Roadway tunneling efficient rock breaking method based on ultrasonic vibration pre-slotting

An ultrasonic and rock-breaking technology, which is applied in the field of high-efficiency rock-breaking in roadway excavation based on ultrasonic vibration pre-cutting, can solve problems such as no ultrasonic waves, and achieve the effects of improving rock-breaking efficiency, high footage, and saving consumable materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

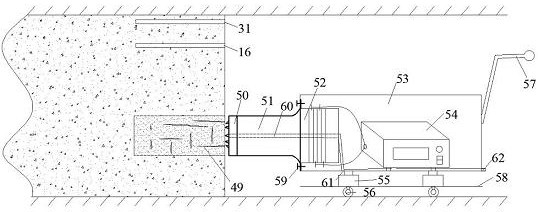

[0033] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

[0034] Select a tunneling face in a certain mine for construction. The specific construction method is as follows:

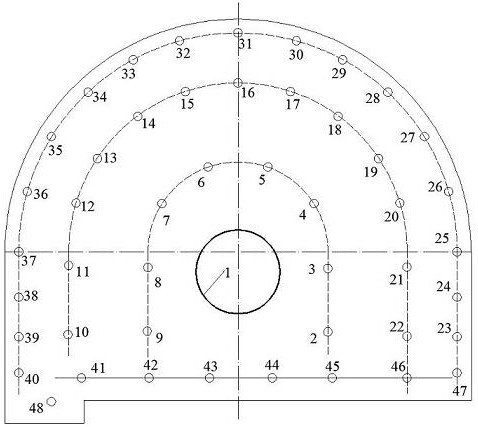

[0035] The first step is to design and plan the cutting range area and prepare ultrasonic vibration equipment;

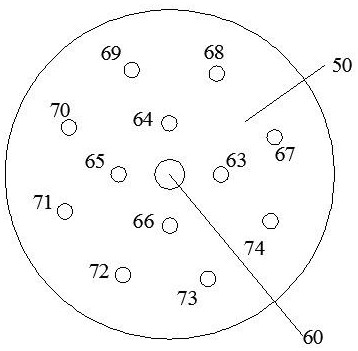

[0036] In the second step, because the excavation rock formation is relatively hard, the design cutting depth is required to be 2.2 m, so the power of the ultrasonic generator 54 is adjusted to 40 kW, the ultrasonic frequency is 25 kHz, and the ultrasonic vibration time within one footage is set to 10 minutes, and the amplitude is selected. Amplify the horn 51 with an amplification factor of 3:1, and then perform ultrasonic vibration on the cutting range area 1; at the same time, use a common drilling machine to drill the peripheral holes 23~48;

[0037] In the third step, as the range and depth of the cutout increase...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com