Dedicated clamp for reaming sheath of connecting rod of engine

A technology of engine connecting rod and special fixture, which can be used in clamping, manufacturing tools, metal processing mechanical parts, etc., and can solve problems such as skew, air pressure ratio reduction, and leakage of piston group.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

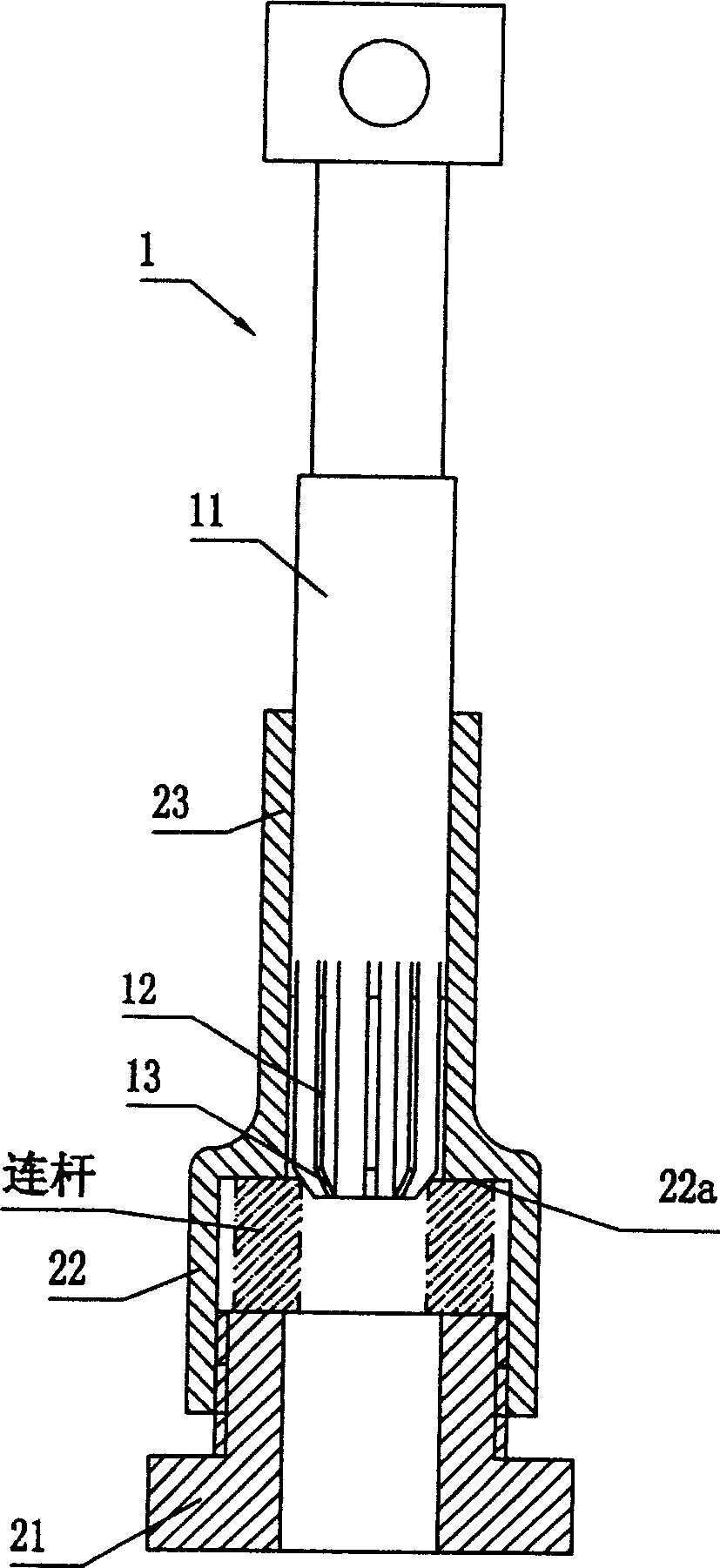

[0008] The special clamp for reaming of the engine connecting rod sleeve, as shown in the accompanying drawings, includes a clamp body 22, a gland 21 and a guide sleeve 23. The clamp body 22 has a positioning plane 22a that can fit the reference end surface of the connecting rod; the gland 21 is screwed to the clamp body 22, and the gland 21 is provided with a reaming hole in the axial direction for the reamer 1 to pass through When turning the gland 21, the connecting rod can be clamped on the positioning plane 22a. The inner hole of the guide sleeve 23 is in clearance fit with the guide cylinder 11 of the reamer, and the axis of the inner hole is perpendicular to the positioning plane 22a of the chuck body 22 . The guide sleeve 23 is integrated with the clamp body 22, so that the structure of the clamp is more concise and practical.

[0009] The above-mentioned reamer 1 consists of a cone-shaped cutting edge 13 positioned at the head, a correcting blade 12 adapted to the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com