Geological bit and its manufacturing method

A drill bit and geological technology, which is applied in the direction of drill bits, drilling equipment, earthwork drilling, etc., can solve the problems of poor quality stability, poor quality stability, and low drilling time efficiency of concentric tooth drill bits, and achieve simple and reliable manufacturing methods and good steering performance , high timeliness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

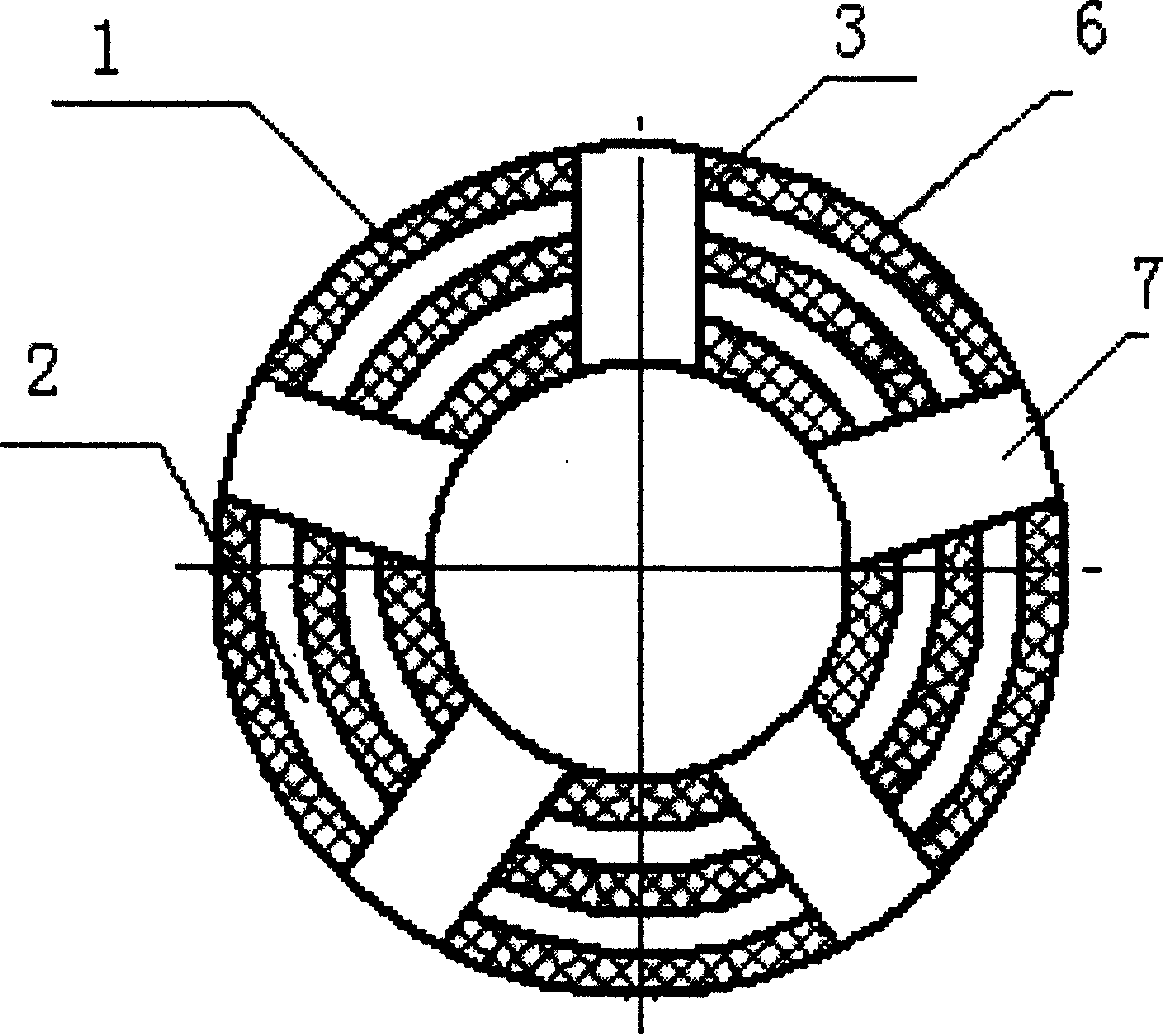

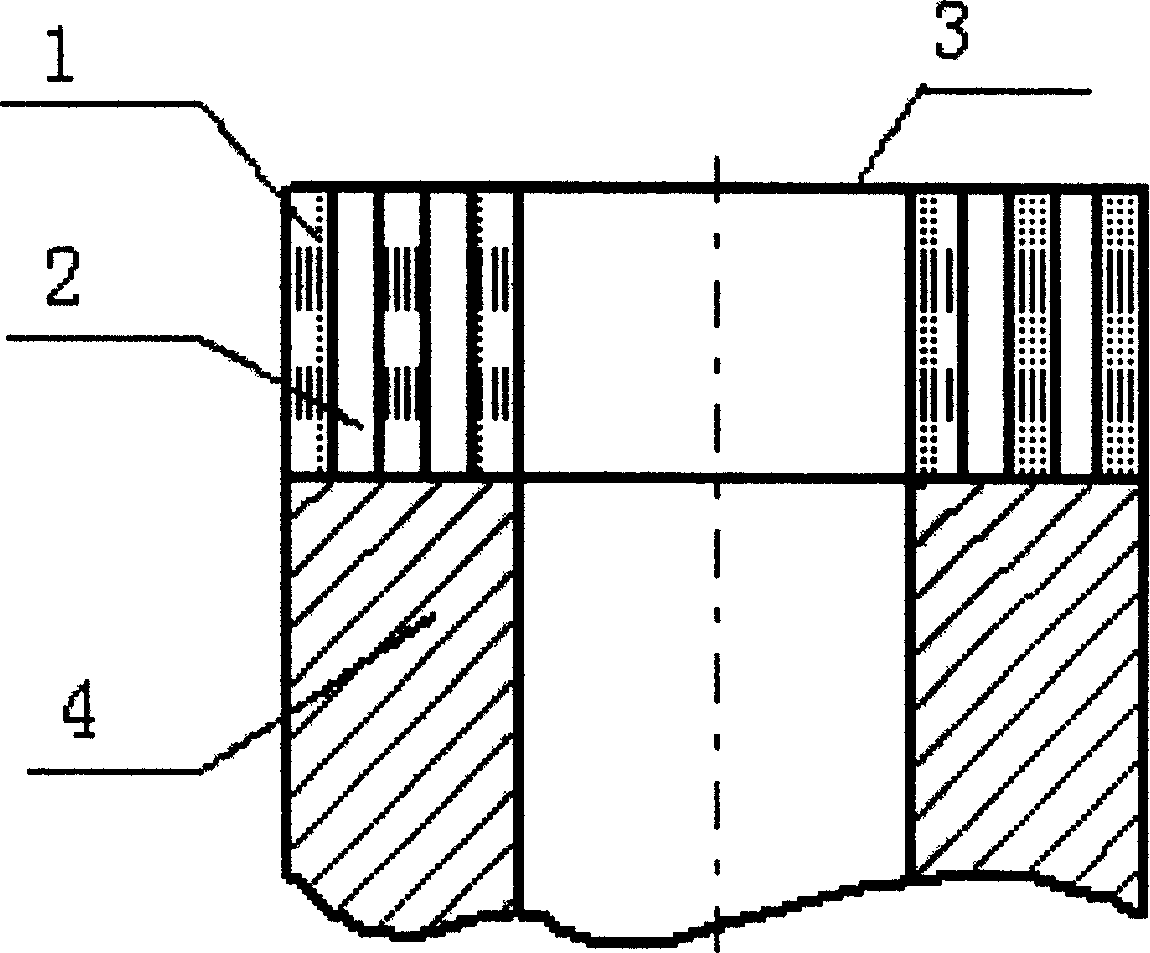

[0019] see figure 1 and figure 2 The carcass 3 is sintered on the top of the steel body 4 by cold pressing and hot pressing. The carcass 3 is composed of hard-wearing layers 1 and easy-wearing layers 2 arranged coaxially and radially alternately. The wear layer 1 and the carcass 3 are evenly divided into a plurality of wing blocks 6 by water guide grooves 7 . The material of the wear-resistant layer 1 is diamond + the first metal powder, and the material of the easy-wear layer 2 is the second metal powder or diamond + the second metal powder.

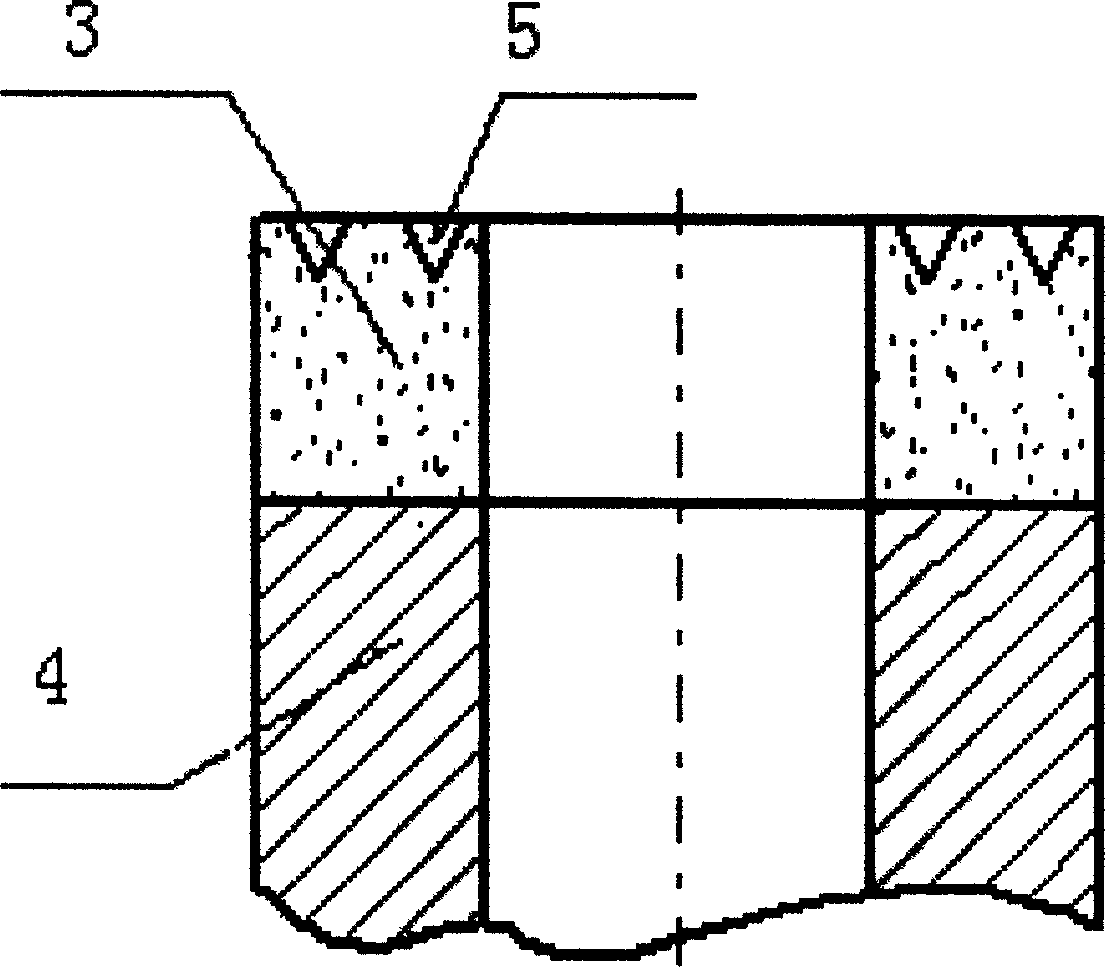

[0020] see figure 1 , figure 2 and image 3 , during the entire drilling process, the tile-shaped hard-wear layer 1 of the matrix 3 cuts and drills the rock surface, while the tile-shaped easy-wear layer 2 is worn by the rock surface, and the lip surface of the drill bit will appear serrated 5, correspondingly Multiple rock ridges are formed on the surface of the drilled rock formation to form multiple free surfaces, which "fit" ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com