Torque pulse motor

A motor and pulse generator technology, applied in the field of torsion punching motors, can solve the problems of stick-slip vibration of drill bits, high processing and manufacturing costs, and prolonging operation cycle, so as to reduce the torque required for drilling, reduce processing and manufacturing costs, and solve mutual problems. wear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

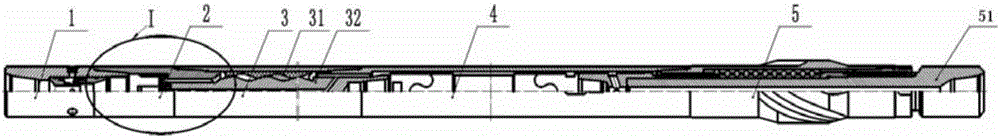

[0023] Such as Figure 1 to Figure 4 As shown, a twisting motor of the present invention includes a bypass valve assembly 1, a motor assembly 3, a cardan shaft assembly 4 and a transmission shaft assembly 5 connected in sequence from left to right, and the bypass valve Assembly 1, motor assembly 3, cardan shaft assembly 4 and transmission shaft assembly 5 are similar in structure to ordinary screw drilling tools. The motor assembly 3 includes a screw stator 31, and the screw stator 31 is provided with a Screw rotor 32 with axial center hole. The transmission shaft assembly 5 includes a lower joint 51 for connecting a drill bit.

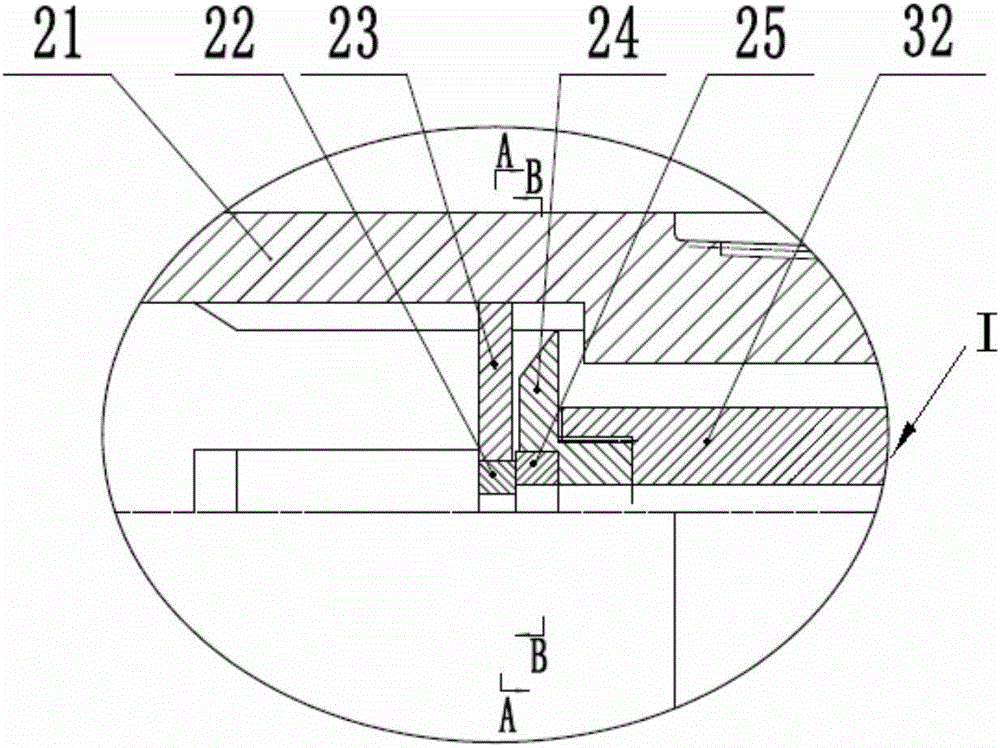

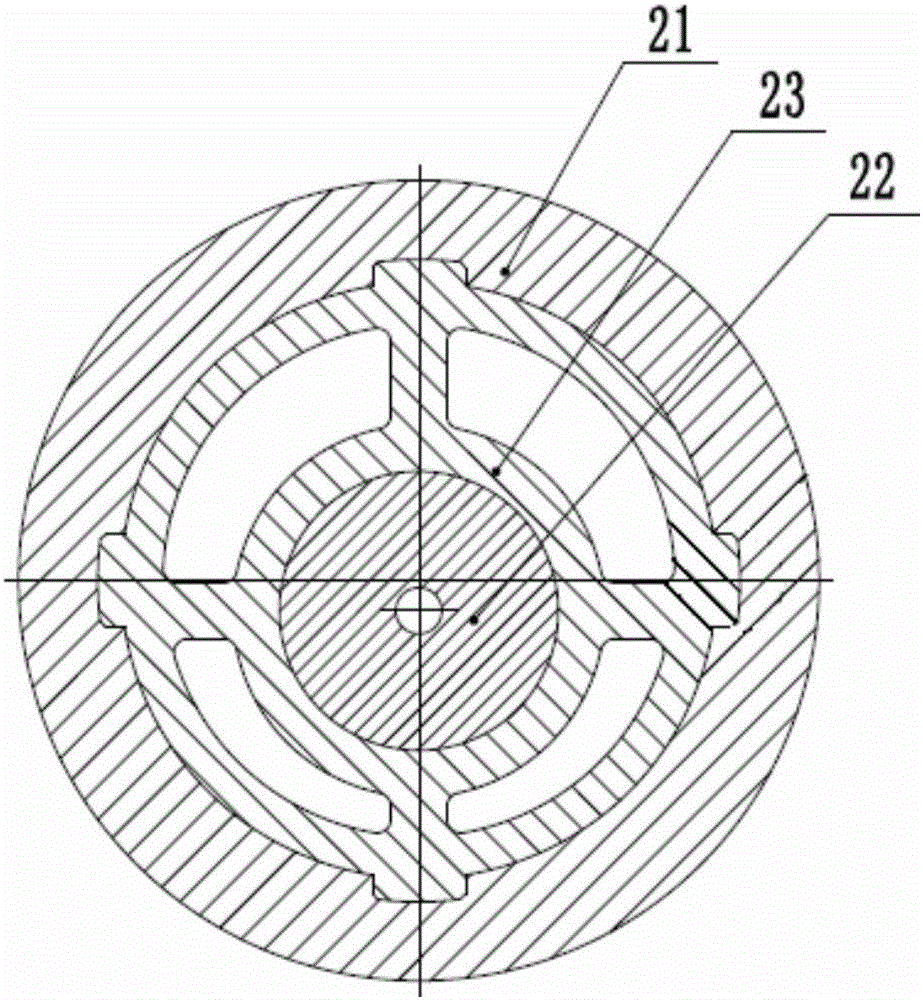

[0024] A torque pulse generator 2 is connected between the bypass valve assembly 1 and the motor assembly 3. The torque pulse generator 2 includes a sleeve joint 21, and the left end of the sleeve joint 21 is provided with a bypass valve ass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com