Composite drill bit

A composite drill bit and bit body technology, which is applied to drill bits, drilling equipment, earth-moving drilling, etc., can solve the problems of low drilling efficiency and low ROP, so as to increase the footage of the drill bit, increase the ROP, and ensure smooth drilling. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The above-mentioned technical features and advantages of the present invention will be clearly and completely described below in conjunction with the accompanying drawings. Apparently, the described embodiments are only some, not all, embodiments of the present invention.

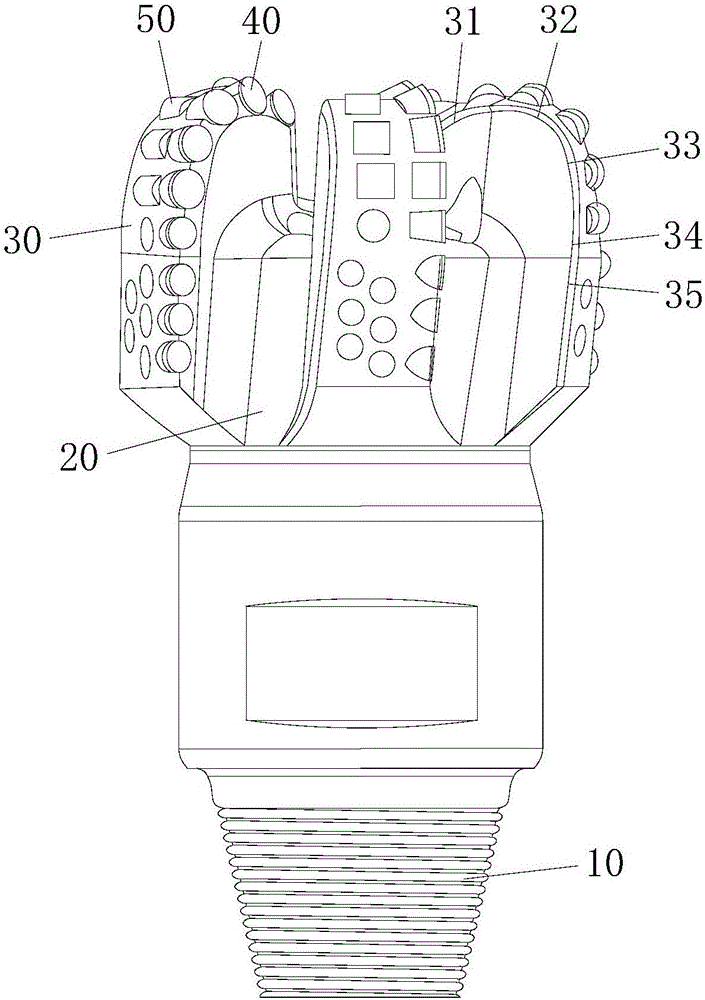

[0040] see figure 1 Shown, a kind of compound drill bit, it comprises columnar joint 10 and the drill body 20 that is connected on the joint 10, compound drill bit also comprises at least three blades 30, and at least three blades 30 are uniform along the circumferential direction of drill body 20 Arranged on the drill body 20 , each blade 30 extends from inside to outside along the radial direction of the drill body 20 , and each blade 30 has a crown profile on its outer surface, and the crown profile is a curve.

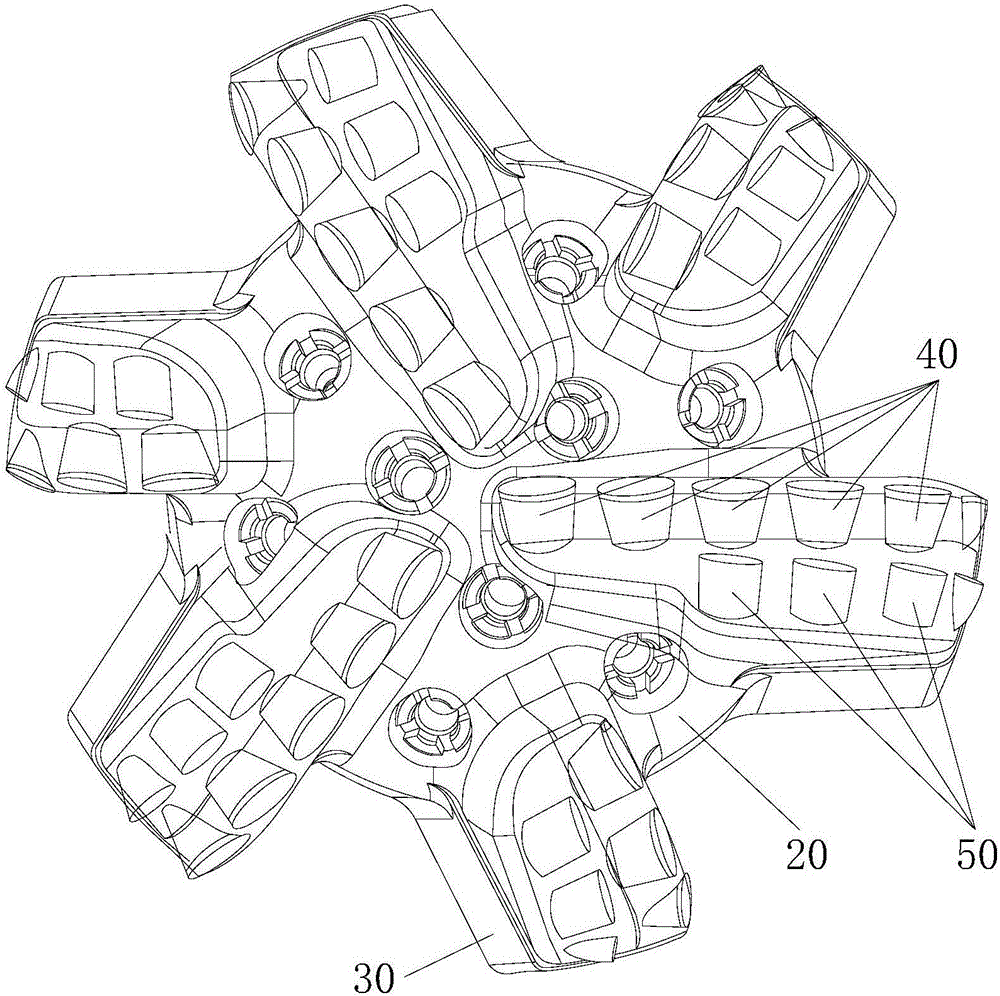

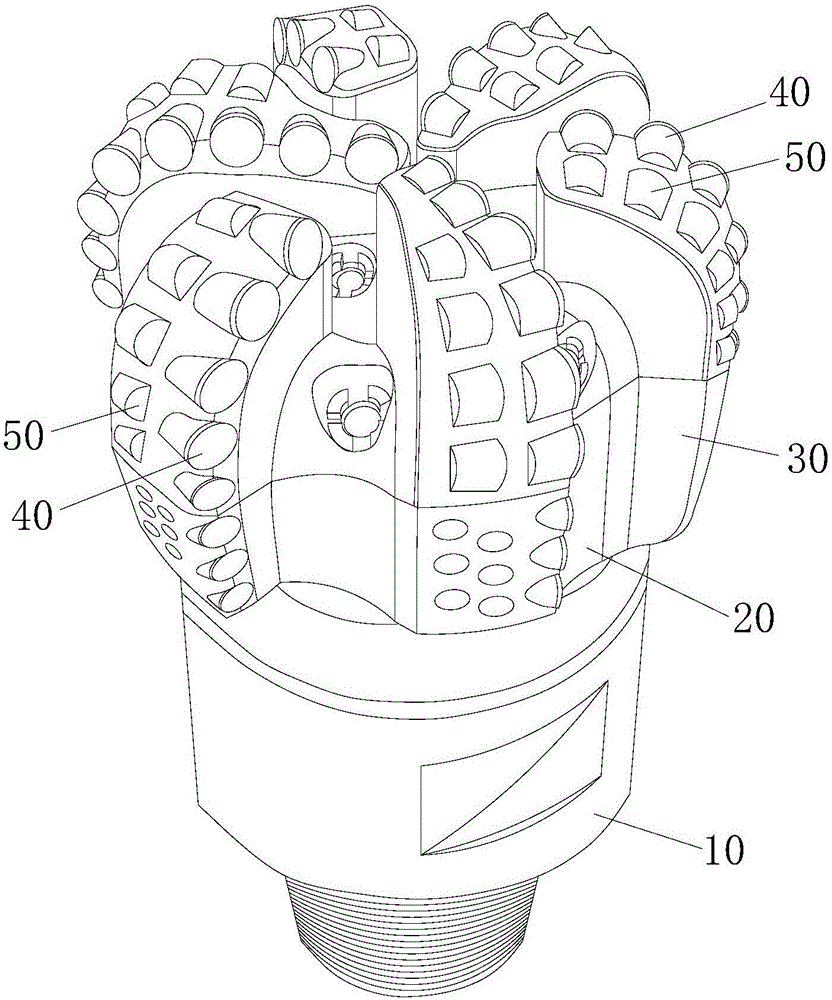

[0041] see figure 2 and image 3 As shown, the composite drill bit also includes a plurality of cutting teeth 40 and a plurality of grinding teeth 50 fixedly arranged on the contour of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com