Self-balancing double-core reamer bit

A self-balancing, reaming bit technology, used in drill bits, drilling equipment, earth-moving drilling, etc., can solve the problems of unbalanced force and unstable working conditions of the double-center reaming bit, and achieve improved structural design and layout. Tooth method, improve the service life, the effect of stable working condition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to have a clearer understanding of the technical features, objectives and effects of the present invention, specific embodiments of the present invention will now be described with reference to the accompanying drawings.

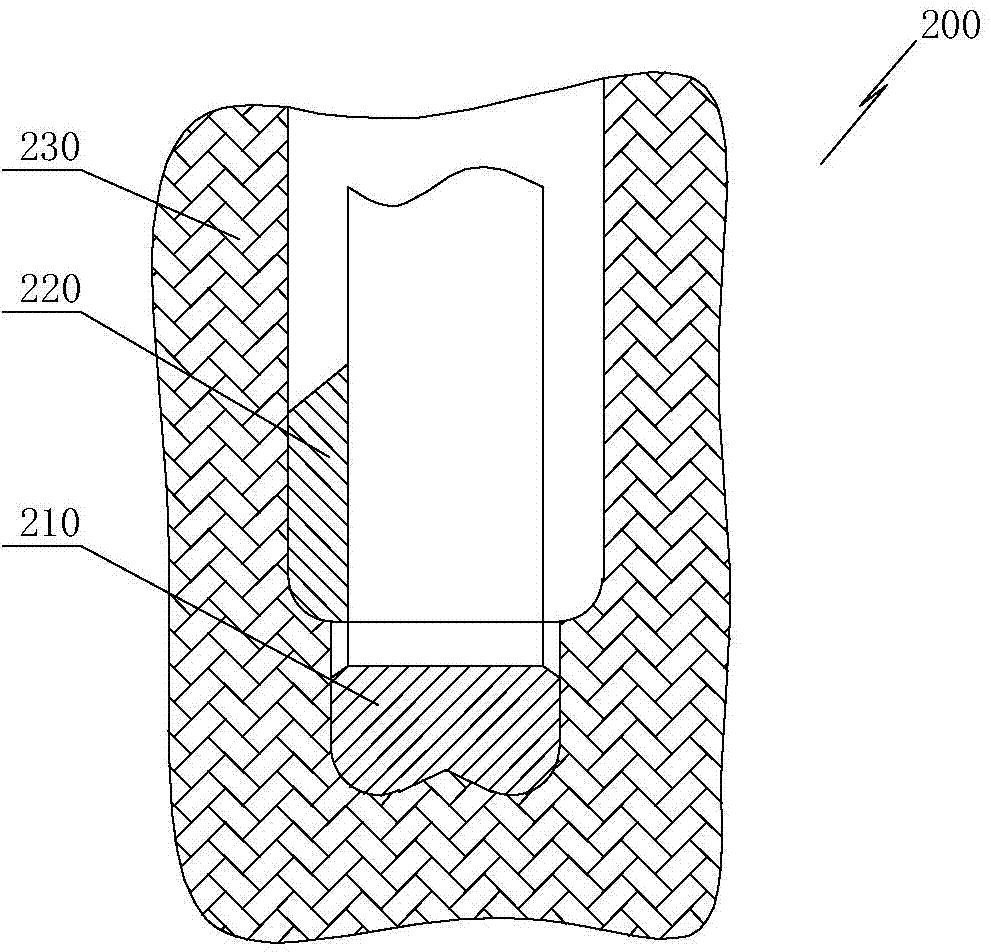

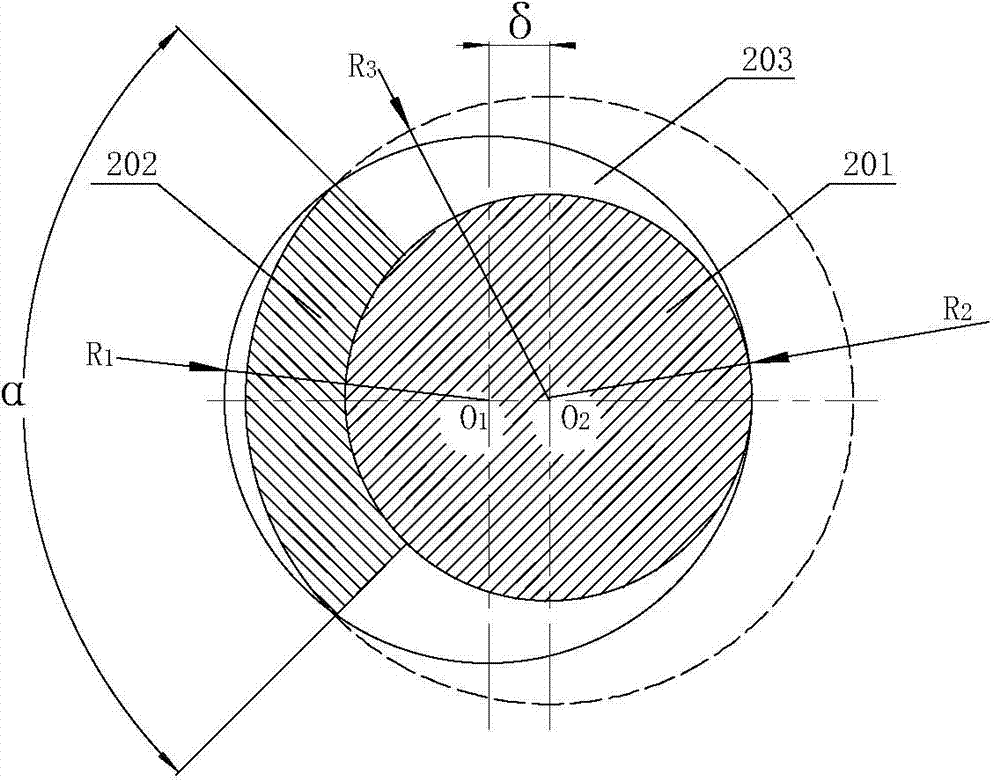

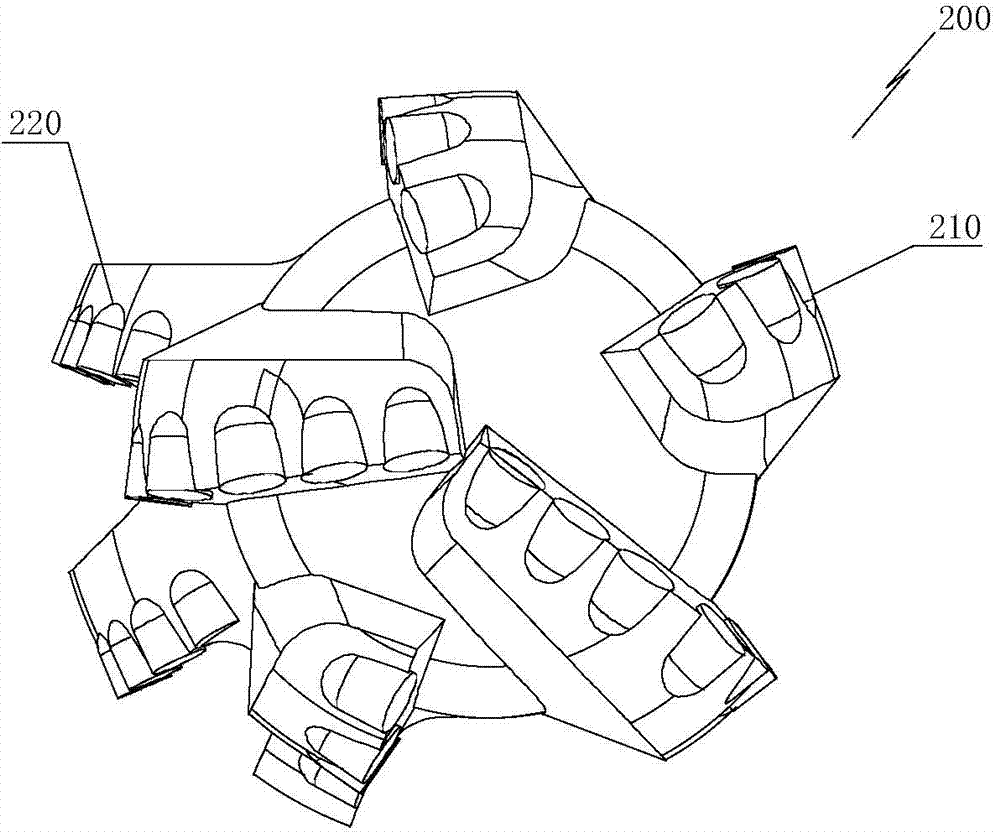

[0028] Such as Figure 5 , Image 6 As shown, the self-balancing double-core reamer bit 100 of the present invention includes an upper pilot bit 1 and a lower reamer blade group 2. The pilot bit 1 includes a drill body 11, and the top of the drill body 11 is circumferentially arranged There are the first wing 12 of the pilot eye, the second wing 13 of the pilot eye, the third wing 14 of the pilot eye and the fourth wing 15 of the pilot eye; the upper top of the first wing 12 of the pilot eye is located at the top center of the pilot bit 1 A row of cutting teeth 3 is evenly arranged from the tip of the blade to the end of the blade on the side of the first blade wing 12 of the pilot eye facing the direction of rotation (PDC cutting teeth are gener...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com