Detecting and sorting machine for SOT packaged products

A technology for sorting machines, products, applied in the direction of sorting, conveyor items, transportation and packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

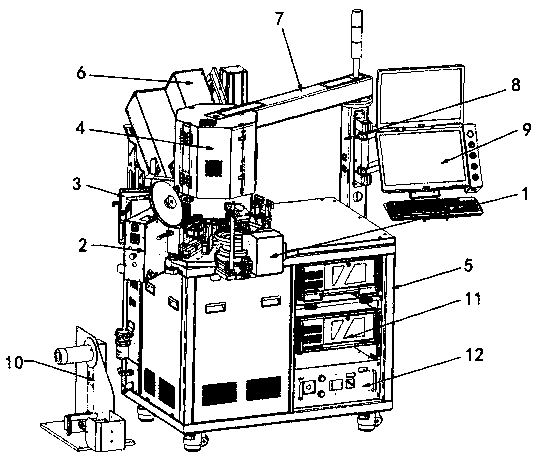

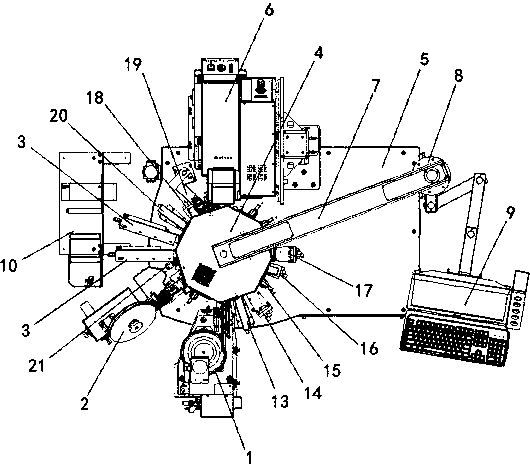

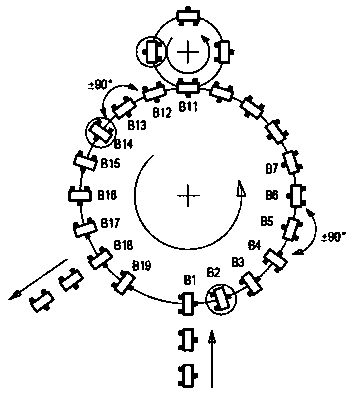

[0048] see Figure 1-3 Shown, a kind of SOT packaging product detection and sorting machine comprises a workbench 5, and the table top of described workbench 5 is provided with by feeding station B1, visual inspection presence and direction station B2, polarity detection station Bit B3, primary throwing station B4, primary direction rotation station B5, first function test station B6, second function test station B7, coding station B11, secondary throwing station B12, secondary direction Rotation B13, 3D detection pin station B14, first and third throwing box station B15, second and third throwing box station B16, product presence or absence detection station B17, receiving and packaging station B18 and full throwing box Counterclockwise circular station composed of station 19;

[0049] A feeding mechanism 1 is installed on the fee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com