Patents

Literature

56results about How to "Increase footage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

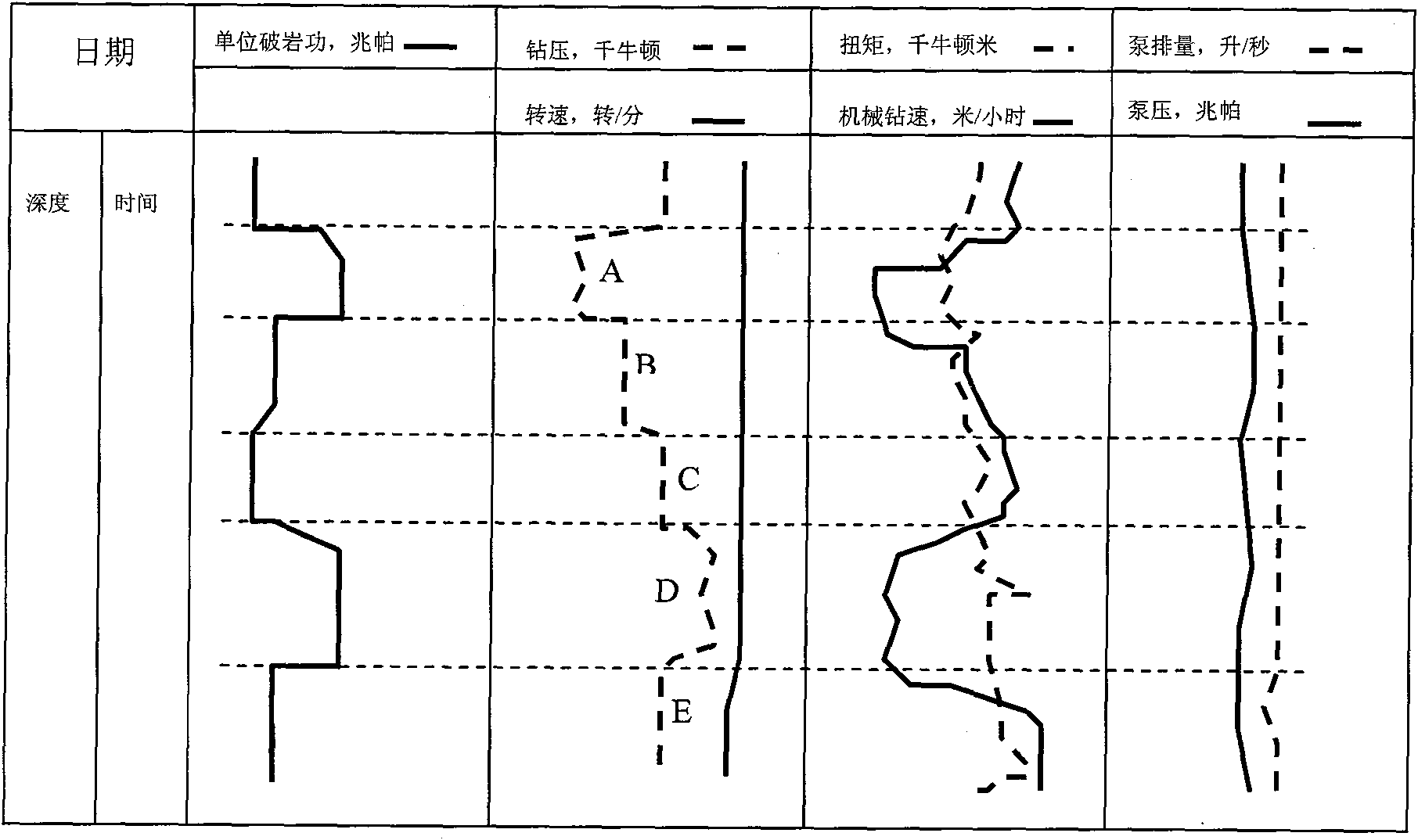

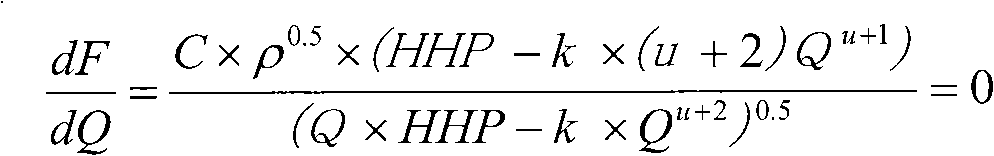

Real-time on-site drilling full parameter optimization method

The invention provides a real-time on-site drilling full parameter optimization method which mainly comprises three parts of hydraulic optimization, bit pressure optimization and rotating speed optimization. The method comprises the following steps of: determining an optimal hydraulic parameter according to a relation between a pump output and a pump pressure, which is obtained by field measurement, and selecting the size of a bit nozzle; and under this premise, determining an optimal bit pressure and a rotating speed relative to a current drilling stratum through observing variation of unit rock fracture work of a bit in real time when the bit pressure and the rotating speed are adjusted. Drilling site operators can accordingly optimize the drilling hydraulic power, the bit pressure and the rotating speed in real time and on the site, thereby maximizing drilling efficiency and drilling mechanical penetration speed and prolonging service lift of the bit or improving drilling footage of a single bit.

Owner:HALLIBURTON ENERGY SERVICES INC

Anti-impact diamond layer, diamond composite sheet and preparation method for diamond composite sheet

The invention discloses an anti-impact diamond layer, an anti-impact diamond composite sheet and a preparation method for the diamond composite sheet. Coarse granular diamond is used as a main raw material, graphite is used as a filling agent, and iron-based powder is used as an accelerant; the diamond layer comprises the following components in part by weight: 70 to 80 parts of diamond, 10 to 20 parts of graphite powder, and 3 to 12 parts of accelerant; and the accelerant consists of the following materials in part by weight: 45 to 60 parts of iron, 15 to 20 parts of nickel, 5 to 15 parts of cobalt, 5 to 20 parts of manganese, and 3 to 10 parts of silicon. The method comprises the following steps of: mixing the raw materials in the ratio uniformly, pre-pressing the mixture and a hard alloy matrix into a composite sheet, filling into a pyrophyllite block to form a structural block, putting the structural block into a 6-surface diamond presser, sintering and electrolyzing at a high temperature under high pressure, and thus obtaining the diamond composite sheet. The diamond composite sheet has the characteristics of big pores and a mesh connection structure, and is quite suitable for drilling medium hard and hard strata due to excellent sharpness and impact toughness.

Owner:河南亚龙金刚石制品股份有限公司

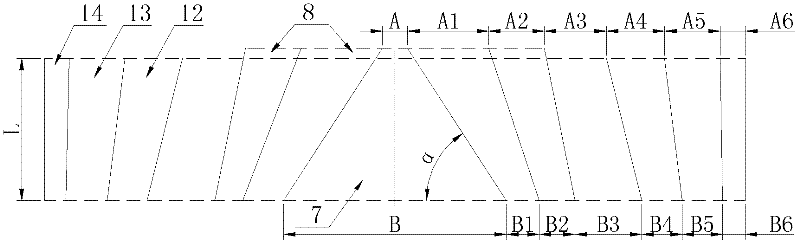

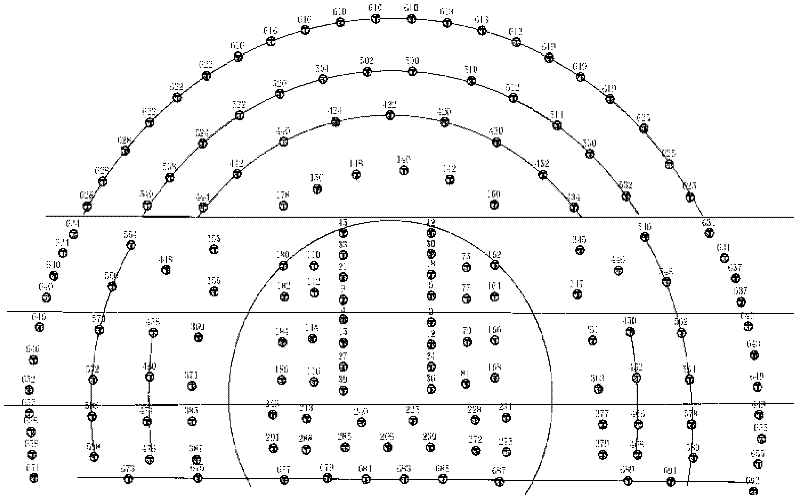

Full-face blasting vibration control construction method for tunnel electronic millisecond electric detonator

ActiveCN102506622AGuaranteed shock absorptionIncrease Single Cycle FootageBlastingDetonatorTime delays

The invention discloses a full-face blasting vibration control construction method for a tunnel electronic millisecond electric detonator, relating to the blasting vibration control technology. The method comprises the following step of: performing a full-face blasting damping control drilling-blasting design by combining blasting vibration requirements according to a tunnel engineering geological condition, an excavated section, an excavating method, a tunneling circulation footage, drilling machine tools and blasting equipment, wherein the drilling-blasting design is as follows: in order to realize the single blasting of cutting holes, auxiliary holes and base plate holes, peripheral holes which are blasted simultaneously are grouped, and the detonator time delay of each shot hole is set, so that the misphase blasting damping is realized; a use flow of the electronic millisecond electric detonator is designed, and the electronic millisecond electric detonator is used according to the flow; an analysis is carried out in the construction process according to the blasting effect and the vibration waveform obtained by blasting monitoring, information is fed back to guide the construction, and blasting parameters are adjusted continuously. The blasting construction method has the advantage of capability of obviously reducing the full-face blasting vibration.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD

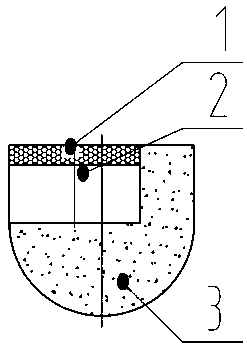

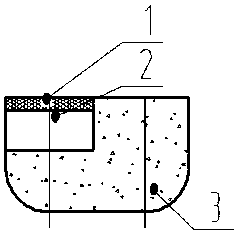

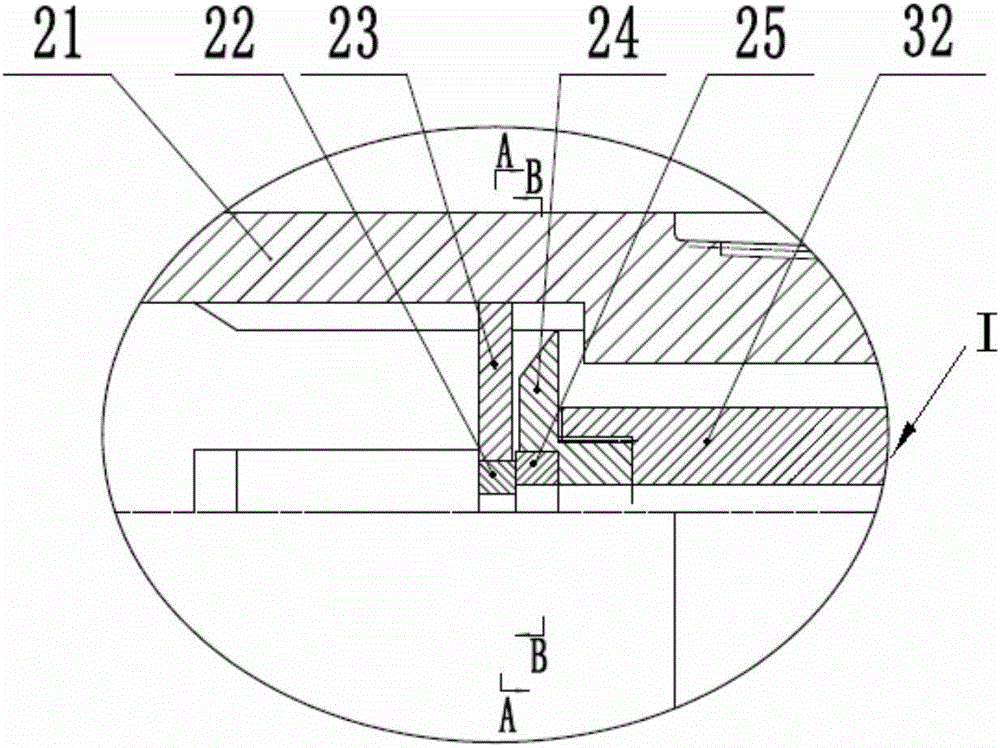

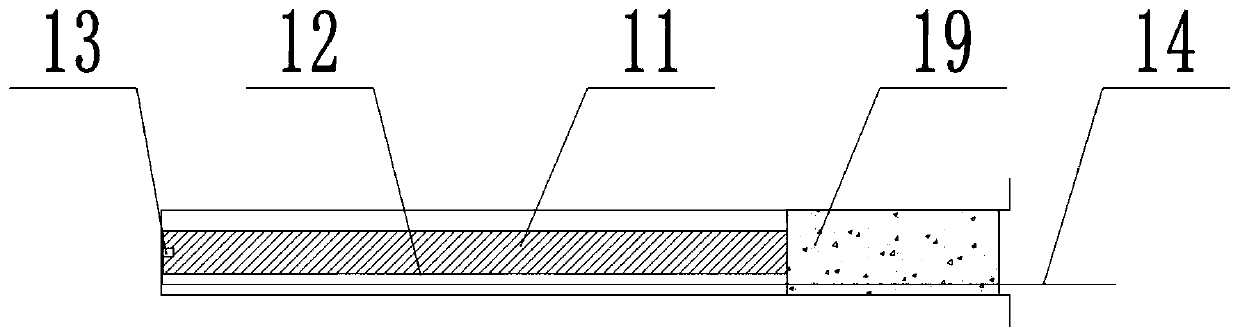

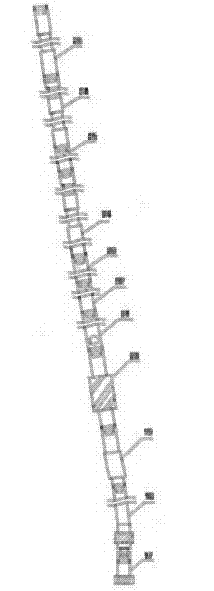

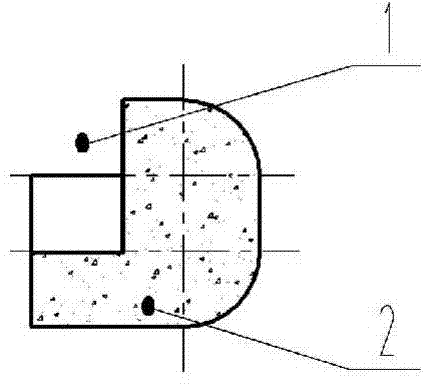

Pressure yielding internally-grouted anchor cable

InactiveCN103410543AExpand the scope of diffusionImprove reinforcementAnchoring boltsSteel tubeCable tray

A pressure yielding internally-grouted anchor cable comprises a hollow internally-grouted cable body, an anchor cable tray, an anchor cable rigging and a pressure yielding pipe, the hollow internally-grouted cable body is formed by winding a plurality of steel strands around a hollow rubber grouting core pipe, a plurality of groups of grout outlet holes are drilled in the hollow rubber grouting core pipe at intervals, the plurality of steel strands at the position of every group of grout outlet hole are processed into a honeycomb-shaped grout outlet section, and the tail portion of the hollow internally-grouted cable body is provided with an anchoring agent mixing head; the pressure yielding pipe is a specially-made steel pipe with the middle portion protruding outwards to form an arc-shaped protrusion, the pressure yielding pipe is sleeved outside the hollow internally-grouted cable body in a penetrating mode and arranged between the anchor cable tray and the anchor cable rigging, and the yield load of the pressure yielding pipe is smaller that of the cable body steel strands. The pressure yielding internally-grouted anchor cable achieves the integration of deep grouting reinforcement and pressure yielding support coupling of surrounding rock of roadway, expands the diffusion range of the grout and enhances the reinforcement function and can yield pressure timely when under relatively large deformation pressure of the surrounding rocks to avoid being broken through pulling and to further avoid losing efficacy, and can effectively improve the stability of deformed surrounding rock of the roadway.

Owner:CHINA UNIV OF MINING & TECH

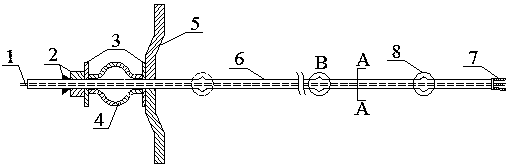

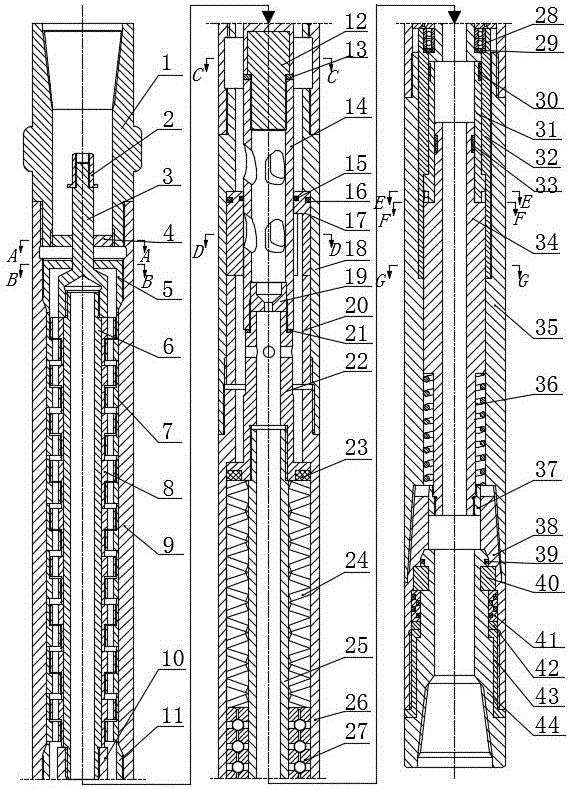

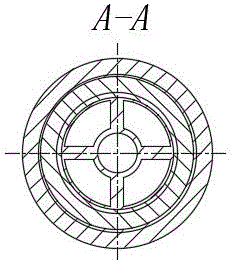

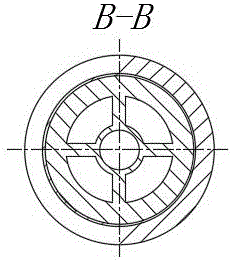

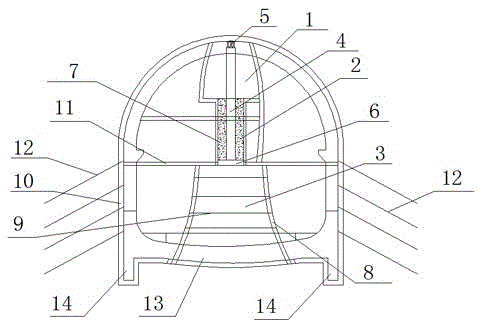

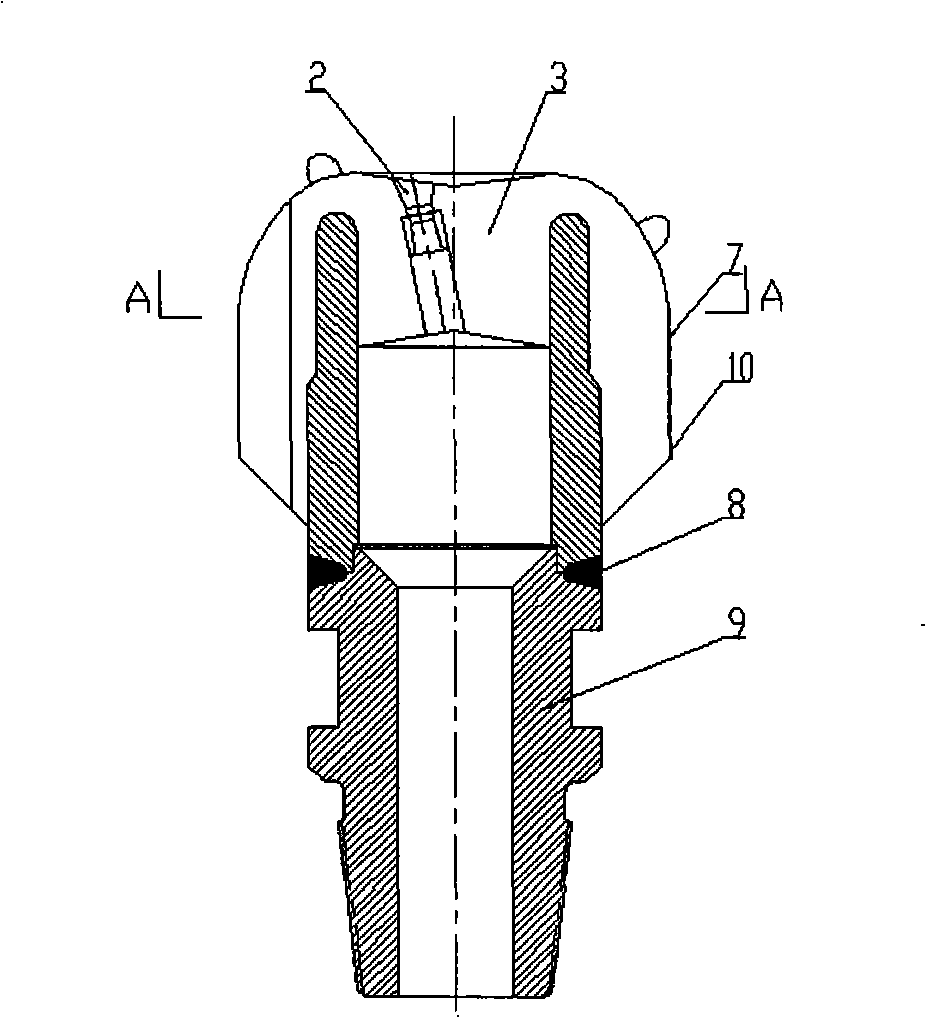

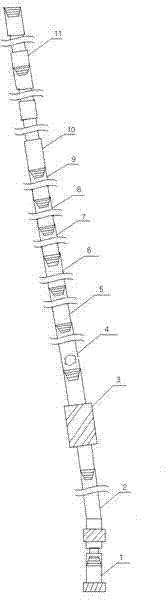

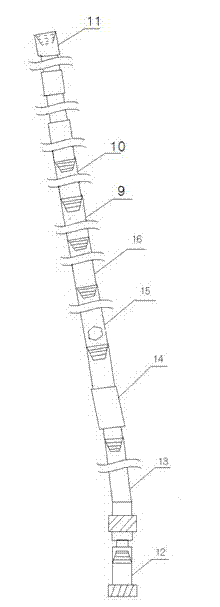

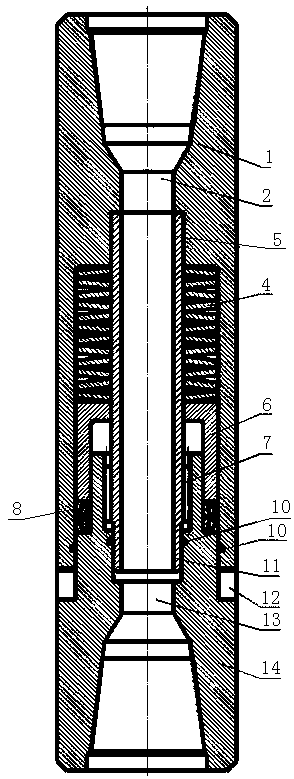

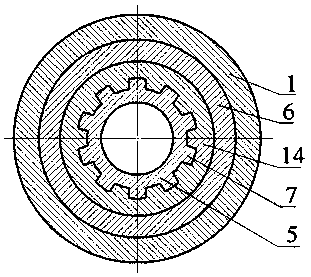

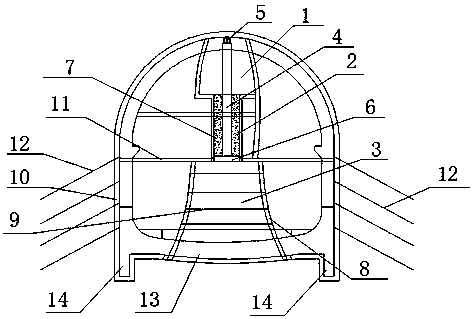

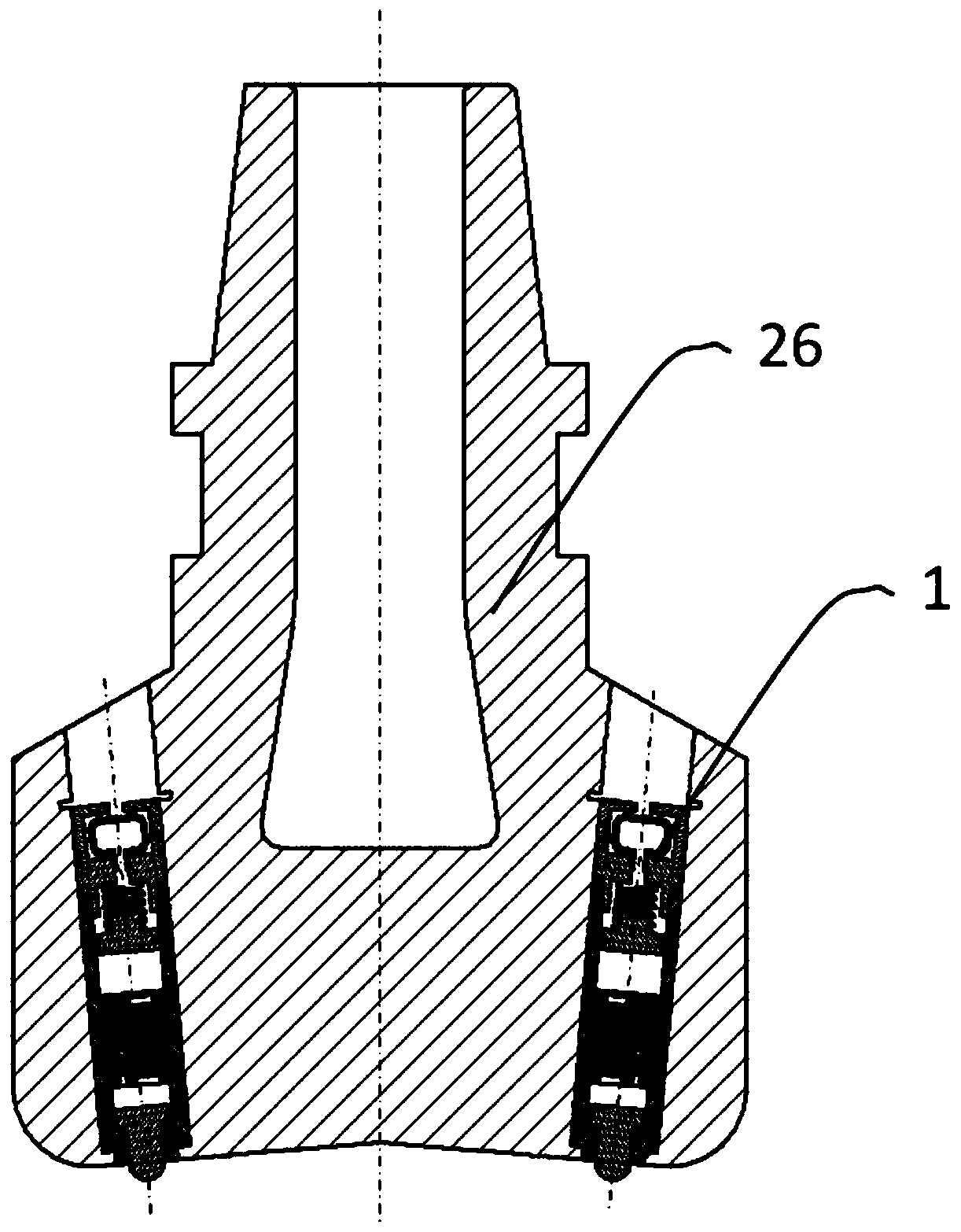

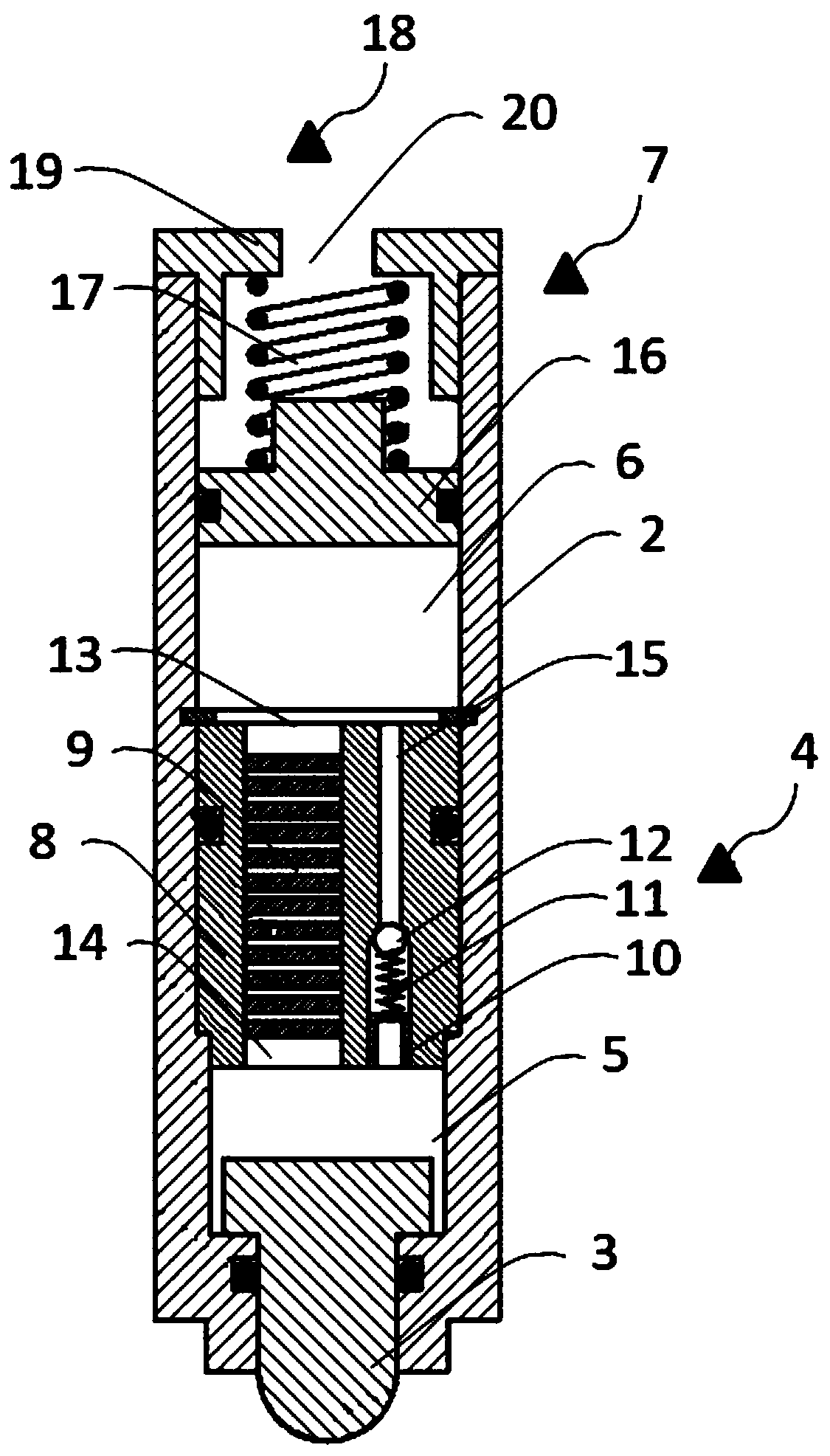

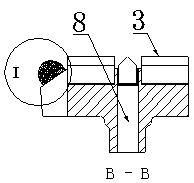

High-frequency torsion-restoration axial vibration impacting tool

ActiveCN106639943AAvoid uneven wearExtended service lifeVibration devicesAxial displacementWell drilling

The invention relates to a high-frequency torsion-restoration axial vibration impacting tool for well drilling engineering of petroleum and natural gas. The tool is connected to the upper portion of a drill bit in a threaded mode and comprises a turbine assembly, a switching assembly and an impacting assembly. The front end of the switching assembly is connected with the impacting assembly, the rear end of the switching assembly is connected with the turbine assembly, and periodical change of a mud channel is achieved through the switching assembly; and a sliding sleeve is pushed to slide forwards through the differential pressure generated by flow channel change, axial displacement and acting force are generated to act on an impacting spline for driving the impacting spline and an impacting hammer to move forwards together, a torsional spring at the front end of the impacting hammer is compressed, an anvil is impacted by the impacting hammer, when the sliding groove moves backwards, the torsional spring exerts a rotating torque on the impacting hammer to enable the impacting hammer to rotate, and after the impacting hammer enters another spline groove, periodic movement is repeated. The high-frequency torsion-restoration axial vibration impacting tool is simple in structure, high in adaptability for the drill bit and the stratum and capable of improving well drilling efficiency.

Owner:靖江市中亿汽车配件制造有限公司

Method for achieving blasting excavation of large-section tunnel with area larger than 400 m2 or above based on electronic detonator

ActiveCN111043926AFast forming timeImprove construction progressBlastingTunnelsDetonatorArchitectural engineering

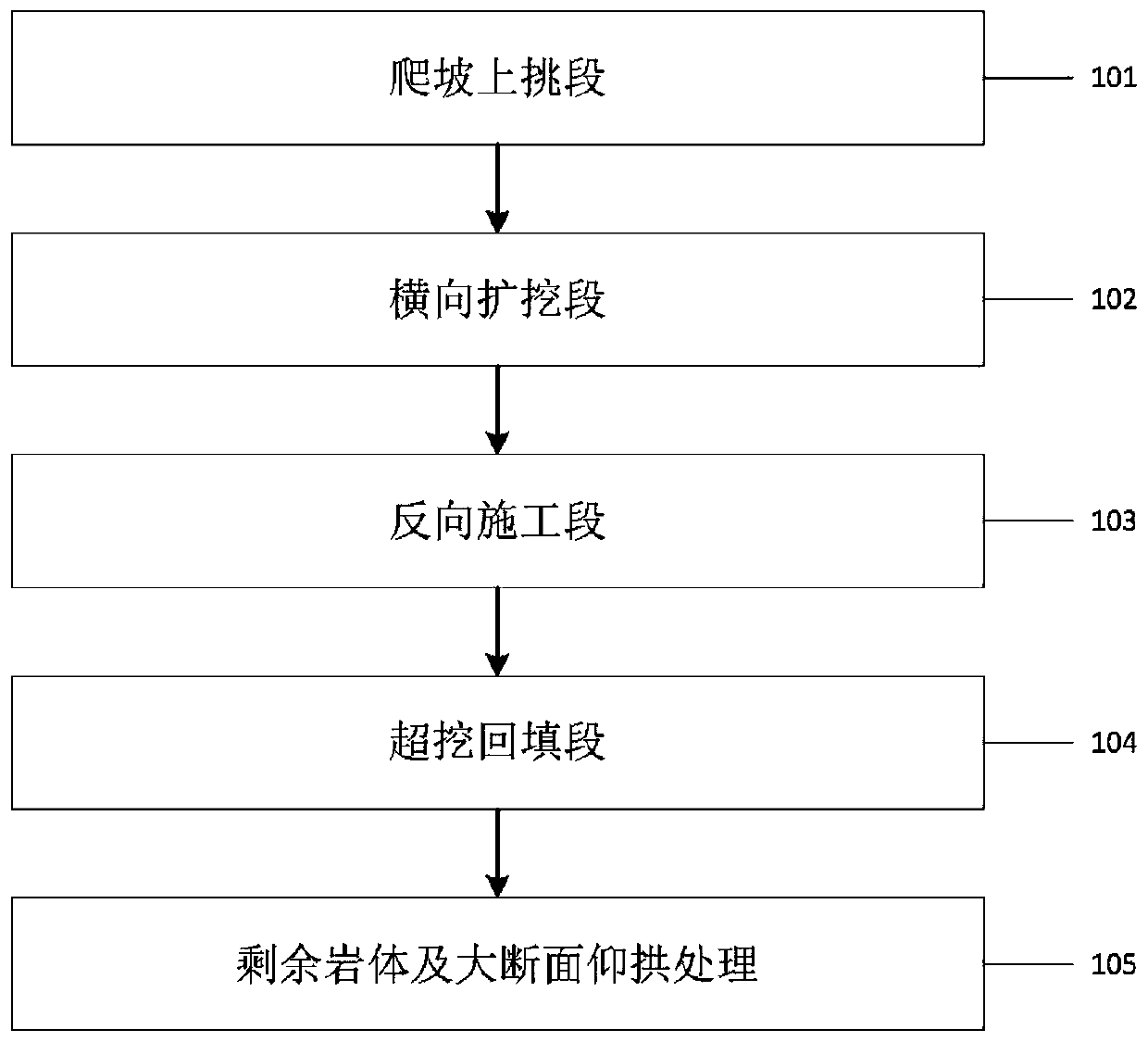

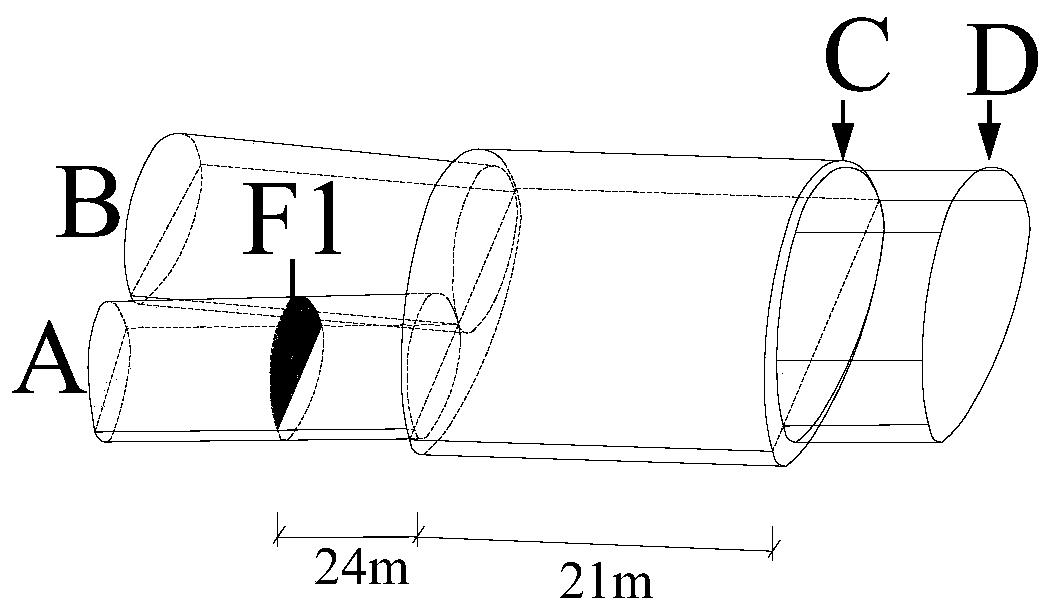

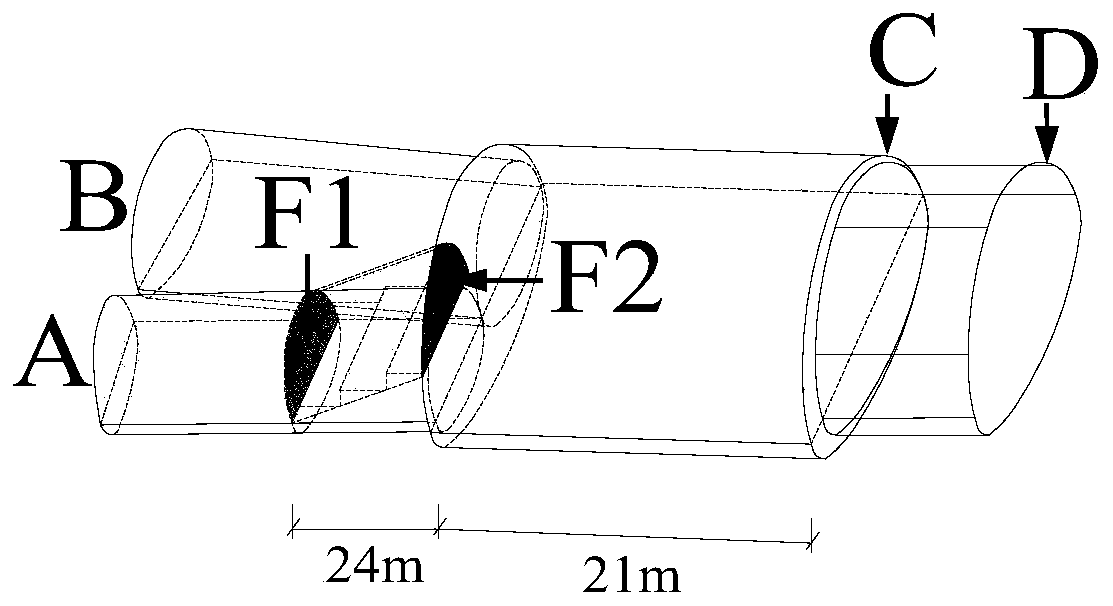

The invention relates to a method for achieving blasting excavation of a large-section tunnel with the area larger than 400 m2 or above based on an electronic detonator and belongs to the field of tunnel blasting construction. The blasting excavation method comprises the five stages of a climbing uplifting section, a transverse expanding excavation section, a reverse excavation construction section, an over-excavation backfill section, a residual rock mass and large-section inverted arch treatment. The climbing uplifting section adopts a common detonator controlled blasting technology, and thetransverse expanding excavation section and the reverse excavation construction section both adopt a digital detonator hole-by-hole blasting technology. According to the method, the requirements forlow vibration speed precise control, high circulating footage and safe construction can be met at the same time in ultra-large section blasting construction.

Owner:CHONGQING ZHONGHUAN CONSTR +1

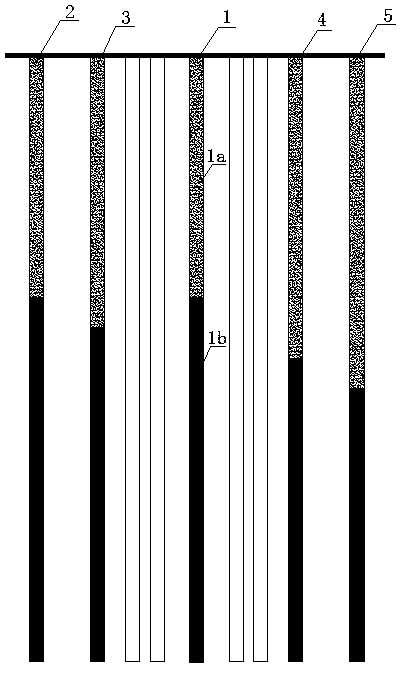

Vertical prestress steel pipe supporting structure for large-section subsurface tunnel and construction process

ActiveCN104453948AReduce adverse effectsReduce the impact of damageUnderground chambersTunnel liningPre stressJoist

The invention discloses a vertical prestress steel pipe supporting structure for a large-section subsurface tunnel and a construction process. Firstly, a lower small guide hole is constructed, and a strip foundation is constructed; then an upper small guide hole is constructed, manual hole digging is conducted on the upper small guide hole so that a vertical channel can be formed, a vertical steel pipe support is installed, a movable end is arranged at the bottom end of the steel pipe support, the support is located on the strip foundation, and a fixing end is arranged at the top end of the steel pipe support and supported by an arch joist steel profile steel longitudinal beam; a free face is formed by the upper small guide hole, the lower small guide hole and the vertical channel, so that the adverse influences of explosion on the steel pipe support are reduced; reliable preliminary linings and the vertical support with high rigidity are quickly formed on an arch, prestress is applied in the digging process according to an information monitoring result, and active control is conducted on deformation of the arch. By the adoption of the technical scheme, the vertical prestress steel pipe supporting structure has the advantages that arch crown settlement can be effectively controlled, the explosion vibration speed is reduced, the temporary support is protected, construction safety is guaranteed, the construction period is shortened, and cost is low.

Owner:RANKEN RAILWAY CONSTR GROUP

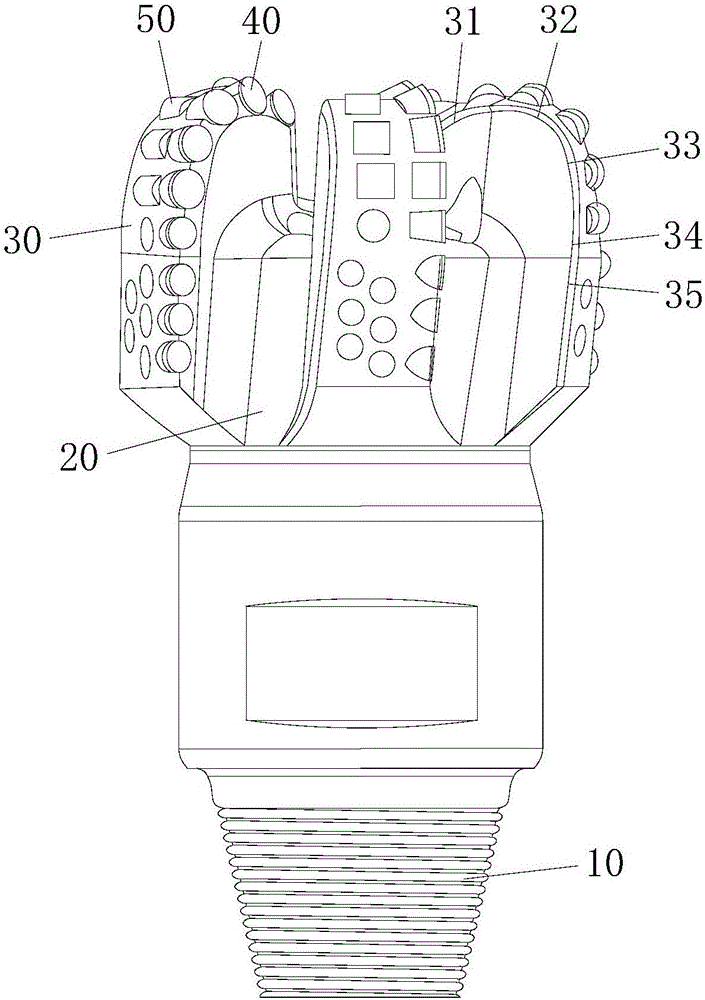

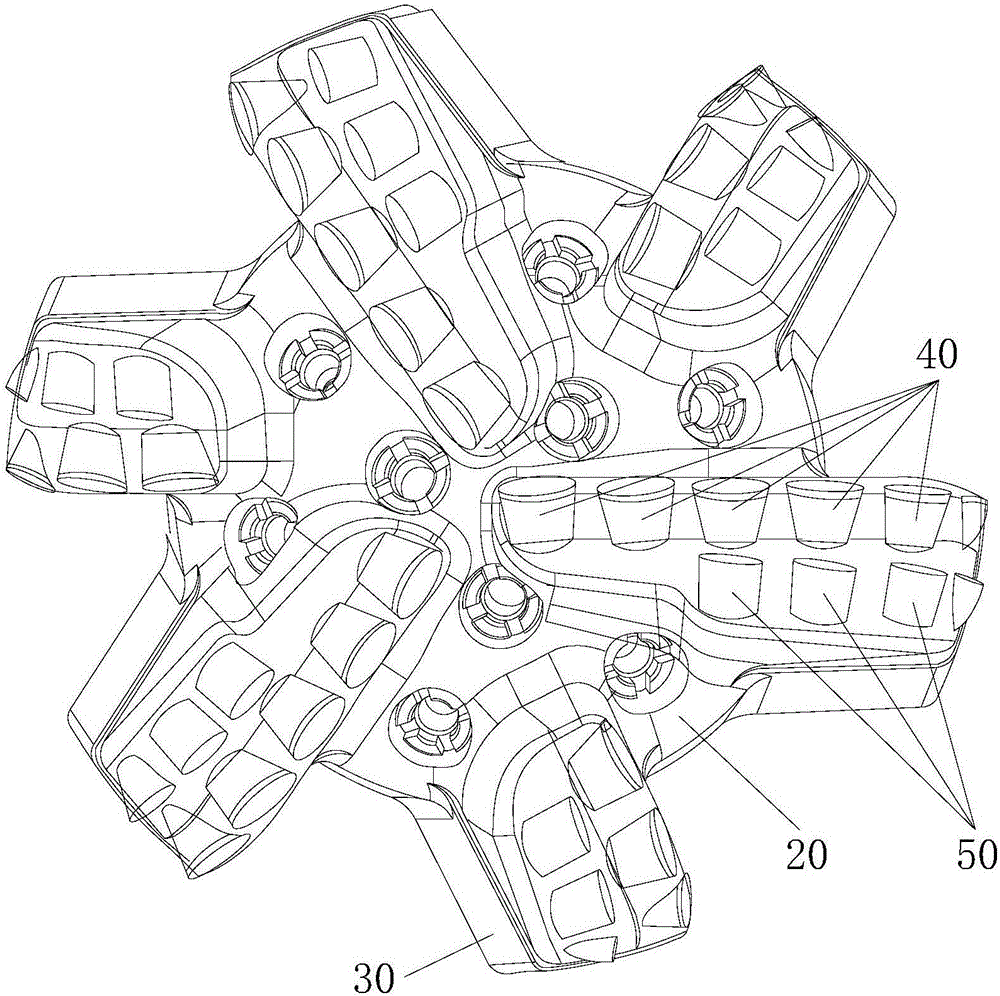

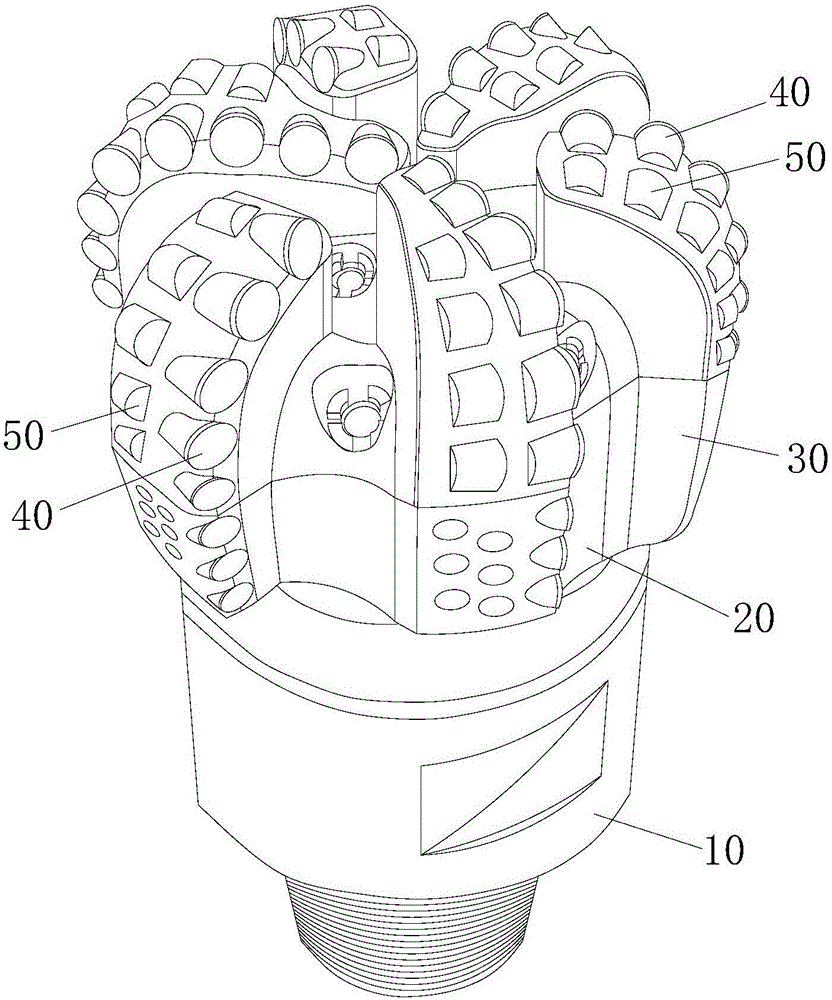

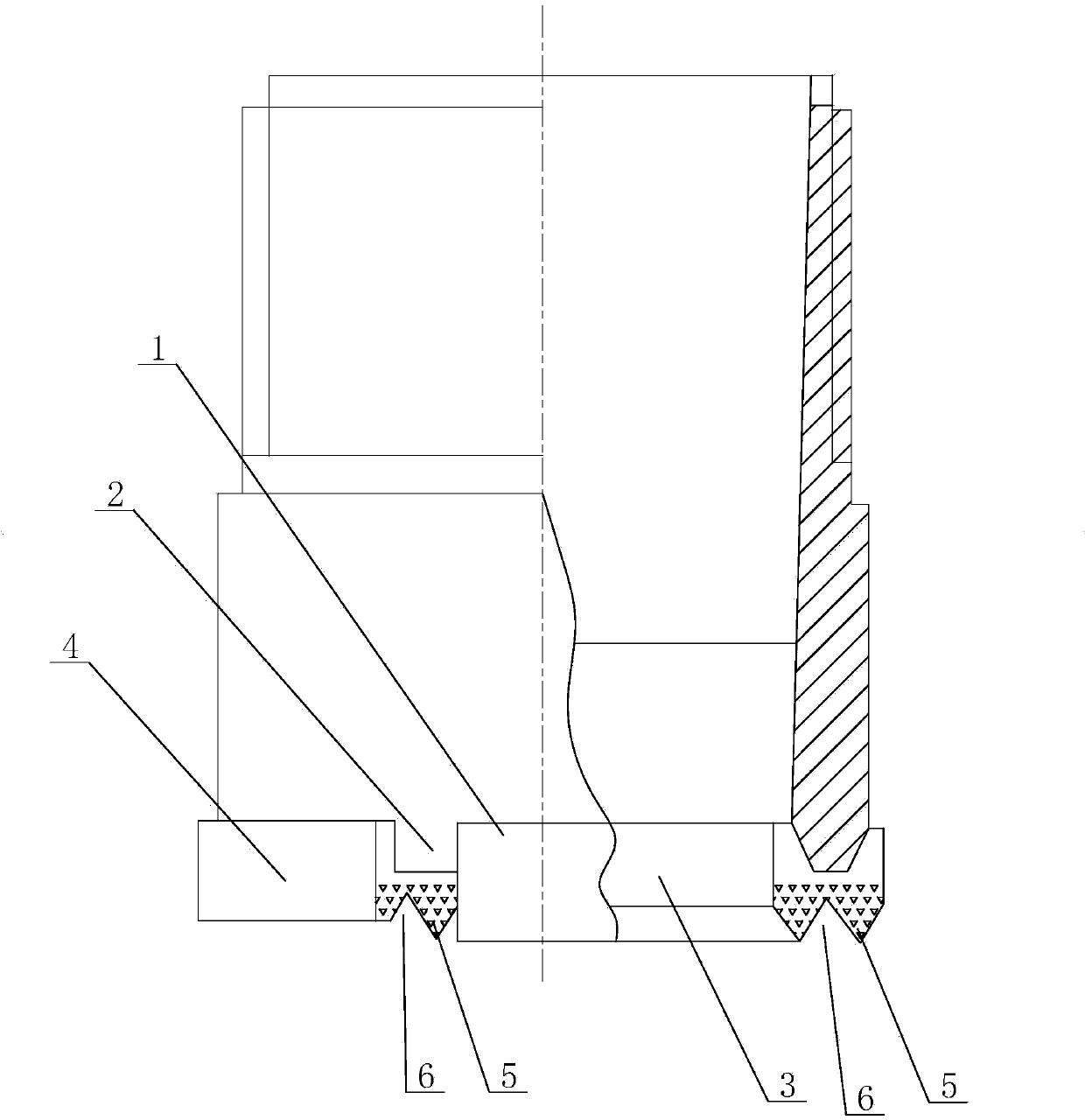

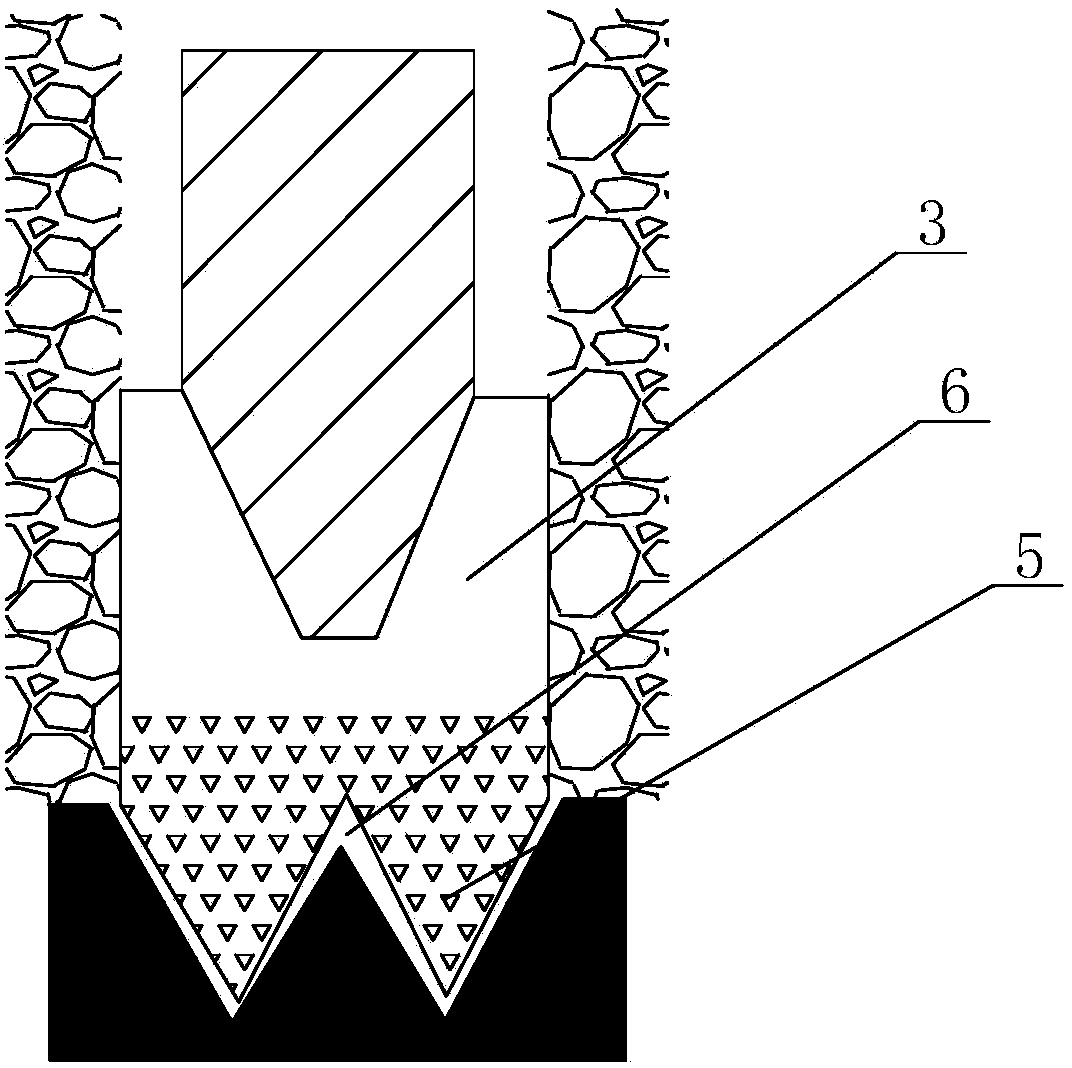

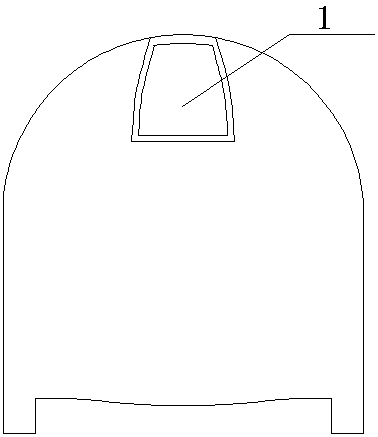

Composite drill bit

InactiveCN106639890AStrong cutting forceImprove rock breaking abilityDrill bitsConstructionsKnife bladesGrinding teeth

The invention provides a composite drill bit. The composite drill bit comprises a columnar connector and a drill bit body connected to the connector. The composite drill bit further comprises at least three knife blades arranged on the drill bit body evenly in the circumferential direction of the drill bit body. All the knife blades extend from inside to outside in the radial direction of the drill bit body. The outer side face of each knife blade is provided with a crown profile which is a curve. The composite drill bit further comprises a plurality of cutting teeth and a plurality of grinding teeth which are all fixedly arranged on the crown profiles. All the cutting teeth are arranged in a row in the extending direction of the knife blades. All the grinding teeth are arranged in a row in the extending direction of the knife blades. The row where all the grinding teeth are located is located behind the row, where all the cutting teeth are located, in the rotary direction of the drill bit body. The peak heights of all the grinding teeth are smaller than that of the cutting teeth on the same circumference. Through the composite drill bit, machine drilling speed and drill bit drilling depth are increased, the service life is prolonged, and the drilling rock breaking efficiency of the drill bit is also improved.

Owner:PETROCHINA CO LTD

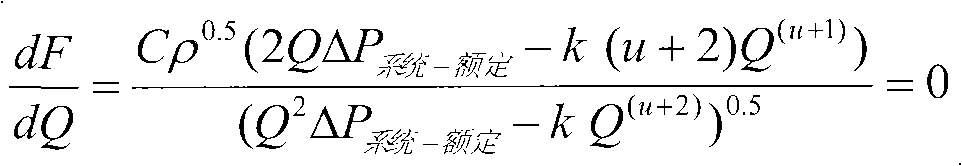

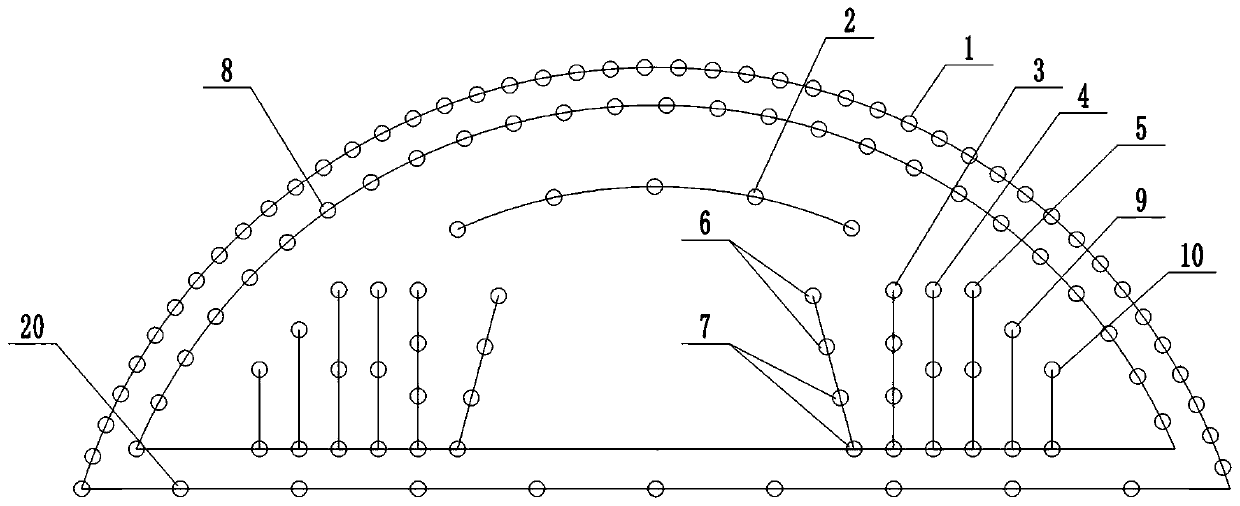

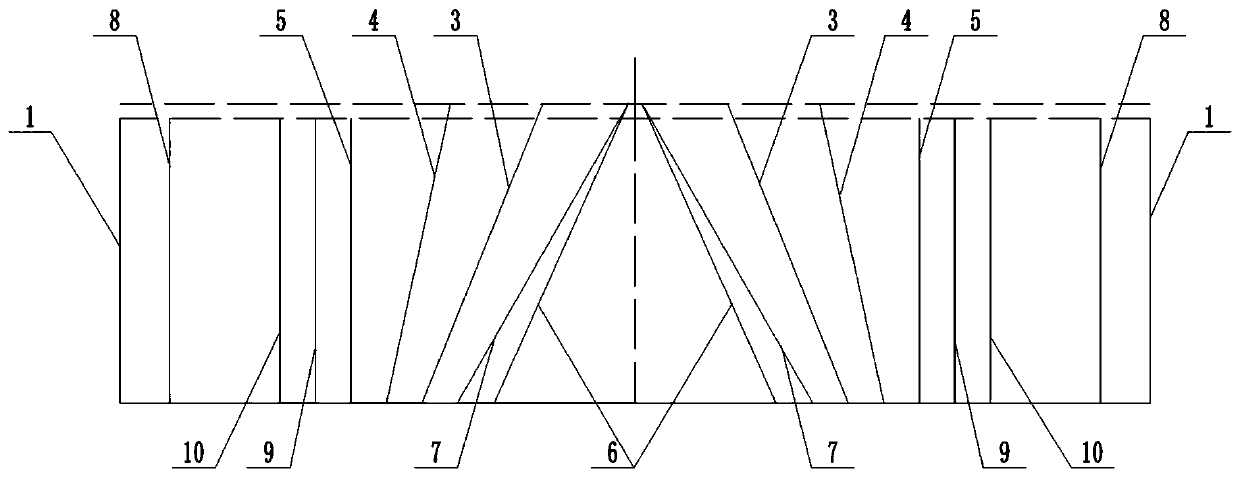

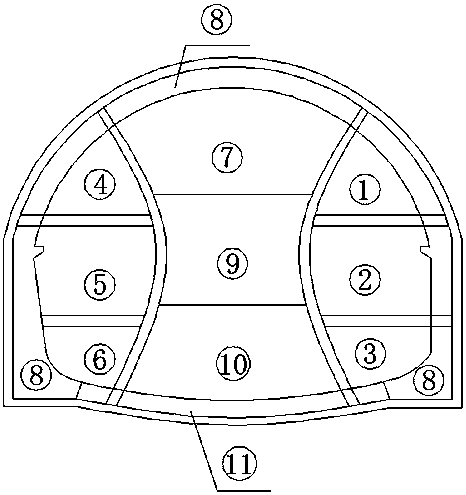

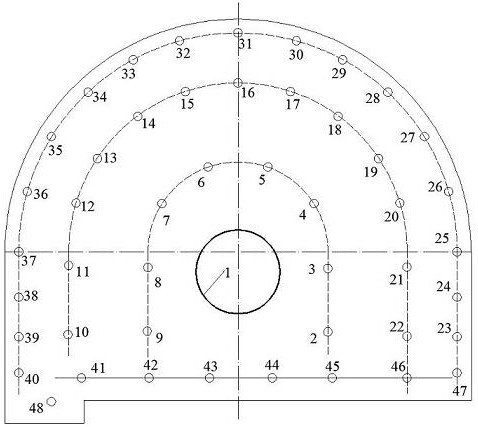

Soft rock stratum underground excavation large-section tunnel construction method and supporting system

ActiveCN105604576ASmall secondary subsidenceEffective blastingUnderground chambersTunnel liningSupporting systemPipe support

A soft rock stratum underground excavation large-section tunnel construction method comprises the following steps of conducting excavation on the upper portion of the center of an arc part to form an arc part small pilot tunnel, and arranging an arc crown vertical supporting system in the arc part small pilot tunnel; conducting excavation to form a left upper pilot tunnel, a left middle pilot tunnel, a right upper pilot tunnel, a left lower pilot tunnel and a right lower pilot tunnel in sequence, and reserving a core rock wall in each pilot tunnel; pouring inverted arc concrete on the left side and right side and inverted arc backfill; pouring the arc part of a tunnel and a side wall secondary lining; excavating the core rock walls; pouring inverted arc concrete and inverted arc backfill. A supporting system adopted in the construction method comprises the arc part small pilot tunnel, a manual hole digging pile, the arc crown vertical supporting system, a side wall preliminary bracing and a core rock wall bracing, wherein the arc crown vertical supporting system comprises a steel pipe support penetrating through the manual hole digging pile and the arc part small pilot tunnel, and an independent foundation is arranged on the bottom of the steel pipe support and located on the bottom of the manual hole digging pile. According to the soft rock stratum underground excavation large-section tunnel construction method and the supporting system, sedimentation of the arc part of the tunnel can be effectively controlled, excavation footage is large, construction progress is accelerated, arc part secondary lining can be realized early, and construction safety is guaranteed.

Owner:RANKEN RAILWAY CONSTR GROUP

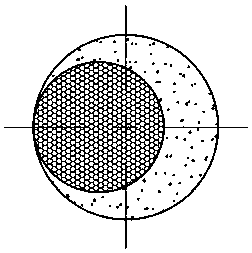

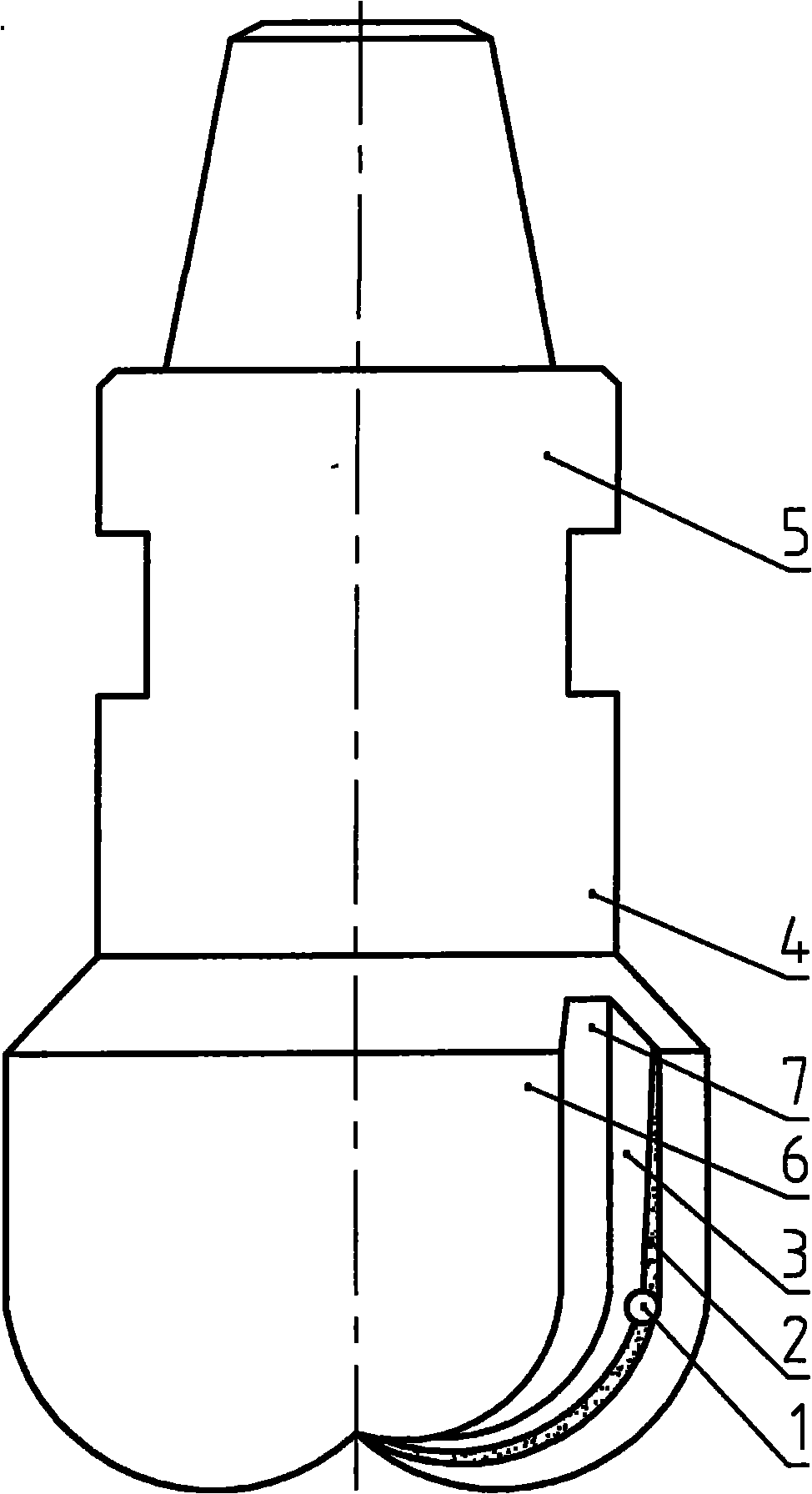

PDC and diamond-impregnated composite block

The invention discloses a PDC and diamond-impregnated composite block, which is composed of a polycrystalline diamond layer, a hard alloy layer and a diamond-impregnated layer. The polycrystalline diamond layer takes diamond micro-powder as a skeleton and cobalt and silicon as an adhesive; and the diamond-impregnated layer is formed by being subjected to hot-pressed sintering or cold-pressed sintering by adopting tungsten carbide, or a combination of the tungsten carbide and one or more of silicon carbide or silicon nitride or titanium carbide as a skeleton, nickel, silicon, chromium, copper,tin, iron, cobalt, zinc, phosphorus and rare earth elements as an adhesive, and diamond monocrystals as a cutting element. Practice proves that the PDC and diamond-impregnated composite block is usedfor a diamond drill bit, the mechanical drill speed and footage of the diamond drill bit are greatly increased, the labor intensity of workers is lowered, then the drilling cost is lowered, and the exploration and development speed of oil and gas fields and mines is increased.

Owner:中石化石油工程技术服务有限公司 +2

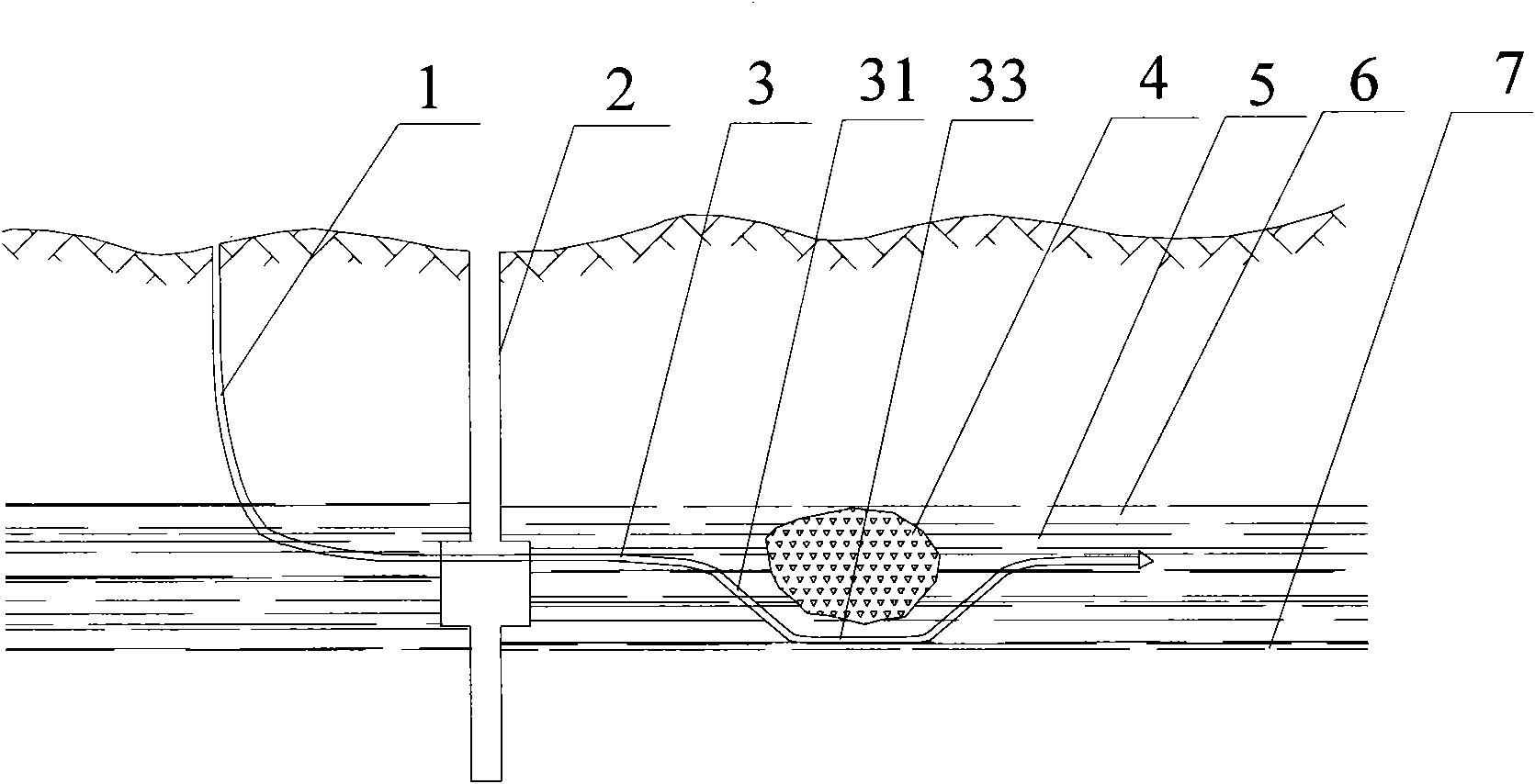

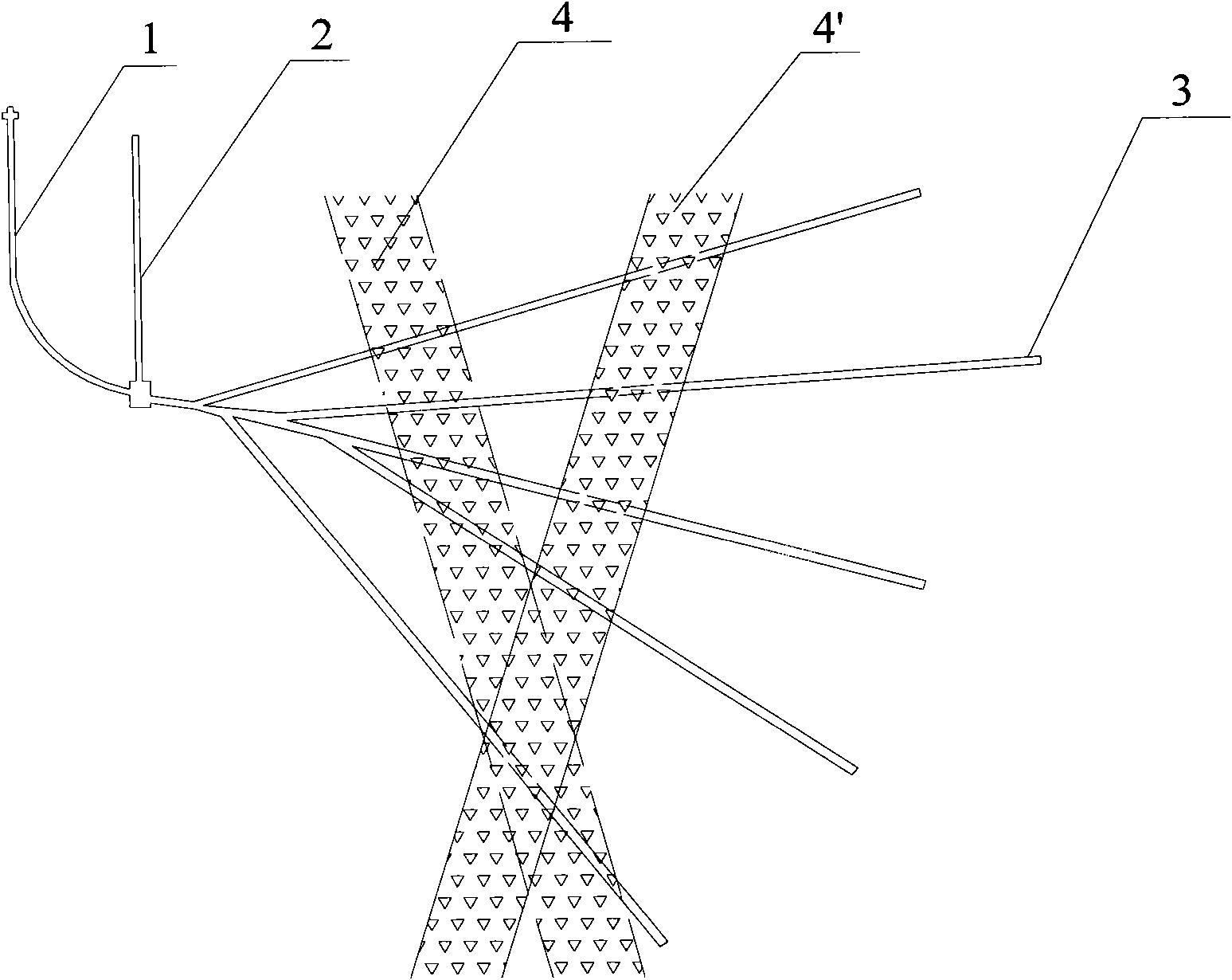

Method for guiding drilling and bridging of horizontal coal bed methane well

ActiveCN101936154AIncrease coal seam footageImprove the mining effectFluid removalCoalEnvironmental geology

The invention provides a method for guiding the drilling and bridging of a horizontal coal bed methane well, which is characterized by comprising the following steps of: acquiring regional earthquake data of an area to be exploited; pre-exploring a straight well according to the regional earthquake data of an area to be exploited, and measuring the actual condition of a coal bed; pre-exploring a horizontal well according to the measured actual condition of the coal bed, and measuring actual information parameters of a shatter zone in the coal bed; determining a bridging route according to the actual condition of the coal bed, the actual information parameters of the shatter zone and the deflecting capacity of a drilling tool; and moving round the position of the shatter zone by using the drilling tool according to the determined bridging route. By drilling the horizontal well according to the method for guiding the drilling and bridging of the horizontal well, the coal bed methane in a coal bed area on the other side of the horizontal well relative to the shatter zone can be reasonably utilized, the coal bed footage of the horizontal well is increased, and the yield of the coal bed methane is improved.

Owner:BEIJING ORION ENERGY TECH DEV

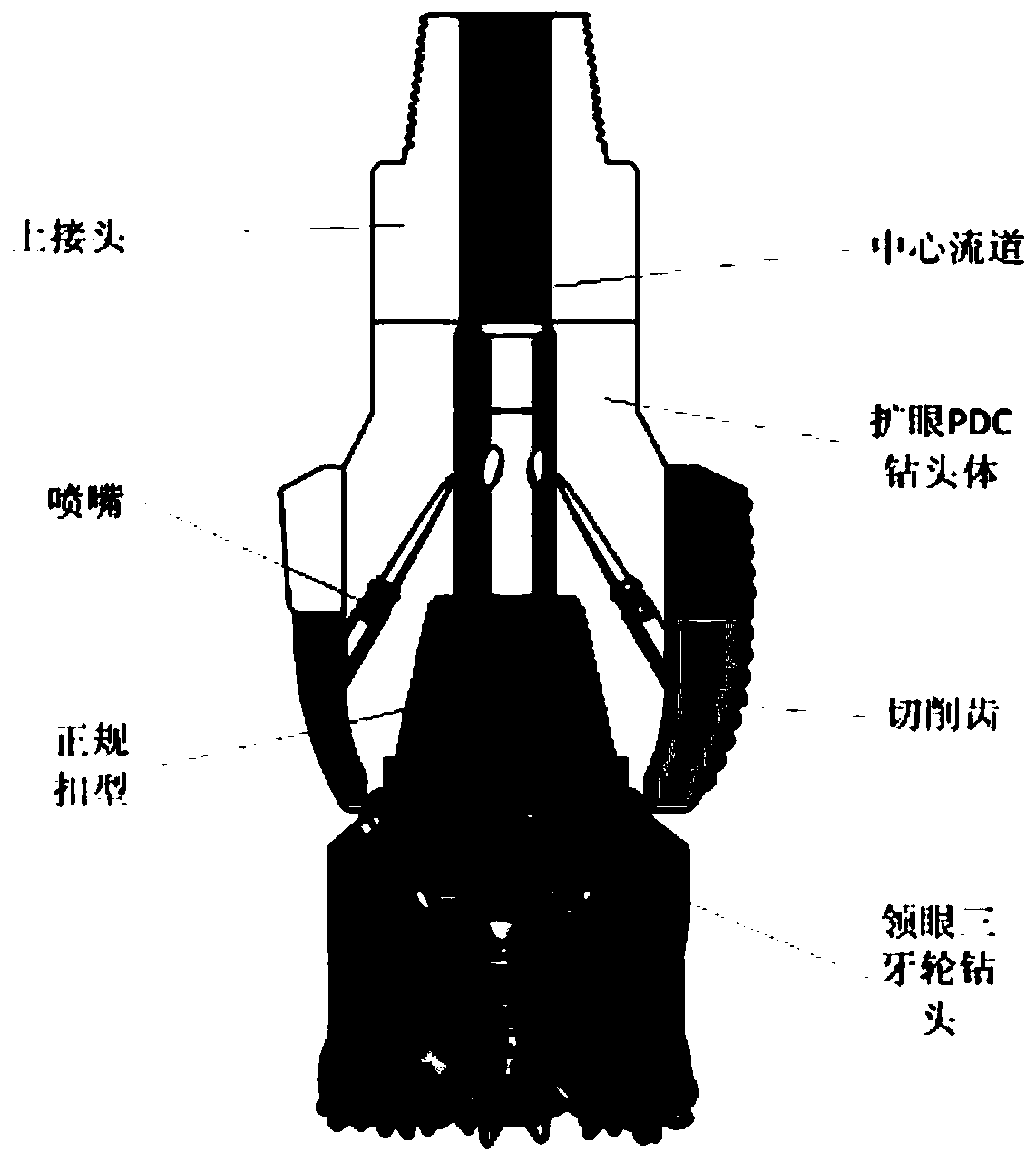

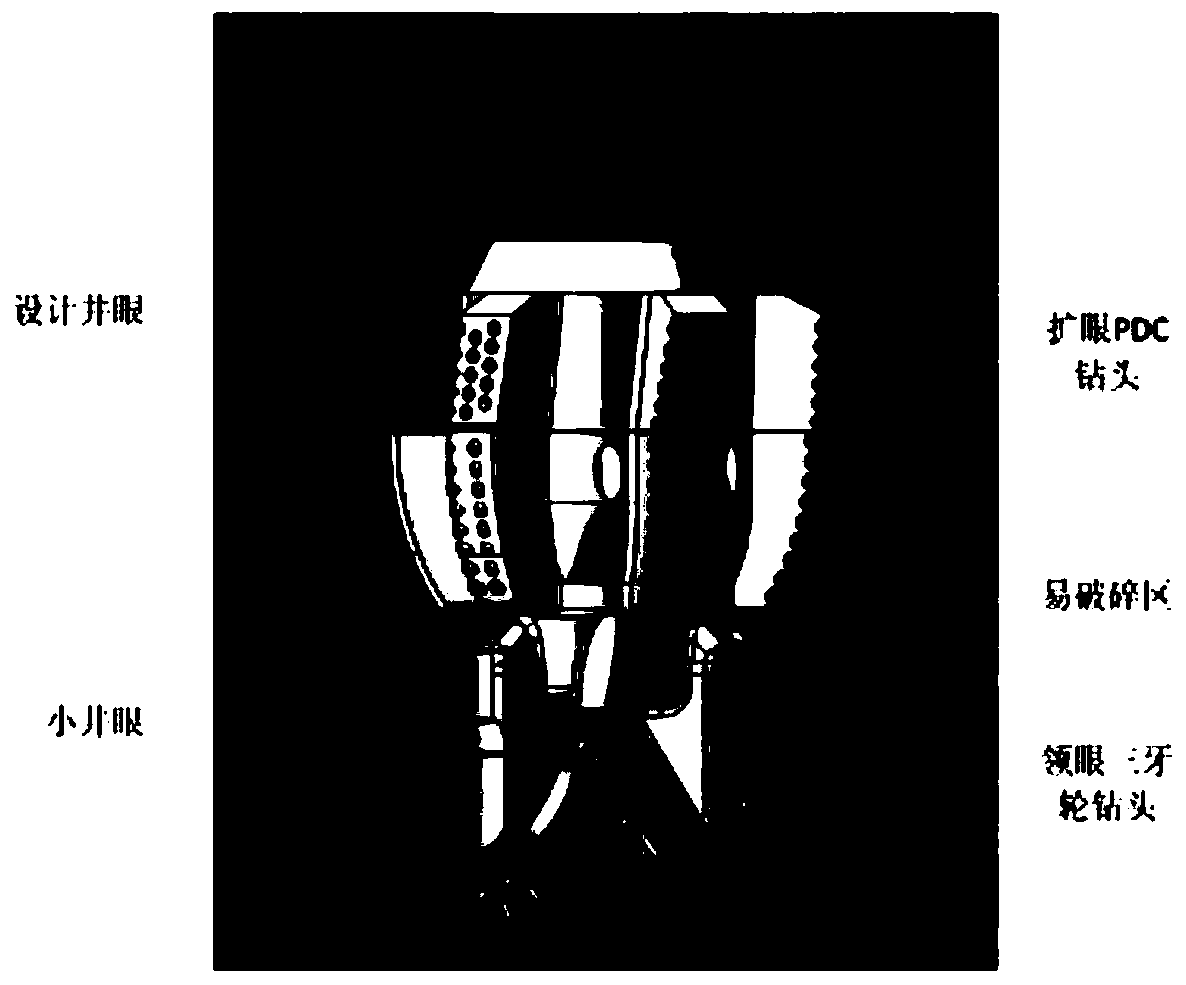

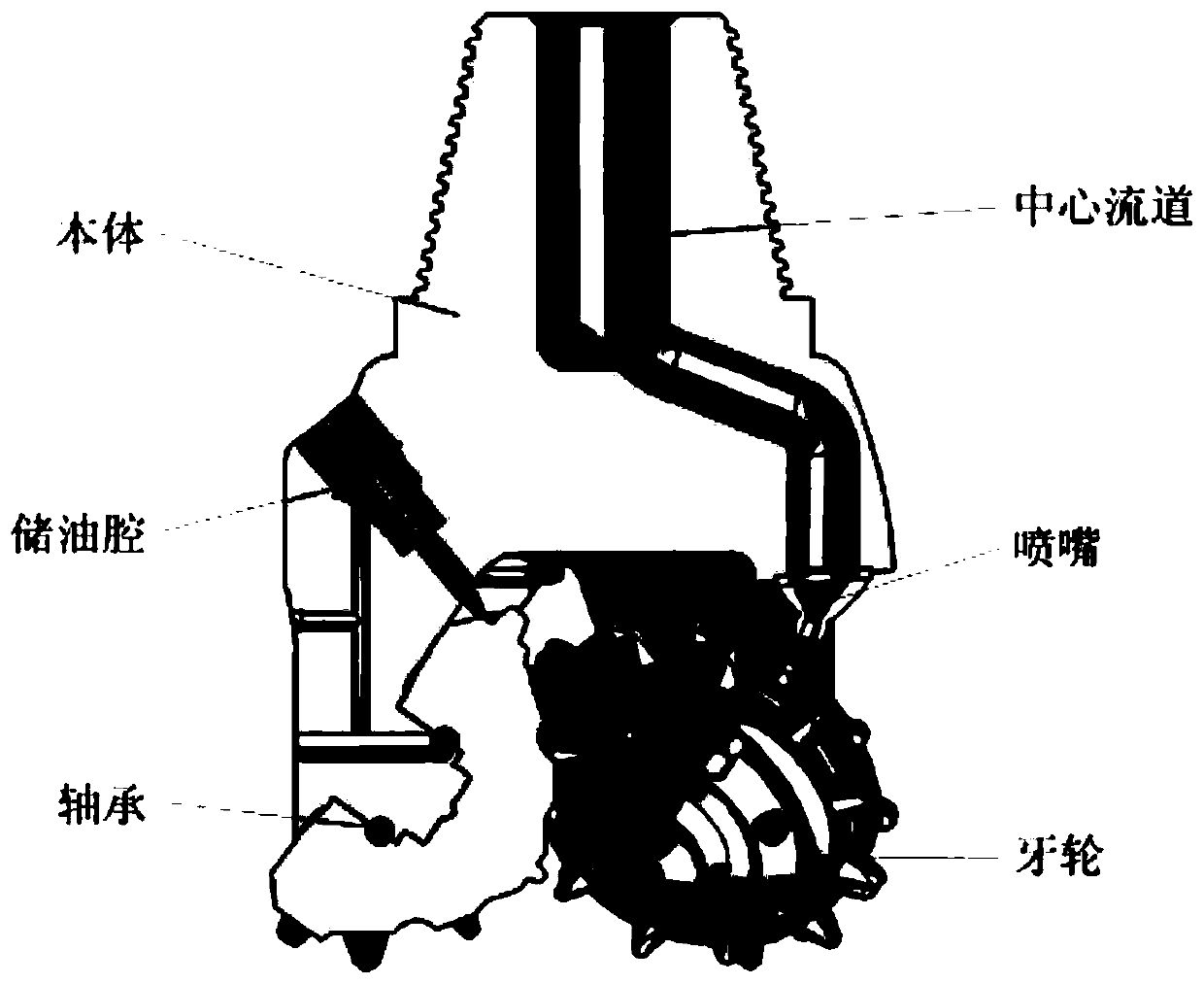

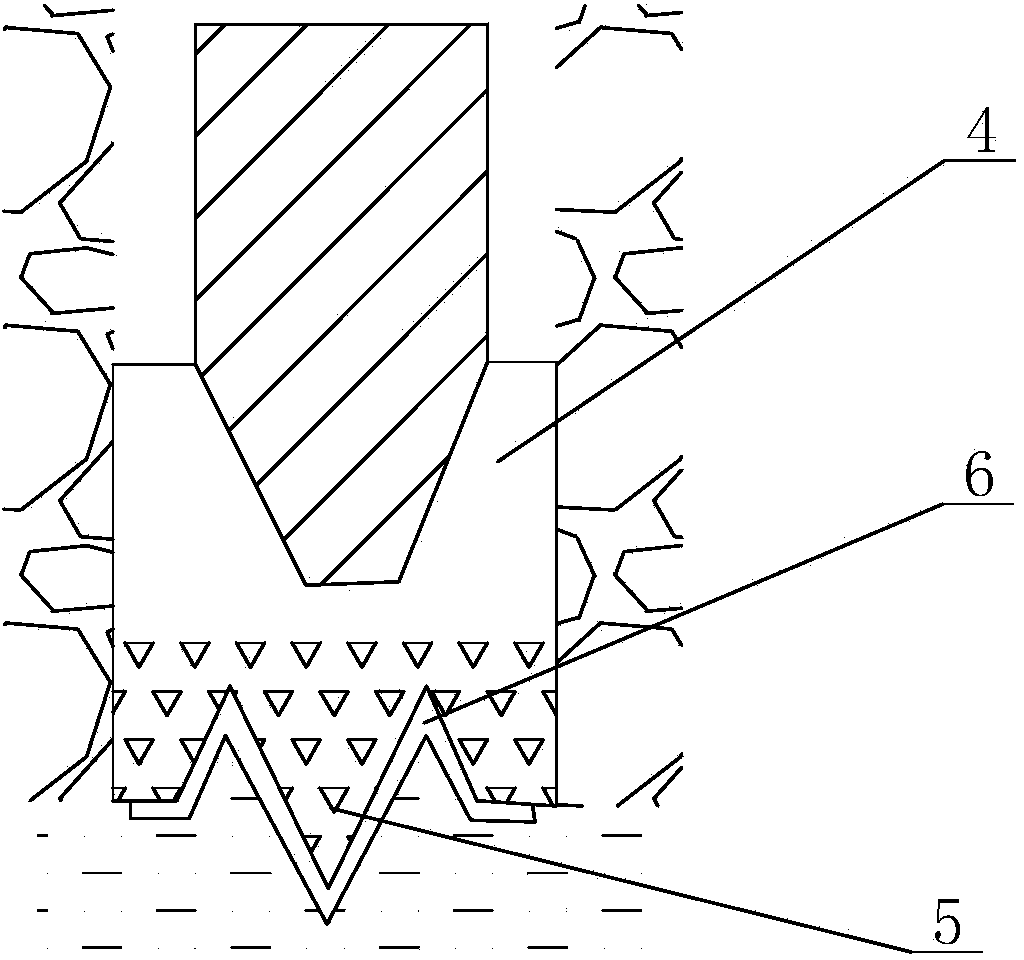

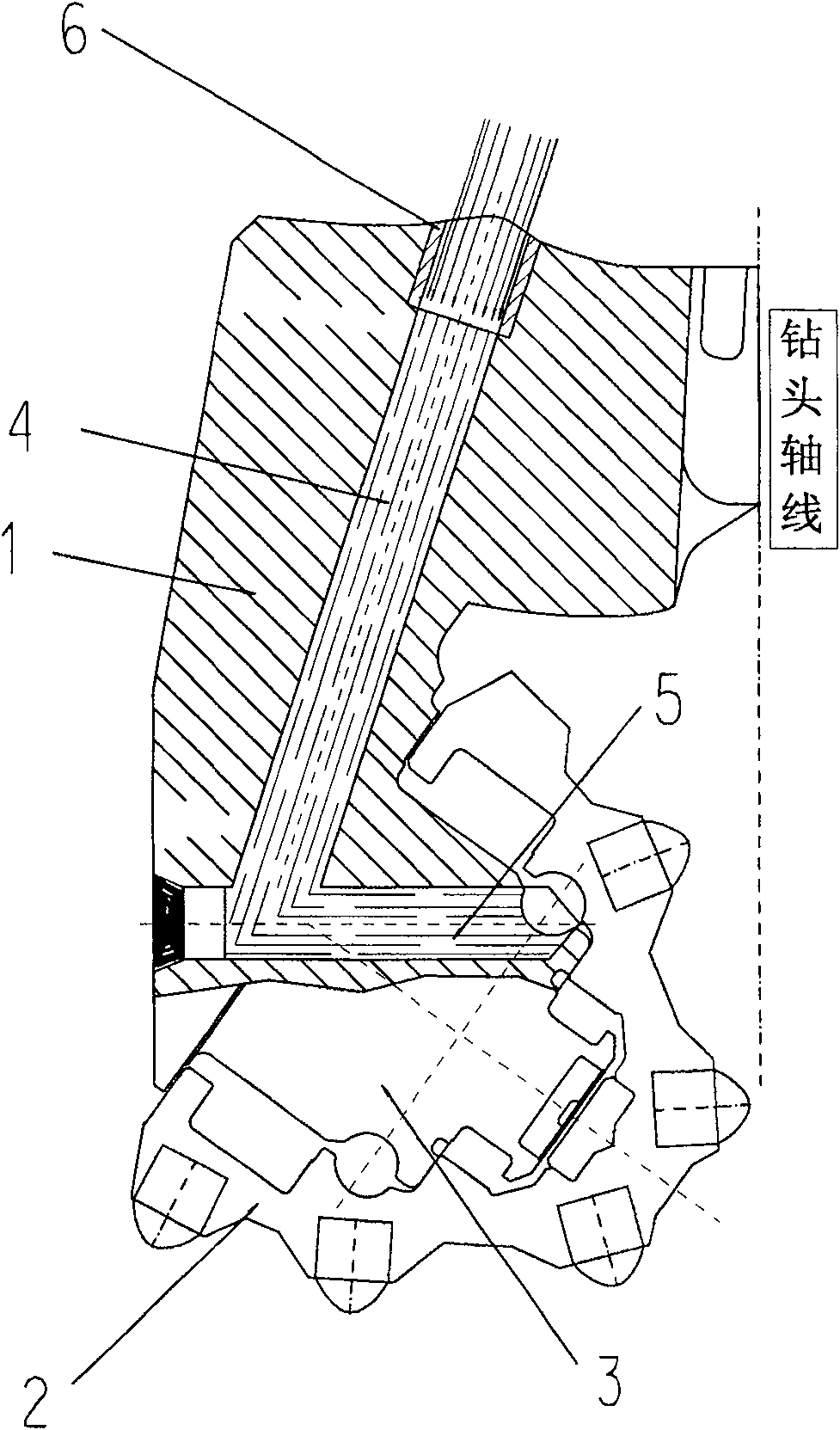

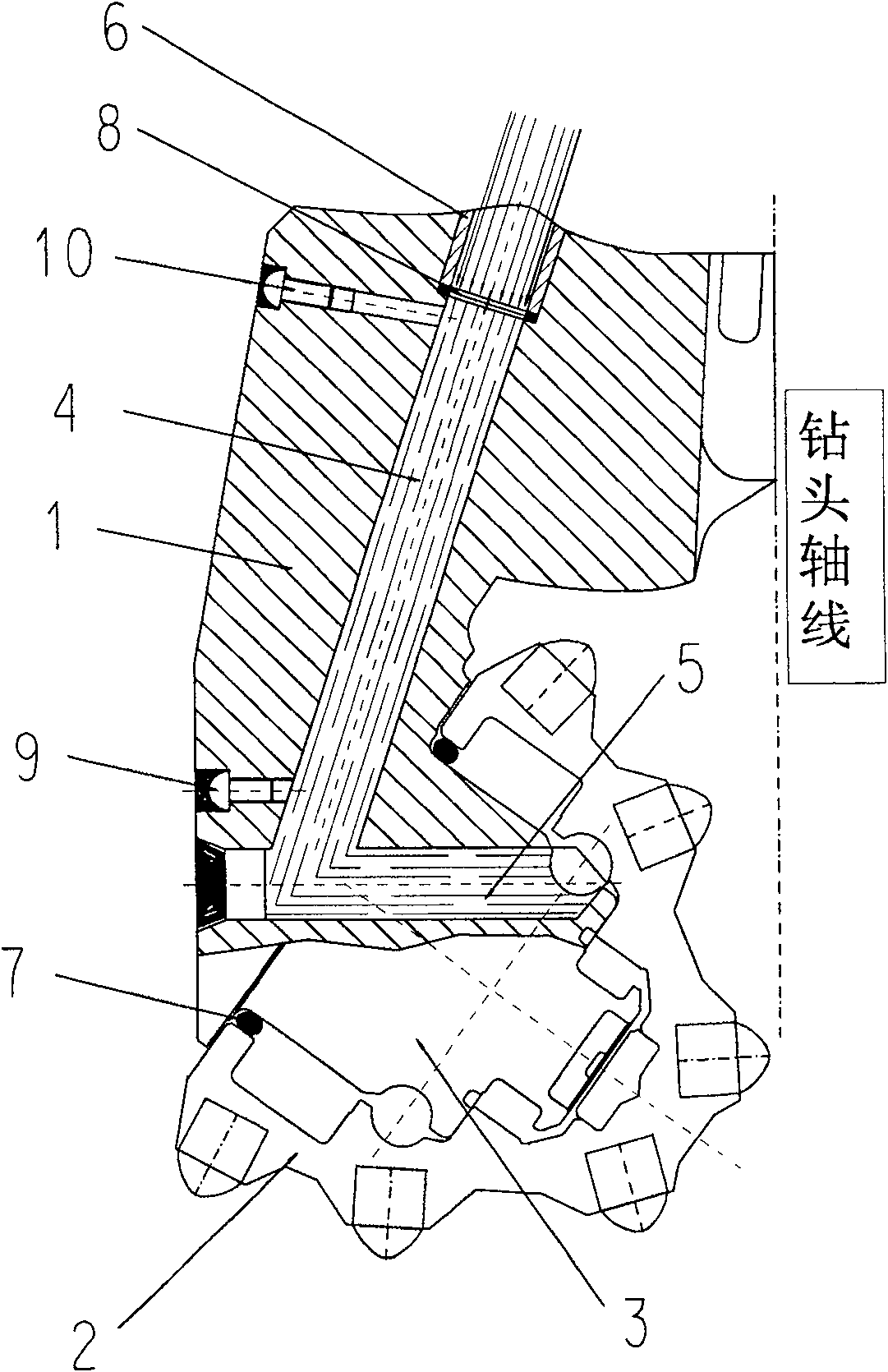

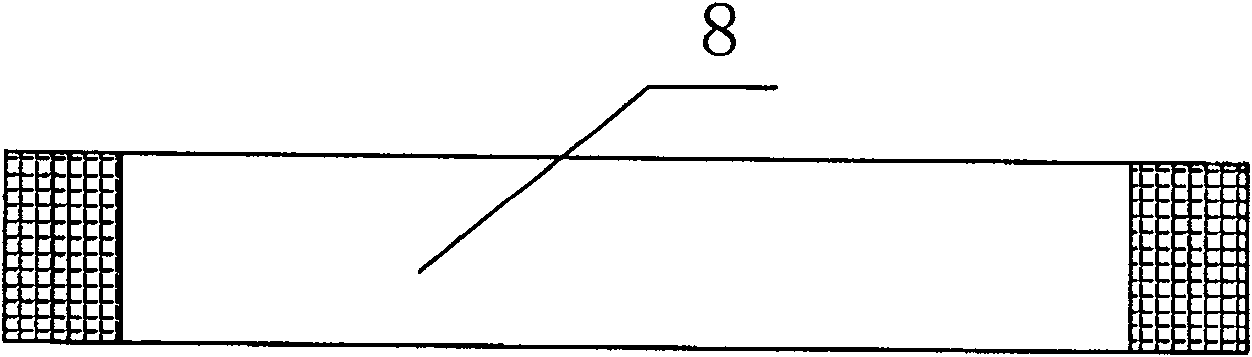

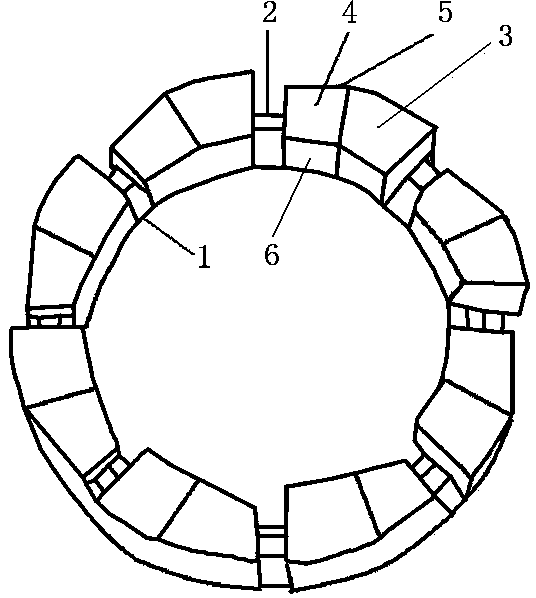

Tricone PDC concentric drill bit

InactiveCN110359847AIncrease drilling speedIncrease footageDrill bitsConstructionsRock breakingDrill bit

The invention provides a tricone PDC concentric drill bit. The tricone PDC concentric drill bit consists of a tricone PDC concentric drill bit and a PDC drill bit, wherein a pilot bit at the front endof the lower part of the tricone PDC concentric drill bit is the tricone PDC drill bit, and an reaming bit following an opening of the tricone PDC concentric drill bit is the PDC drill bit, so that atwo-stage drill bit is formed; the rotating axes of the upper and lower two-stage drill bits are overlapped; and the tricone PDC drill bit and the PDC drill bit are connected in a regular buckling manner through conical threads. The tricone PDC concentric drill bit is the combination of the tricone drill bit and the PDC drill bit; the tricone drill bit is the pilot bit with smaller diameter, thePDC drill bit is an expanding bit with larger diameter, and the rotating axes of the tricone drill bit and the PDC drill bit are overlapped, so that the advantages of the tricone drill bit and the PDCdrill bit are combined, and the efficient rock breaking of the two-stage drill bits is realized; the mechanical drilling speed potential is high; the mechanical drilling speed is improved; the drilling footage of the drill bit is increase; the underground accidents such as mud bags are decreased; the stratum applicability is wide; and a new technical scheme for improving the speed and the efficiency of the ground drilling operation with high deep hardness is supplied.

Owner:河北锐石钻头制造有限公司

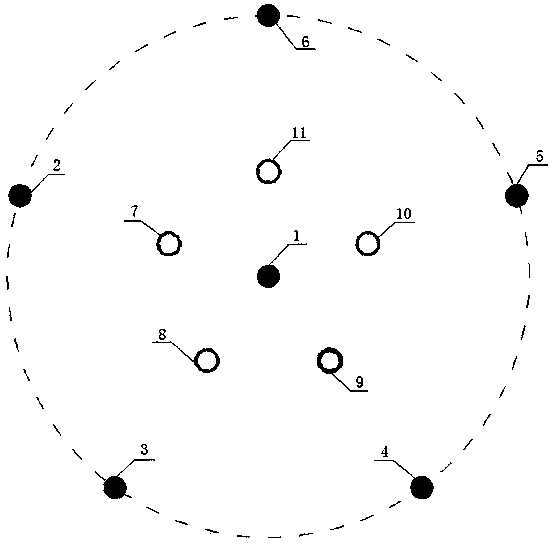

Starlike energy-saving hole blasting method

The invention discloses a starlike energy-saving hole blasting method. The starlike energy-saving hole blasting method comprises the following steps that firstly, a central main blasting hole is formed in the working surface, then five secondary blasting holes with the same hole depth are formed around the central main blasting hole, the secondary blasting holes are evenly formed around the main blasting hole according to the shape of a five-pointed star, and empty holes with the same hole depth and the same distance are formed around the main blasting hole and used as the compensation space for the hole blasting; the loading quantity of the main blasting hole accounts for 60% of the hole depth, and the loading quantity of each central secondary blasting hole accounts about 40-60% of the hole depth; and at the time of detonation, the main blasting hole firstly detonates, and the secondary blasting holes detonate in sequence. The starlike energy-saving hole blasting method combines theadvantages of a parallel empty hole straight blasting method, has the characteristics of simple operation process, fast drilling, high footage rate, low blasting cost and the like, and is suitable forvarious sections; and security risks such as roof failure can be reduced in the fracture section excavation.

Owner:GUIZHOU XINLIAN BLAST ENG GRP

Full radial protection PDC bit

InactiveCN101353947AGauge largeRealize the righting effectDrill bitsManufacturing technologyPolycrystalline diamond

The invention discloses a full-gauge-protection PDC drill bit which is used in oil drilling and other industries; the PDC drill bit consists of a fluid flowing waterway, a nozzle, a bit body, a gauge-cylinder gauge protection and polycrystalline diamond compacts (PDC); a layer of castings are fixed on the fluid flowing waterway at the periphery of the fluid flowing waterway; the casings connect the outside diameters of the gauge-cylinder gauge protection into a smooth integration so that the gauge-cylinder full gauge protection is formed; the gauge protection of the drill bit in the invention can reach the maximum, thereby realizing the own rectification effect of the drill bit, reducing the whirl of the drill bit, prolonging the service life of the drill bit, greatly increasing the size of the drill bit and the drilling speed of a machinery and having simple manufacturing technology.

Owner:JIANGSU POLYTECHNIC UNIVERSITY

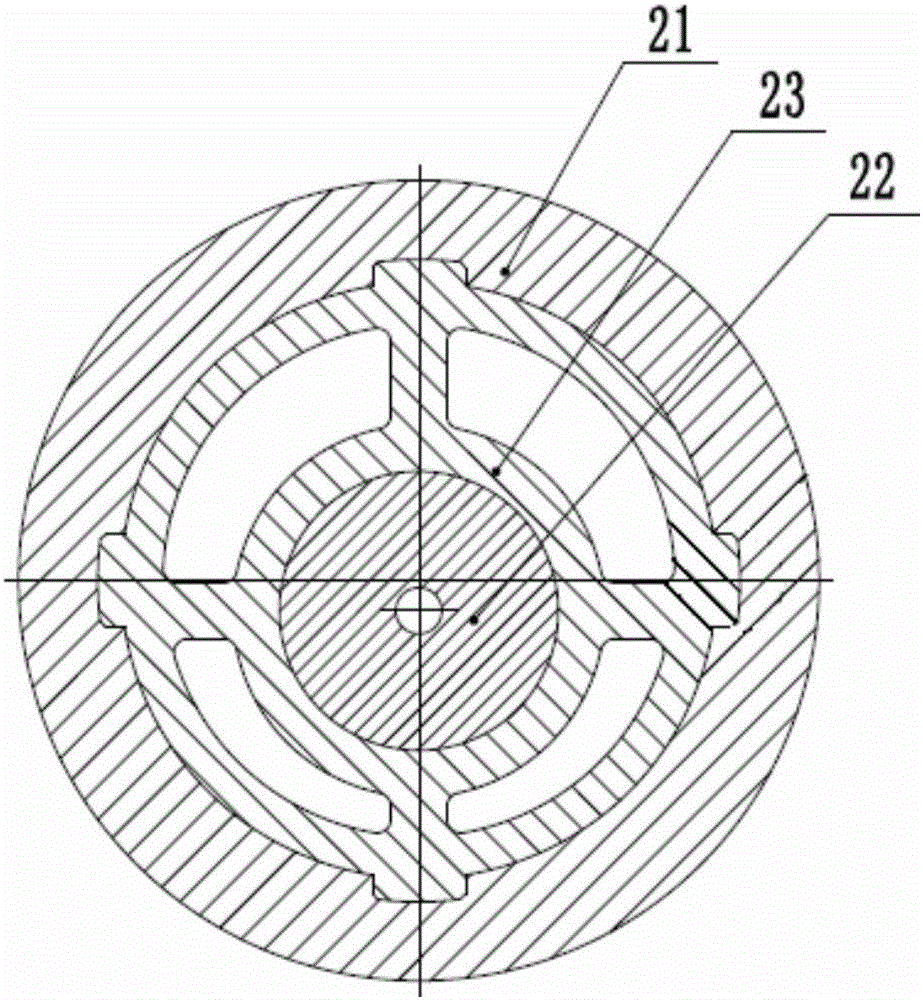

Torque pulse motor

InactiveCN106089024AEliminate stick-slip vibrationImprove working conditionBorehole drivesDrive shaftEngineering

The invention discloses a torque pulse motor which comprises a bypass valve assembly, a motor assembly, a universal shaft assembly and a transmission shaft assembly, wherein the bypass valve assembly, the motor assembly, the universal shaft assembly and the transmission shaft assembly are sequentially connected from left to right. The motor assembly comprises a screw rod stator and a screw rod rotor with a central hole. A torque pulse generator is connected between the bypass valve assembly and the motor assembly. The torque pulse generator comprises a sleeve connector, and a stator flow divider valve and a rotor flow divider valve are arranged in the sleeve connector. An upper nozzle is eccentrically arranged in the stator flow divider valve. Axial through holes are formed in the stator flow divider valve along the circumference. The right end of the rotor flow divider valve is connected with the screw rod rotor. A lower nozzle is arranged in the central hole of the rotor flow divider valve, and the axis of a central hole of the lower nozzle is parallel to the axis of a central hole of the upper nozzle. Flow fluctuation is generated by drilling fluid passing through the torque pulse generator, so that the rotating speed of a transmission shaft in the transmission shaft assembly varies, the stick-slipping and vibration phenomena of a PDC drill bit-drill stem in the drilling process are eliminated, the drilling speed is increased, and the service life of a drill bit is prolonged.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Soft rock single-step deep hole slotting, vibration attenuation, bottom flattening and smooth blasting structure in tunnel

ActiveCN111023927AImprove self-stabilityBreaking rock time extendedBlastingTunnelsVibration attenuationDetonation

The invention discloses a soft rock single-step deep hole slotting, vibration attenuation, bottom flattening and smooth blasting structure in a tunnel. Multiple blast holes are formed in the tunnel tobe blasted, and explosives are arranged in the multiple blast holes. The blast holes include peripheral holes, groove expanding holes, slotting holes, auxiliary holes and bottom plate holes. The groove expanding holes, the slotting holes, the auxiliary holes and the bottom plate holes are internally provided with explosives of continuous loaded structures. Explosives of spaced loading structuresare arranged in the peripheral holes, and the blast holes are blocked through stemming. According to the soft rock single-step deep hole slotting, vibration attenuation, bottom flattening and smooth blasting structure in the tunnel, due to the arrangement of the positions of the blast holes and due to the fact that the explosives of the different structures are arranged in the blast holes, the explosives are blocked in the blast holes through the stemming, the explosive blasting stress and detonation gas are blocked in the blast holes, the rock breaking time is prolonged, the blasting energy utilization rate is increased, the footage is increased, the blasting vibration is reduced, the self-stabilization capability of surrounding rock is improved, and the construction speed is greatly increased.

Owner:CHINA RAILWAY 18TH BUREAU GRP CO LTD

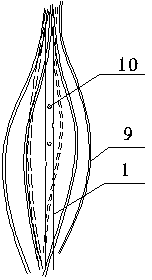

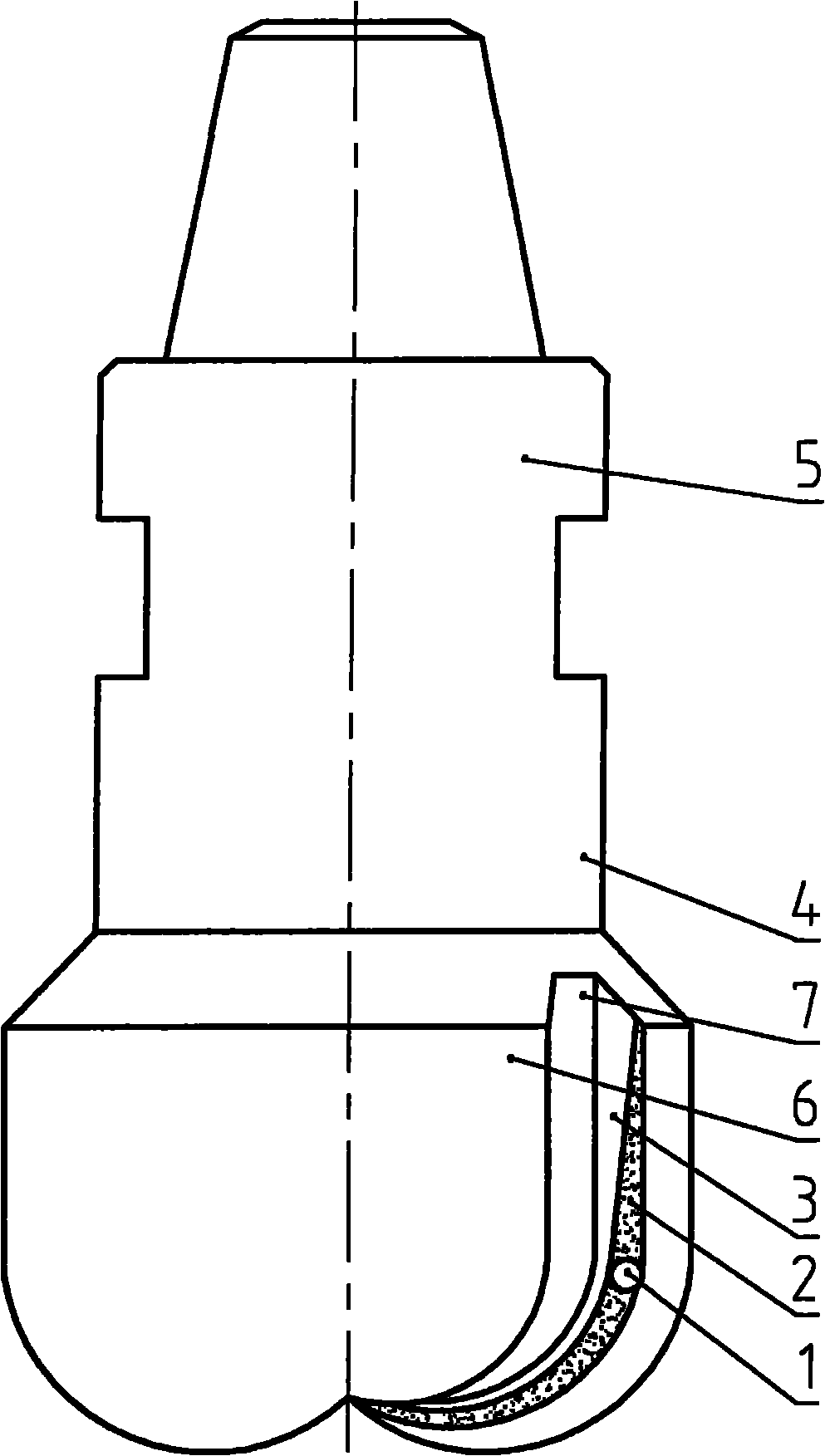

Impregnated PDC bit

The invention relates to an impregnated PDC bit. The impregnated PDC bit consists of a PDC composite sheet, a diamond-impregnated layer, a matrix, a steel core and a joint, wherein the diamond-impregnated layer, the matrix and the steel core are sintered into a bit body; a flow channel is formed on the diamond-impregnated layer and the matrix of the bit body; the PDC composite sheet is soldered in the diamond-impregnated layer or in the diamond-impregnated layer and the matrix; when 0-PDC composite sheet diameter / 3 is exposed, the composite sheet stays in a surface impregnated state; the PDC composite sheet covers the crown contour line of the bit; and the joint is connected with the bit body. The impregnated PDC bit not only keeps the advantages of high rate of penetration of PDC bits for shearing and crushing rocks, but also furthest protects the PDC composite sheet by using an impregnated structure. Meanwhile, the diamond-impregnated layer has the functions of plowing, so that the diamond content of the bit is increased, the service life is effectively prolonged and the drilling footage of the bit is improved.

Owner:SHENGLI PETROLEUM ADMINISTRATION BUREAU DRILLING TECH ACAD SINOPEC

Natural gas horizontal well drilling mechanism

InactiveCN103485719AImprove construction efficiencyImprove sand carrying capacityDirectional drillingWell drillingRate of penetration

The invention discloses a natural gas horizontal well drilling mechanism. The construction efficiency of all well sections is effectively improved and the drilling period is shortened by optimizing drilling tool assemblies. A drilling tool structure of a straight well section is optimized, and well deviation is effectively controlled by 1.5-degree screws. A drilling tool of an inclined well section is optimized, a bent screw is used in cooperation with a PDC drill bit to directly point the direction, and the construction efficiency of the inclined well section is improved. A drilling tool structure of a horizontal section is optimized, a 1.25-degree screw is adopted, the well deviation abrupt changing is correct, the sliding proportion is reduced, and the rate of penetration in the horizontal section is improved.

Owner:中国石油集团川庆钻探工程有限公司长庆钻井总公司

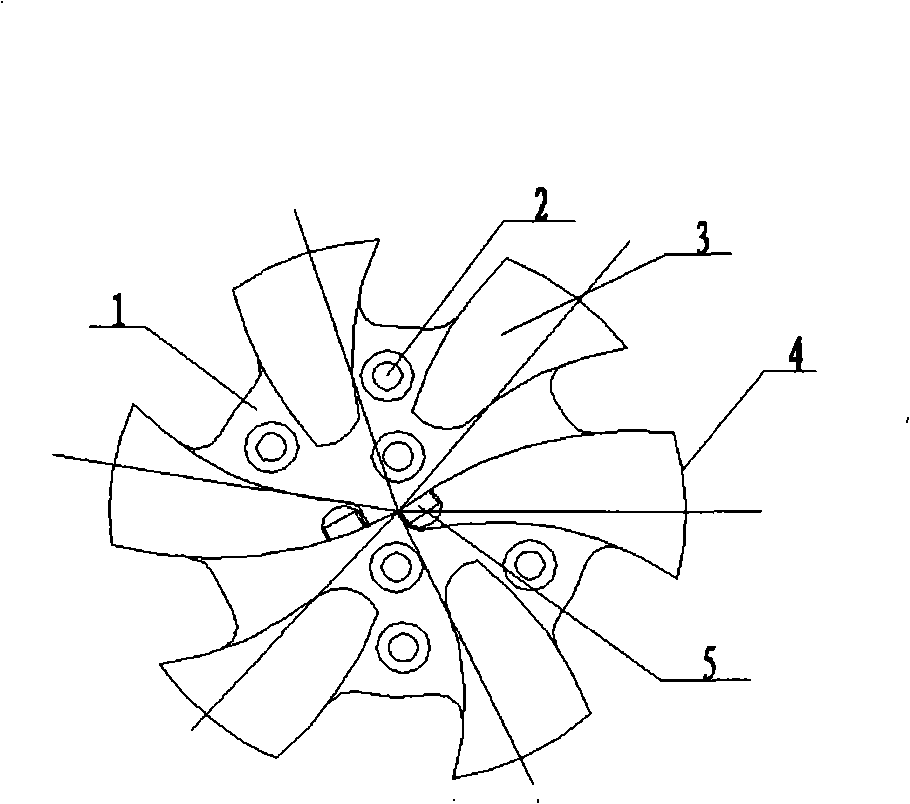

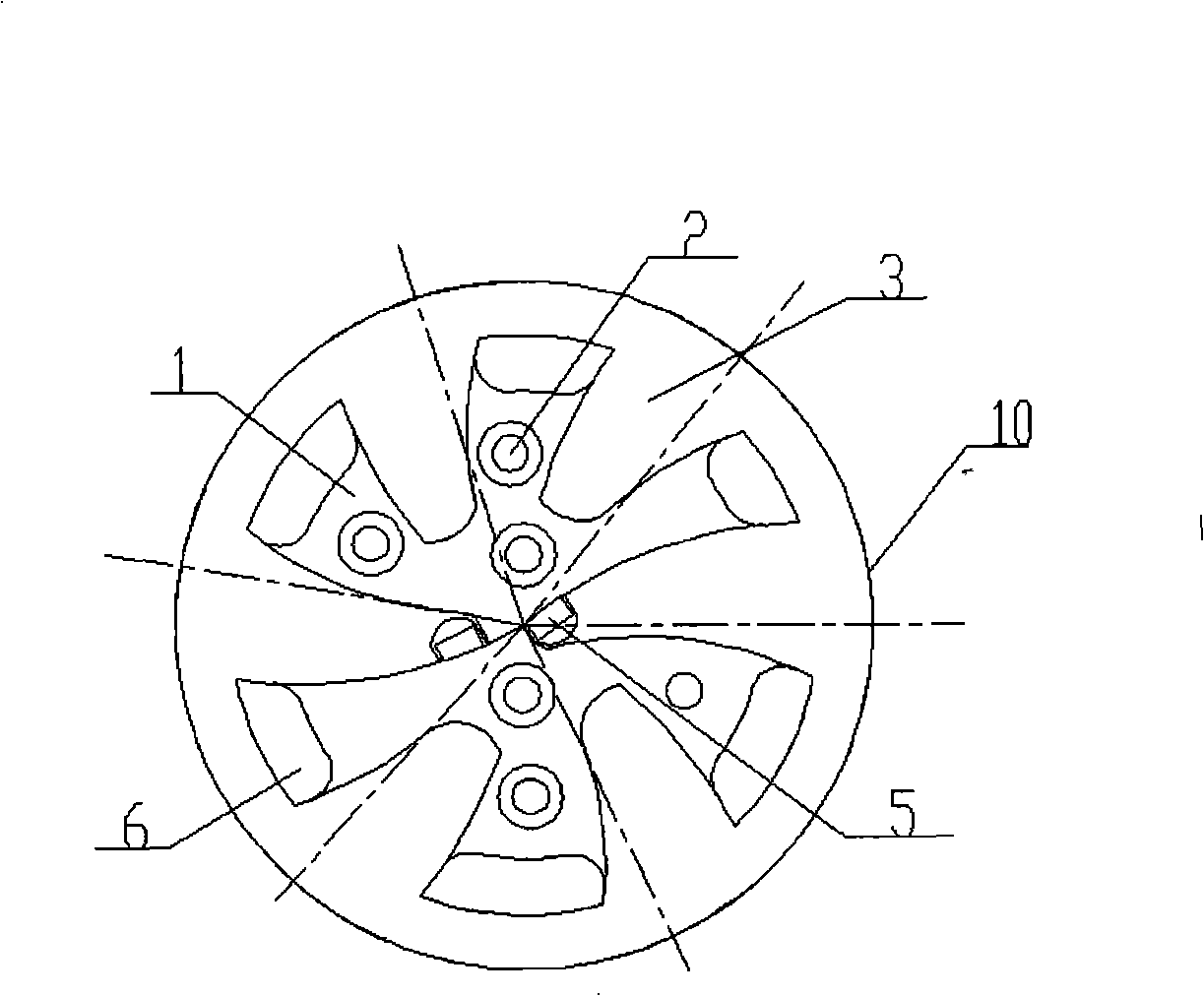

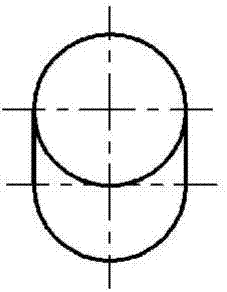

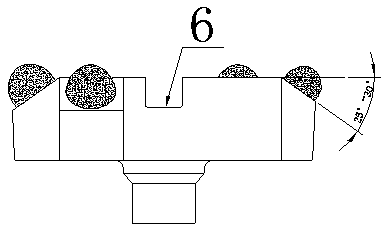

Comb-like fan-shaped block diamond-impregnated bit

ActiveCN103742078AEfficient exclusionIncrease footageDrill bitsConstructionsEngineeringConcentric ring

The invention discloses a comb-like fan-shaped block diamond-impregnated bit. The comb-like fan-shaped block diamond-impregnated bit comprises a bit blank, wherein the bit blank is provided with a concentric ring groove consisting of a plurality of fan-shaped block; the fan-shaped blocks are provided with cutting teeth; each cutting tooth comprises a projecting portion and a depressed portion; the fan-shaped blocks comprise first and second fan-shaped blocks which are arranged alternatively; the depressed portions of the cutting teeth on the first fan-shaped blocks correspond to the projecting portions of the cutting teeth on the second fan-shaped blocks; the projecting portions of the cutting teeth on the first fan-shaped blocks are unequal to the projecting portions of the cutting teeth on the second fan-shaped blocks in heights. When the diamond bit is used for smashing rock, the rock is cut saw tooth forms by using the first fan-shaped blocks, and the projecting portions of the first fan-shaped blocks are cut off by using the second fan-shaped blocks. The cut rock debris is prevented from repeatedly abrading the working layers of the fan-shaped blocks, thereby discharging the rock debris more effectively, and increasing the mechanical drilling speed, bit footage and drilling technical index.

Owner:中地装(无锡)钻探工具有限公司

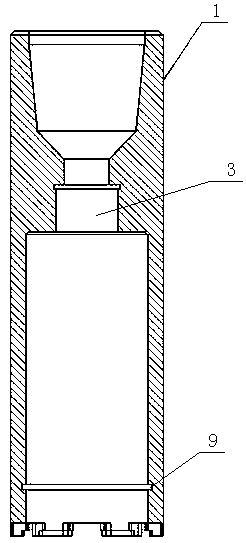

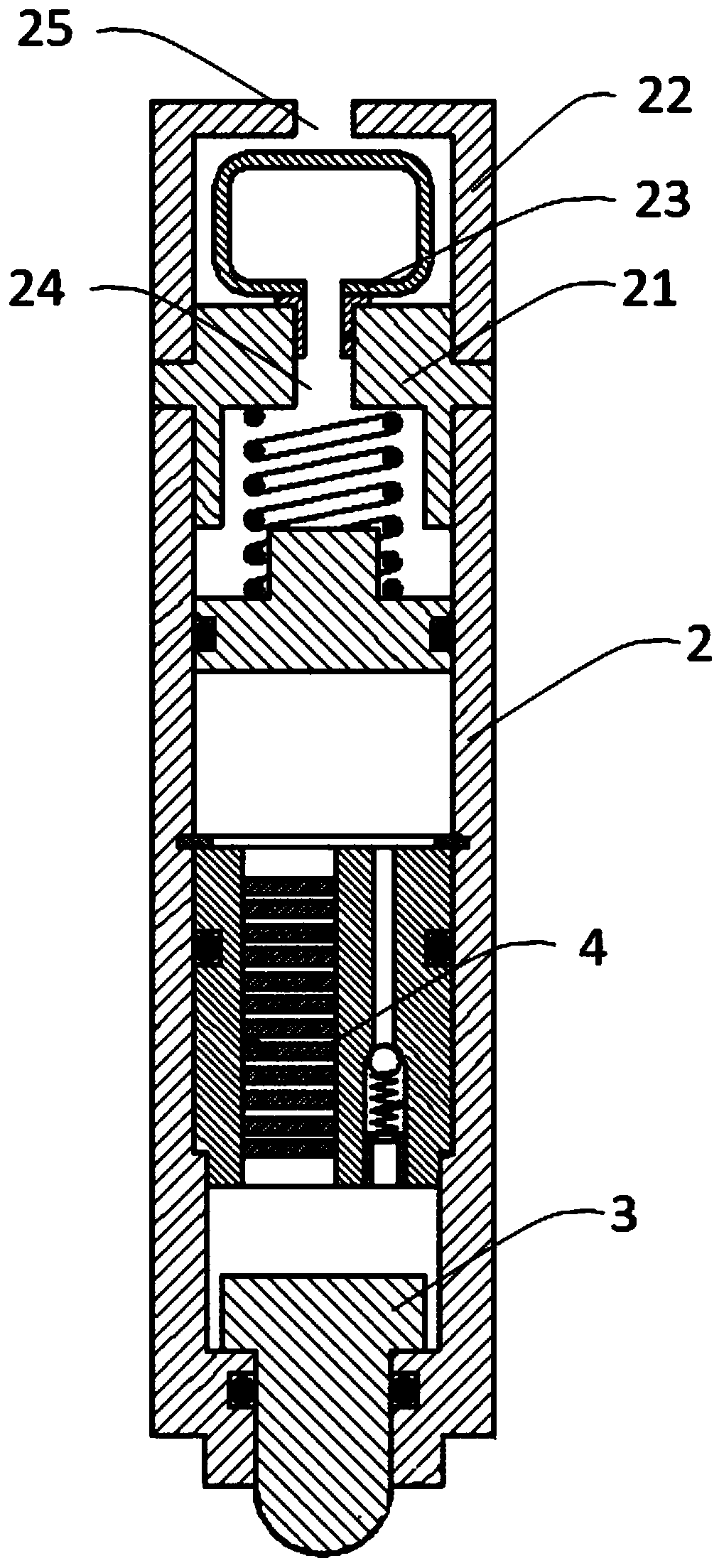

Composite shock absorber for PDC (polycrystalline diamond compact) bit

ActiveCN111456648ASolution to short lifeAvoid damageDrilling rodsDrilling casingsPolycrystalline diamondEngineering

The invention relates to a composite shock absorber for a PDC (polycrystalline diamond compact) bit. The composite shock absorber comprises a drilling tool body, an impact body, a disc spring set, a torsion bar spring and an annular pressing sleeve, wherein the bit vibration impact force is transmitted between the drilling tool body and the impact body through a torsion transmission joint, the impact body is arranged at the lower end of the drilling tool body and forms a shock absorption cavity, the drilling tool body is provided with a water inlet, the impact body is provided with a water outlet, the torsion bar spring is a cylindrical body, the upper end of the torsion bar spring is provided with an external thread, the lower part of the torsion bar spring is provided with a spline, thetorsion bar spring is positioned in the shock absorption cavity, the upper end of the torsion bar spring is connected to the drilling tool body in a threaded mode, the lower part of the torsion bar spring extends into an impactor and is connected to the impactor through the spline, the disc spring set sleeves the outer side of the torsion bar spring, the annular pressing sleeve is arranged at thelower end of the disc spring set, and a bearing set is arranged between the lower end surface of the annular pressing sleeve and an annular step, located in the drilling tool body, of the impact body.According to the composite shock absorber, the damage of the slippage effect to PDC cutting teeth can be weakened, the axial vibration from a drill string can be absorbed, and the service life of thebit can be effectively prolonged.

Owner:NORTHEAST GASOLINEEUM UNIV

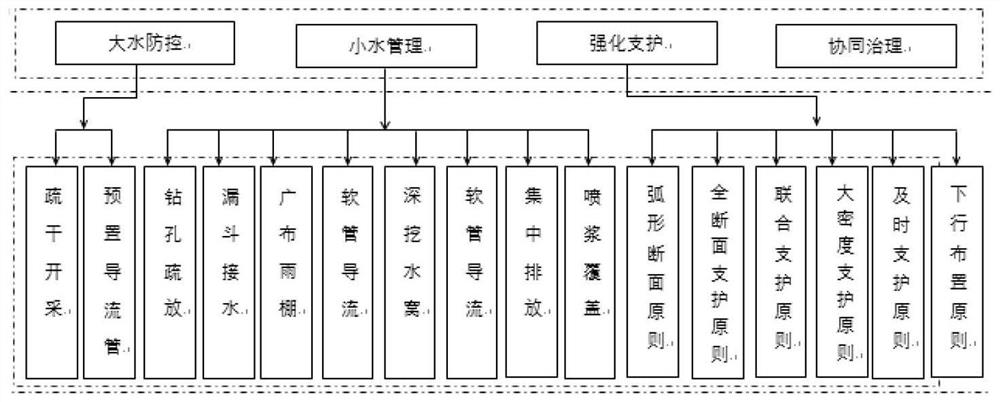

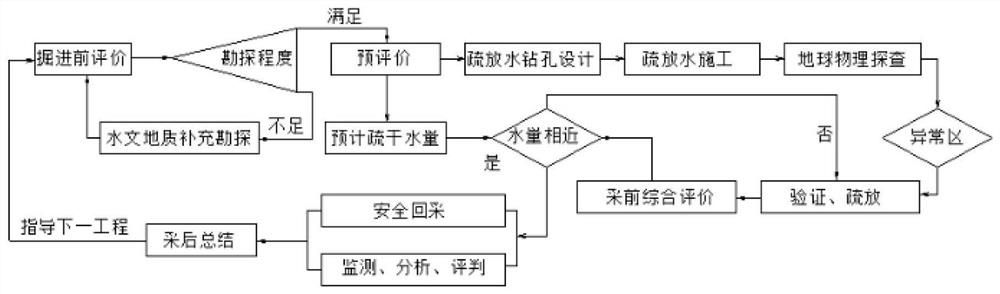

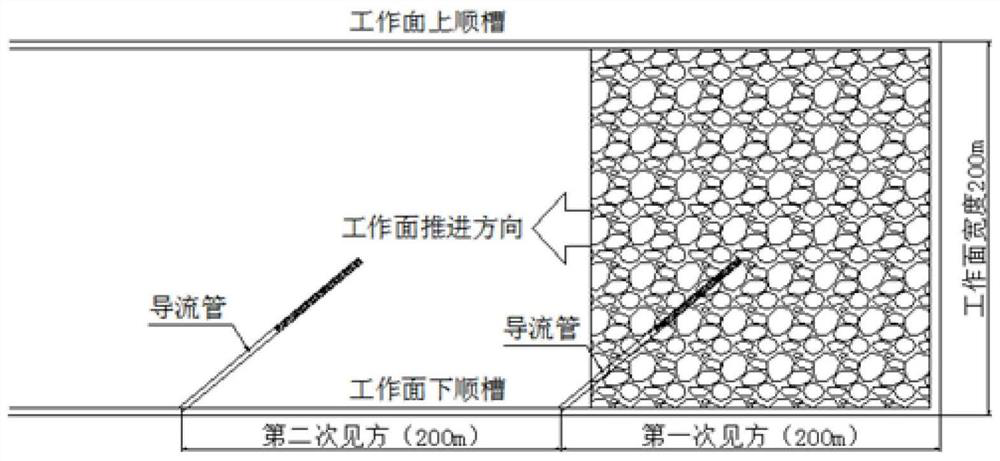

Degradation effect control method for weak-cementation strong-expansion high-water-rich soft rock

PendingCN113217094AIncrease footageControl deformationUnderground chambersDrainageWater useSoil science

The invention relates to the technical field of mineral exploitation, in particular to a degradation effect control method for weak-cementation strong-expansion high-water-rich soft rock. The method comprises the following steps that drainage is conducted in the tunneling working process; top plate water spraying, bottom plate water seepage and production water are managed in the production process, and water is prevented from making contact with rocks; and reinforced support is carried out on a roadway. By means of massive water prevention and control, small water volume management and reinforced support as well as cooperative management of massive water prevention and control, small water volume management and reinforced support, the water yield condition of a stratum and the water catchment time condition of a separation space can be changed through massive water prevention and control, the source treatment effect is obvious, water disasters are avoided, and then the coal mining efficiency is improved; and through small water volume prevention and control, a tunneling working face is not troubled by water any more, the tunneling working face does not return to a rear way for repair during tunneling, and the monthly tunneling footage is stably improved under the condition that the mechanization degree is not obviously improved. The deformation of the roadway is effectively controlled through reinforced support and collaborative management.

Owner:内蒙古上海庙矿业有限责任公司

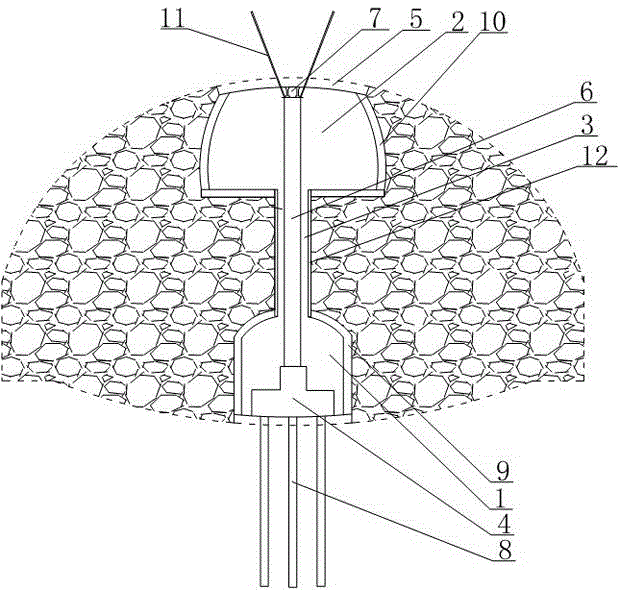

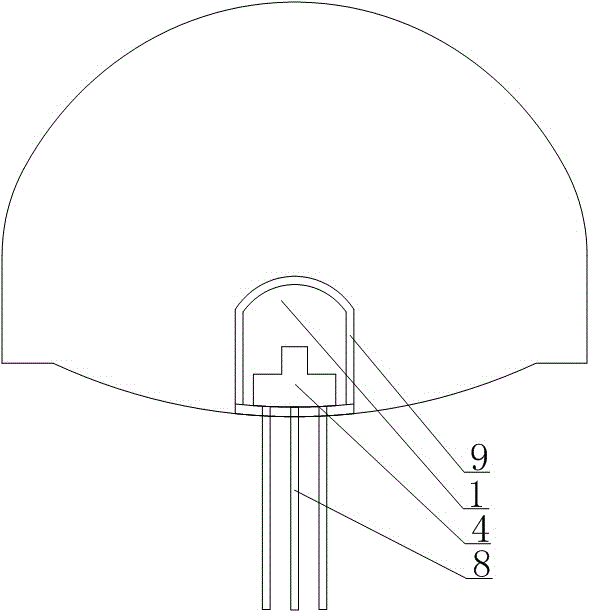

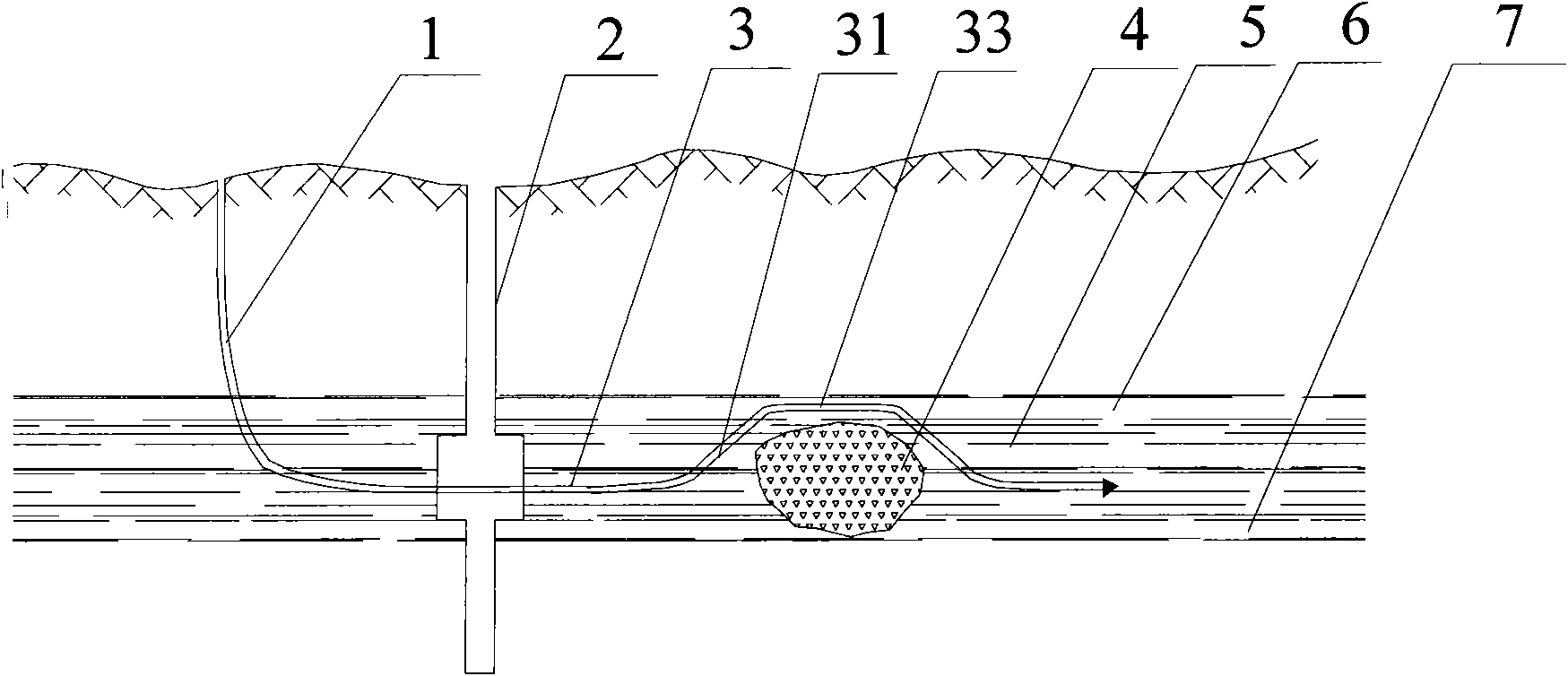

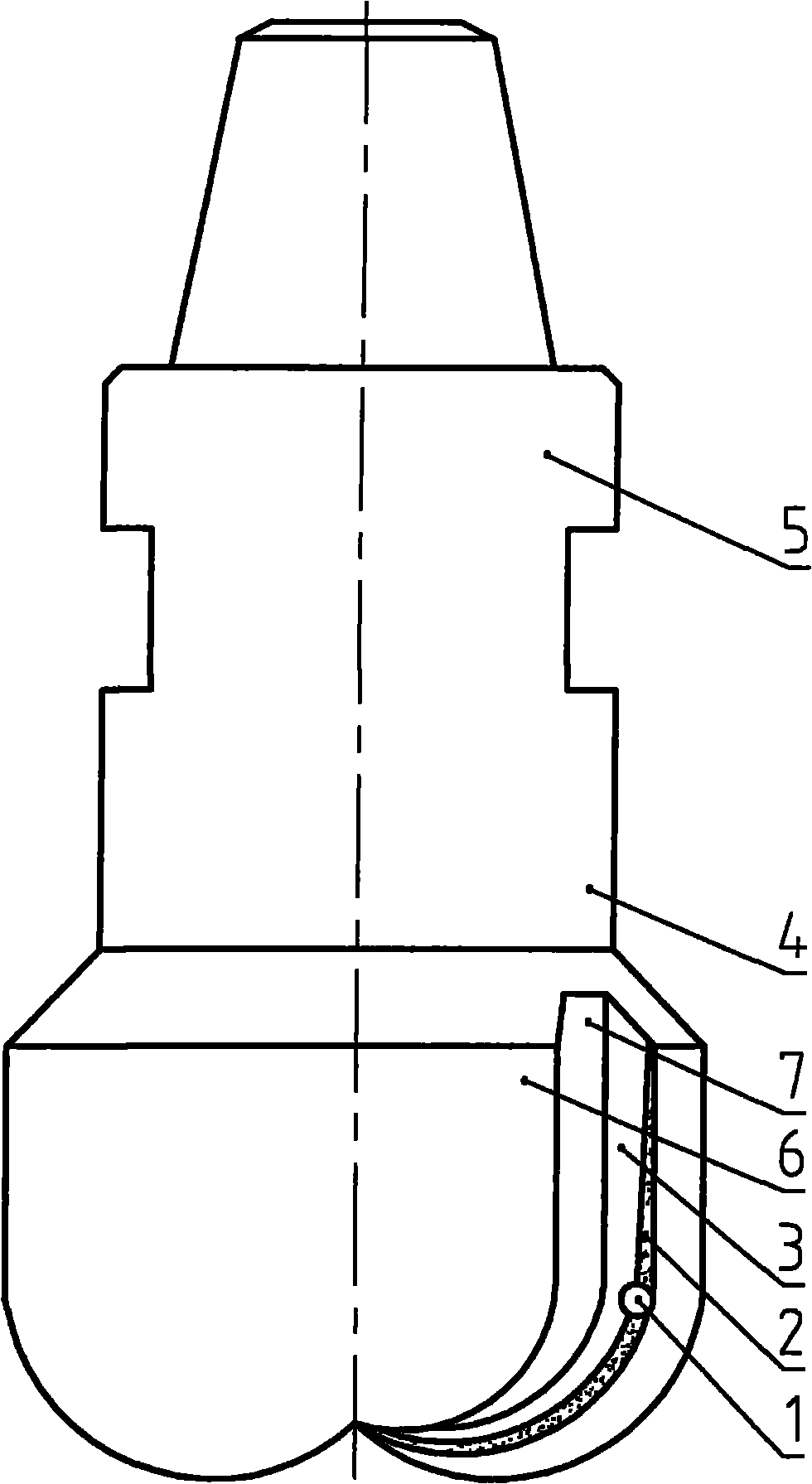

Diamond impregnated segment with tooth cavities

The invention relates to a diamond impregnated segment with one to five tooth cavities, comprising one to five cutting elements and a segment body. The cutting elements are inserted into the tooth cavities arranged in one side of the segment body. The tooth cavities are as many as the cutting elements. The tooth cavities are in one or multiple of shapes, such as cylinder, sector column, wedge, hexahedron, elliptic cylinder and prism; the cutting elements matching with the tooth cavities are also in one or multiple of the shapes, such as cylinder, sector column, wedge, hexahedron, elliptic cylinder and prism. The diamond impregnated segment is applied to the center of a diamond impregnated bit, is low in linear speed and generates little heat; the cutting elements can run normally; the cutting elements coordinate with the diamond impregnated segment, allowing double safety, coring of the diamond impregnated bit is well prevented, and drilling footage can be increased. The diamond impregnated segment is suitable for petroleum and geological drill bits.

Owner:CHINA PETROCHEMICAL CORP +1

A construction method for underground excavation of large-section tunnels in soft rock formations

ActiveCN105604576BSmall initial settlementImprove support stiffnessUnderground chambersTunnel liningSupporting systemPipe support

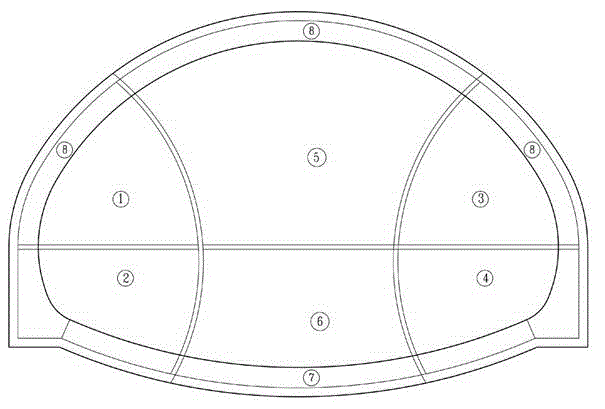

A soft rock stratum underground excavation large-section tunnel construction method comprises the following steps of conducting excavation on the upper portion of the center of an arc part to form an arc part small pilot tunnel, and arranging an arc crown vertical supporting system in the arc part small pilot tunnel; conducting excavation to form a left upper pilot tunnel, a left middle pilot tunnel, a right upper pilot tunnel, a left lower pilot tunnel and a right lower pilot tunnel in sequence, and reserving a core rock wall in each pilot tunnel; pouring inverted arc concrete on the left side and right side and inverted arc backfill; pouring the arc part of a tunnel and a side wall secondary lining; excavating the core rock walls; pouring inverted arc concrete and inverted arc backfill. A supporting system adopted in the construction method comprises the arc part small pilot tunnel, a manual hole digging pile, the arc crown vertical supporting system, a side wall preliminary bracing and a core rock wall bracing, wherein the arc crown vertical supporting system comprises a steel pipe support penetrating through the manual hole digging pile and the arc part small pilot tunnel, and an independent foundation is arranged on the bottom of the steel pipe support and located on the bottom of the manual hole digging pile. According to the soft rock stratum underground excavation large-section tunnel construction method and the supporting system, sedimentation of the arc part of the tunnel can be effectively controlled, excavation footage is large, construction progress is accelerated, arc part secondary lining can be realized early, and construction safety is guaranteed.

Owner:RANKEN RAILWAY CONSTR GROUP

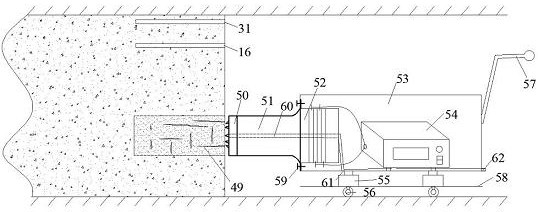

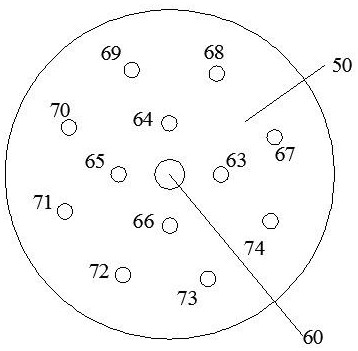

Roadway tunneling efficient rock breaking method based on ultrasonic vibration pre-slotting

ActiveCN112610223AAdjustable powerAdjustable frequencyDisloding machinesBlastingRock engineeringClassical mechanics

The invention belongs to the field of roadway tunneling rock efficient breaking, and particularly relates to a roadway tunneling efficient rock breaking method based on ultrasonic vibration pre-slotting. In order to solve the problem of efficient breaking of hard rock, during hard rock roadway tunneling, the advantages of good ultrasonic directivity, energy concentration and the like are utilized; firstly, ultrasonic vibration equipment is adopted to vibrate and impact a rock mass in a target area, internal cracks are promoted to rapidly expand and rapidly reach breaking, and pre-slotting is achieved; and in combination with optimized arrangement of auxiliary holes and peripheral holes, the efficient breaking of rock is achieved. The method provided by the invention has the advantages that the slotting range and depth can be controlled by adjusting the ultrasonic frequency and power; the time of work procedures such as hole drilling and explosive charging can be effectively reduced; explosives are saved; the tunneling cost is reduced; and the method can be widely applied to rapid tunneling of roadways in hard rock engineering.

Owner:CHINA UNIV OF MINING & TECH

Anti-impact diamond layer, diamond composite sheet and preparation method for diamond composite sheet

InactiveCN102794447BImprove impact resistanceGood cutting sharpnessMetal layered productsManganeseAlloy

The invention discloses an anti-impact diamond layer, an anti-impact diamond composite sheet and a preparation method for the diamond composite sheet. Coarse granular diamond is used as a main raw material, graphite is used as a filling agent, and iron-based powder is used as an accelerant; the diamond layer comprises the following components in part by weight: 70 to 80 parts of diamond, 10 to 20 parts of graphite powder, and 3 to 12 parts of accelerant; and the accelerant consists of the following materials in part by weight: 45 to 60 parts of iron, 15 to 20 parts of nickel, 5 to 15 parts of cobalt, 5 to 20 parts of manganese, and 3 to 10 parts of silicon. The method comprises the following steps of: mixing the raw materials in the ratio uniformly, pre-pressing the mixture and a hard alloy matrix into a composite sheet, filling into a pyrophyllite block to form a structural block, putting the structural block into a 6-surface diamond presser, sintering and electrolyzing at a high temperature under high pressure, and thus obtaining the diamond composite sheet. The diamond composite sheet has the characteristics of big pores and a mesh connection structure, and is quite suitable for drilling medium hard and hard strata due to excellent sharpness and impact toughness.

Owner:河南亚龙金刚石制品股份有限公司

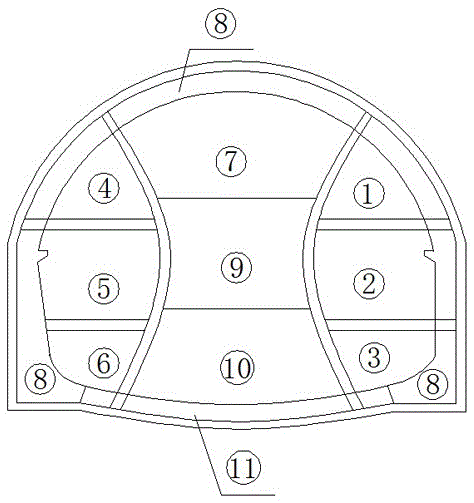

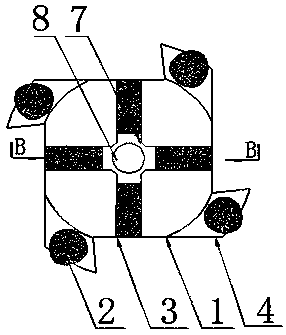

Three teeth roller bit for mining

ActiveCN100567697CPlay the role of lubricating bearingsImprove the lubrication effectDrill bitsGear wheelWell drilling

The invention relates to a drill, which is a 3-gear-wheel drill for drilling in mines or for gas well drilling, and comprises a head section and gear wheels. On the head section, a long air hole and a bearing are arranged. On the long air hole, a ballast-stopping pipe is provided. Between the journal of the head section and the gear wheel, a sealing is provided. The upper end of the long air hole is provided with a sealing membrane. Any grease can be sealedly stored in the bearing cavity and the long air hole of the 3-gear-wheel drill for mines. Comparing with the not-sealed no-lubrication bearing structure in prior 3-gear-wheel mining drill, the invention can lubricate well the bearing in given time, when the sealing fails and the grease is used off, the 3-gear-wheel mining drill will continue to work as usual. As some lubrication time is added, comparing with prior 3-gear-wheel mining drill, the invention can improve the comprehensive indexes of the drill 15-20%.

Owner:SHAREATE TOOLS

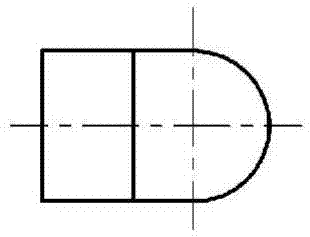

Diamond bit with wedge-shaped matrix crown contours

InactiveCN104131783AEliminates the effects of dynamic loads (vibration)Reduce energy consumptionDrill bitsEnergy consumptionMaterials science

The invention provides a diamond bit with wedge-shaped matrix crown contours. The diamond bit with wedge-shaped matrix crown contours comprises a drill bit body, the matrix crown contours and water ways. The matrix crown contours are arranged on the drill bit body in a surrounding mode. The water ways are arranged between the matrix crown contours. Each matrix crown contour is composed of a fan-shaped block, a matrix wedge surface, a hole wall forming portion and a core forming portion, wherein the whole matrix crown contour is in a wedge shape, the matrix wedge surface, the hole wall forming portion and the core forming portion both incline relative to the fan-shaped block, and the inclination angle of the matrix wedge surface relative to the upper surface of the fan-shaped block, the inclination angle of the hole wall forming portion relative to the outer surface of the fan-shaped block and the inclination angle of the core forming portion relative to the inner surface of the fan-shaped block all range from 15 degrees to 40 degrees. According to the diamond bit, the wedge-shaped matrix crown contours are adopted, an effective pre-breaking area and a breaking area are generated during drilling, the influence of a dynamic load is eliminated, the energy consumption is reduced during rock breaking, and the drill bit is suitable for breaking hard rock and quite hard rock under a complicated crack condition and drilling a rock stratum of a stratum with interbedding of soft and hard rocks and increases the drilling rate and the footage per bit.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

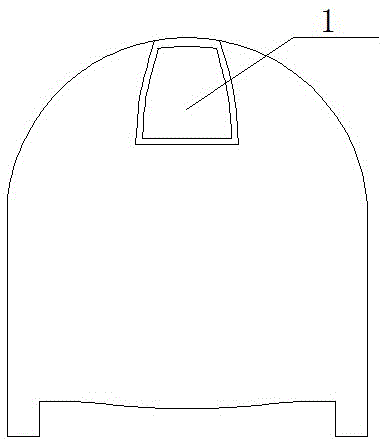

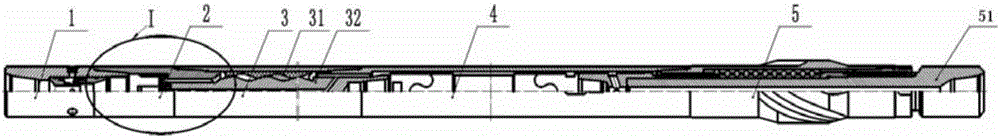

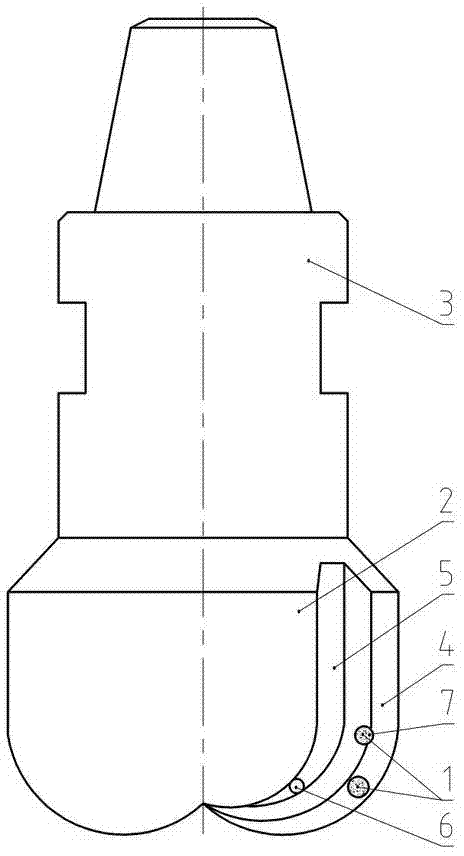

Cutting depth self-adjusting mechanism and drill bit

PendingCN110439471AAvoid failureExpand the stable operating areaDrill bitsConstructionsDamping functionControl engineering

The invention provides a cutting depth self-adjusting mechanism and a drill bit, and belongs to the field of oil exploitation. The cutting depth self-adjusting mechanism comprises an outer cylinder, aball head tooth, a throttle damping valve and a hydraulic reset assembly, wherein the ball head tooth is movably installed at one end of the outer cylinder and can retract in or extend out of the outer cylinder; the throttle damping valve is installed in the outer cylinder, and divides an inner cavity of the outer cylinder into a first hydraulic cavity and a second hydraulic cavity, wherein the first hydraulic cavity and the second hydraulic cavity are filled with hydraulic fluid; and the hydraulic reset assembly is movably installed at the other end of the outer cylinder and can move under the driving of the hydraulic fluid in the second hydraulic cavity. Through the double damping function of the throttle damping valve and the hydraulic reset assembly, the impact on the bit by the rockis reduced, cutting teeth of the bit are further protected, the bit footage is increased, and the bit service time is prolonged.

Owner:KINGDREAM PLC CO +1

Combined metallurgical furnace taphole drill bit and tooth fixing process thereof

InactiveCN110241279APrevent deviationAvoid displacementBlast furnace componentsBlast furnace detailsPunchingToughness

The invention discloses a combined metallurgical furnace taphole drill bit and a tooth fixing process thereof. The drill bit comprises a drill bit body, wherein four windmill-shaped alloy bases are arranged at the four corners of the side wall of the drill bit body, a blind hole is arranged at the top center of each alloy base, and cylindrical tooth alloy is welded in the blind holes ;an alloy groove is formed in the top surface of the drill bit body, and sheet alloy is welded in the alloy groove; the center of the end face of the drill bit body is provided with a positioning block, and the positioning block is provided with a ventilation hole overlapped with the central axis of the drill bit body. According to the drill bit, a punching mode crushing is combined with a shearing mode crushing, so that accurate positioning can be realized, steped grading drilling footage can be carried out, deviation and displacement of the drill bit in the tapping process can be prevented, impact force and crushing tasks can be decomposed on each grain of columnar tooth alloy and sheet alloy, and the utilization rate of alloy on the drill bit and the service life of the drill bit are improved; copper alloy solder is adopted to weld the column tooth alloy in the blind holes, so that the column tooth alloy is not easy to fall off and has high temperature resistance and certain toughness.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

Steel body type diamond-impregnated bit

The invention relates to a steel body type diamond-impregnated bit, and belongs to the field of boring tools. The steel body type diamond-impregnated bit is composed of an impregnated body, a bit body and a joint, wherein the bit body is a steel body type bit body; a blade, a nozzle and a flow channel are processed on the steel body type bit body, and the impregnated body is arranged on the blade and exposed; the steel body type diamond-impregnated bit is characterized in that the impregnated body and a cutting material have dual rock breaking functions of shearing fracture and plough cutting; the whole intensity of the steel body type bit body is high, the steel body type bit body is beneficial to developing the large-size steel body type diamond-impregnated bit, designing a long blade and a deep chip groove and increasing the height of the impregnated body; the wearability of the steel body type bit body is poor, the impregnated body is easy to expose, the mechanical drilling speed and drilling footage are increased, the cost of the steel body type bit body is lower than that of a fetal body, and the bit cost is greatly reduced; the impregnated body is manufactured through a hot pressing agglomeration technology, the quality is better, the drilling footage is improved, and the cost is reduced through serialization; and an impregnated body and steel body type bit body fission type structure is beneficial to form an industry group and accelerating research and development and the updating speed.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com