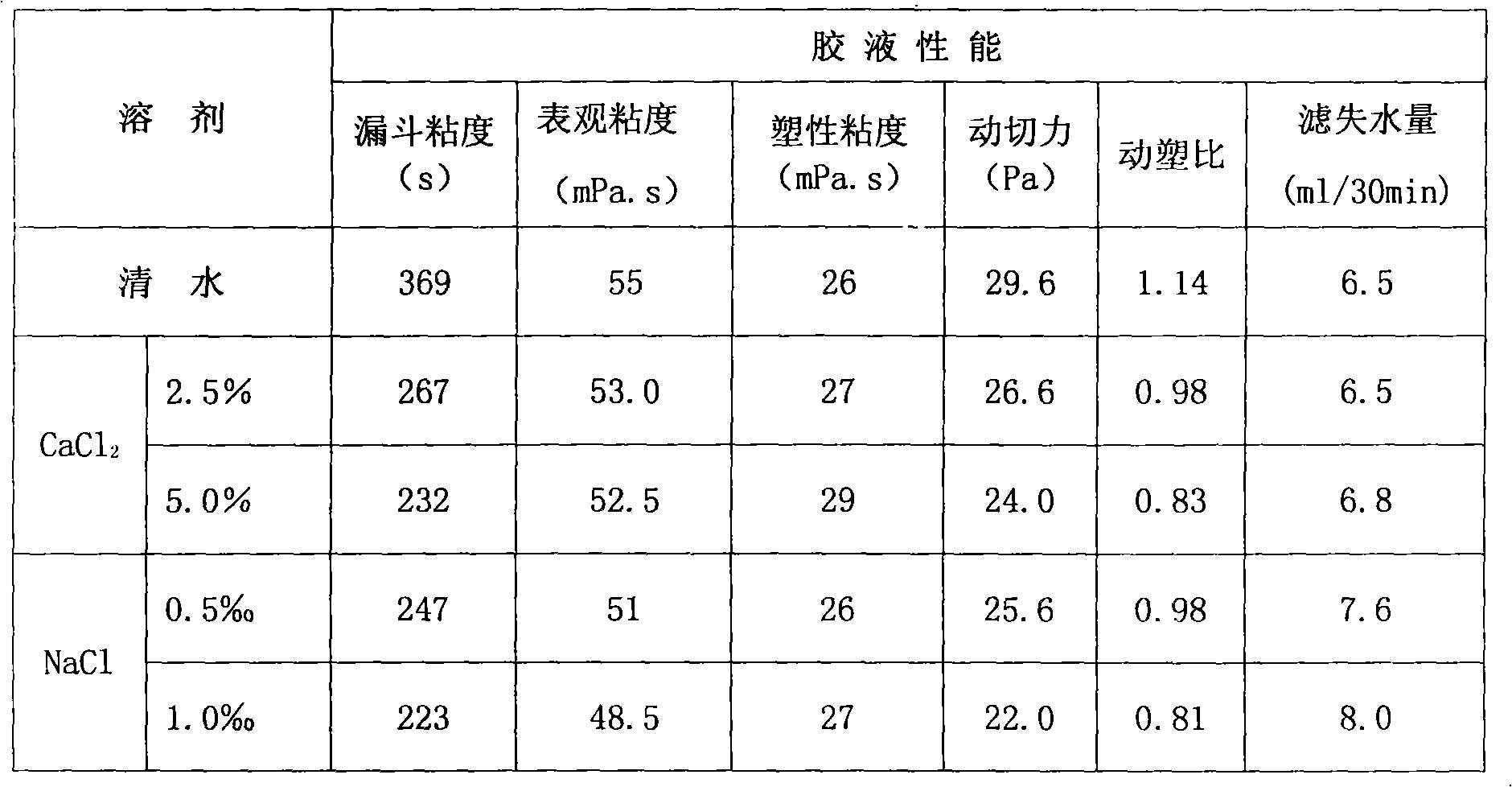

Slurry in use for directional drilling into drifting sand layer in horizontal

A slurry used for running sand layer of horizontal positioned drilling is prepared from alta-mud, collapse-proof agent, polyacrylamide, dehydration reducing agnet, sulphonating Arcolite, lubricant and water. The prepared slurry can prevent drilled hole from collapse and driller from seizing-up in course of horizontal positioned drilling.

Owner:大庆油田建设集团

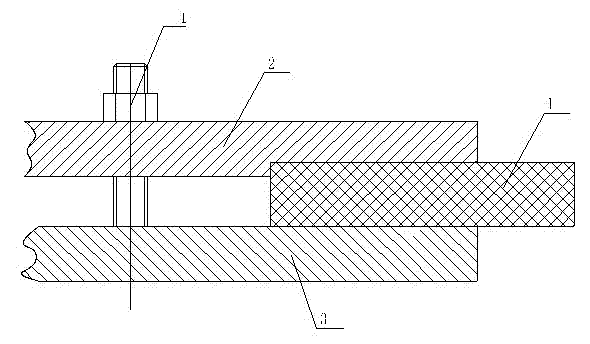

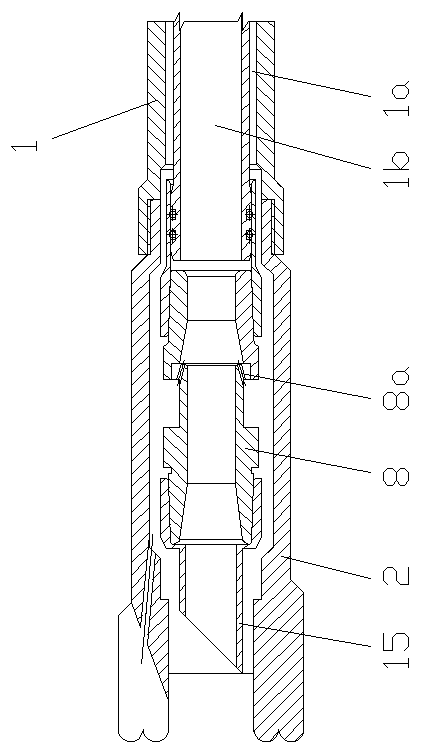

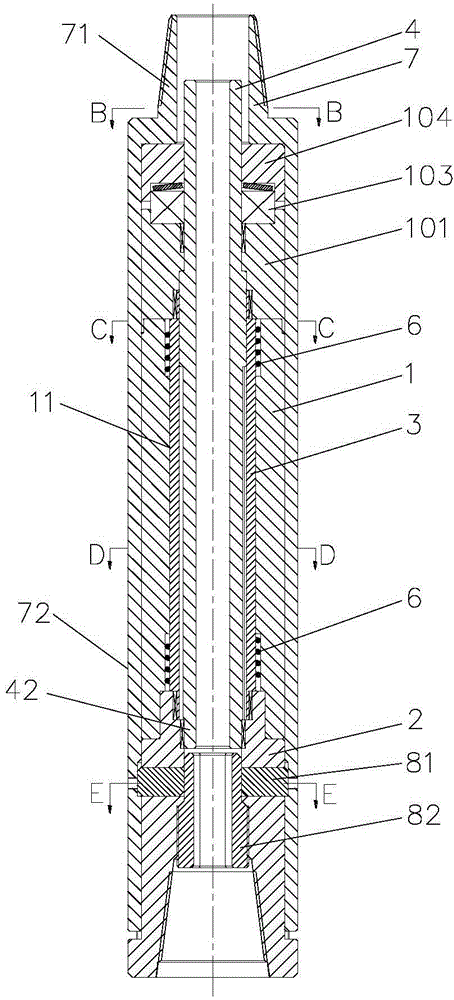

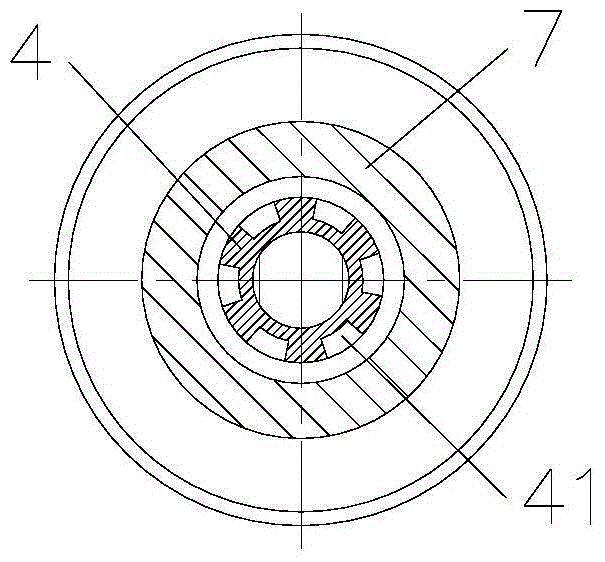

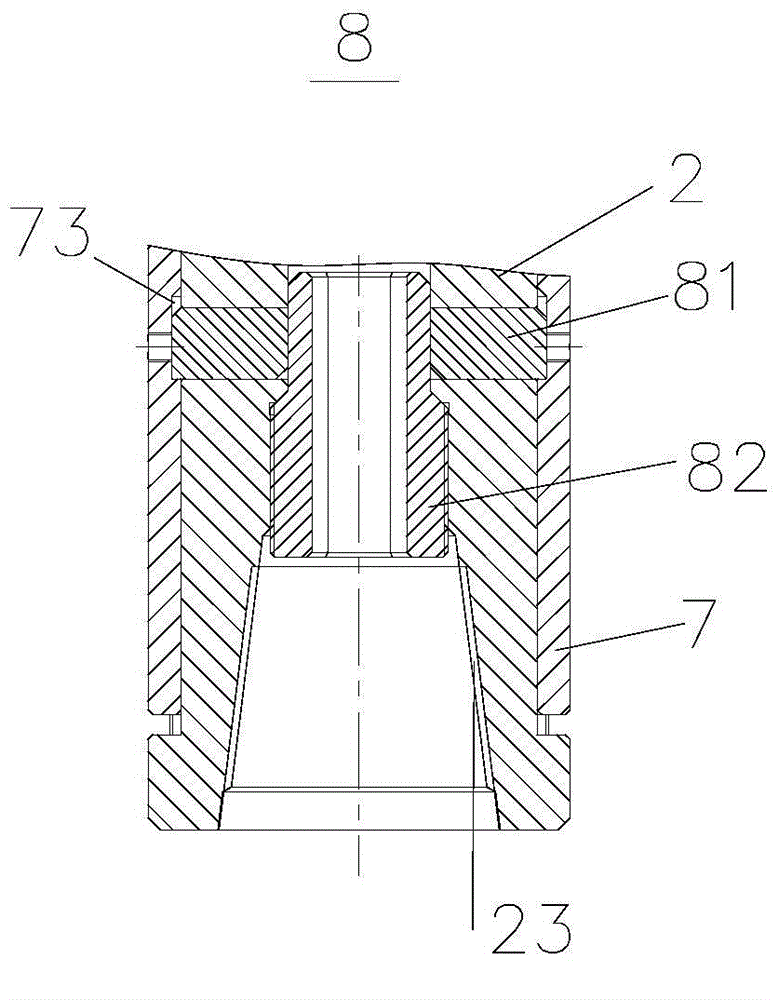

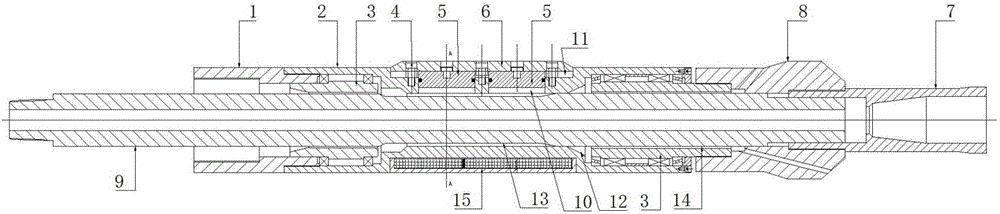

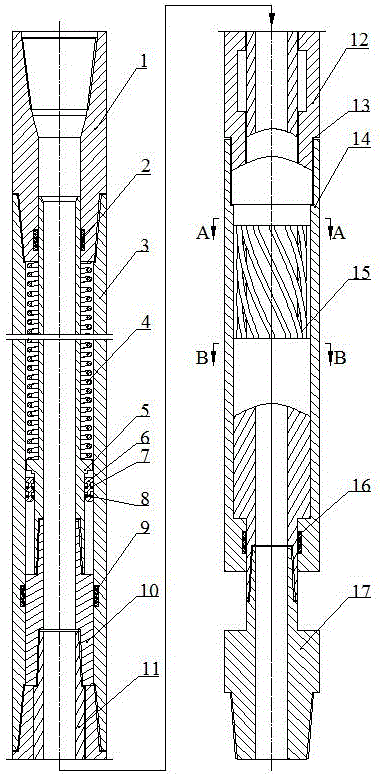

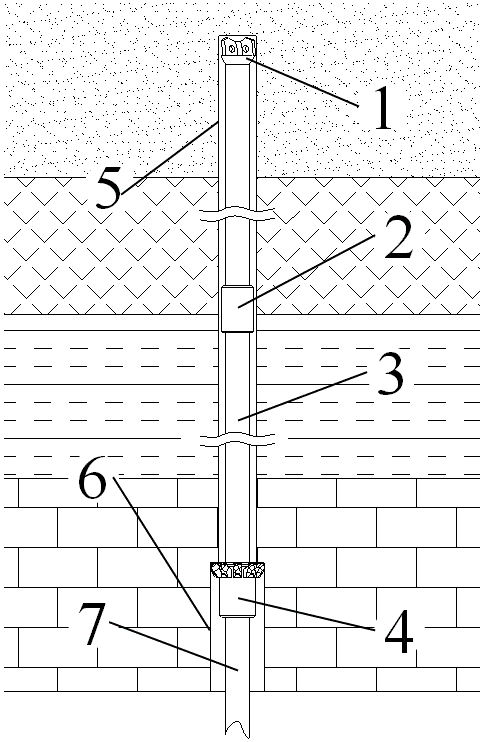

Rotary tail pipe hanger capable of respectively drilling and completing

ActiveCN101358512ADrilling smoothlySitting and Hanging RealizationBorehole/well accessoriesWell cementingOperational safety

The invention relates to a rotating tail tube suspending device which can respectively carry out drilling and well completion and mainly solves the problems that the existing tail tube suspending device can not participate in drilling and can not accomplish well cementing under the condition of rotating the tail tube. The invention is characterized by consisting of a hollow stopper mechanism, a sitting-suspending mechanism, a sitting-sealing mechanism and a feed mechanism. When operating, the tail tube suspending device not only can participate in drilling, but also can carry out rotating well cementing; besides, the tail tube suspending device can be independently used as the well completion tool of the rotating tail tube suspending device under a rotating condition and has the characteristics of reliable drilling, safe operation and excellent well cementing quality.

Owner:DAQING PETROLEUM ADMINISTRATION +1

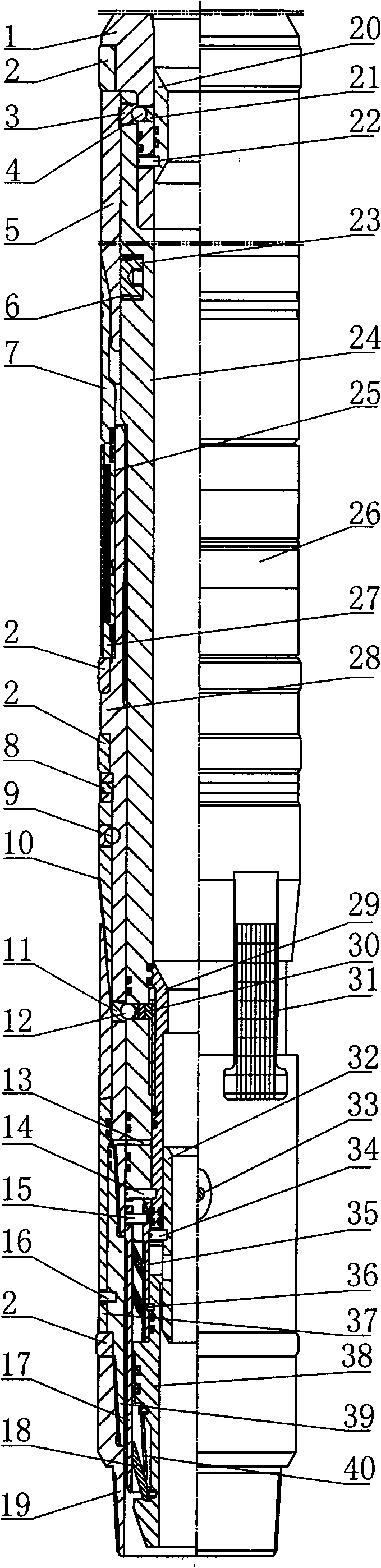

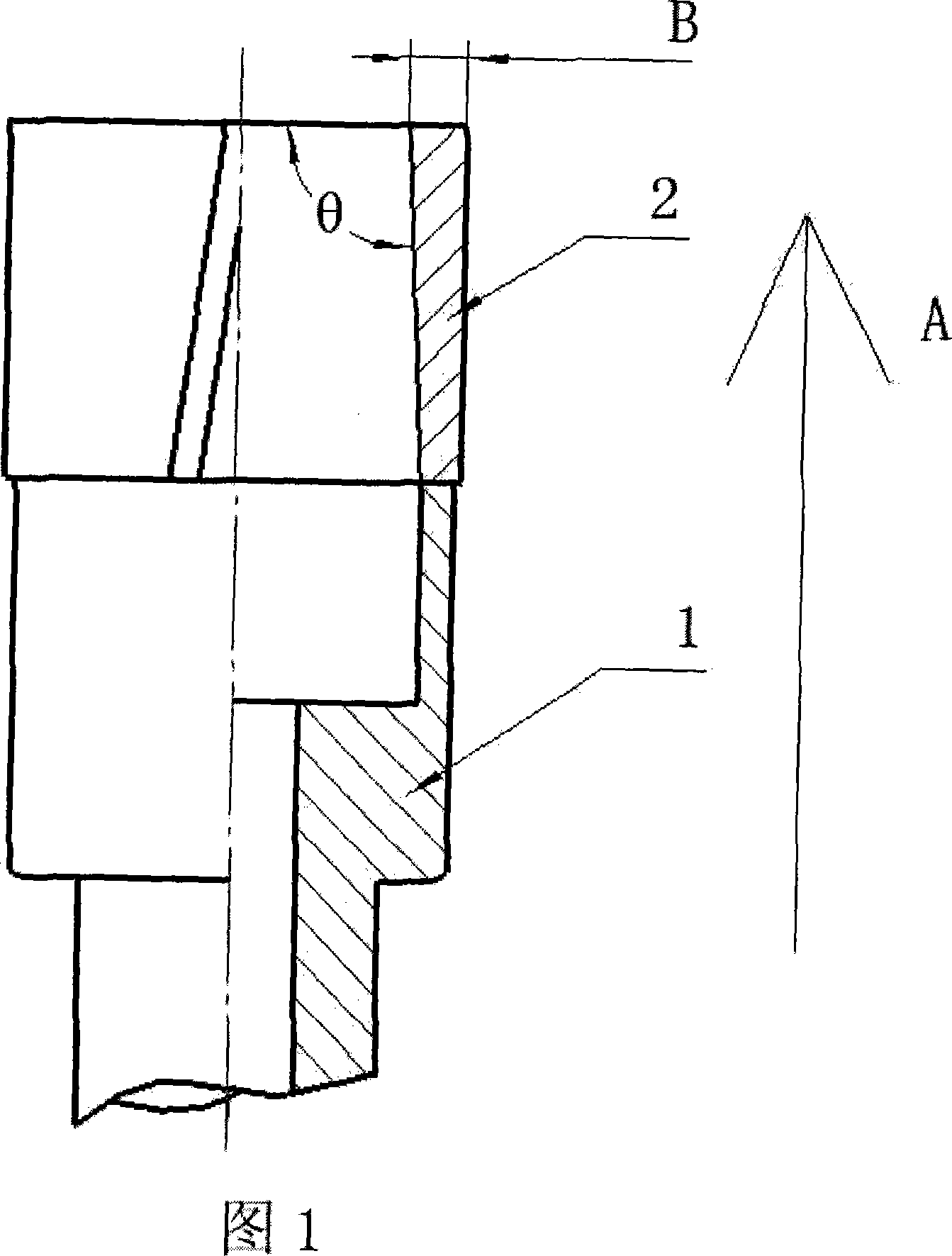

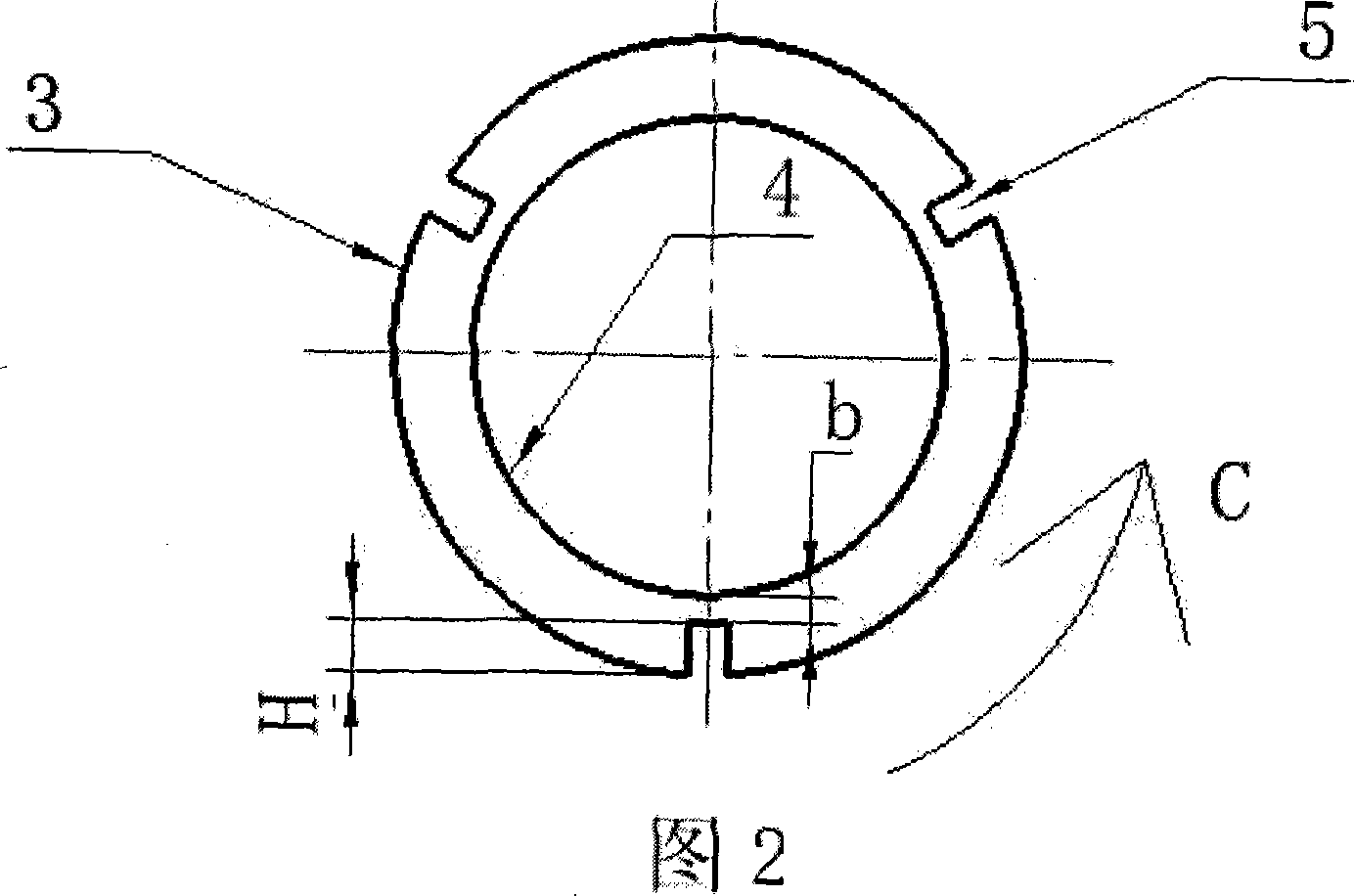

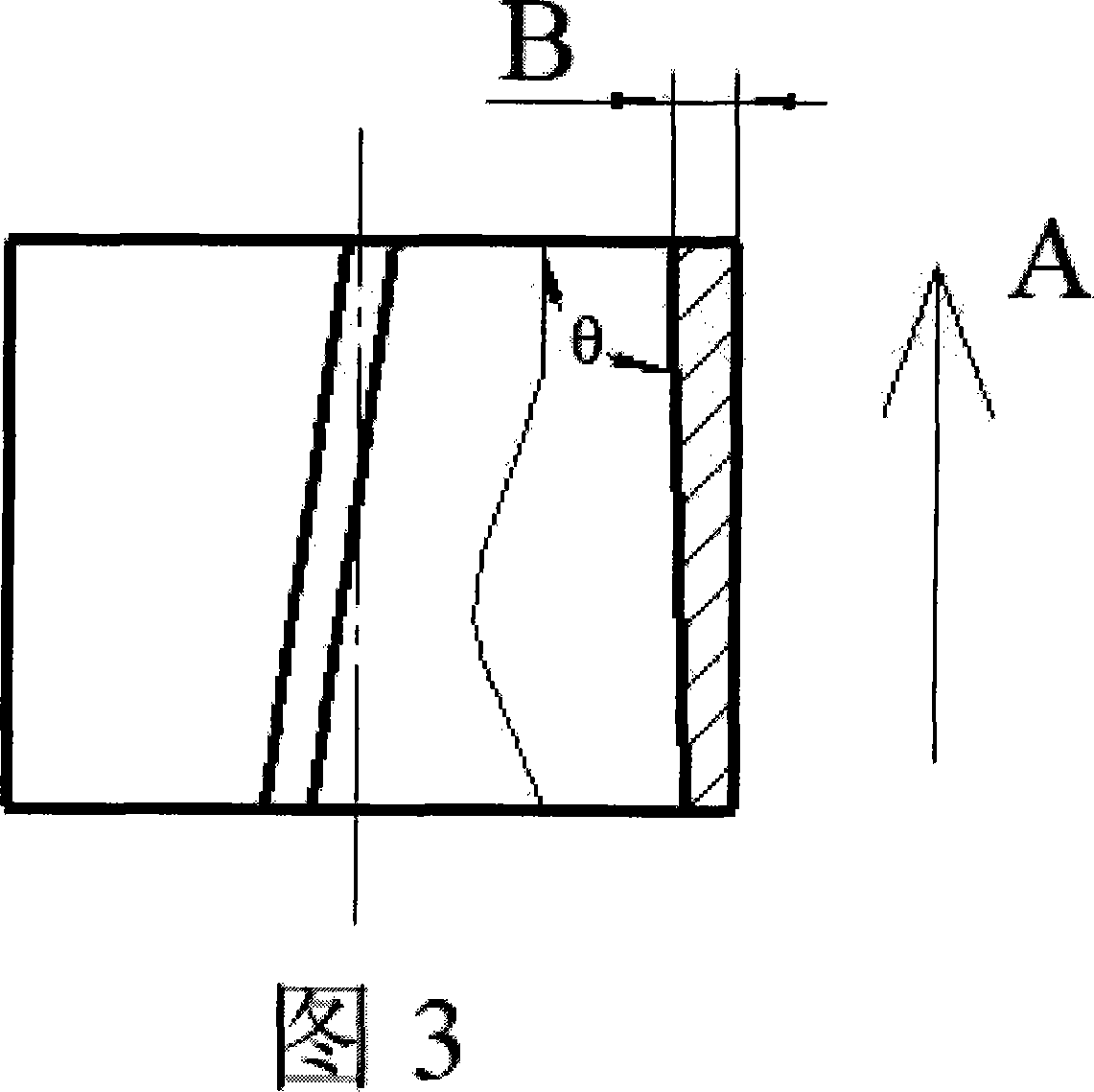

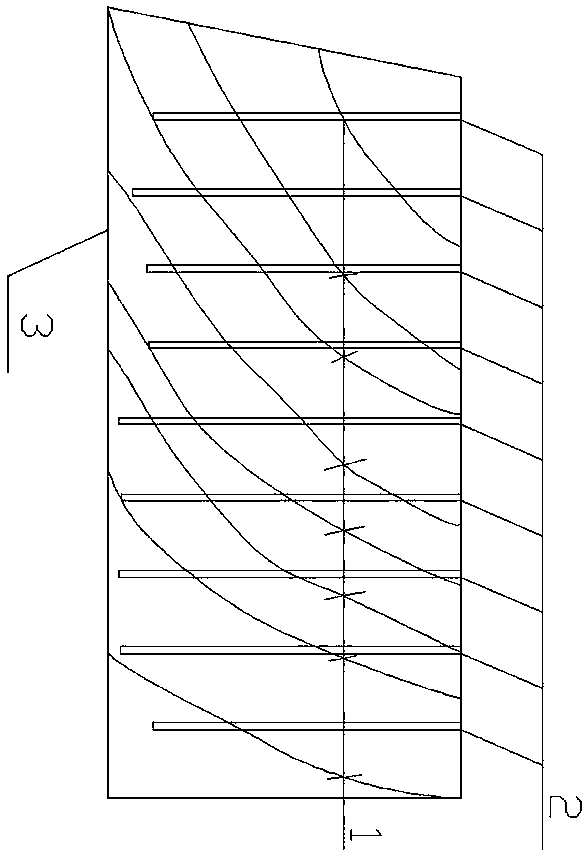

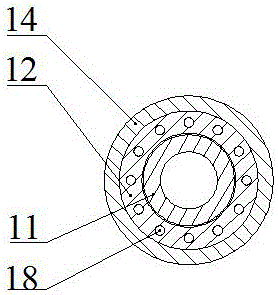

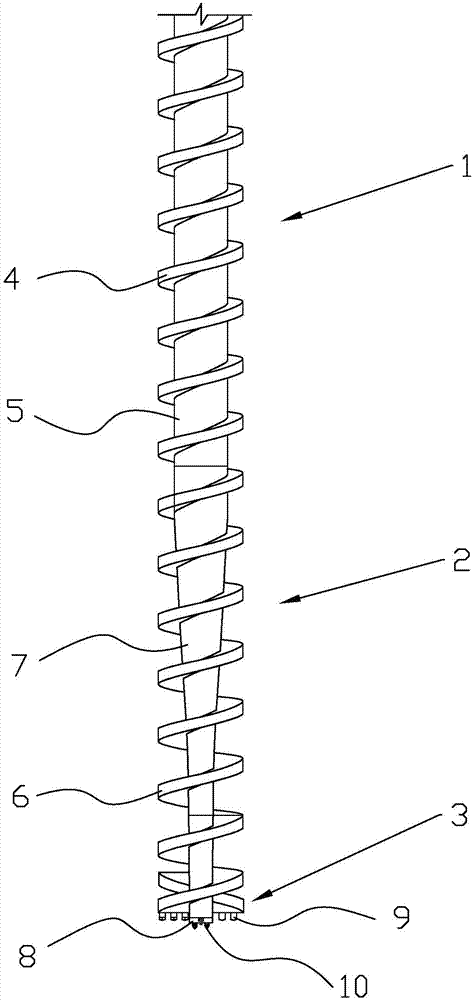

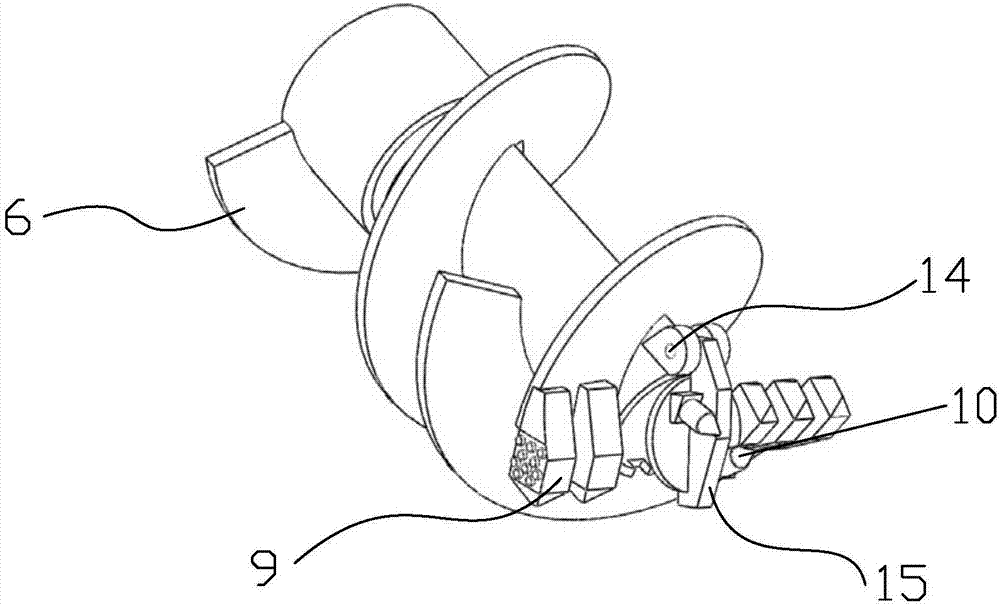

Mechanical torsional impact drilling tool

ActiveCN106150348AAvoiding the Drawbacks of Stick-Slip PhenomenonExtended service lifeBorehole drivesPenetration rateDrill bit

The invention relates to a mechanical torsional impact drilling tool, comprising an upper base body which is provided with a hollow region inside and is provided with at least an installing groove on an inner peripheral wall, a lower base body which is connected with the upper base body, an impact hammer assembly passing into the hollow region, and a central rotating shaft. The impact hammer assembly is provided with an impact hammer portion which protrudes outward in a radial direction and is in an installing groove. The central rotating shaft passes through the internal part of the impact hammer assembly until a passing-in end contacts with the lower base body. The central rotating shaft is provided with an outer boss which protrudes outwards in a radial direction and is used to drive the impact hammer portion to swing in a reciprocated manner in the installing groove. The impact drilling tool is advantaged in that a defect of stick-slip phenomenon of a drill in a well drilling process is prevented, and the tool is advantaged by improving penetration rate, stabilizing a drilling process, and improving service life of a drill stem and a PDC bit.

Owner:CHINA PETROLEUM & CHEM CORP +1

Diamond drill and method for making same

InactiveCN101032842ADrilling smoothlyNot easy to collapseStone-like material working toolsSlugDrilling force

The diamond drilling bit includes one steel bit body and one thin wall diamond cone integrated with the steel bit body. The thin wall diamond cone has linear or spiral slug slot and one un-slotted smooth surface. The slot makes the bit operating in intermittent, rather than continuous, grinding in enhanced drilling force, high drilling speed, fluent slug removing and reduced drilling resistance and heat. Timely cooling of the drilling bit and the machined material can avoid deformation and burns.

Owner:GUILIN CHAMPION UNION DIAMOND CO LTD

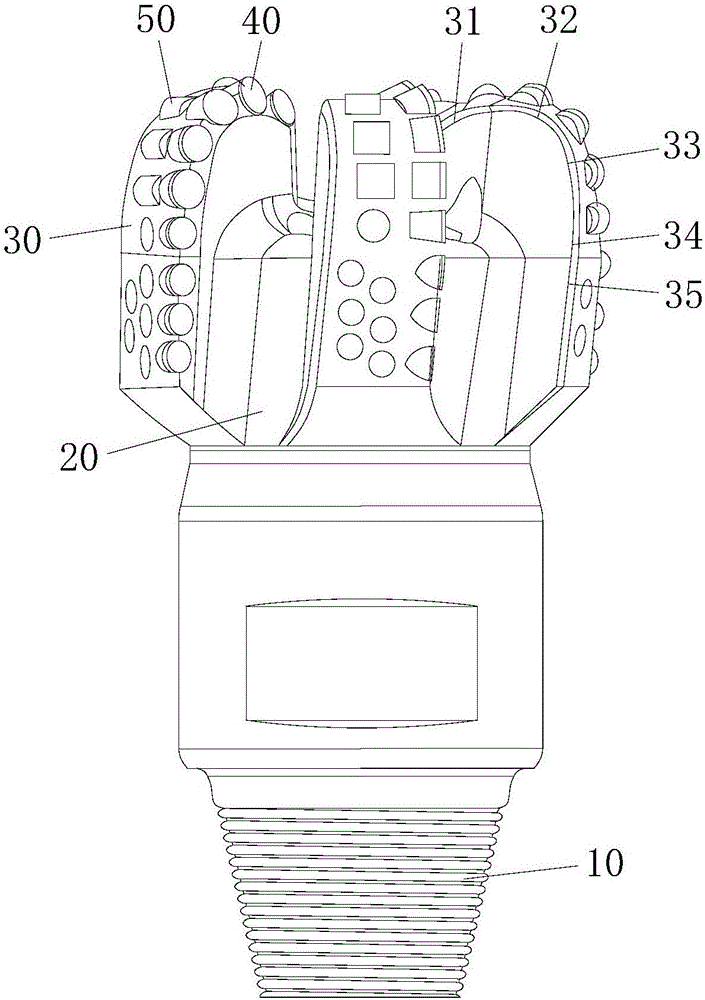

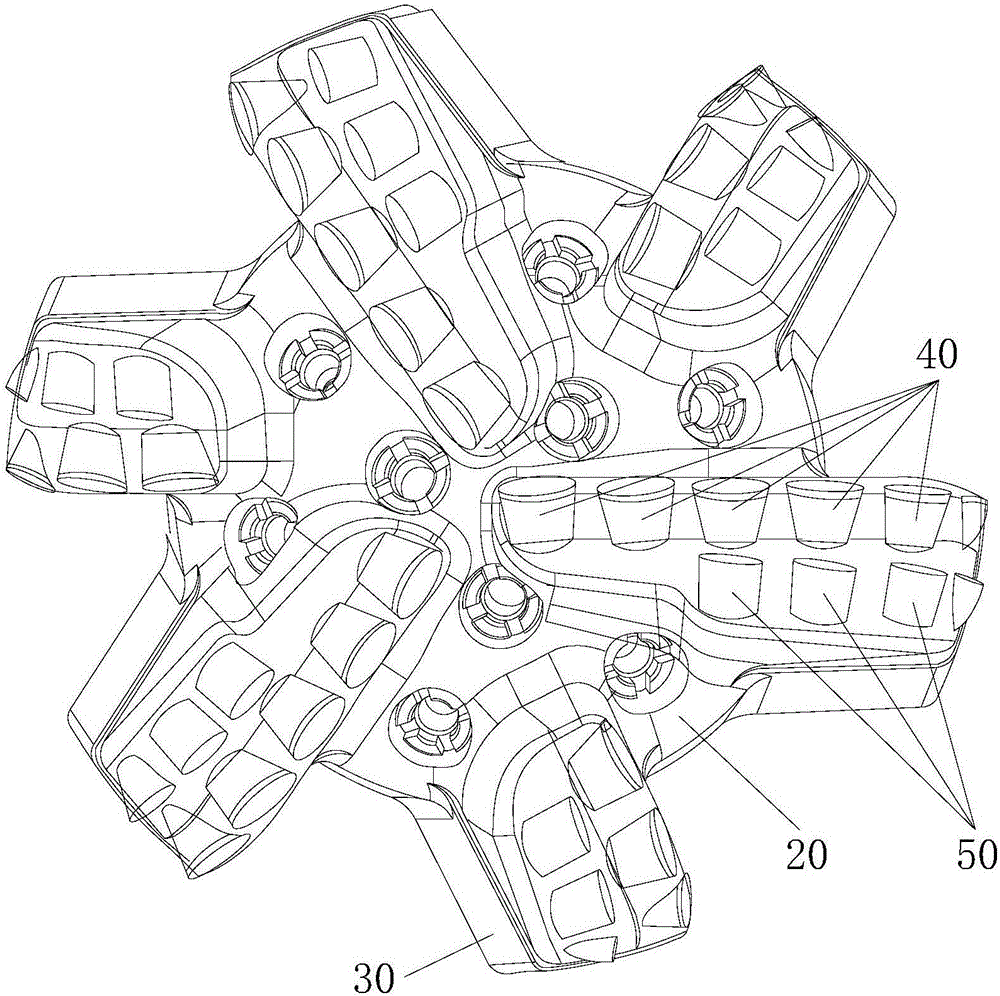

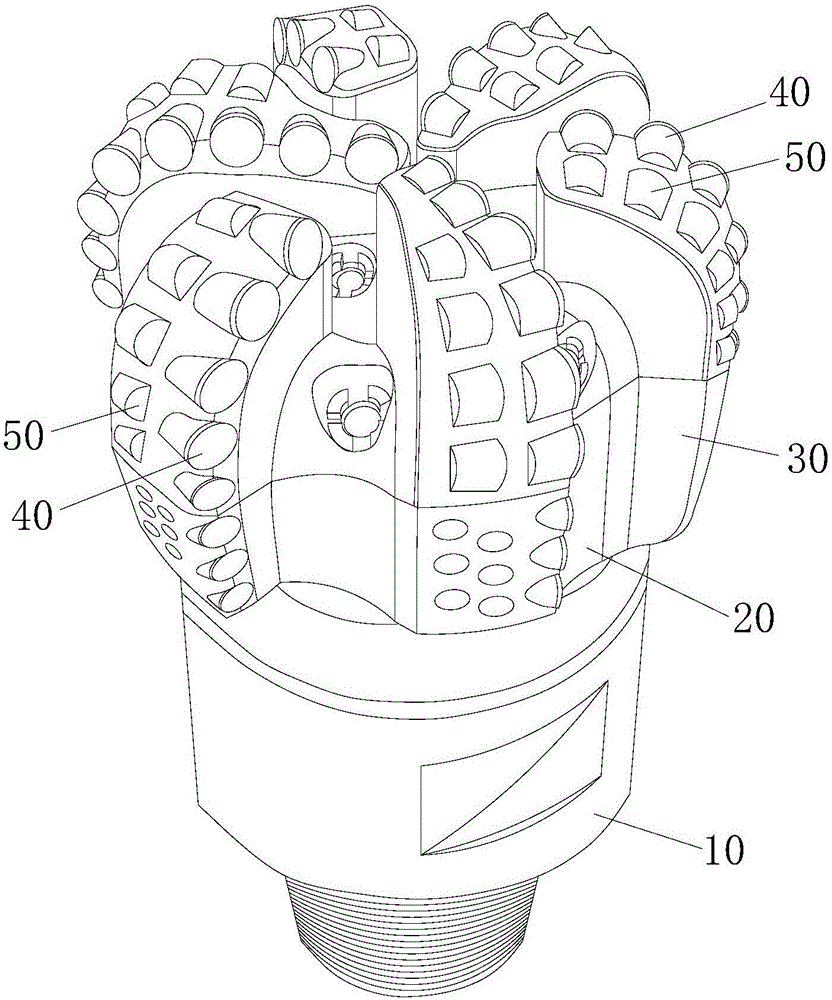

Composite drill bit

InactiveCN106639890AStrong cutting forceImprove rock breaking abilityDrill bitsConstructionsKnife bladesGrinding teeth

The invention provides a composite drill bit. The composite drill bit comprises a columnar connector and a drill bit body connected to the connector. The composite drill bit further comprises at least three knife blades arranged on the drill bit body evenly in the circumferential direction of the drill bit body. All the knife blades extend from inside to outside in the radial direction of the drill bit body. The outer side face of each knife blade is provided with a crown profile which is a curve. The composite drill bit further comprises a plurality of cutting teeth and a plurality of grinding teeth which are all fixedly arranged on the crown profiles. All the cutting teeth are arranged in a row in the extending direction of the knife blades. All the grinding teeth are arranged in a row in the extending direction of the knife blades. The row where all the grinding teeth are located is located behind the row, where all the cutting teeth are located, in the rotary direction of the drill bit body. The peak heights of all the grinding teeth are smaller than that of the cutting teeth on the same circumference. Through the composite drill bit, machine drilling speed and drill bit drilling depth are increased, the service life is prolonged, and the drilling rock breaking efficiency of the drill bit is also improved.

Owner:PETROCHINA CO LTD

Floor heave prevention anchor pipe drilling machine

The invention provides a floor heave prevention anchor pipe drilling machine. The floor heave prevention anchor pipe drilling machine comprises a base, a machine frame, a jacking device and a drilling rig; wherein the base is supported on the ground; the front end of the machine frame is connected with the base in a pivoted mode; one end of the jacking device is fixed on the base, and the other end of the jacking device is fixed to the machine frame; the drilling jig is arranged on the machine frame in a sliding mode and comprises a power device, a drilling pipe and a drill; the jacking device drives the machine frame to pivot relative to the base, and the drilling jig on the machine frame reaches a drilling angle; the power device of the drilling jig drives the drill to conduct drilling through a drilling rod; during drilling, the drilling jig slides downwards along the machine frame. Rock dregs produced during hole drilling is successfully discharged through a through hole in the double-wall drilling rod under the action of positive pressure, and therefore an anchor pipe hole can be successfully drilled in the bottom of a roadway.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Geological bit and its manufacturing method

The present invention discloses one kind of geological bit. The geological bit has carcass, which is sintered onto the top of steel body via cold pressing and hot pressing process, is constituted with coaxial and radially alternately set hard-to-wear layers and easy-to-wear layers including the outmost and the inmost hard-to-wear layers, and is divided with the water channels into several winged blocks. The present invention also discloses the making process of the geological bit. The geological bit has high efficiency, high quality stability, simple structure, easy manufacture, and reliable performance.

Owner:HUNAN FLYDISC NEW MATERIAL

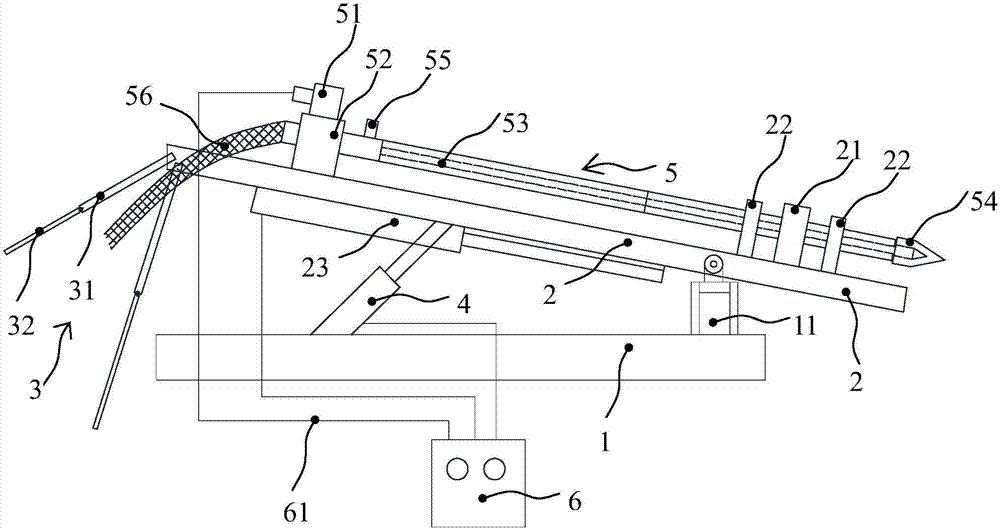

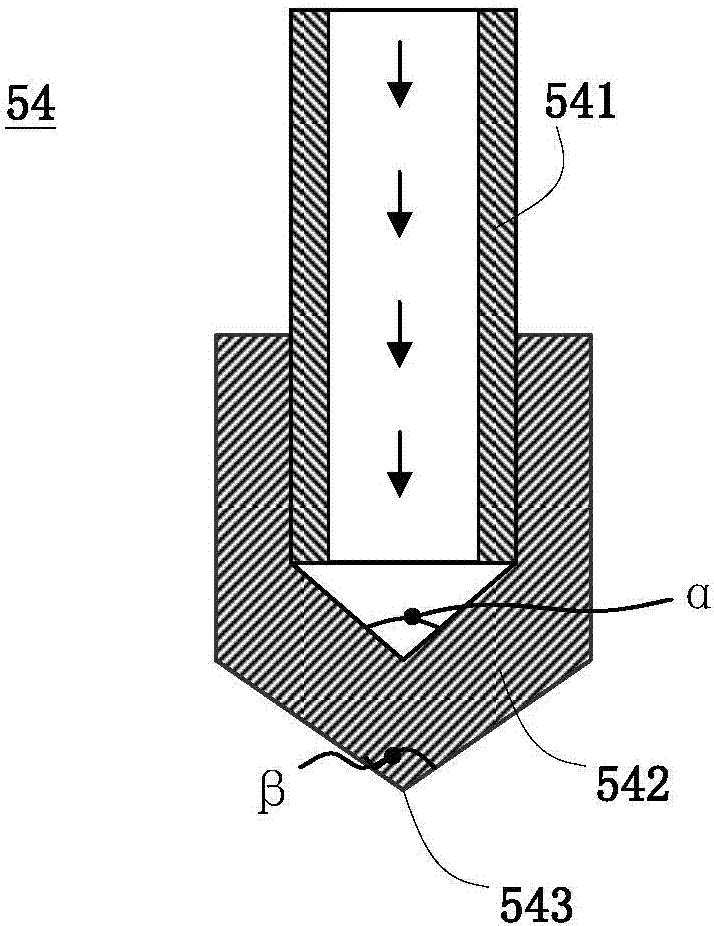

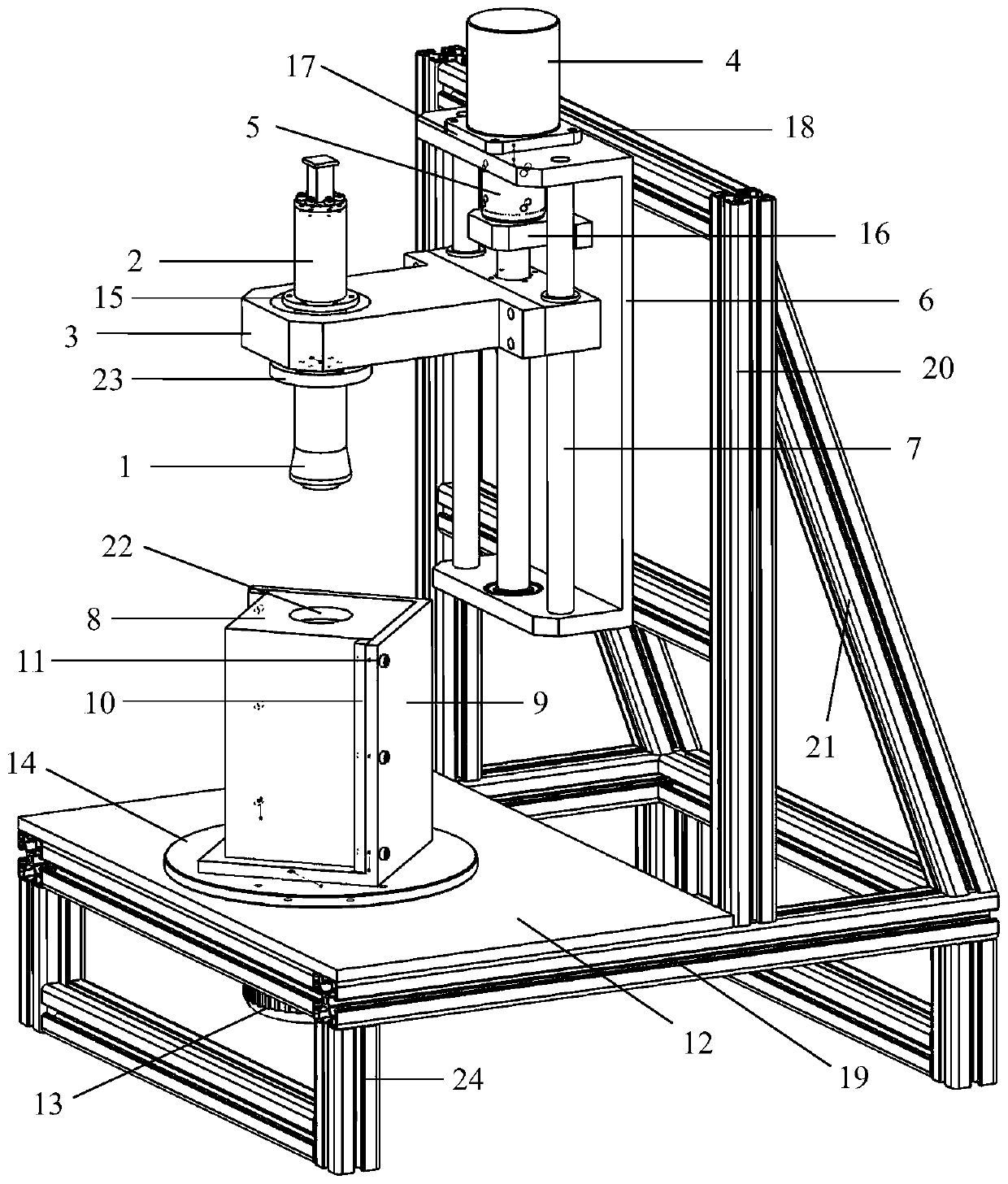

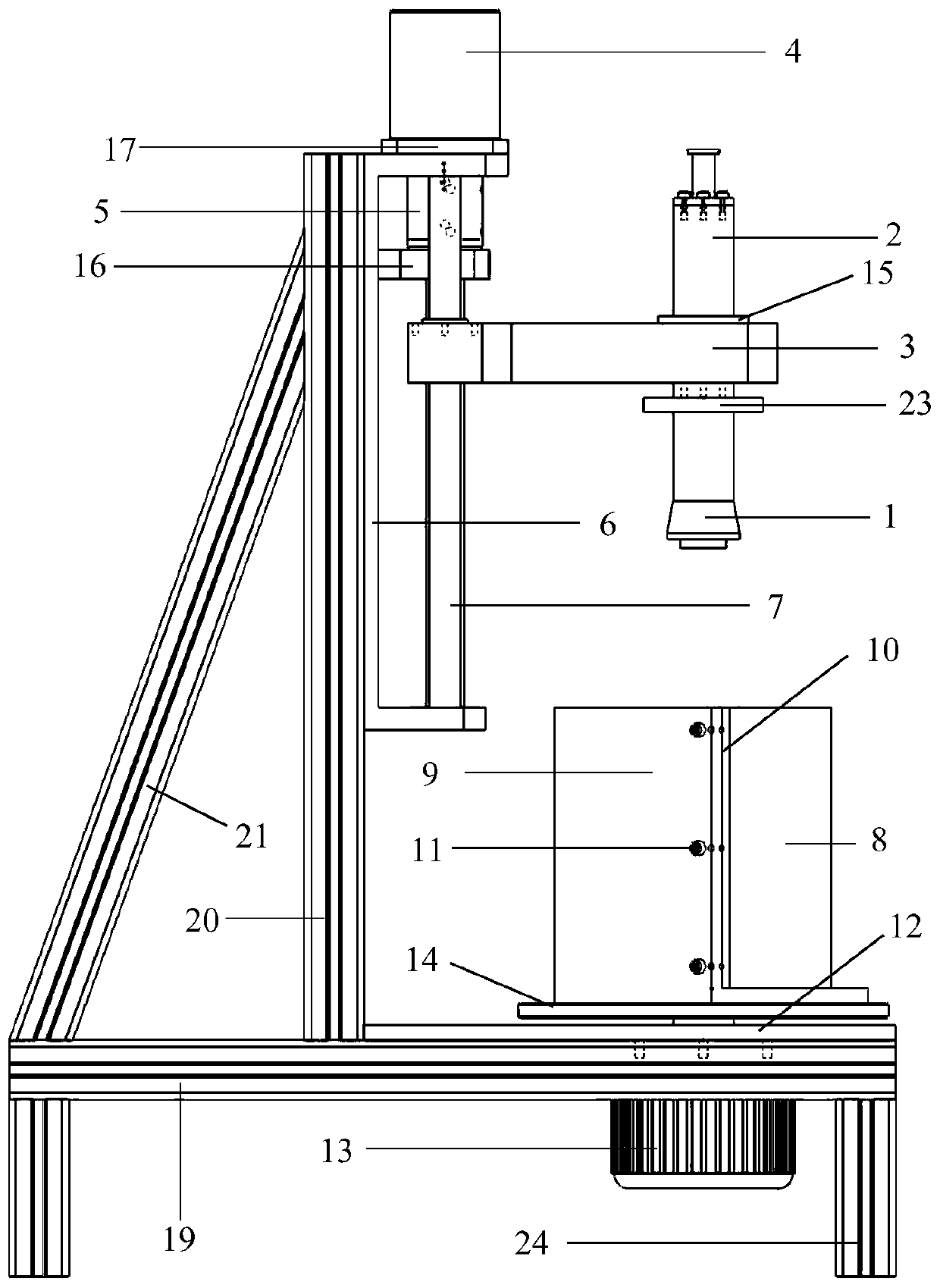

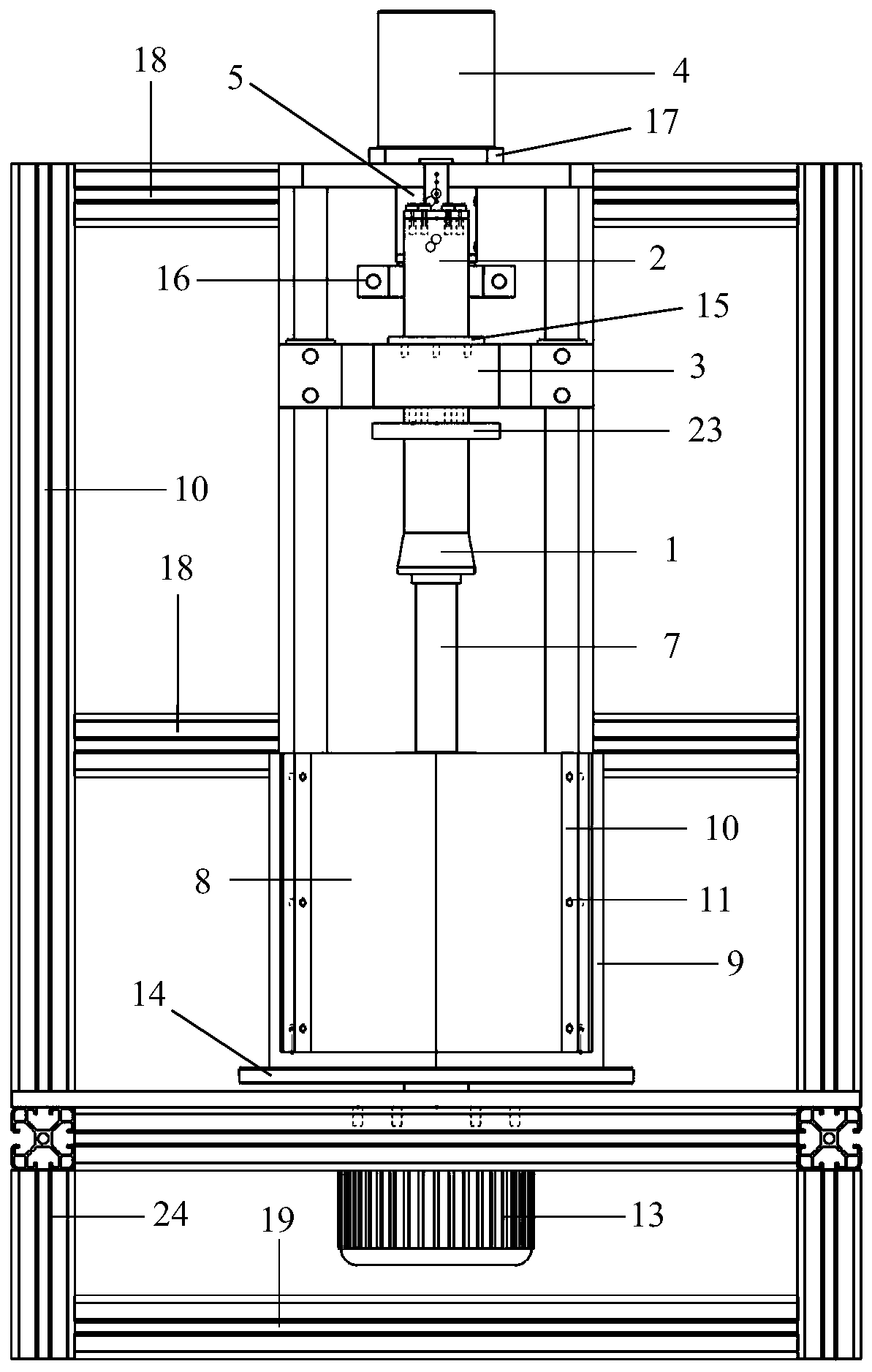

Rock wear resistance digital drilling test system and method

PendingCN111238982AEasy to operateDrilling smoothlyInvestigating abrasion/wear resistanceMining engineeringTunnel boring machine

The invention discloses a rock wear resistance digital drilling test system. The rock wear resistance digital drilling test system comprises a digital drilling device for drilling a hole in a rock tobe tested, a rock fixing device, a rotating device, a digital sensor arranged on the digital drilling device and a rack. The digital drilling device is mounted at the upper part of the rack. The rockfixing device is mounted at the lower part of the rack and is aligned with the digital drilling device. The rotating device is installed below the rock fixing device so that the rotating device can drive rock fixed to the rock fixing device to rotate when working. The invention also relates to a rock wear resistance digital drilling test method. By monitoring the digital response information of the drilling tool, the unit drilling displacement in the rock drilling process is obtained and used for evaluating the abrasion resistance of rocks of different qualities, so that the hard rock tunnel boring machine is guided to reasonably select hob parameters, the construction efficiency is improved, and the cost is reduced.

Owner:水利部水利水电规划设计总院 +1

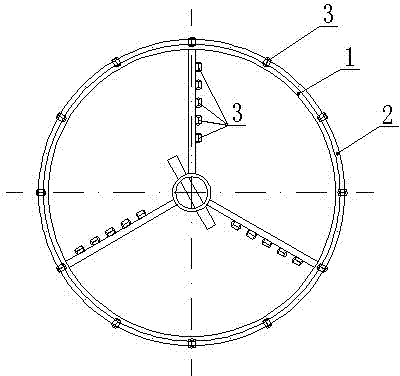

Double drill push-the-bit type guide section

ActiveCN106522826ASmall hole diameterReduced risk of collapseDrilling rodsConstructionsPistonPlunger

The invention discloses a double drill push-the-bit type guide section which includes an oil cylinder outer wrap, an oil cylinder, an internal drill pole and a support plate. The internal drill pole is arranged in the oil cylinder outer wrap and moves along the direction of the axle of the oil cylinder outer wrap. An accommodating cavity is arranged on the outer wall of the oil cylinder outer wrap. A decompression hole is formed in the bottom of the accommodating cavity. The oil cylinder is arranged in the decompression hole. The hole wall of the oil cylinder and the decompression hole slides correspondingly. A seal ring is used for sealing between the hole wall and the oil cylinder. The plunger of the oil cylinder is fixedly connected with the support plate. The oil cylinder outer wrap includes a drilling end and a dynamic end. A convex plate is arranged along the circumference of the inner wall of the oil cylinder outer wrap which is between the accommodating cavity and the dynamic end. The internal drill hole includes a drill pole neck and a drill pole body. The outer diameter of the drill pole body is greater than the outer diameter of the drill pole neck. When the drill pole neck of the internal drill pole moves to correspond to the convex plate, the place between the drill pole neck and the convex plate is provided with an annulus. When the drill pole body of the internal drill pole moves to correspond to the convex plate, the drill pole body is matched with the gap of the convex plate. The double drill push-the-bit type guide section adjusts the extension length of the support plate by adjusting the pressure of the drilling fluid and thus the rate of deviation change of the drilling tools is adjusted.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

Excavation support construction method for high slope of oblique stratum

InactiveCN109238054AGood excavation effectReduce overmine and undermineBlastingExcavationsOverburdenPre cracking

The invention discloses an excavation support construction method for a high slope of an oblique stratum. The method includes the construction procedures of site cleaning, excavation of cover layers,gradient segment drilling and blasting excavation, excavation of building foundation surface protection layers, research on safety and stability to determine support modes and optimization and adjustment. Gradient excavation is adopted in the excavation process; the step height is determined according to the principle that pre-cracking is conducted on slope design lines from top to bottom and fromoutside to inside, excavation of the cover layers and alluvium of all the layers is conducted first, then stonework excavation is conducted after free faces are formed, and riding tracks adopt the excavation mode that protective layers are reserved; according to geological conditions of the oblique stratum, a blasting technology is reasonably studied, blasting parameters are reasonably adjusted to achieve a great excavation effect, and overbreak, underbreak and secondary treatment are reduced to ensure the excavation quality. According to the provided excavation support construction method for the high slope of the oblique stratum, the excavation quality is improved, the overbreak is avoided, and the stability of the slope and the construction safety are ensured.

Owner:CHINA HYDROPOWER ELEVENTH ENG BUREAU ZHENGZHOU CO LTD +1

Anti-seizing tool capable of avoiding drill clamping and reducing sticky slipping

ActiveCN106567681AExtend your lifeAvoid drill stickingDrilling rodsDrilling casingsEngineeringDrill bit

The invention discloses an anti-seizing tool capable of avoiding drill clamping and reducing sticky slipping to solve the problem that the rock breaking efficiency is low due to clamping and slipping in the drilling process. According to the main technical scheme, an upper connector, an upper shell, an adapter and a lower shell are sequentially connected through a thread; a compression spring is mounted on a compression spring guide rod, the low end of the compression spring guide rod pushes an anti-falling connector to enable a mandrel to stretch, and the anti-falling connector is connected with a mandrel thread and axially positioned through an adapter shaft shoulder; a steel wire rope system is arranged in a left-rotation mode, the upper and lower ends of the steel wire rope system are separately fixed to the lower end of the adapter and fixed into a circular groove in the upper end of a mandrel boss, the upper and lower ends of steel wire ropes are mounted by 30-40 degrees in an inclined mode, and the steel wire ropes are in a tensional state initially; during work, drilling pressure is transferred to the mandrel through the compression spring, and torque is transferred to the mandrel through the steel wire rope system; and when the mandrel rotates backwards, the steel wire rope system retracts to enable the mandrel to compress the compression spring to axially retract so as to decrease the cutting depth of a drill bit, and the drill bit is in a rock mass in the whole process.

Owner:沛县昌运机械制造有限公司

Rotary excavating drilling machine squeezing hole-forming construction technique

ActiveCN107842313AReduce construction costsImprove compactnessDrill bitsDirectional drillingDrill bitDrill pipe

The invention belongs to the technical field of building construction and particularly discloses a rotary excavating drilling machine squeezing hole-forming construction technique. The rotary excavating drilling machine squeezing hole-forming construction technique comprises the following steps that (1), construction preparation is conducted; (2), pile position setting out is conducted; (3), a rotary excavating drilling machine is in place, and a drill bit slowly touch downs the ground and rotates to conduct drilling; (4), when the drill bit of the rotary excavating drilling machine penetratesthrough a soft layer section, a drill bit special for squeezing hole forming is replaced and mounted to slowly conduct drilling; (5), in the drilling process, drilling resistance is obviously increased, the drilling speed is lower than 0.1 m / min, a drilling rod of the rotary excavating drilling machine is reversely rotated to evenly and slowly lift the drill bit special for squeezing hole forming, and the lifting speed is well controlled according to the torque; and (6), when hole collapse occurs in the hole forming process, the hole collapse position is backfilled with clay, and the drill bit special for squeezing hole forming is driven through the rotary excavating drilling machine to conduct drilling again to squeeze the clay to the periphery of a hole to form a compact and stable protection wall. Through the construction technology, the hole collapse risk can be reduced, even if hole collapse occurs, remediation can also be rapidly conducted, and the construction progress is prevented from being affected.

Owner:CHONGQING HUASHUO CONSTR

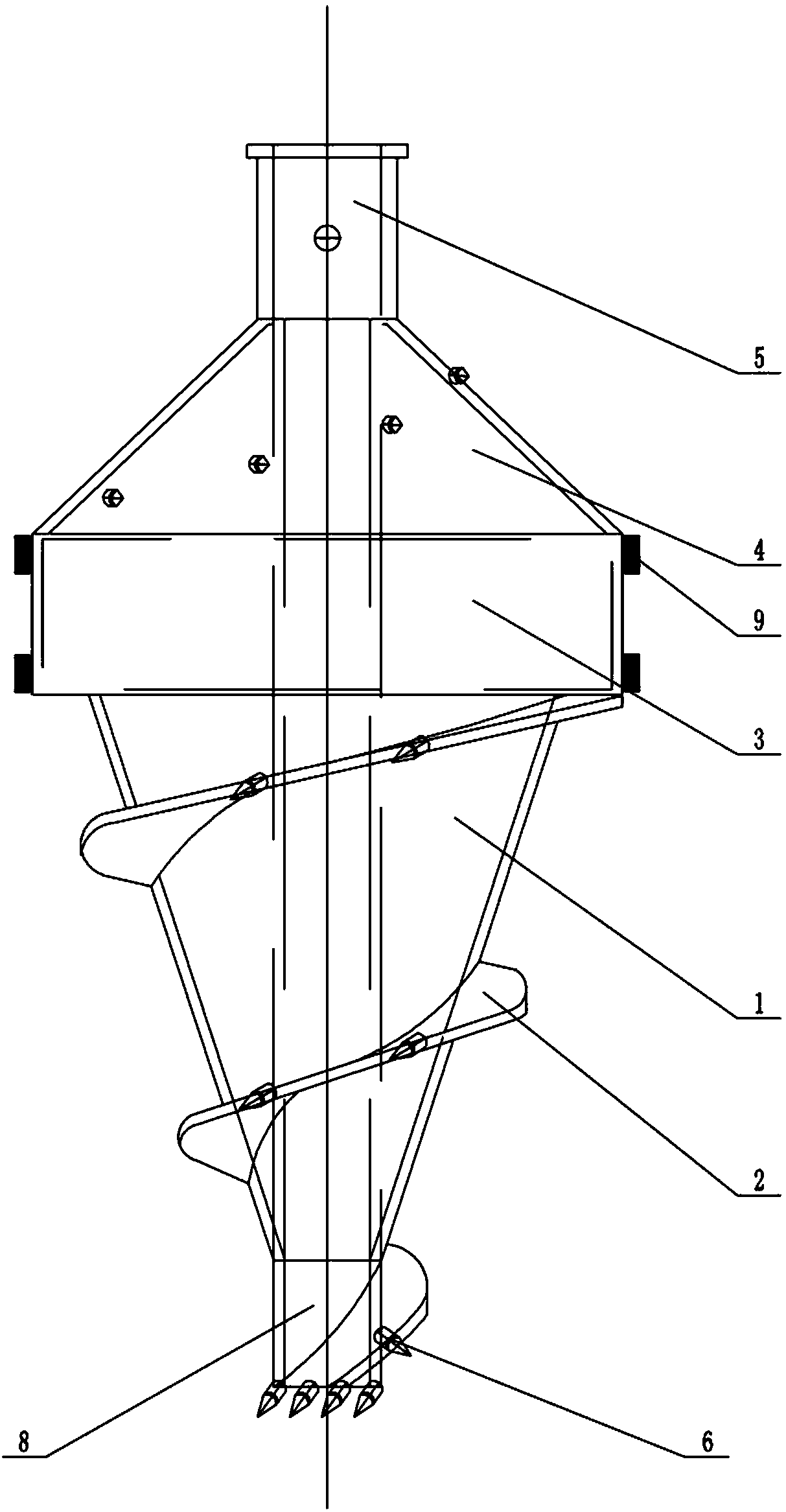

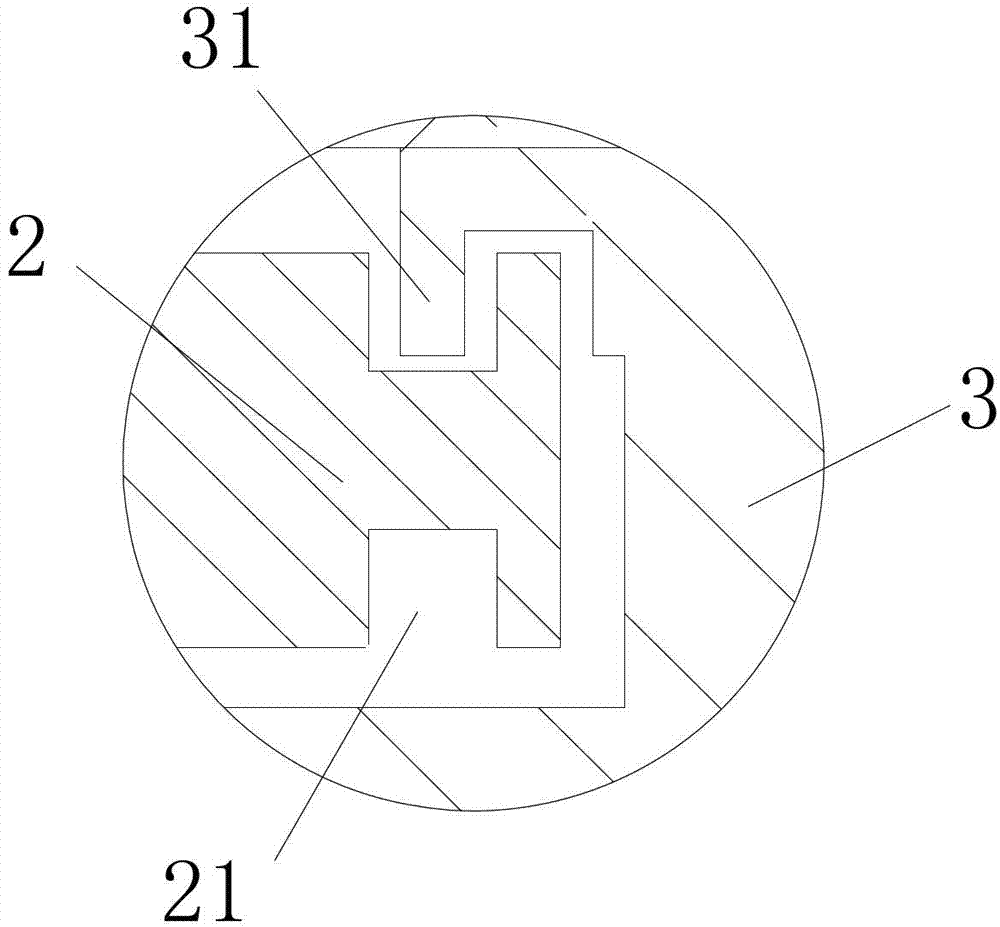

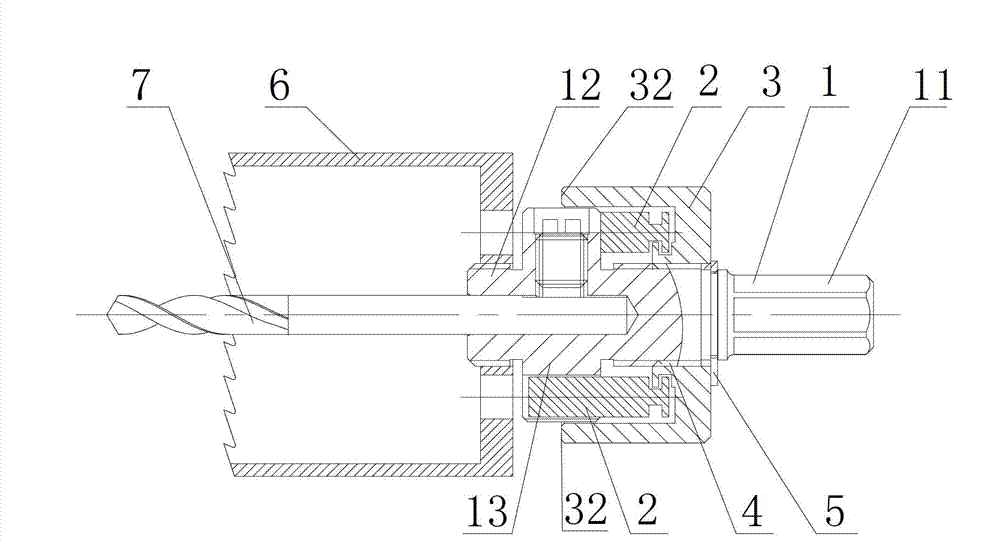

Bimetal hole saw connecting shank

ActiveCN103111664AImprove the finishThere will be no breakageTransportation and packagingTrepanning drillsHole sawEngineering

The invention discloses a connecting shank, and particularly discloses a bimetal hole saw connecting shank. The invention provides the bimetal hole saw connecting shank for preventing a hole saw from swaying after the hole saw is installed. The bimetal hole saw connecting shank comprises a connecting shank body and a transmission pin, wherein the connecting shank body comprises a motive power connecting end, a drilling saw connecting end provided with hole saw connecting threads and a spotter installing hole, and an installing part which is provided with an installing through hole. The installing part is arranged between the motive power connecting end and the drilling saw connecting end, and the transmission pin is arranged in the installing through hole and can move along the axial direction of the installing through hole. The bimetal hole saw connecting shank further comprises a hole saw firming device, wherein the hole saw stable device is arranged on the connecting shank body through a thread structure and can moves along the axis of the connecting shank body through the thread structure, and the hole saw stable device firms the hole saw through the movement along the axis of the connecting shank body. After the hole saw is connected with the drilling saw connecting end and the transmission pin is pushed into a pin hole, the hole saw firming device is continued to be twisted to be attached tightly to the top surface of the hole saw, so that the hole saw cannot sway in use.

Owner:CHENGDU VALUEMAX TOOLS MFG

Melt casting type diamond drill bit

InactiveCN101200997AExtended service lifeImprove machining accuracyDrill bitsRebarReinforced concrete

The invention provides a melt-casted diamond drill bit, belonging to the superhard material cutting tool technical field. The technical proposal of the invention is capable of producing melt-casted diamond core drill, diamond geological drill, diamond deep well drill, etc. compared with sintered diamond drill bit, the melt-casted diamond drill bit has manufacturing accuracy several times higher, and is wear resistant and sharp; compared with galvanized drill bit and brazed diamond drill bit, the melt-casted diamond drill bit has lower manufacture cost and longer service life; compared with dry drill, the abrasion resistance of the melt-casted diamond drill bit is several times higher; thereby, the melt-casted diamond drill bit is applicable for various drilling work, such as the drilling work in marbles, glasses, bituminous road surfaces, concrete road surfaces, reinforced concrete engineering components, and even in hard granitoid, and even harder and more brittle silicon crystal.

Owner:于贵生

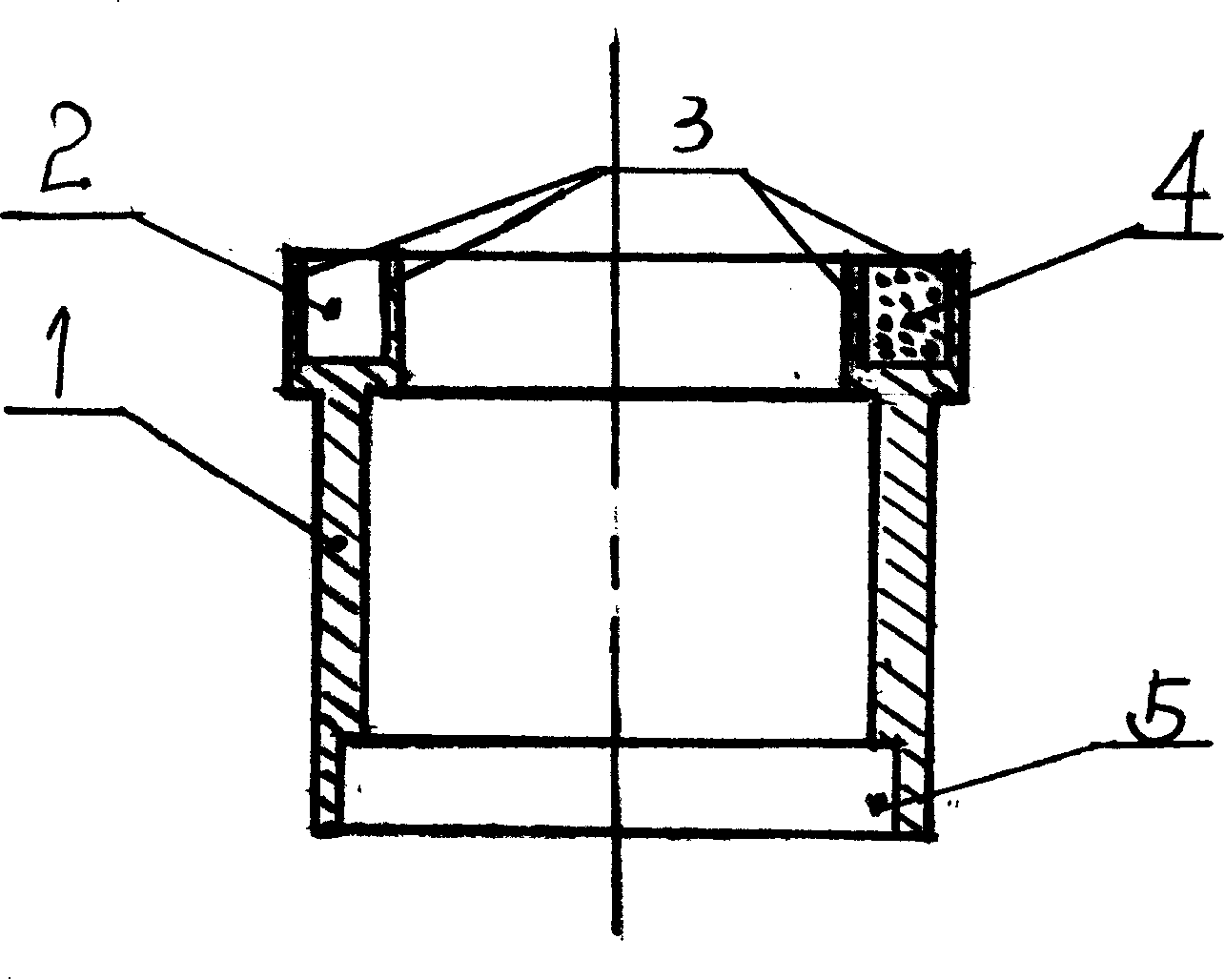

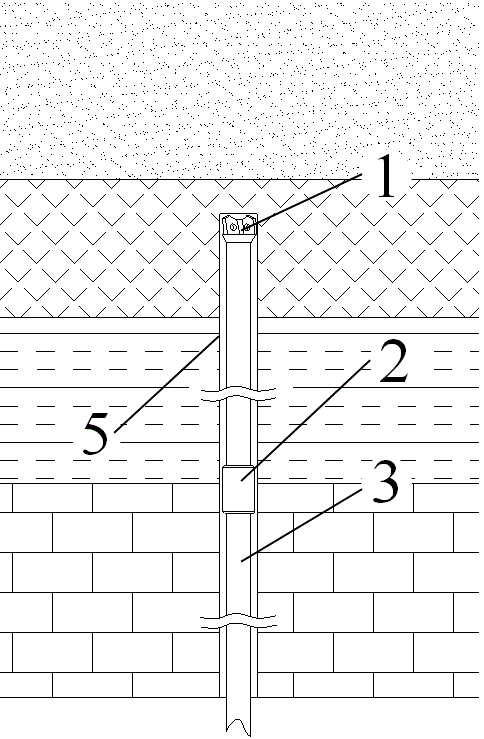

Abrasion drill bit device for processing uneven geology

The invention discloses an abrasion drill bit device for processing the uneven geology and belongs to the technical field of pile foundation construction. The abrasion drill bit device comprises an abrasion drill bit and is characterized in that the abrasion drill bit is sleeved with a steel sleeve (2), an outer circle of a drill bit surrounding wall (1) of the abrasion drill bit is fixedly connected with the inner side wall in the upper end of the steel sleeve (2). Multiple alloy teeth (3) are evenly arranged on the periphery of the lower end face of the steel sleeve (2). The abrasion drill bit device is simple in structure and capable of effectively ensuring that when the drill bit encounters the uneven geology, the drill bit can proceed stably and vertically, thus, the quality of a formed hole is ensured and the quality of a pile foundation is ensured. The abrasion drill bit device for processing the uneven geology is simple in structure, simple in principle, low in cost and high in practicability and materials are convenient to obtain.

Owner:CHINA RAILWAY NO 10 ENG GRP NO 1 ENG CO LTD

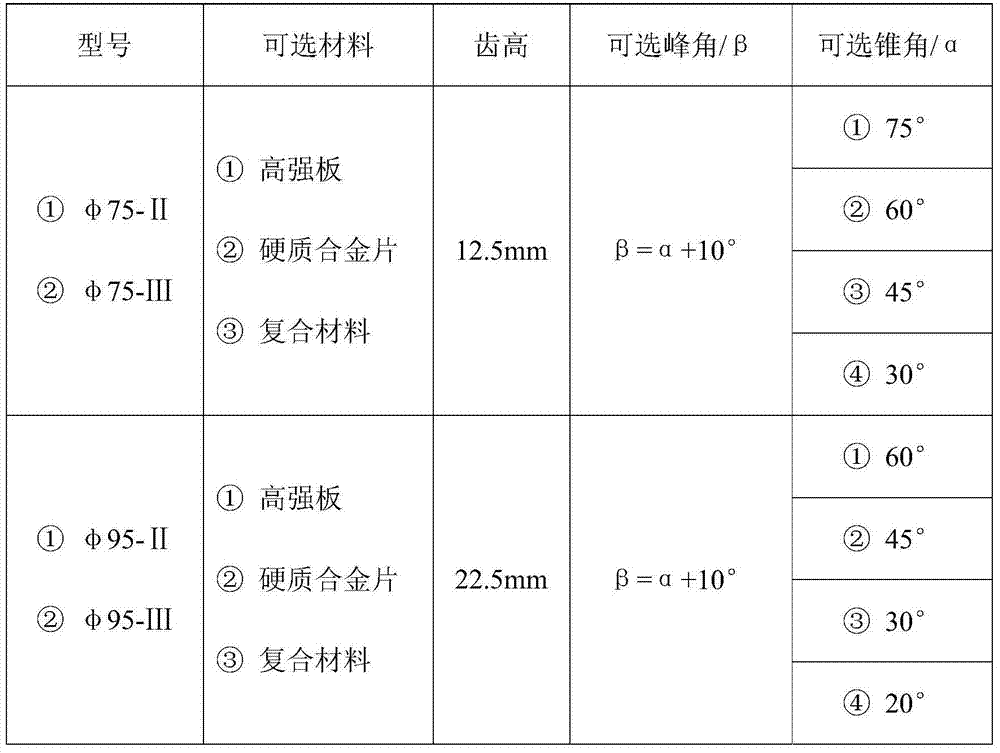

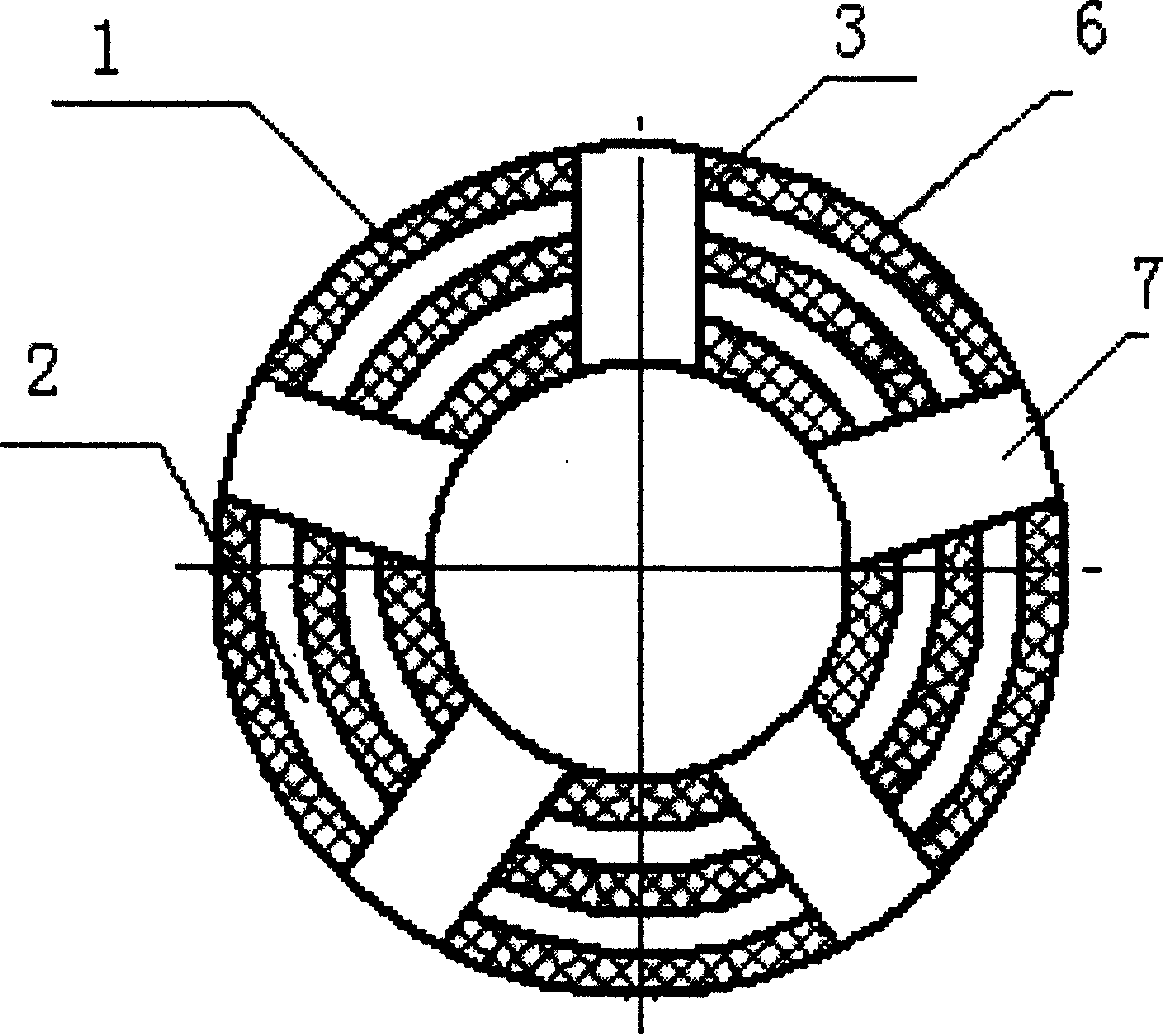

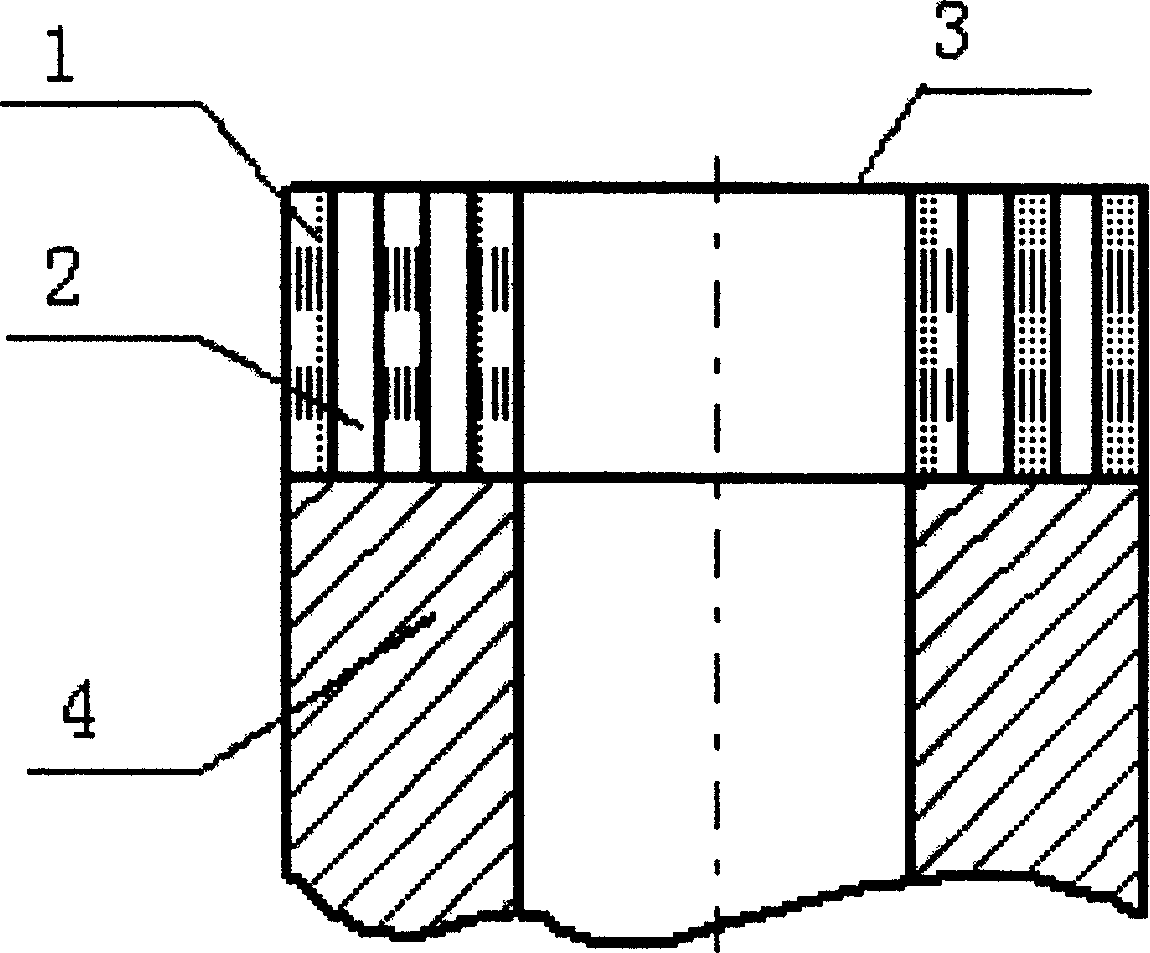

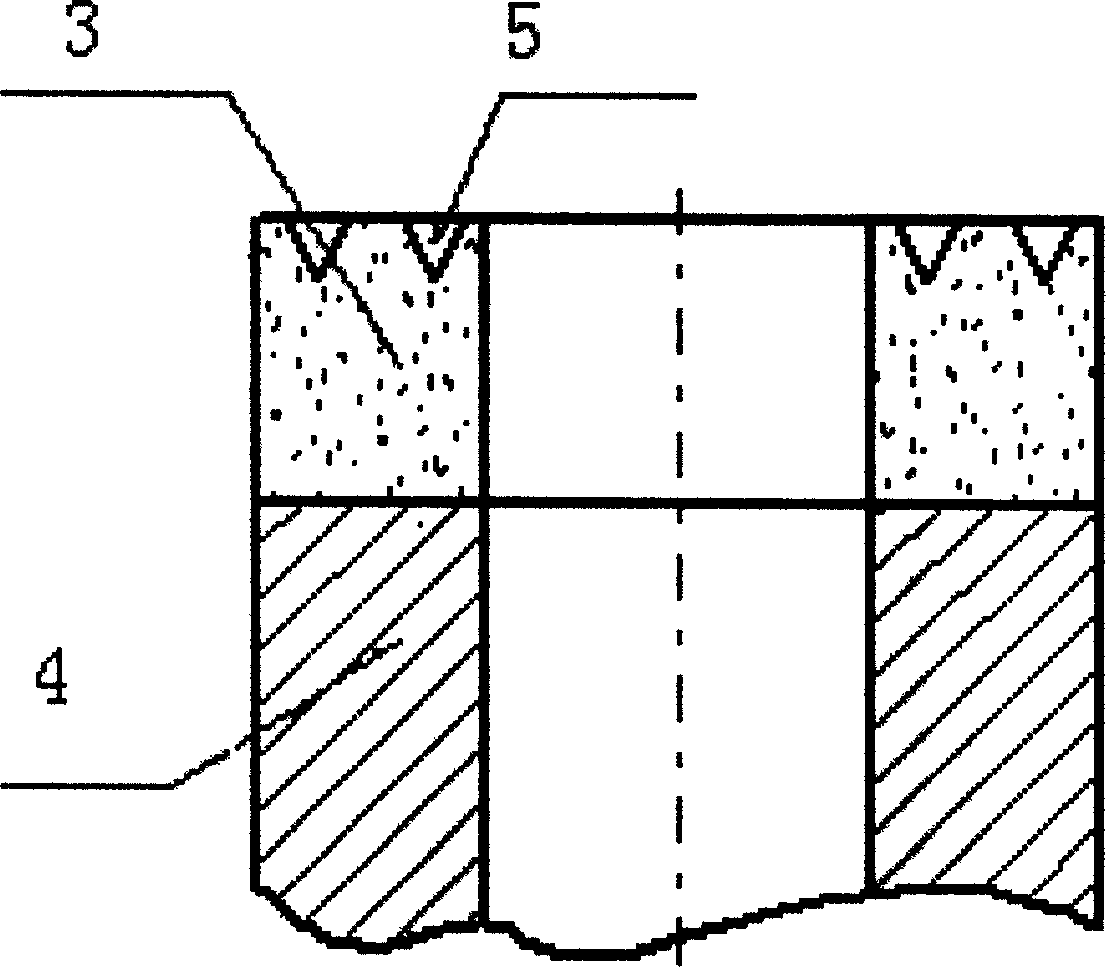

Quick broaching method and structure

InactiveCN105298392AGuarantee the quality of reamingQuality assuranceDrilling machines and methodsEngineeringDeep hole

The invention relates to a quick broaching method and structure. In the deep hole drilling process, a drilling procedure does not need to be changed, a connector with cutting teeth is adopted to be connected with a drill pipe on the outmost side, and thus drilling in a deep part and broaching in a shallow part are simultaneously achieved. Meanwhile, orientation of a drill hole deep part drill bit is used for ensuring that a small-diameter drill hole in the deep part and a large-diameter drill hole in the shallow part are located on the same axis, and broaching quality is ensured while quick broaching is ensured. The cutting teeth are arranged on the outer edge of the connector with the cutting teeth, rock is cut in the broaching process, inner threads matched with outer threads of drill pipes are arranged at the two ends of the connector so that the connector can be connected with the drill pipes, and a water passing channel is formed internally for passing of water used for drilling in the deep part and broaching in the shallow part. Meanwhile, the connector with the cutting teeth can be provided with an upper set of cutting teeth and a lower set of cutting teeth, the dimension of the lower set of cutting teeth is larger than that of the upper set of cutting teeth, the upper set of cutting teeth and the lower set of cutting teeth are aligned, and thus rock drillings can be conveniently discharged. By means of the quick broaching method and structure, high efficiency and high quality of deep hole shallow part broaching work in a roadway or tunnel project can be ensured, and good popularization prospects are achieved.

Owner:HENAN POLYTECHNIC UNIV

Apparatus for evaluating rock properties while drilling using drilling rig-mounted acoustic sensors

ActiveUS9234974B2Better drilling steeringEasy to produceElectric/magnetic detection for well-loggingSurveyLithologyWell drilling

Apparatus for identifying rock properties in real-time during drilling, are provided. An example of an embodiment of such an apparatus includes one or more acoustic sensors positioned to detect drill sounds emanating from the drill bit and the rock encountered during drilling operations, connected to select components of a drilling rig to maximally pick up the drill sounds of the drill bit engaging rock during drilling operations. The apparatus also includes an inductive telemetry, wireless telemetry, or wired transmitting system. The apparatus also includes a computer to analyze the acoustic signals received from the acoustic sensors through the respective transmitting system for lithology type and petrophysical properties.

Owner:SAUDI ARABIAN OIL CO

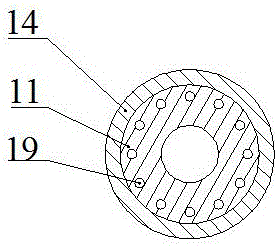

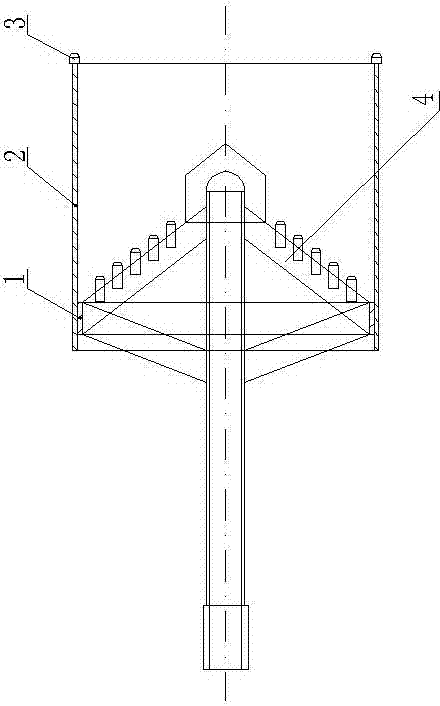

Construction method of screw drilling and squeezing cast-in-place pile and combined screw drill

PendingCN107574818AImprove constructabilityImprove bearing capacityDrill bitsBulkheads/pilesDrill cuttingsConcrete pump

The invention discloses a construction method of a screw drilling and squeezing cast-in-place pile. The construction method comprises the following steps: a combined screw drill is rotated clockwise for drilling and squeezing hole forming in advance; after a designed depth is reached, the combined screw drill is enabled to move upwards and rotated clockwise again to squeeze and expand a pile hole;the combined screw drill is screwed upwards, and at the same time, a concrete pump is started to fill the pile hole with a piling material to a preset height; and then a reinforcement cage is implanted. The combined screw drill comprises a spiral drill pipe at the upper part and a screw-type drilling and tunneling head at the lower part, wherein the upper end of the spiral drill pipe is connectedwith a power head; the lower end of the spiral drill pipe is connected with the screw-type drilling and tunneling head at the lower part; the screw-type drilling and tunneling head consists of a drill reducing segment and a drill cutting pick segment; the diameter of the drill reducing segment is gradually reduced from the upper end to the lower end to a certain set diameter; and meanwhile, alloycutting picks are distributed at the end part of the drill cutting pick segment. The screw drilling and squeezing cast-in-place pile constructed by the combined screw drill has the characteristics ofstrong constructability on a hard stratum, high bearing capacity, small sedimentation, good piling quality, lower cost, less energy consumption and the like.

Owner:浙江坤德创新岩土工程有限公司

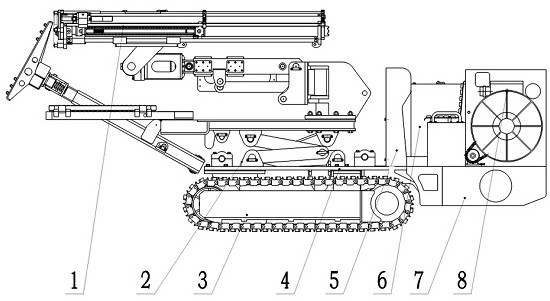

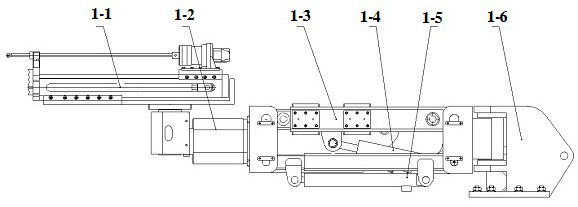

Automatic anchor rod drill carriage

PendingCN112360340AImprove stabilityImprove comfortUnderground chambersElectrical apparatusMarine engineeringMachine

The invention discloses an automatic anchor rod drill carriage, and belongs to the technical field of machinery. The automatic anchor rod drill carriage comprises an anchor drill system, a machine body part, walking systems, a hydraulic system, a waterway system and an electrical system, wherein the machine body part comprises a chassis, and a lifting device, a control console, a pump station, anoil tank and a cable supporting device which are arranged on the chassis; the anchor drill system is arranged on a platform of the lifting device; the two sets of walking systems are symmetrically arranged on the two sides of the lower end of the chassis; a supporting device for realizing top slope supporting through up-and-down rotation is arranged at the front end of the lifting device; the walking systems drive the whole drill carriage to move forwards, backwards or turn; the height of the anchor drill system can be adjusted through the lifting of the lifting device; and a propelling part arranged on the anchor drill system capable of lifting up and down and rotating outwards can horizontally and vertically rotate. According to the automatic anchor rod drill carriage, the mechanical construction of anchor rod holes, blast holes and probe holes at different heights and angles in a roadway can be realized, and the whole machine is reasonable and compact in structure, flexible in workand convenient to operate.

Owner:SHIJIAZHUANG COAL MINING MACHINERY

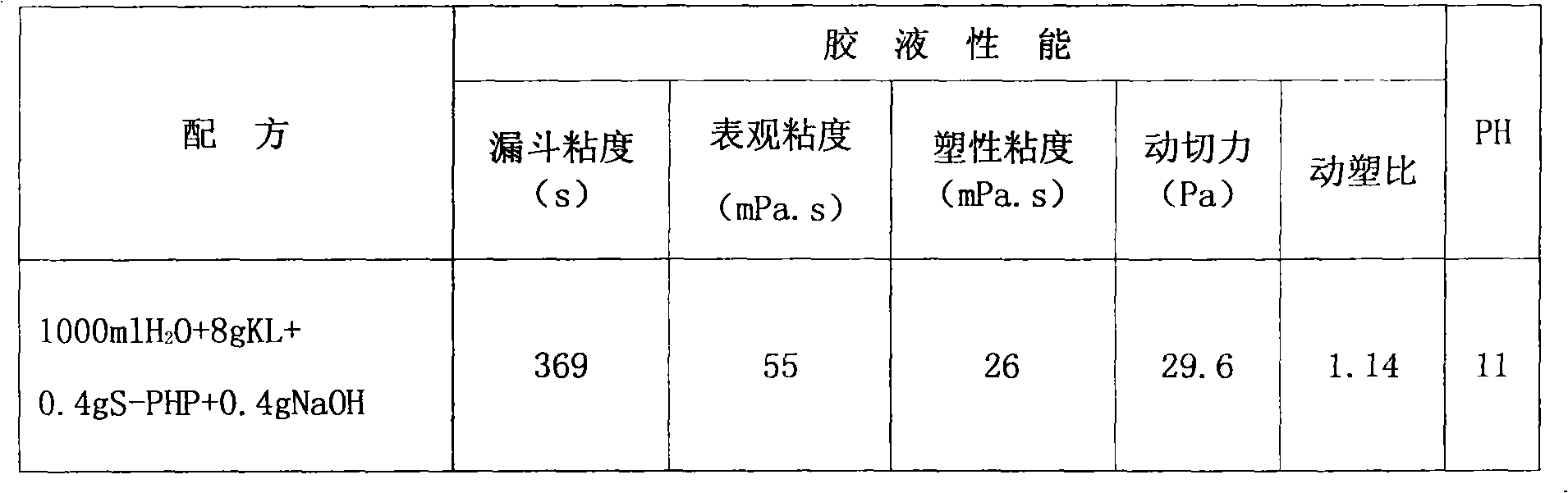

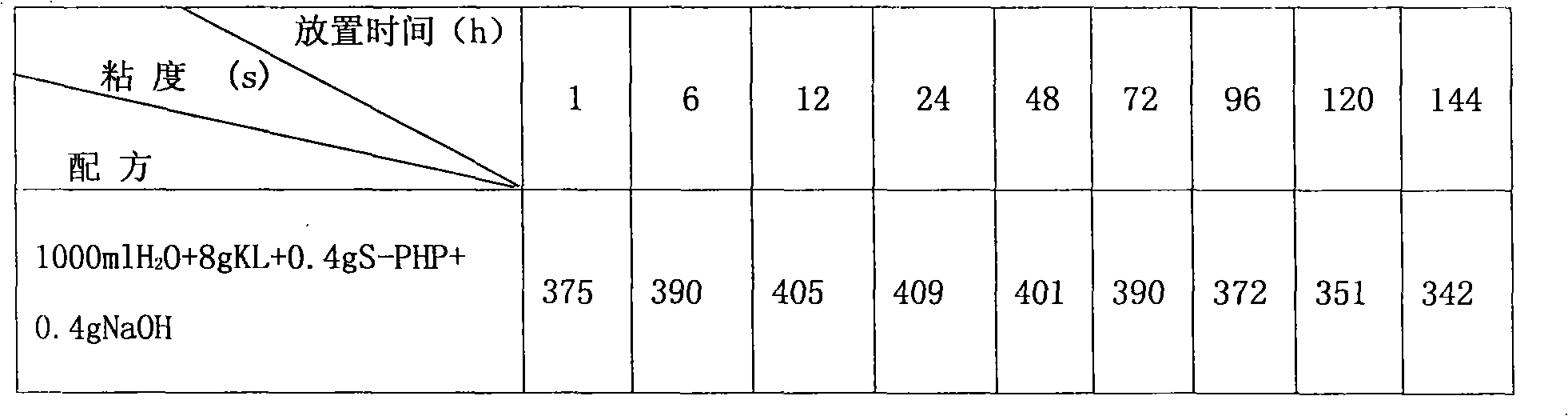

KL bean vegetable gum type environment-protective slurry and preparation thereof

The invention provides a bitter drabanemerosa hebecarpa bean vegetable jelly type environment-friendly slurry, comprising the following components: 6-12g of bitter drabanemerosa hebecarpa bean vegetable jelly, 0.2-0.6g of hydrolyzed polyacrylamide with at least molecular weight of 12 million, 0.2-0.6g of sodium hydroxide and 1,000ml of water. The invention has ready availability of raw materials, stable performance, excellent rheological characteristics, good capability of lubrication, leak stoppage, suspending to remove debris and resisting dilution shearing, simple fabrication operation, low cost and good environment-friendly performance. The invention also provides a method for preparing the bitter drabanemerosa hebecarpa bean vegetable jelly type environment-friendly slurry.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com