Water-in-oil-type biodiesel-based drilling fluid and preparation method thereof

A technology of biodiesel and water-in-oil type, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problem of no technical report of water-in-oil type biodiesel-based drilling fluid and the impact of drilling fluid filter cake filtration reduction In order to avoid problems such as loss of performance and poor viscosification effect of organic soil, it can achieve the effect of strong shale inhibition, excellent operation performance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

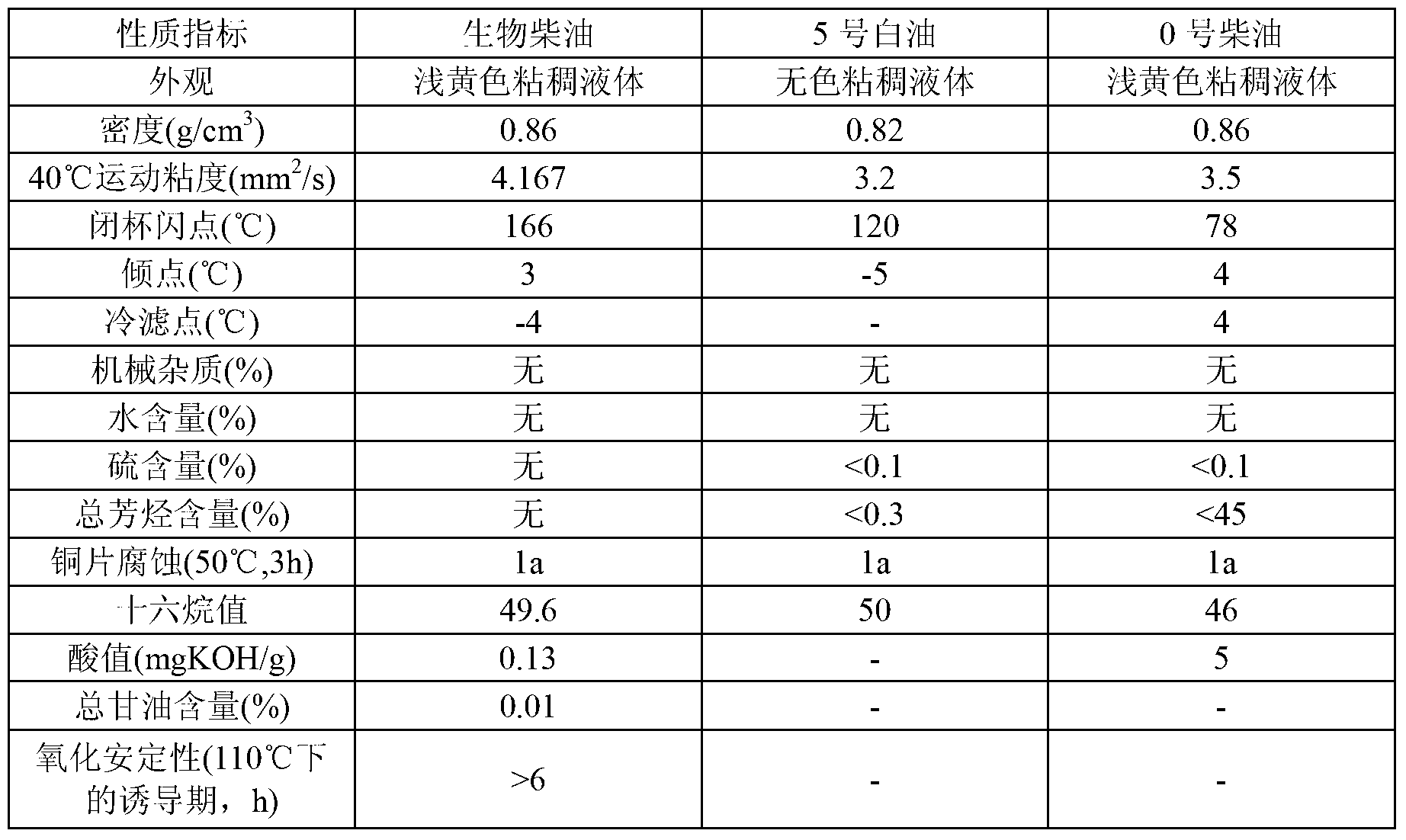

[0063] The specific formula of the water-in-oil type biodiesel base drilling fluid of the present embodiment is:

[0064] Biodiesel (fatty acid methyl ester) volume: 25% calcium chloride brine volume = 80:20, in addition to containing 3.5% primary emulsifier + 2% secondary emulsifier (alkylbenzene sulfonate) + 3% calcium oxide + 4% Organic bentonite + 5% wetting agent (including 4% octylphenol ethoxylate and 1% lecithin PC50) + 4% fluid loss control agent (all lignite).

[0065] The biodiesel base drilling fluid of the present embodiment is prepared according to the following method:

[0066] ① Under high-speed stirring, slowly add the required primary emulsifier, secondary emulsifier, and wetting agent to 80 parts of biodiesel in sequence. After each treatment agent is added, stir for 30 minutes before adding the next one until these components are fully dispersed in the biodiesel.

[0067] ② Prepare a calcium chloride solution with a mass fraction of 25% in water. Dissolv...

Embodiment 2

[0084] The water-in-oil biodiesel-based drilling fluid in this example is based on the formula in Example 1, which is aggravated. The specific formula is:

[0085] Biodiesel (fatty acid ethyl ester) volume: 25% calcium chloride brine volume = 80:20, in addition to containing 3.5% primary emulsifier + 2% secondary emulsifier (alkylbenzene sulfonate: petroleum sulfonate = 8:2 ) + 3% calcium oxide + 4% organic bentonite + 5% wetting agent (formed from 4% octylphenol polyoxyethylene ether and 1% lecithin PC50) + 4% fluid loss control agent (all lignite) +80% Barite Dust. The preparation steps are basically the same as in Example 1. The weighting step is to add the weighting material to the drilling fluid system slowly while stirring after fully mixing other components of the drilling fluid until the density of the system reaches the requirement, and then seal the prepared biodiesel-based drilling fluid and let it stand More than 24 hours.

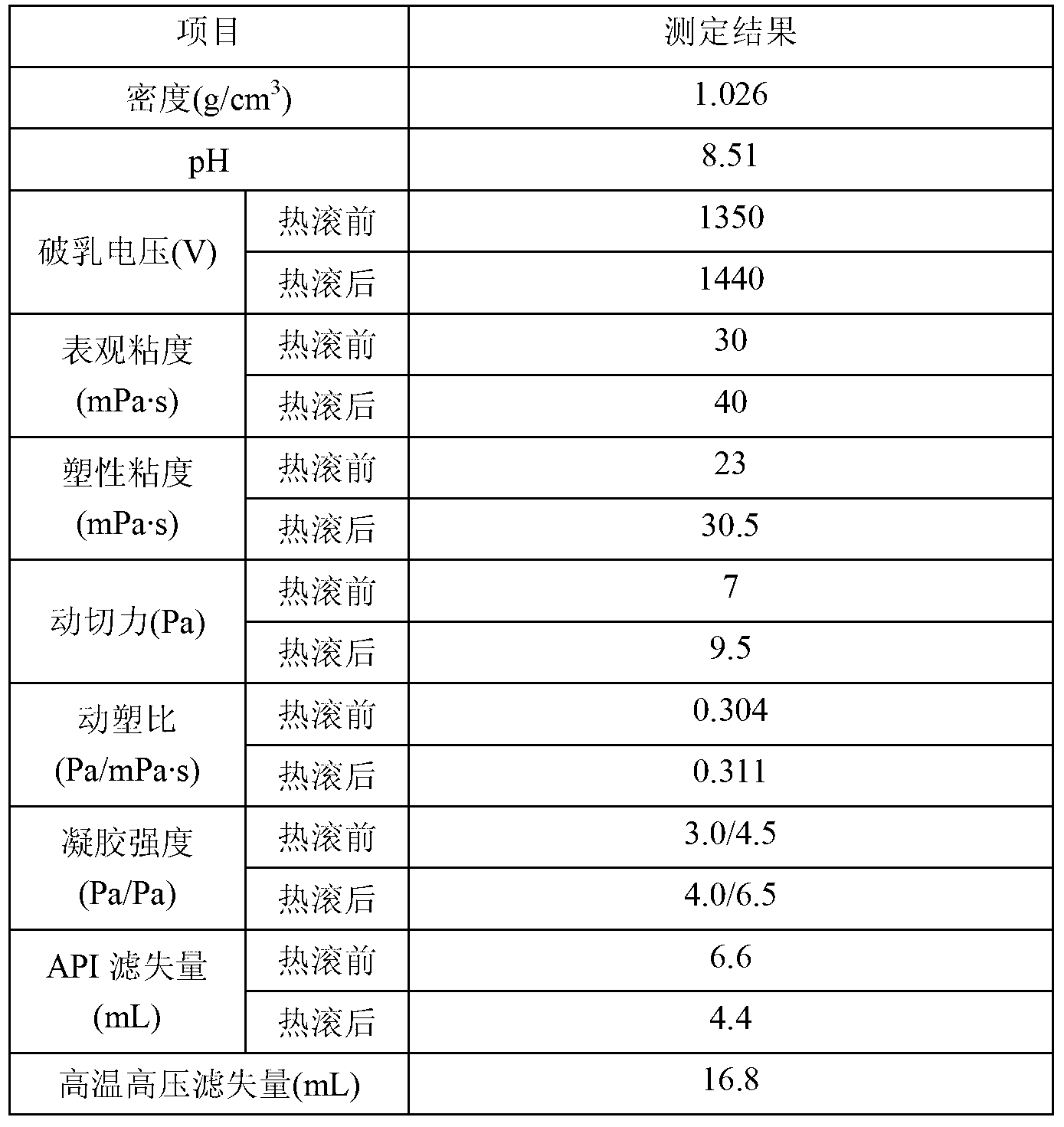

[0086] The basic properties of the o...

Embodiment 3

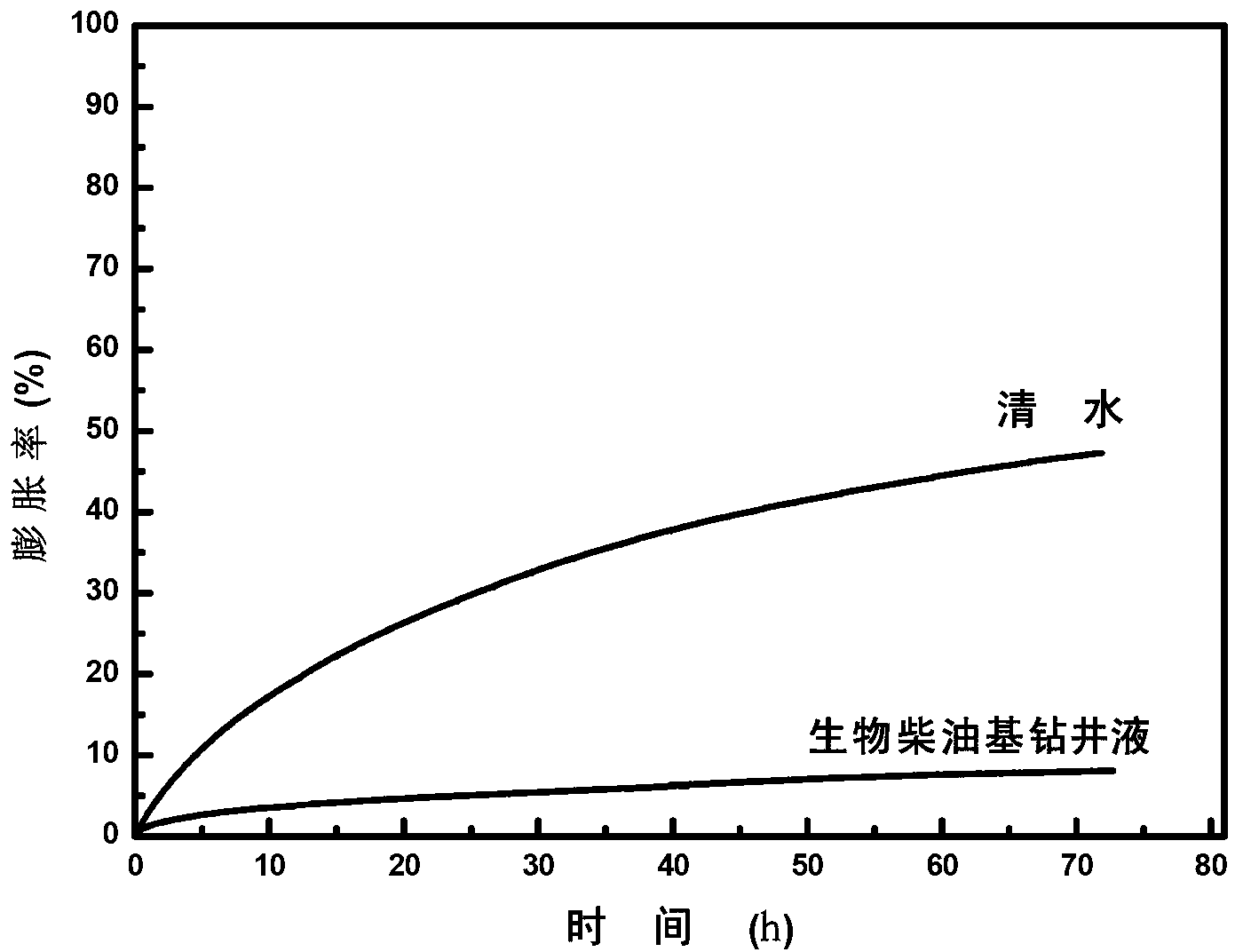

[0091] This embodiment changed the calcium chloride mass fraction in the calcium chloride brine phase on the basis of the aforementioned embodiment 1 (the remainder of the formula is constant), to illustrate that the drilling fluid can be regulated to a certain extent by changing this parameter. Shale inhibition. The specific formula is: biodiesel volume: 35% calcium chloride brine volume = 80:20, in addition to containing 3.5% primary emulsifier + 2% secondary emulsifier + 3% calcium oxide + 4% organic bentonite + 5% wetting agent ( Consists of 4% octylphenol ethoxylate and 1% lecithin PC50) + 4% fluid loss control agent (all lignite). The preparation steps are basically the same as in Example 1. The basic performance of the system is shown in Table 6:

[0092] Table 6 Example 3 Basic Properties of Drilling Fluid System

[0093]

[0094]

[0095] It can be seen from Table 6 that by increasing the concentration of calcium chloride in the brine phase, the basic perform...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com