Quick broaching method and structure

A fast and deep hole drilling technology, which is applied in the fields of drilling equipment and methods, earthwork drilling, drilling equipment, etc., can solve problems such as complex construction, difficult deep hole drilling, and affecting the anchoring effect of supporting materials, so as to ensure The effect of reaming quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

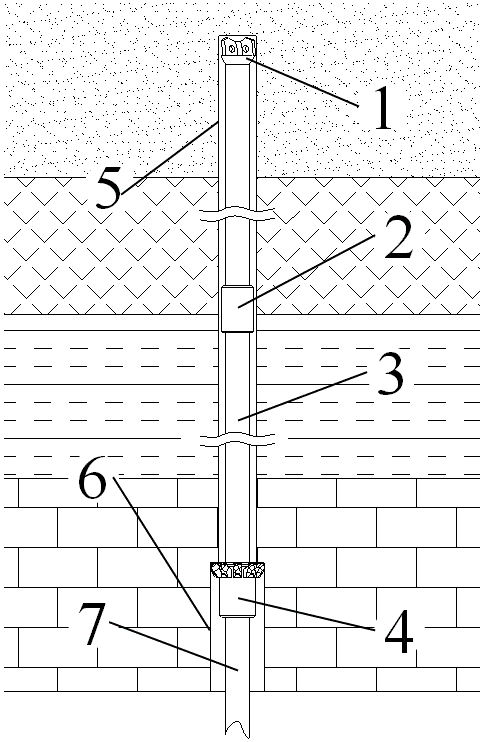

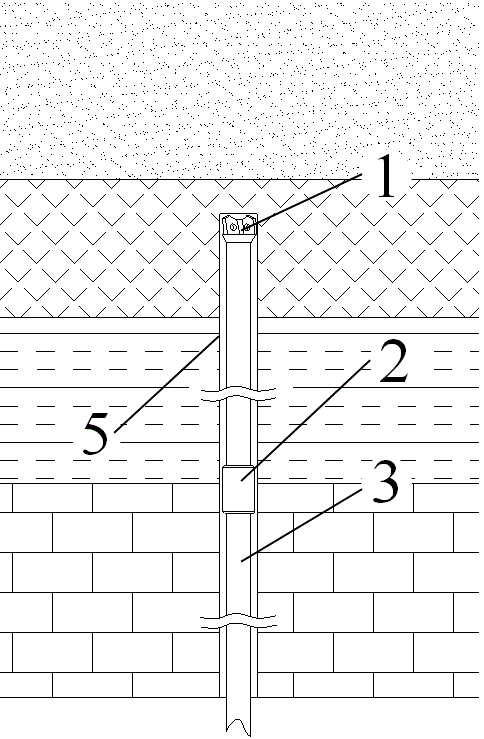

[0016] refer to figure 1 , 2 , 3, 4, 5 illustrate the embodiments of the present invention, a rapid reaming method and structure, in the deep hole drilling process, under the premise of not affecting the deep hole 5, the shallow reaming 6 is performed without To change the drilling process, the outermost drill pipe 7 is connected with the joint head 4 with picks, and the deep drilling 5 and the shallow reaming 6 are realized at the same time, while the connection of the drill pipe 3 inside the deep hole is still connected with the ordinary joint head 2, Utilize the orientation of borehole deep drill bit 1 at the same time, guarantee deep part small-diameter borehole 5 and shallow part large-diameter borehole 6 to be on the same axis, guarantee reaming 6 quality, its reaming 6 lengths are adjustable, connect drill rod 7 at last Quantity and the drilling length of the last connected drill pipe 7 are determined.

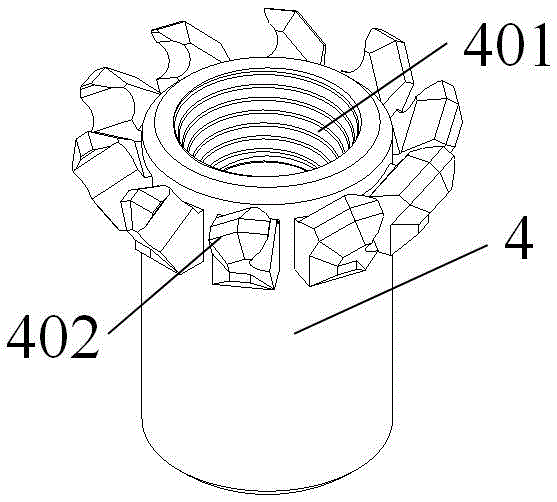

[0017] A pick 402 is provided on the outer edge of the connectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com