Patents

Literature

48results about How to "Grooving speed is fast" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

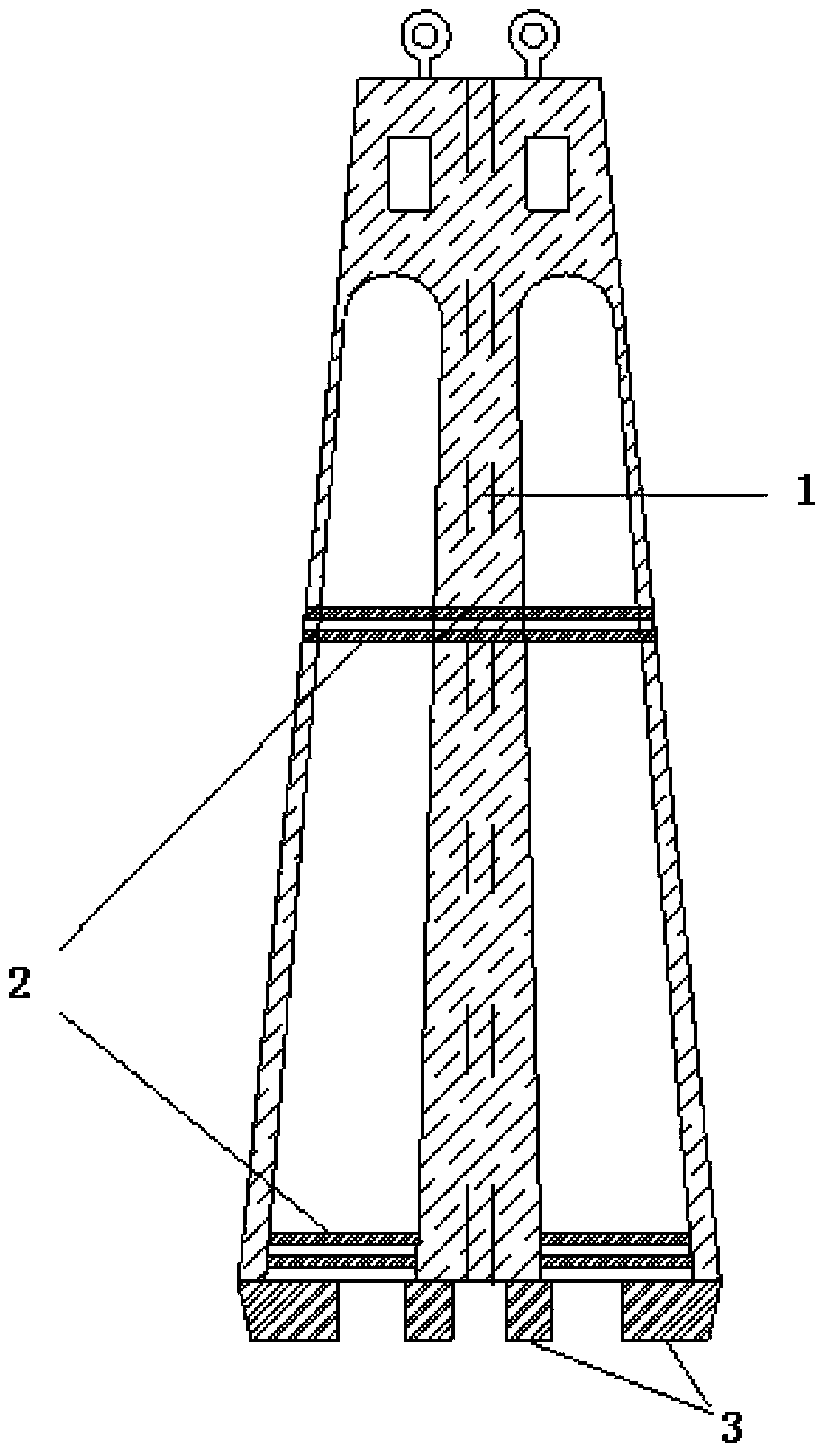

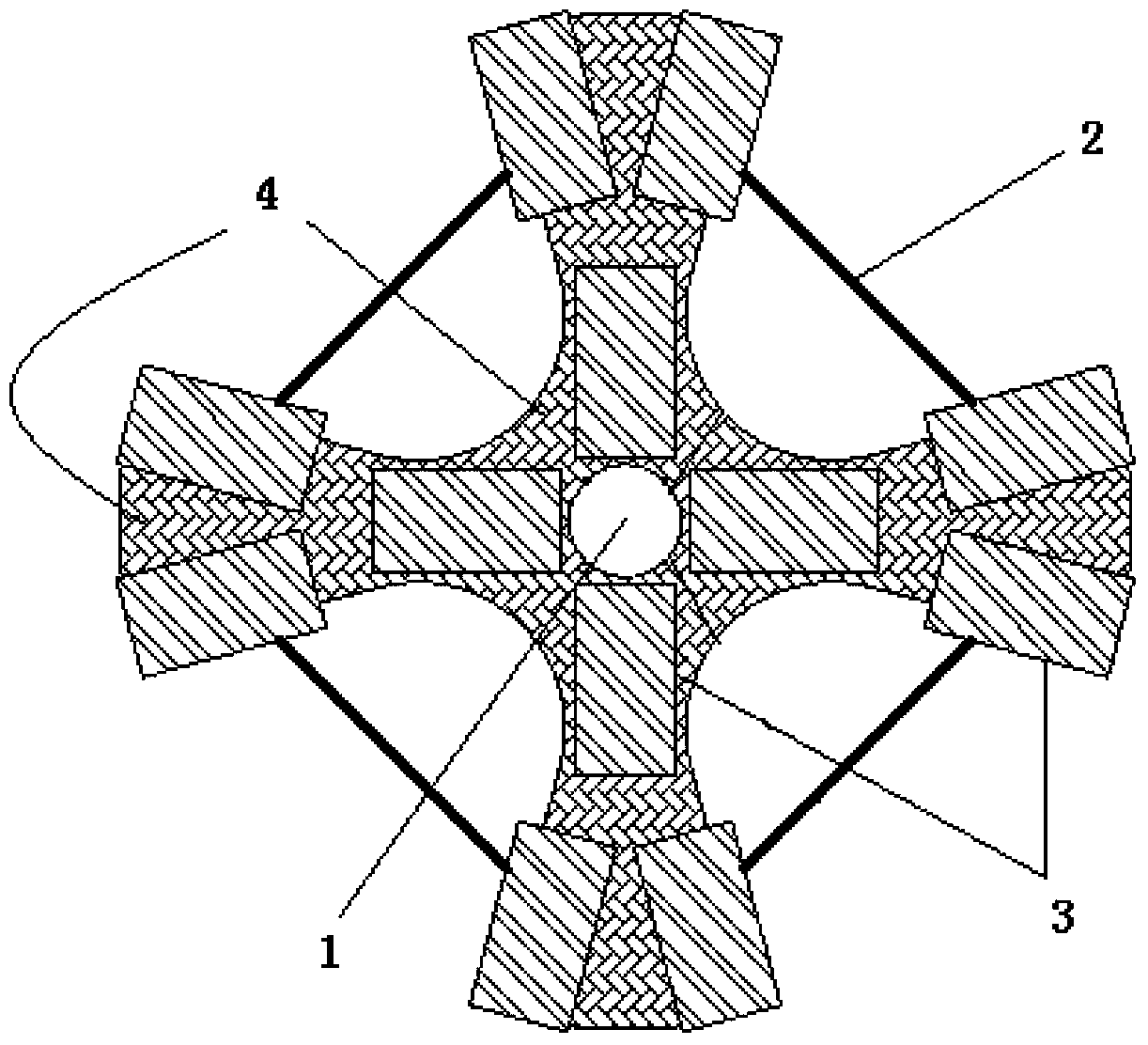

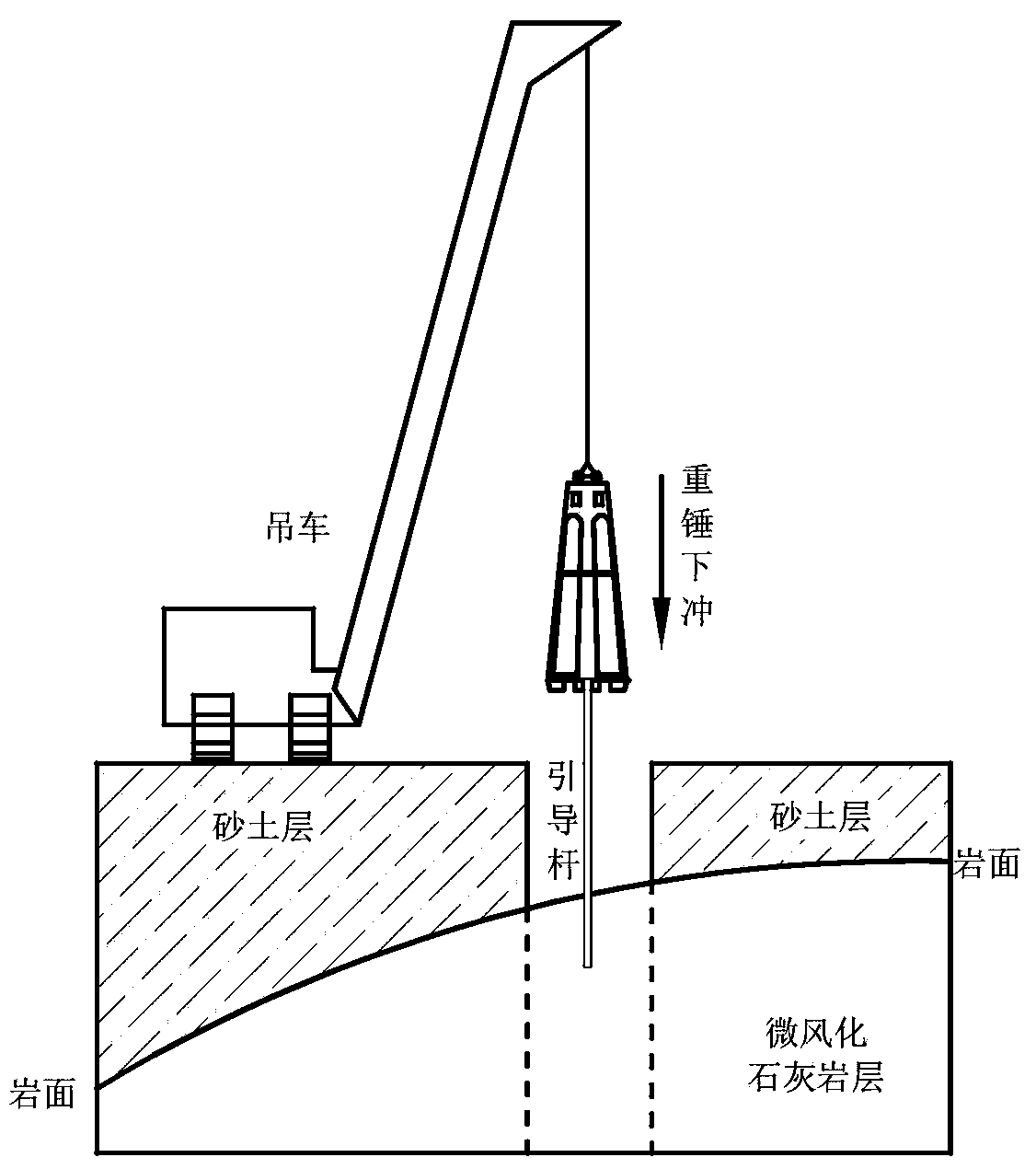

Effective grooving construction method for underground continuous wall in slightly-weathered limestone with overlying sandy soil

ActiveCN103437341AGood hammering effectGood construction performanceArtificial islandsSoil-shifting machines/dredgersSlurry wallEconomic shortage

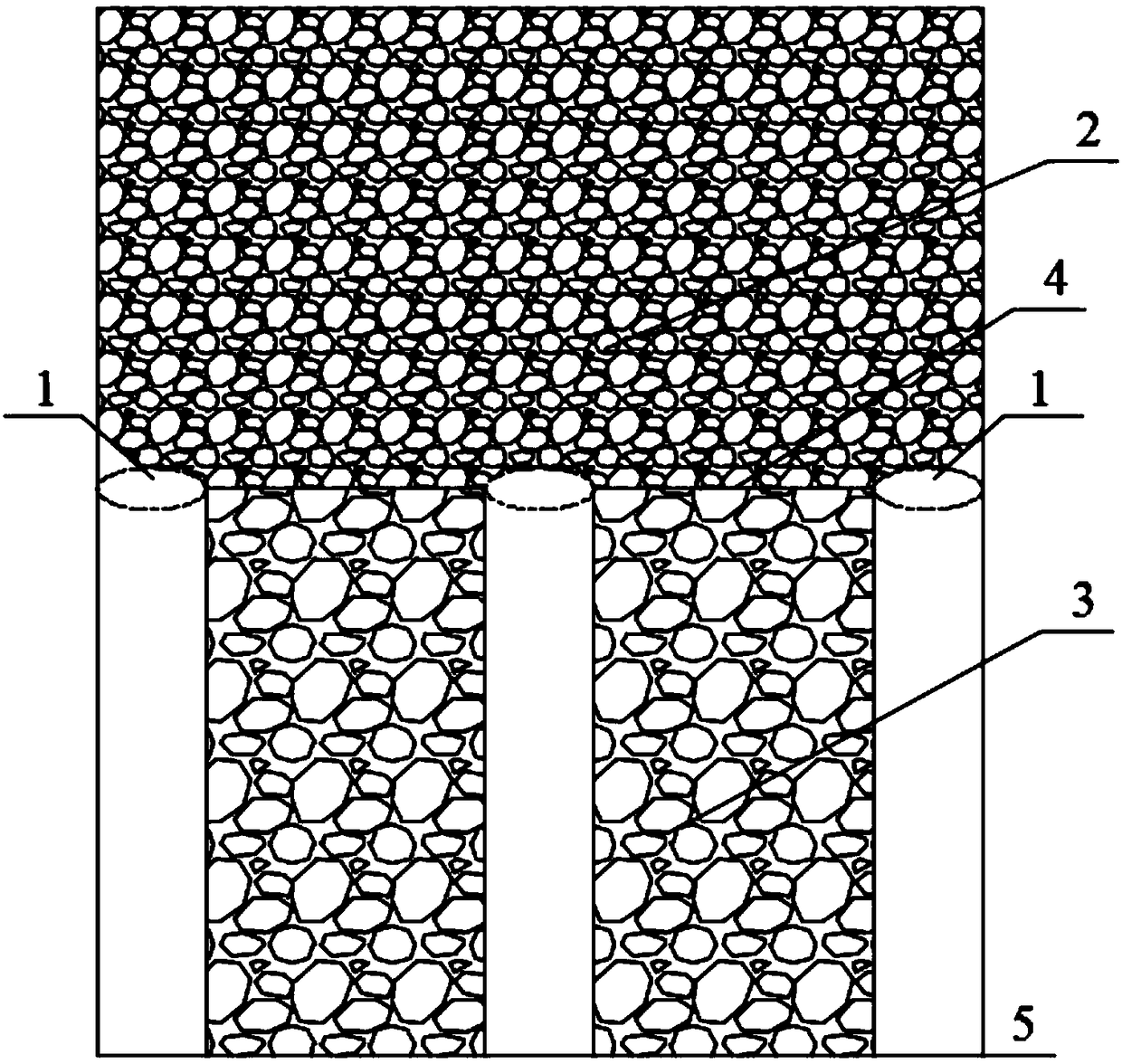

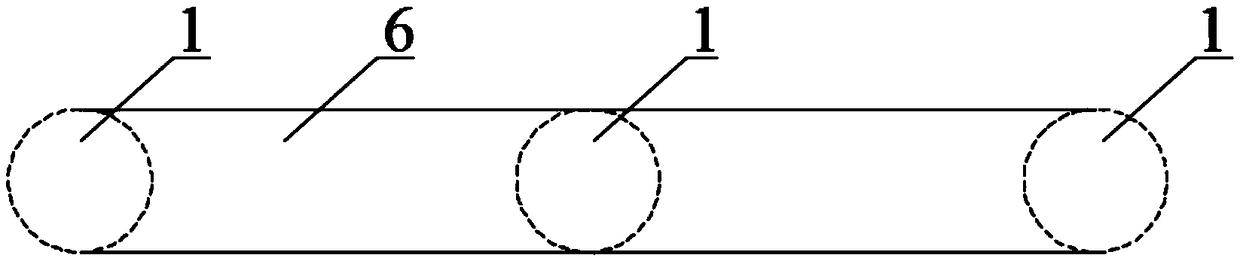

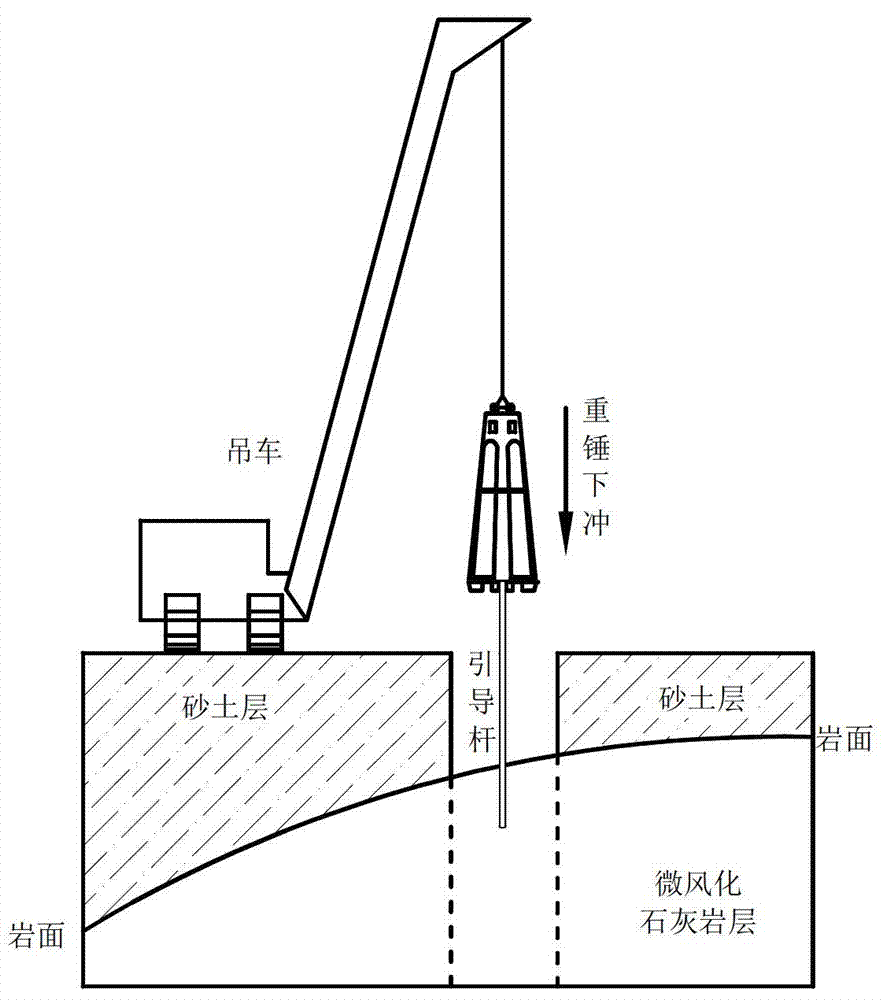

The invention provides an effective grooving construction method for an underground continuous wall in slightly-weathered limestone with overlying sandy soil. The method specifically comprises the steps of 1) performing core drilling in a grooving area to determine rock characters; 2) measuring the position of a setting-out calibration guide wall; 3) performing guide wall construction and determining the distribution of hole punching positions; 4) drilling guide holes, and installing guide rods; 5) punching a rock layer by using a heavy hammer and grabbing crushed rocks by using a grooving machine; 6) brushing a wall by using a square hammer and connecting the holes to form a groove; 7) cleaning the bottom of the groove to finish the grooving construction. The construction method provided by the invention has the advantages that the defects and the shortages of unsafe and unstable factors, slow construction progress, poor grooving quality and the like are overcome, and the effective, low-cost and high-accuracy grooving construction in the slightly-weathered limestone is realized; the construction effect is good, the grooving speed is fast, the construction process is simple and convenient and the construction period is greatly shortened.

Owner:CHINA RAILWAY 16 BUREAU GRP BEIJING METRO ENG CONSTR +1

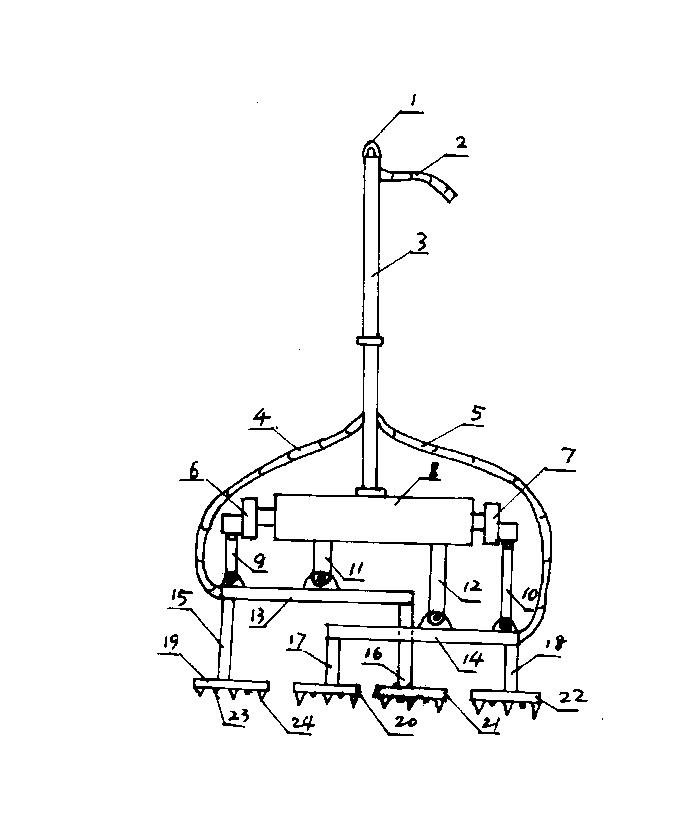

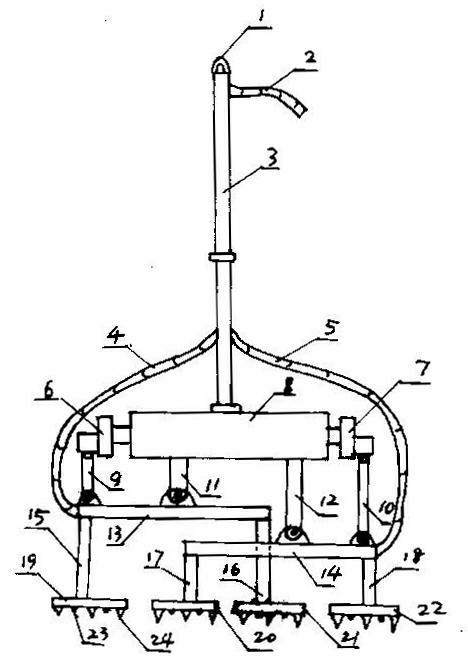

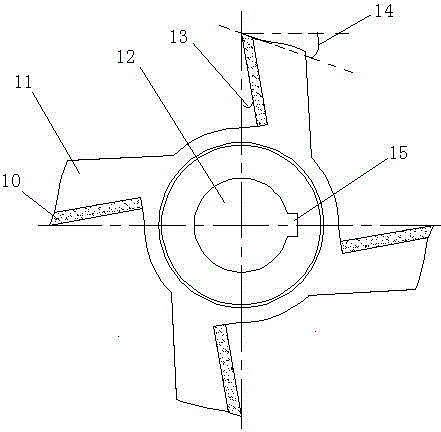

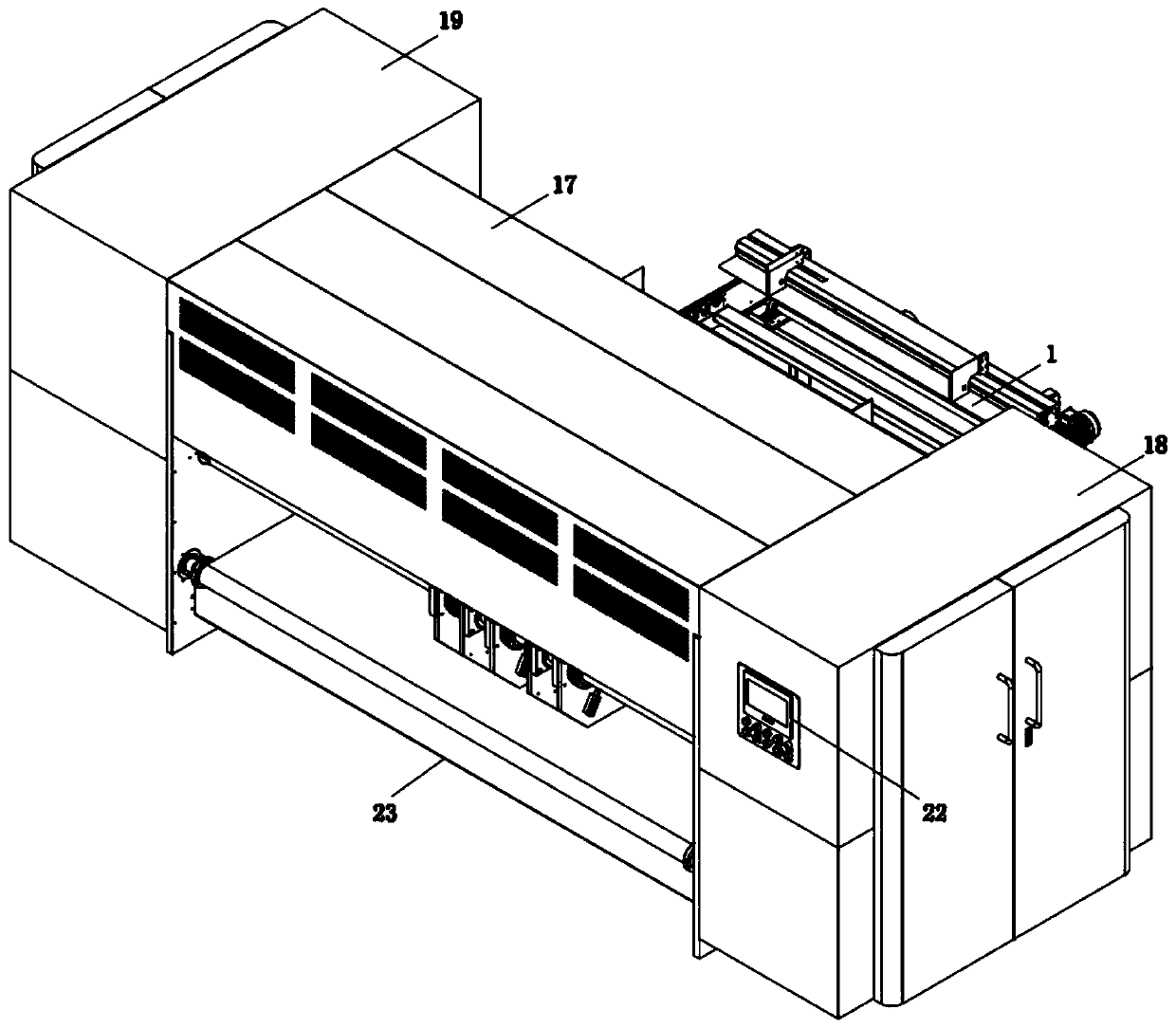

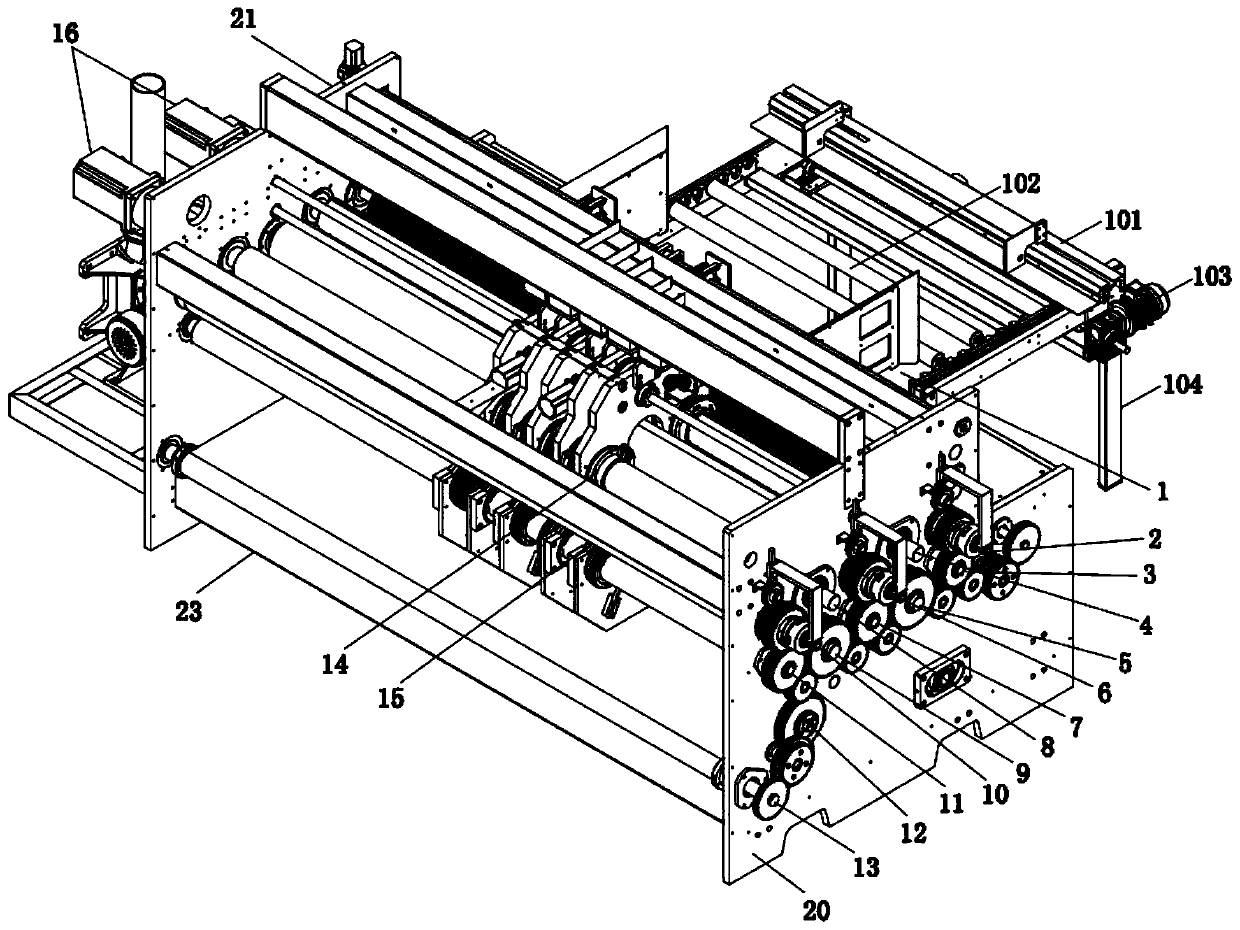

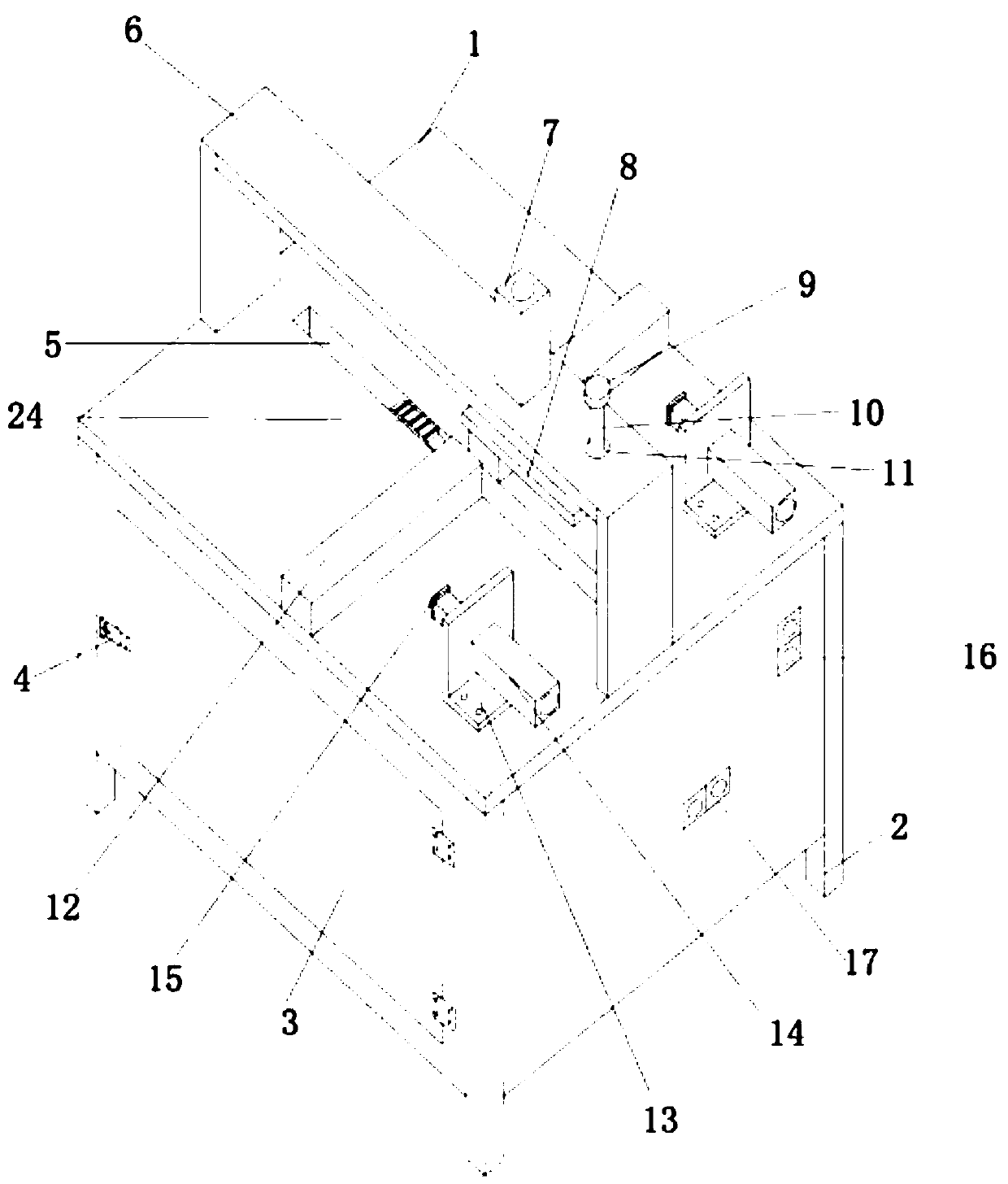

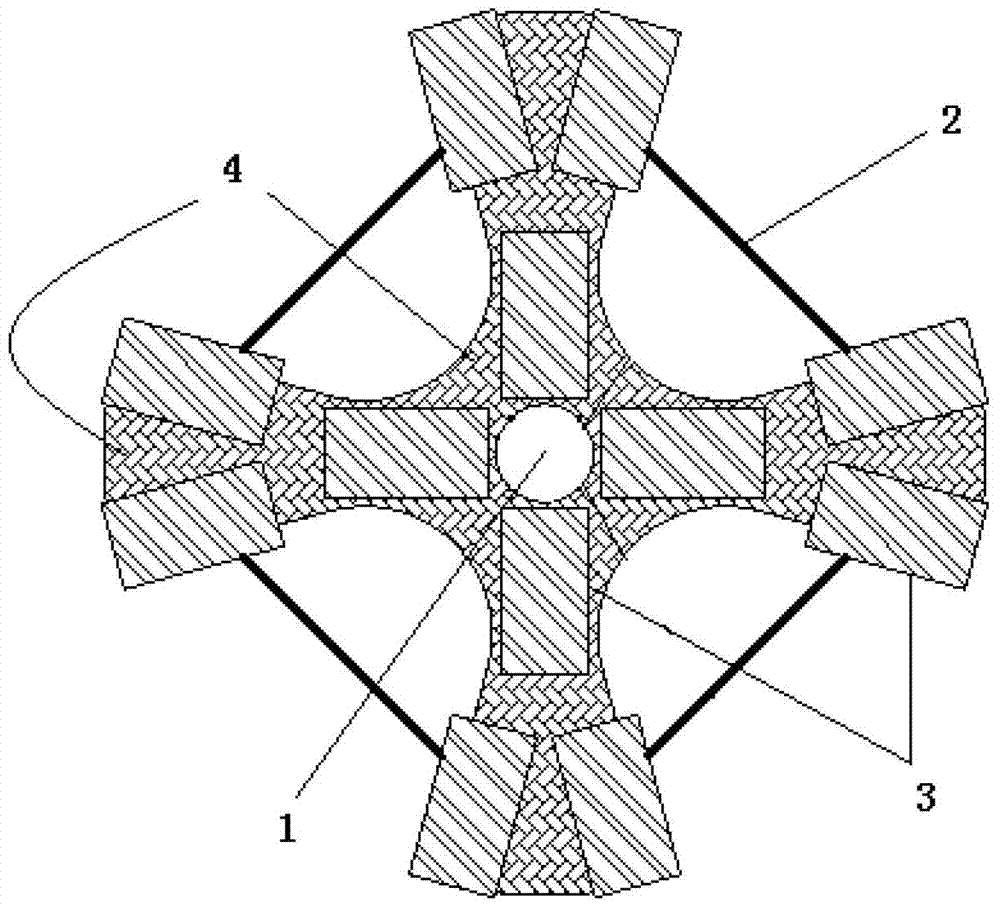

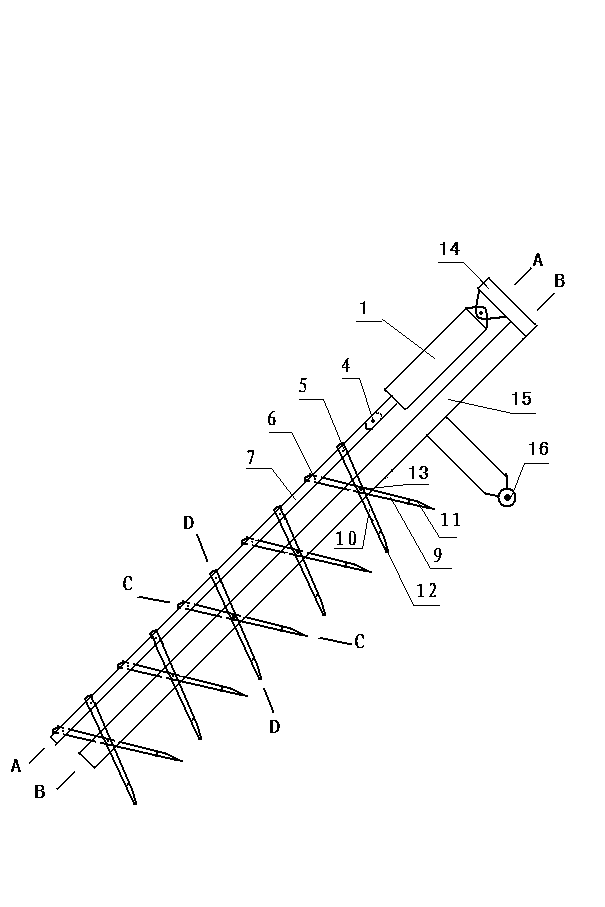

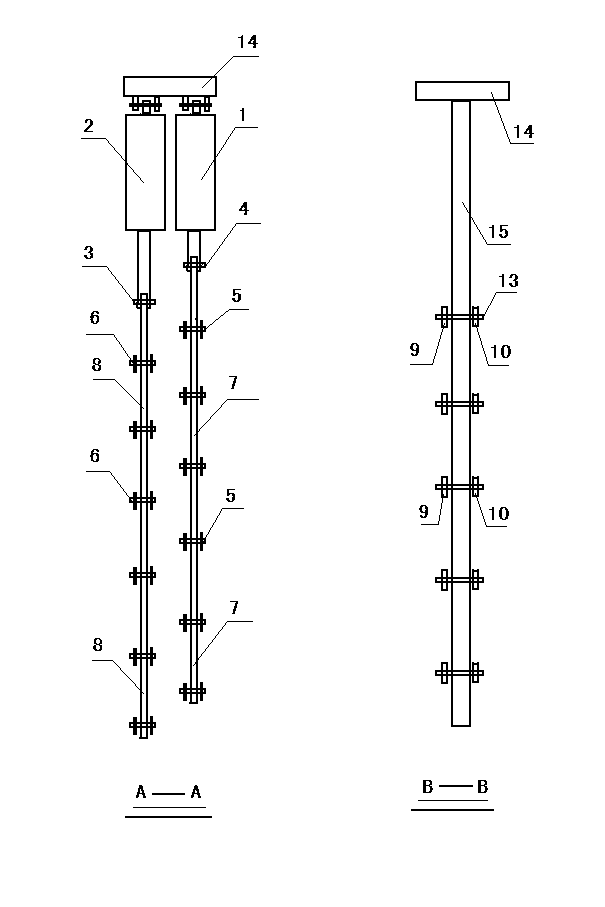

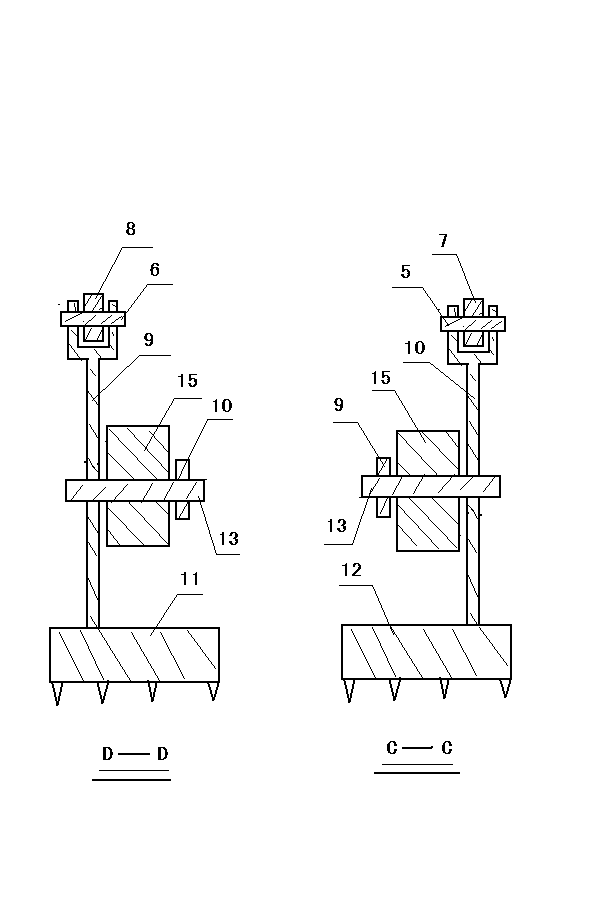

Four-drill trenching machine

A four-drill trenching machine comprises a hanging ring, water inlet rubber hoses, and a water inlet steel pipe, wherein the hanging ring is arranged on the upper portion of the trenching machine, the lower portion of the water inlet steel pipe is divided into two pipes, one of the two pipes is connected with the left end of a transverse pipe A through a left water inlet rubber hose, the other end of the two pipes is connected with the right end of a transverse pipe B through a right water inlet rubber hose; the lower end of the water inlet steel pipe is fixed on a submersible motor, the left end of the submersible motor is provided with a crank A, the right end of the submersible motor is provided with a crank B, the crank A is connected to the upper left end of the transverse pipe A through a connecting rod A, and the crank B is connected to the upper right end of the horizontal pipe B through a connecting rod B; the upper end of an upright rod A is fixed on the lower left portion of the submersible motor, the lower end of the upright rod A is hinged in the middle of the transverse pipe A, the upper end of an upright rod B is fixed on the lower right portion of the submersible motor, and the lower end of the upright rod B is hinged in the middle of the transverse pipe B; and the lower portions of a cutter arbor A, a cutter arbor B, a cutter arbor C and a cutter arbor D are respectively provided with three cutter teeth, and a water spray nozzle is arranged between each of the two cutter teeth of the three cutter teeth. The four-drill trenching machine is a special machine tool for constructing diaphragm walls.

Owner:张家港市欧微自动化研发有限公司

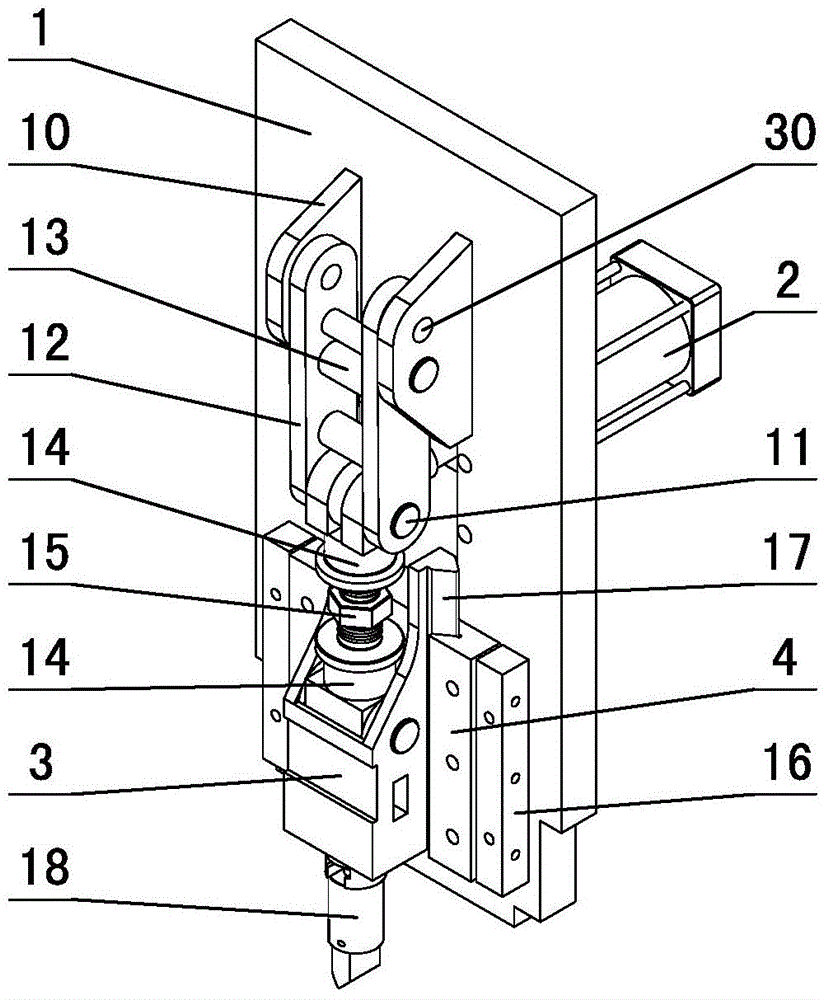

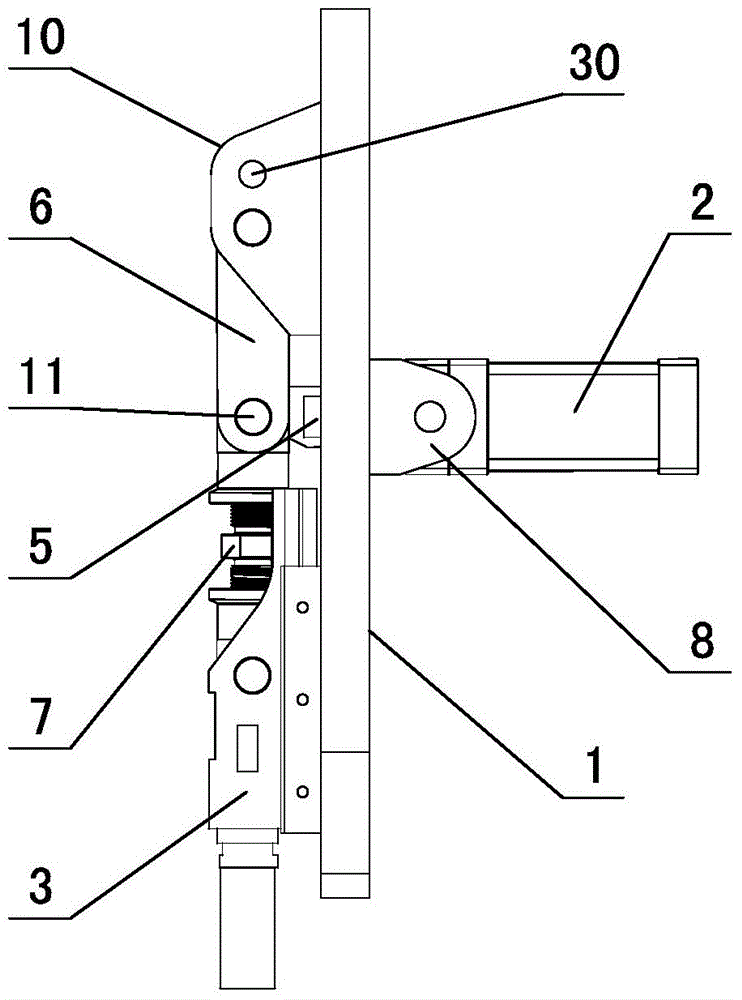

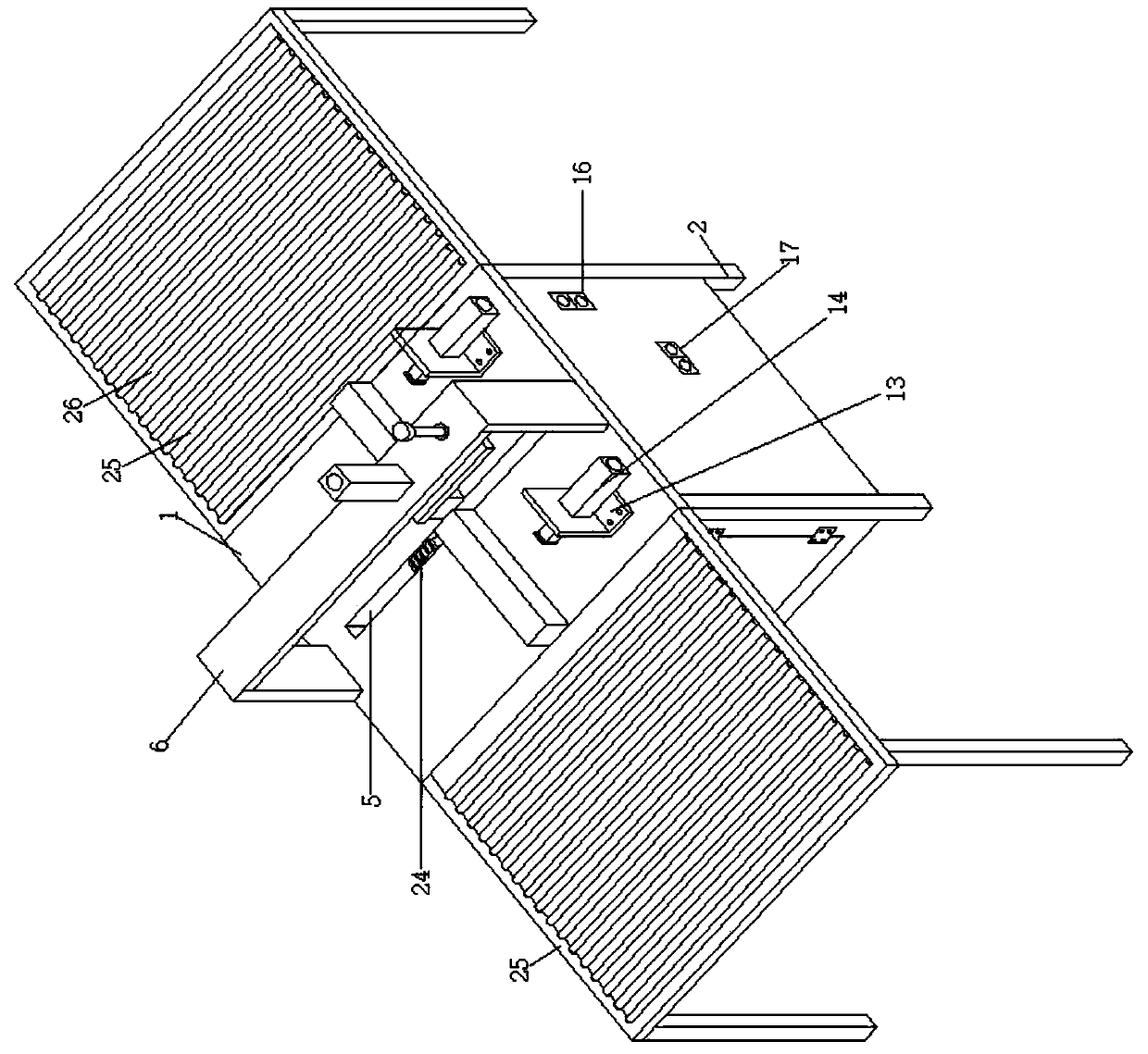

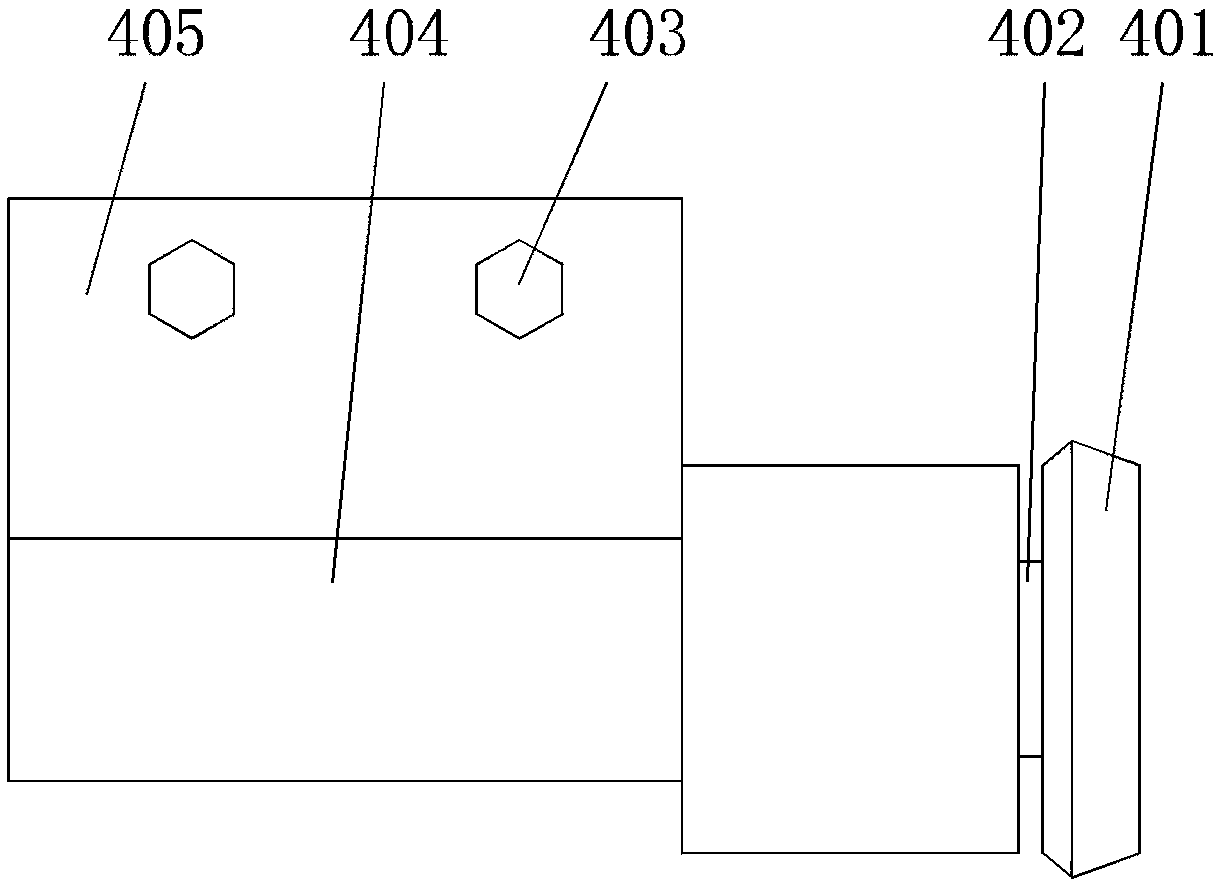

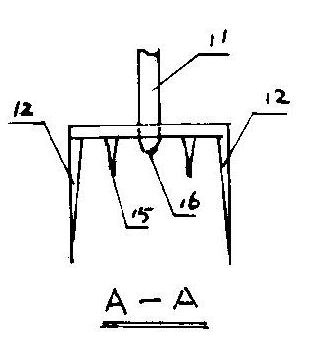

Side face slotting device for cylindrical wood

InactiveCN107379150AImprove production efficiencyEasy slottingWood mortising machinesWood slotting machinesChiselEngineering

The invention discloses a side face slotting device for cylindrical wood. The side face slotting device for cylindrical wood comprises a base plate. The upper surface of the base plate is provided with a first fixing plate and a second fixing plate. The left side face of the second fixing plate is provided with a control panel. The right side face of the first fixing plate is connected with a sliding sleeve in a clamped manner. According to the side face slotting device for the cylindrical wood, the wood is placed on a supporting plate, a second electric push rod extends to tightly press the wood, secondary tight pressing and fixation are conducted on the wood through bolts and nuts, a motor is controlled to rotate, the supporting plate is made to drive the wood to rotate, the first electric push rod is controlled to extend, a second pressing block presses a first pressing block to move leftwards, a sliding rod is made to move leftwards in the sliding sleeve, and then a chisel makes contact with the wood; through control over the extending height of the first electric push rod, the leftward movement distance of the chisel is controlled, so that the slotting depth of the wood is controlled. The side face slotting device for the cylindrical wood is convenient to control and rapid in slotting and improves the manufacturing efficiency of wood products.

Owner:扬州市大悦信息科技有限公司

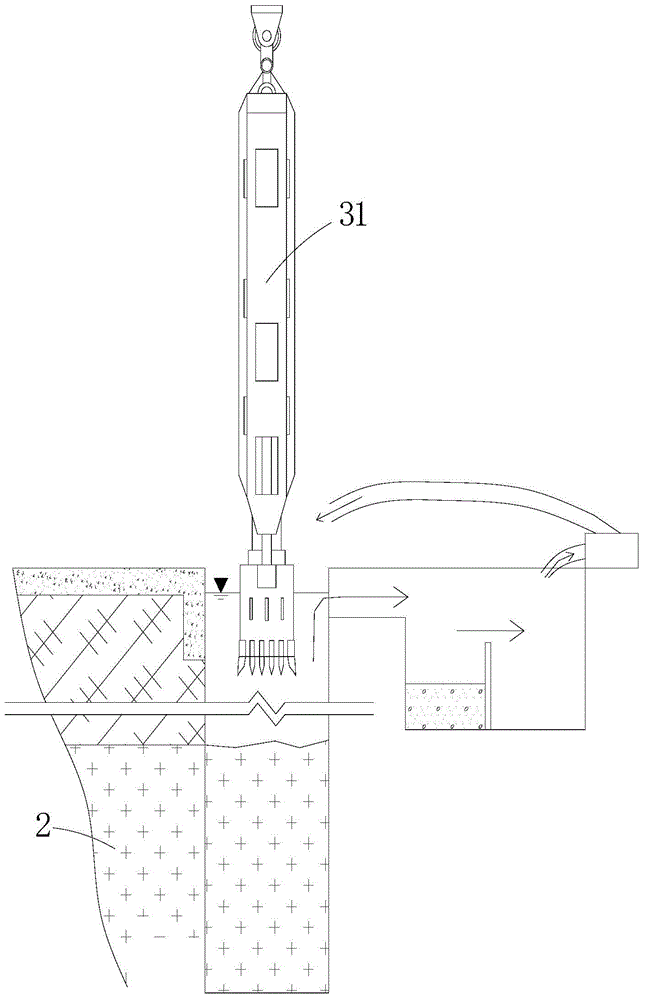

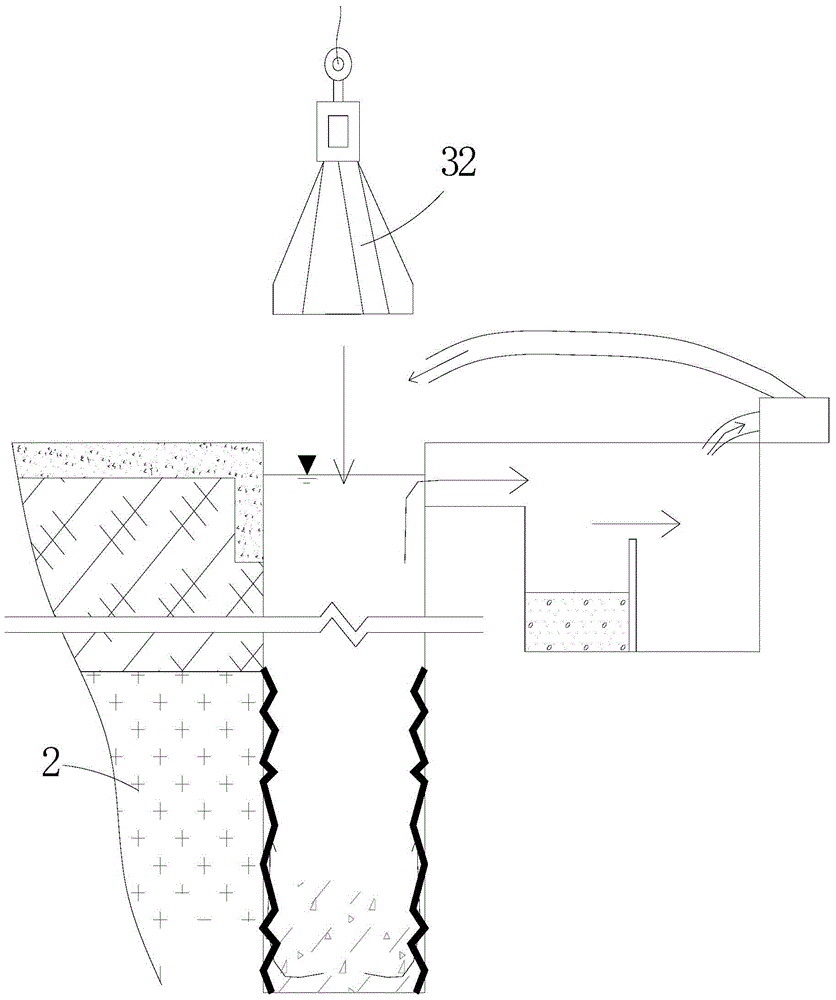

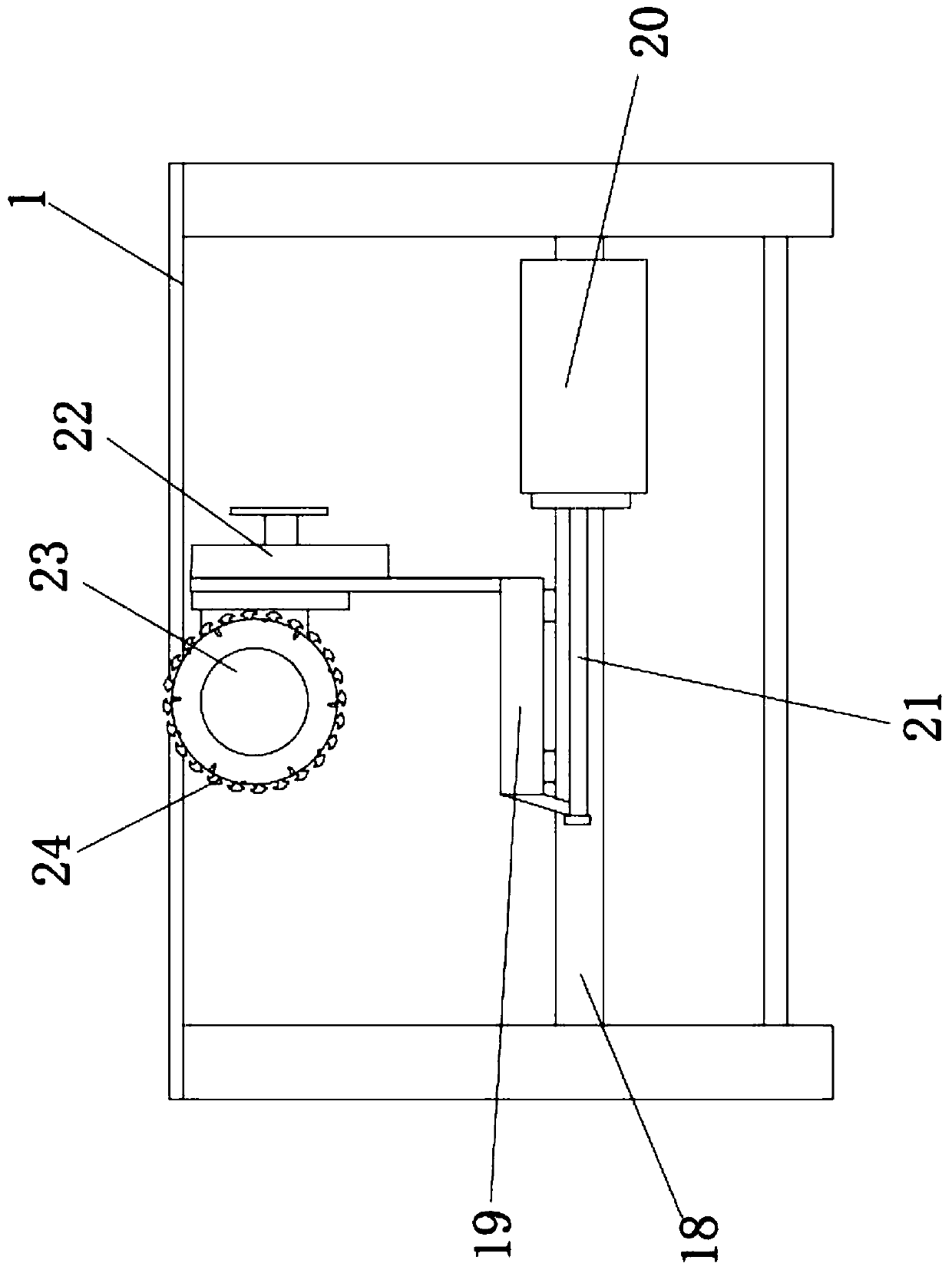

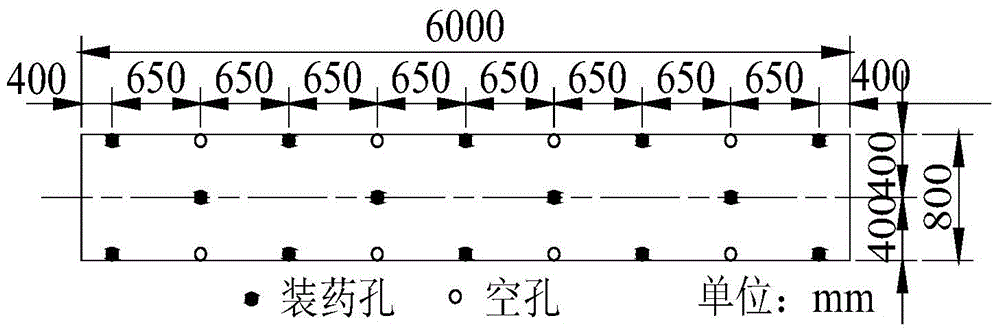

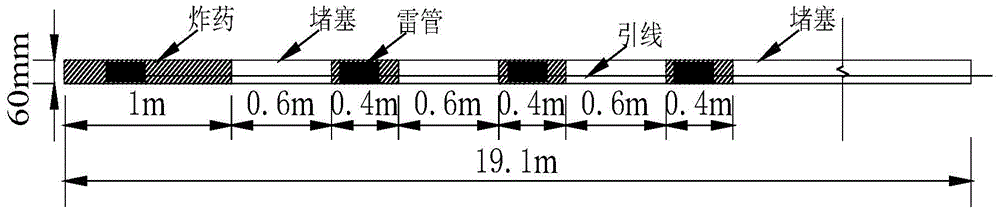

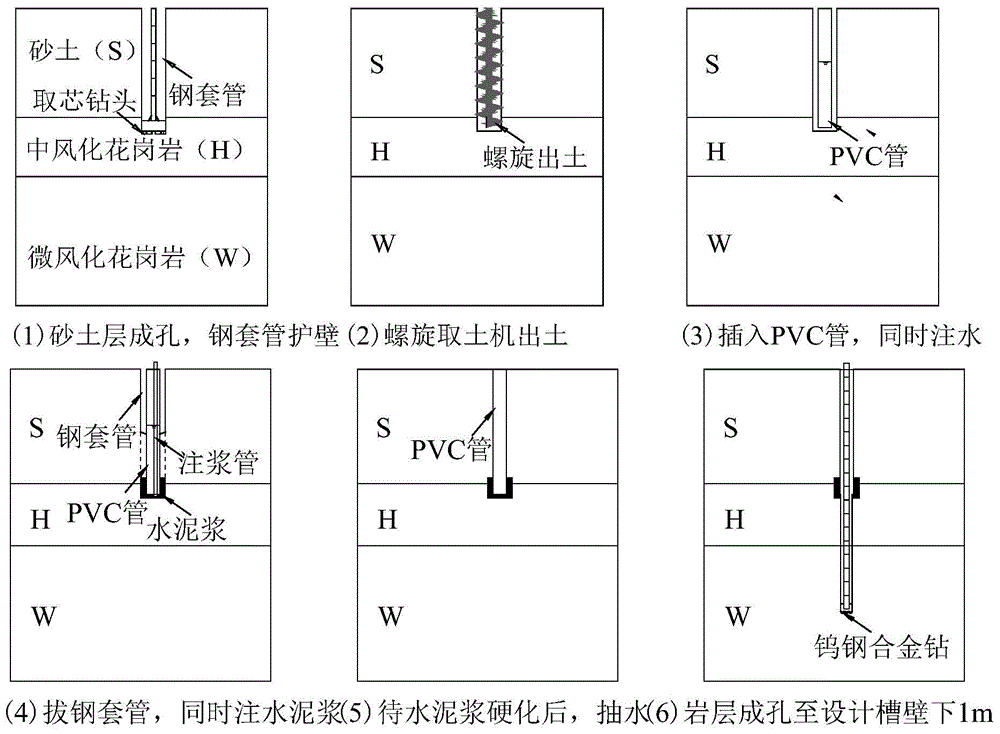

Efficient grooving construction method for underground diaphragm wall in micro-weathered granite

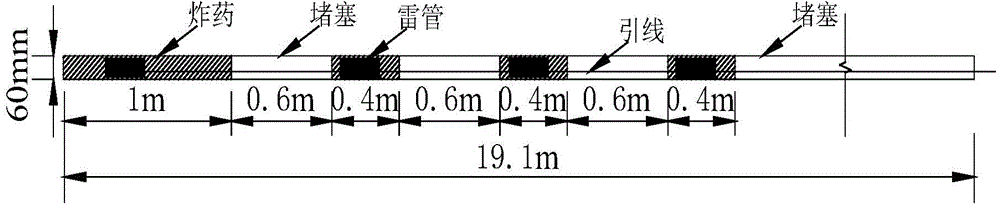

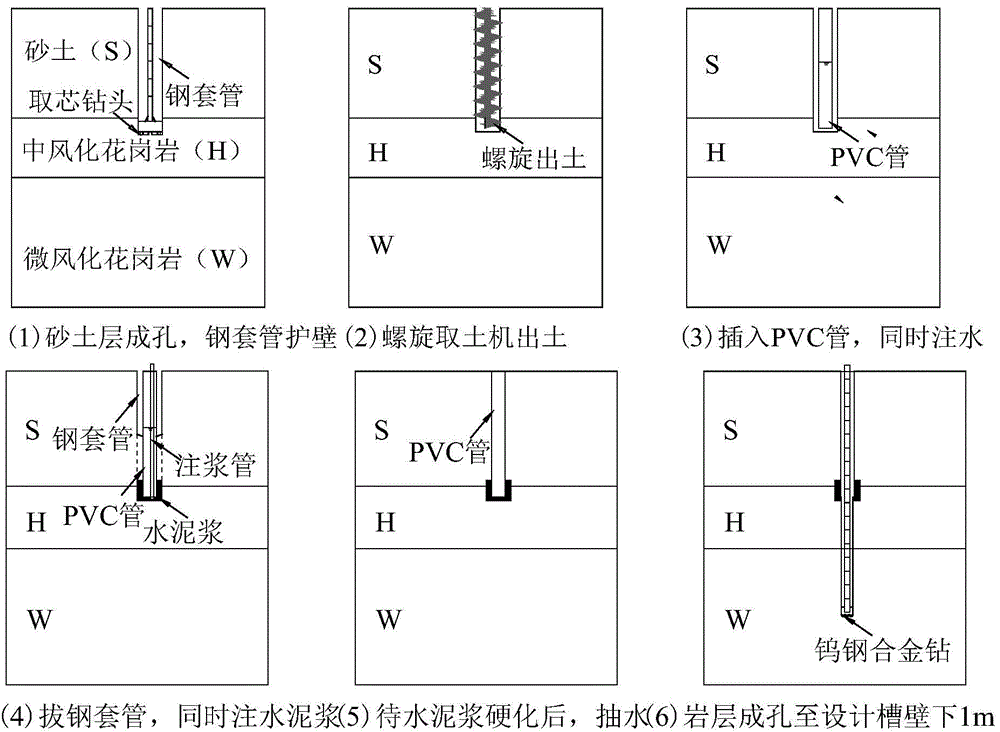

ActiveCN104005415AEfficient trough constructionGood effectBlastingExcavationsSlurry wallPolyvinyl chloride

The invention provides an efficient grooving construction method for an underground diaphragm wall in micro-weathered granite. The method specifically comprises the following steps: 1, geologically surveying the construction site; 2, determining the rock breaking method; 3, determining blasting parameters; 4, drilling holes from a sand layer to the surface of a rock layer, and unearthing; 5, distinguishing a rock sample, and then determining and drilling to reach intermediately-weathered granite; 5, feeding a PVC (Polyvinyl Chloride) pipe for protecting a blasting lead; 7, drilling hole in the rock layer until reaching depth 1m more than the design burial depth; 8, feeding explosive and blasting. With the adoption of the efficient grooving construction method for the underground diaphragm wall in the micro-weathered granite, the defects and shortcomings like difficult construction in the micro-weathered granite or slow construction progress, and poor grooving quality of the existing construction method of covering sand the micro-weathered granite can be overcome; the efficient, high-precision and deep-rock-embedding grooving construction in the micro-weathered granite is realized; the method has a good effect and fast to groove.

Owner:CHINA RAILWAY 16 BUREAU GRP BEIJING METRO ENG CONSTR +2

Grooving construction method for embedding underground continuous wall into rock

The invention relates to the technical field of embedding underground continuous walls into rock and grooving of the underground continuous walls and discloses a grooving construction method for embedding an underground continuous wall into rock. The method includes the steps that firstly, a grab bucket is used for excavating soil so that a groove can be formed, and a residual soil layer is reserved between the groove bottom and a rock face; secondly, a rotary excavating drilling tube is used for drilling holes in the residual soil layer and a seriously-weathered layer, a cutting-tooth drilling tube is used for drilling medium-weathered rock and micro-weathered rock, and rock entering holes in bed rock are formed; thirdly, the second step is repeated, and a plurality of rock entering holes are formed in the length extension direction of a groove segment; fourthly, a plane set-hammer is used for clearing away hard rock tooth edges. According to the construction method, the grooving speed is high, and on-site general layout and civilized construction are facilitated; meanwhile, the cutting-tooth drilling tube is used for performing rotary excavation and entering the rock to take a core, and impacting vibration is avoided; due to the fact that the grooving construction period is short, the exposing time of the groove wall is relatively short, the risk that groove wall soil collapses is reduced, the groove wall is stable, and construction cost is indirectly reduced; the residual soil layer is reserved on the rock face of the bed rock, the rotary excavating drilling tube plays a guiding role in the hole forming process, and the situation that because the inner rock face of the groove segment is inclined, hole drilling deflects is prevented.

Owner:SHENZHEN SUNHUI MECHANICAL CO LTD

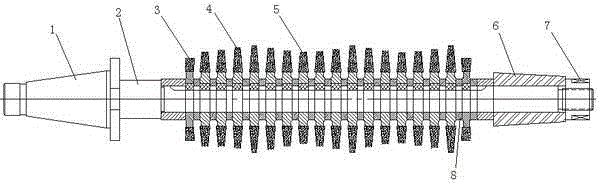

Combined milling cutter used for graphite grooving

InactiveCN105196427AGood slotting qualityBoth quality and efficiencyStone-like material working toolsTool bitMilling cutter

The invention provides a combined milling cutter used for graphite grooving. The combined milling cutter comprises a cutter shaft and 4-20 milling cutter bodies sequentially connected to the cutter shaft in a sleeving mode. Each milling cutter body comprises 4-8 tool bits. One end of the cutter shaft is fixedly connected with a drive rotating plate, and the other end of the cutter shaft is connected with a bearing supporting the cutter shaft. Positioning space rings are arranged between the milling cutter bodies so that the distances between the milling cutter bodies can be regulated. Each milling cutter body has a sleeving rotation angle ranging from 5 degrees to 30 degrees relative to the adjacent corresponding milling cutter bodies. The diameters of part of the milling cutter bodies are different. The front angle of the tool bit of each milling cutter is 8-12 degrees, the rear angle of the tool bit of each milling cutter is 18-22 degrees, and the tool bits are made of hard alloy. The combined milling cutter is rapid in grooving speed and good in grooving quality, and 4-20 grooves can be synchronously formed.

Owner:南通国阳新材料有限公司

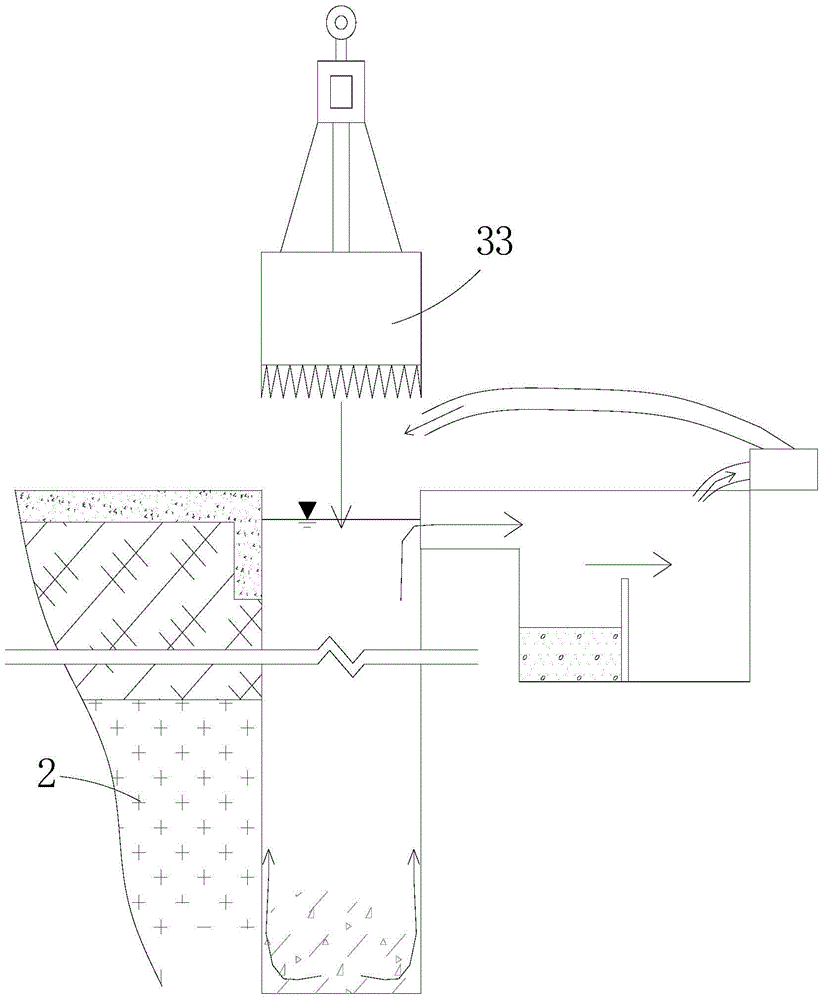

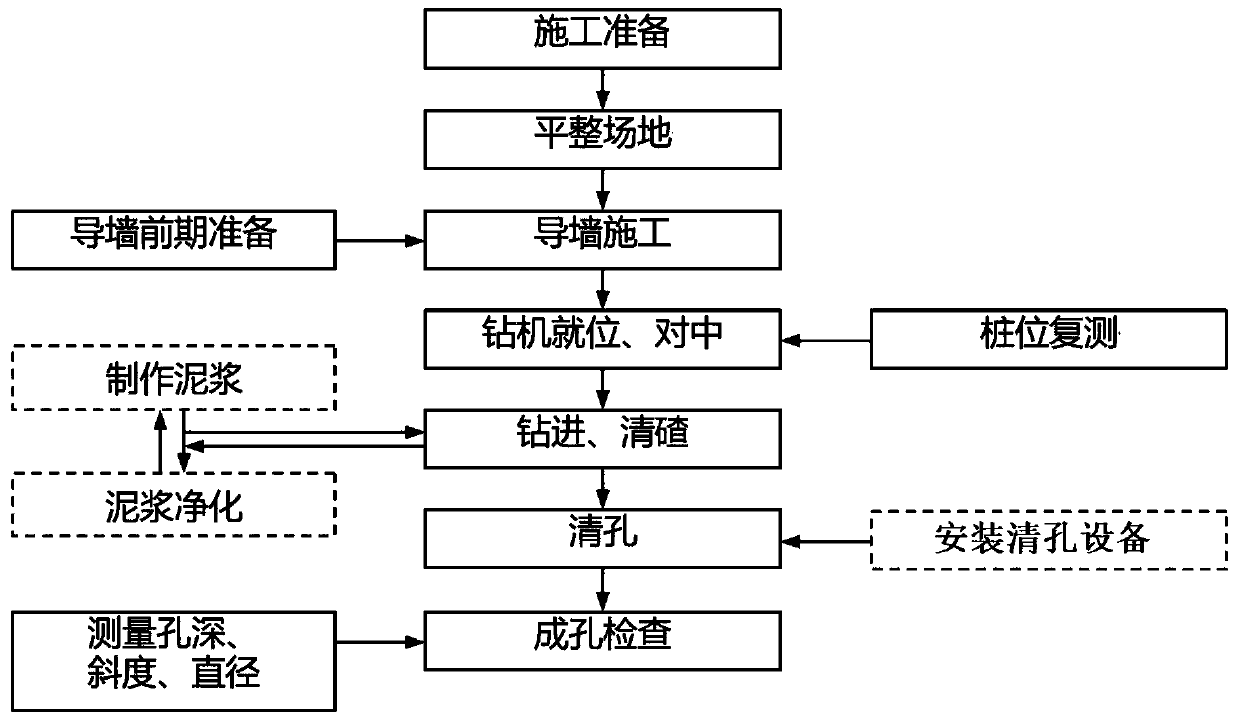

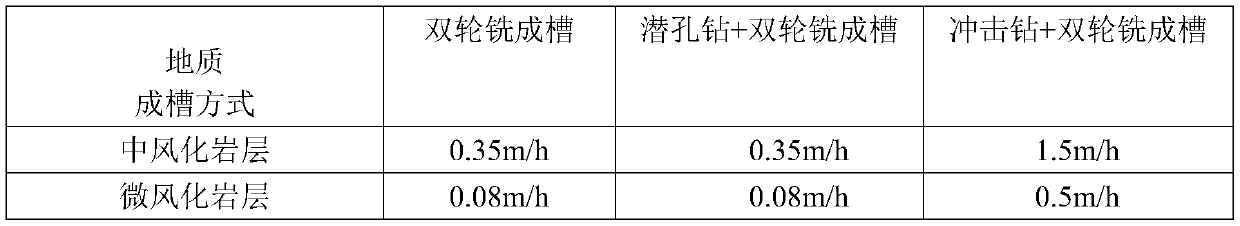

Fast trenching construction method for underground continuous wall in weakly weathered rock

InactiveCN111519679AGuarantee the construction qualityGrooving speed is fastSoil-shifting machines/dredgersSlurryRebar

The invention discloses a fast trenching construction method for an underground continuous wall in weakly weathered rock. The method includes the following steps: (1) surveying and setting out; (2) guide wall construction; (3) slurry preparation; (4) underground continuous wall trenching construction, wherein a hydraulic grab bucket is adopted for trenching in soil layers above rock strata, afterconstruction is started in intensely weathered and low-intensity weakly weathered rock strata, a double-wheel trench cutter is adopted for into-rock drilling, when the rock strength is high, the double-wheel trench cutter is adopted for into-rock drilling after a percussion drill or a rotary drill is adopted for hole guiding, and the percussion drill is adopted to organize construction for underground continuous wall trenching under a 500 kv high-voltage line; (5) bottom cleaning and wall brushing; and (6) trenching acceptance check. The trenching construction method solves the problems that trenching in hard rock or oblique rock is difficult, the trenching verticality cannot be ensured, steel bars are milled, the underground continuous wall has joints and the working efficiency of the double-wheel trench cutter in the weakly weathered rock is low, the trenching speed of a double-wheel trench cutter method is increased, and the construction quality of the underground continuous wall isensured.

Owner:NO 1 ENG CO LTD OF CHINA RAILWAY 22ND CONSTR BUREAU +1

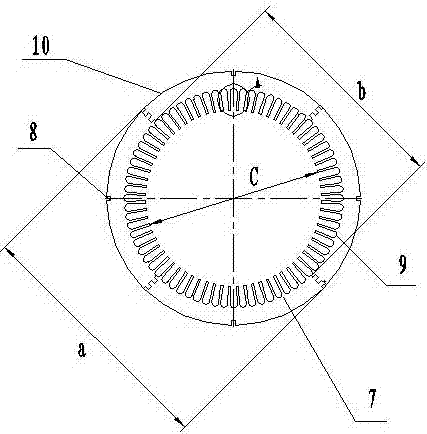

Processing method of motor stator end plate

The invention discloses a processing method of a motor stator end plate. The processing method of the motor stator end plate comprises the steps of (1) cutting a bar stock; (2) using a dedicated die to carry out blanking on arc-shaped blocks with locating grooves; (3) carrying out circle splicing, carrying out two-sided burn-in on splicing connectors through welding rods, and carrying out polishing to achieve smoothness; (4) using an outer circle and the locating grooves to carry out locating, and punching groove profiles. When the processing method of the motor stator end plate is adopted, due to the facts that an original complete circle structure is replaced by an arc-shaped splicing structure, cutting of a square stock is changed into cutting of the bar stock, and an inner circle does not need to be cut, and waste of the area of an inner disk is avoided; due to the fact that the amount of waste produced through blanking of the arc-shaped blocks is much smaller than that of waste produced through cutting of the outer circle, waste of steel plate materials is reduced by about 70%, the use ratio of the materials is greatly improved, and the profit and the competition level of enterprises are greatly improved; in addition, due to the facts that the outer circle and the locating grooves are simultaneously used for locating and punching of the groove profiles, and the groove profiles can be directly punched through a high-speed notching press, the notching speed is high, operation can be carried out through only one person, the punching speed is increased to 300-400 times per minute from 70-80 times per minute of the traditional technology, production efficiency is high, and the requirement for mass rapid production can be met.

Owner:JIANGSU TONGDA POWER TECH

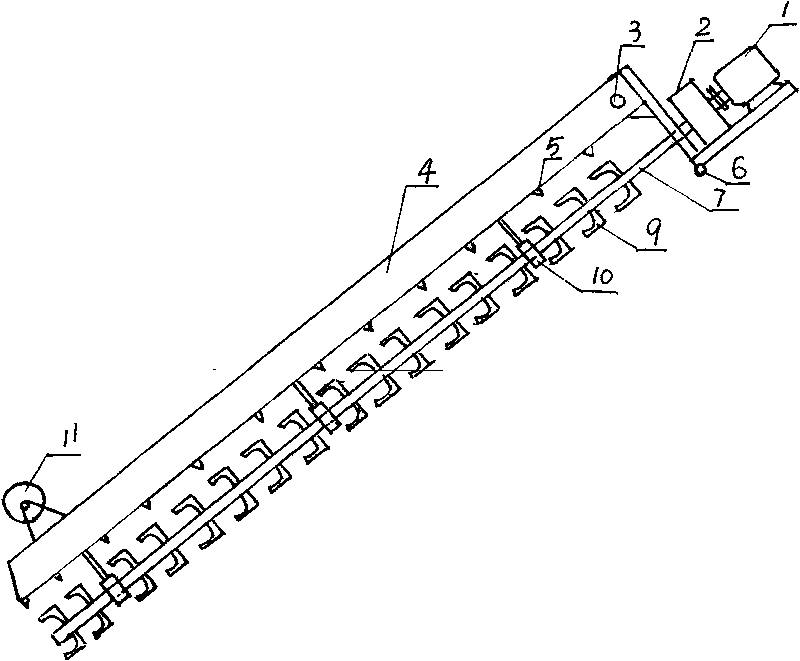

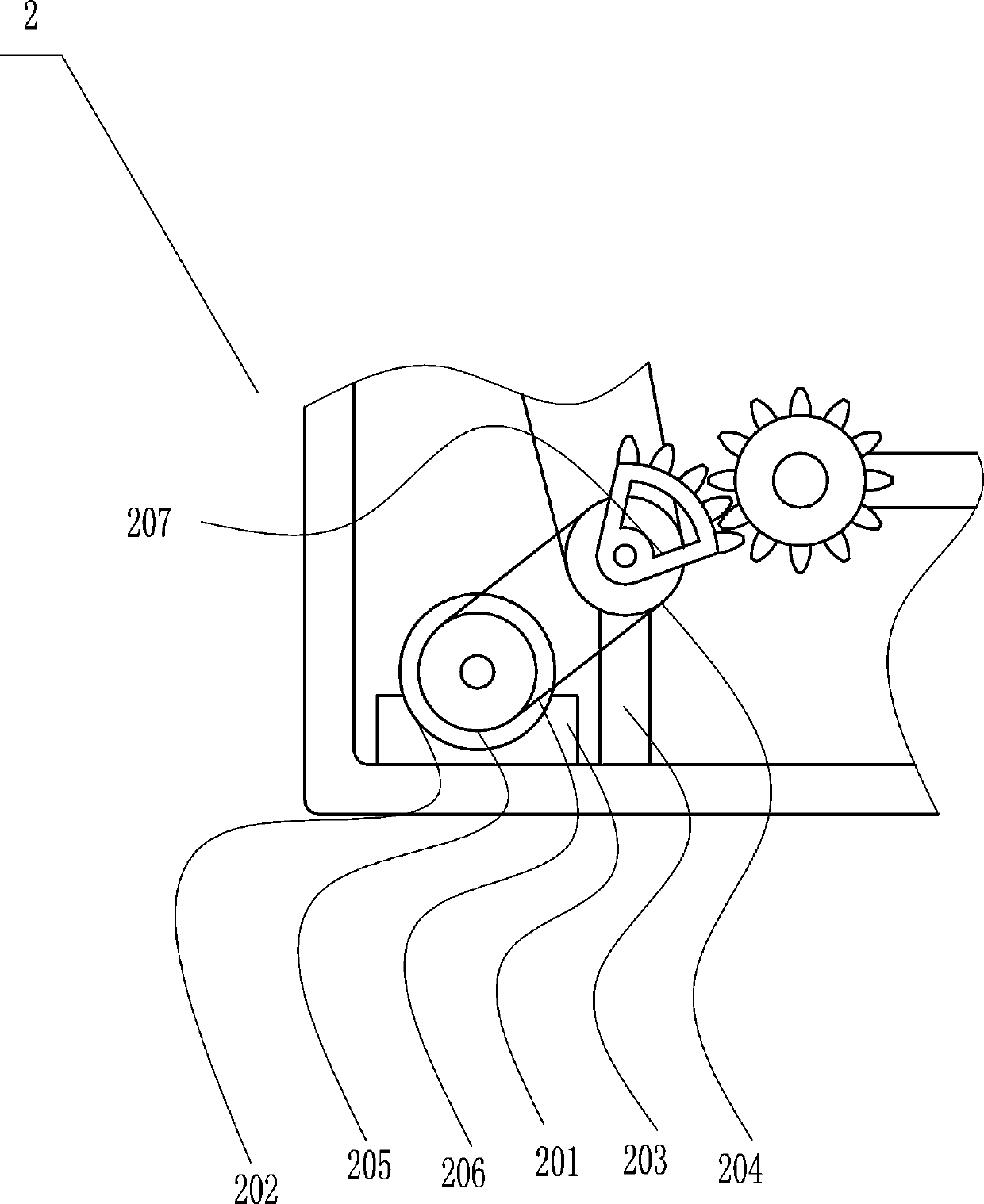

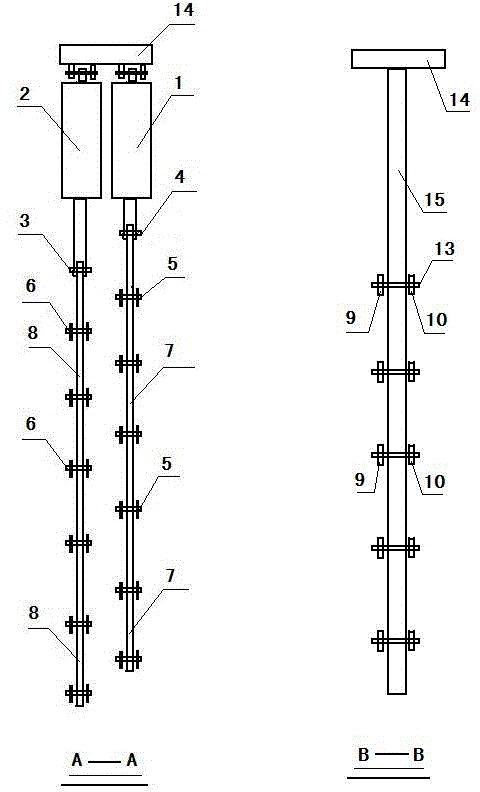

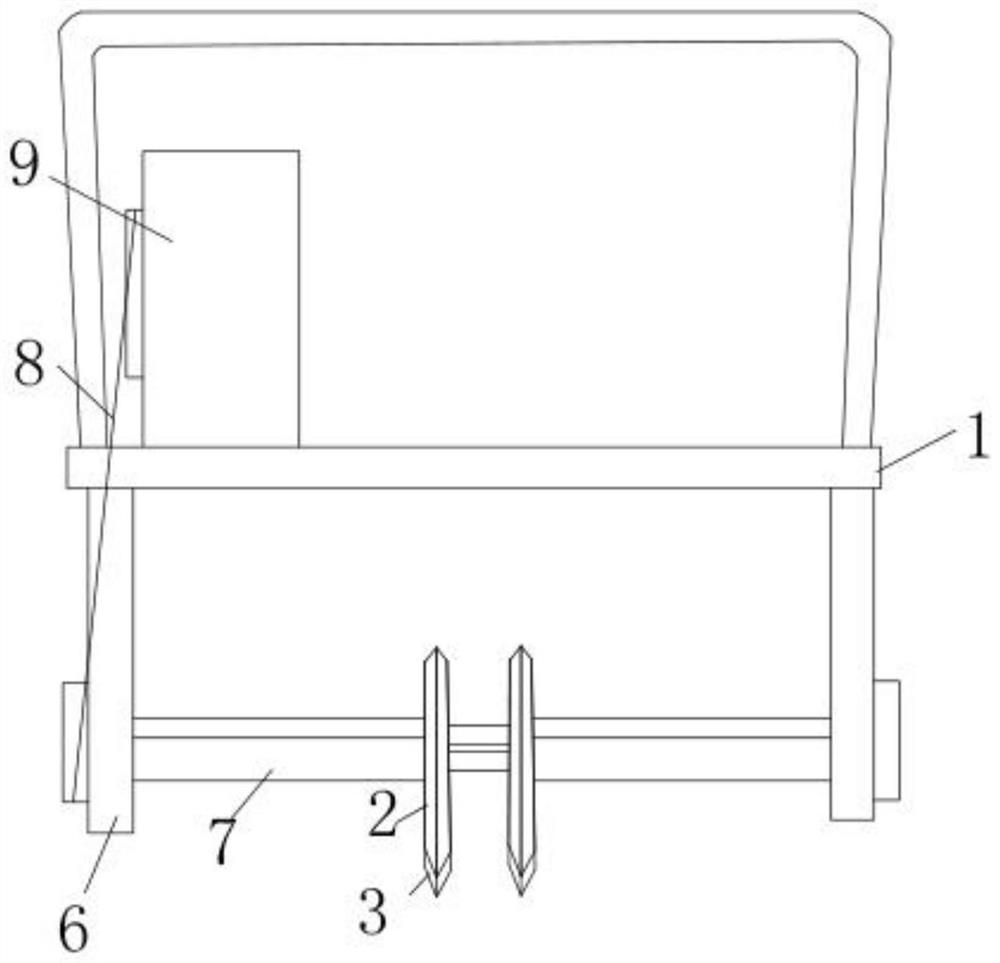

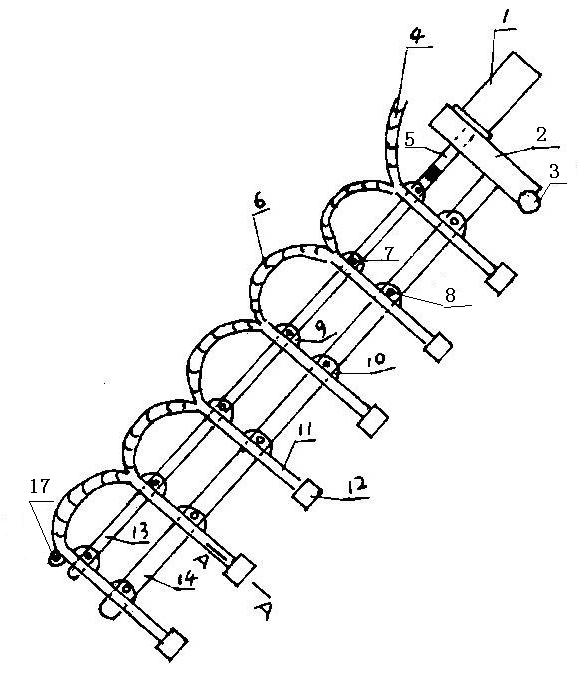

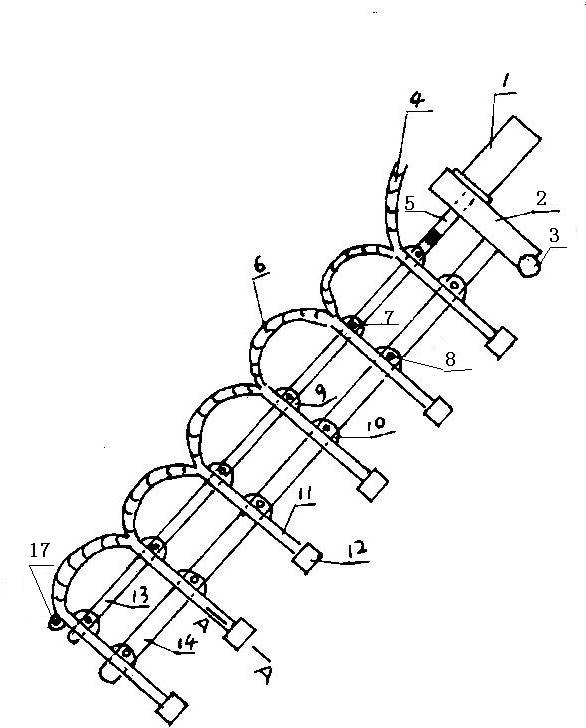

Double-shaft oblique slot forming machine

InactiveCN101705703ASimple styleEasy maintenanceSoil-shifting machines/dredgersPower controlDual axis

The invention discloses a double-shaft oblique slot forming machine comprising a water inflow rubber tube 3, a water inlet tube 4 and a water spray nozzle 5, wherein the water inlet tube is welded by thick walled tubes, can be used for inflow and can support double shafts A and B. A motor 1 drives a power control box 2, leading dynamical shafts A7 and B8 reversely arranged in the control box 2 rotate synchronously; the shafts A and B are respectively provided with a plurality of soil cut digging tools, the double shafts A and B are supported on the water inlet tube by a plurality of support shaft sleeves 10; a lifting tackle 11 is used for lifting the bottom of the slot forming machine; and the upper part of the slot forming machine is supported on a walking chassis by a support shaft. The invention is a vertical plastic spreading slot forming machine and can be also for forming slots to build underground continuous wall.

Owner:NANTONG HUAZHENGLONG STEEL MFG

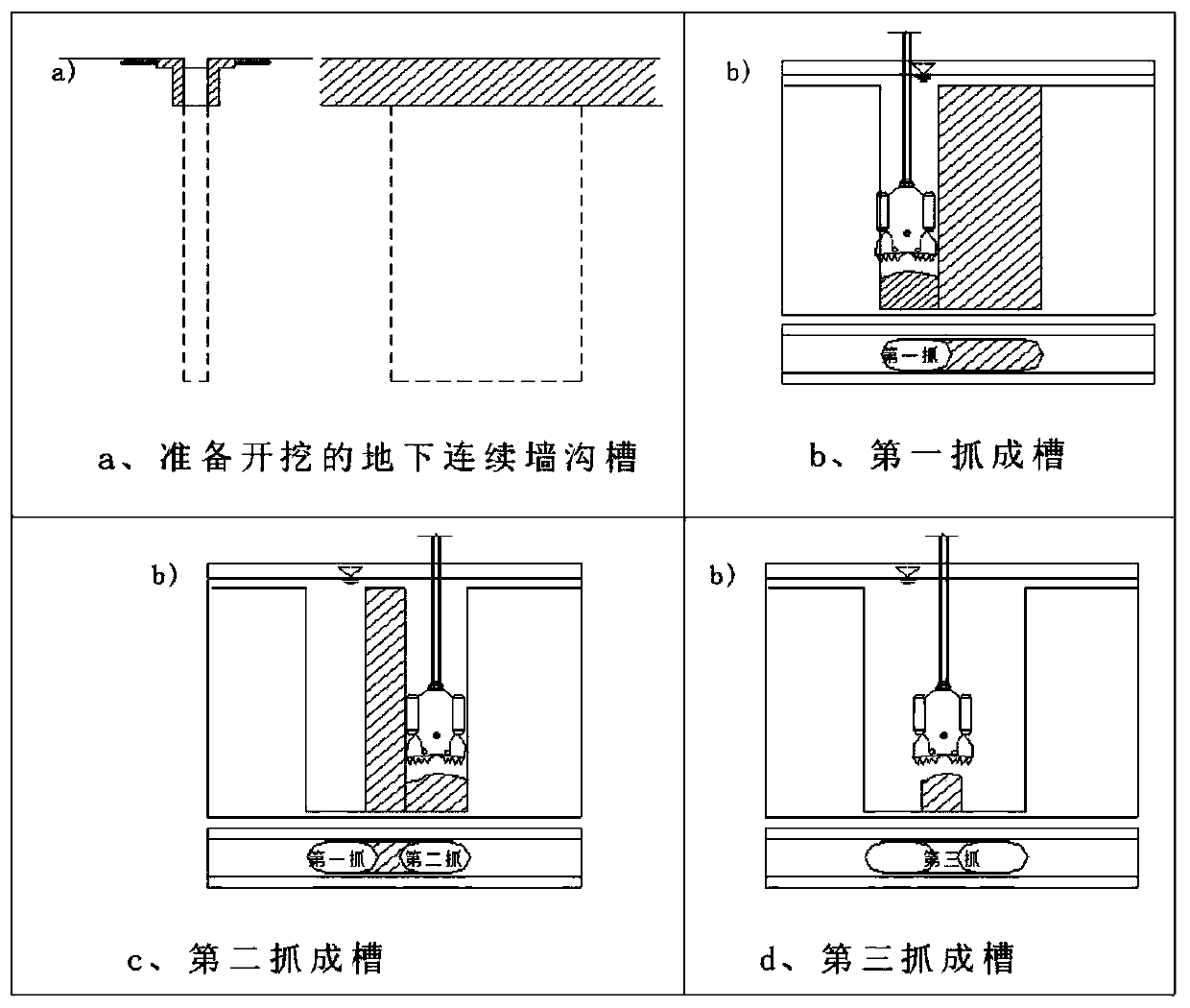

Underground diaphragm wall construction method suitable for pebble and boulder stratums with non-uniform hardness

The invention discloses an underground diaphragm wall construction method suitable for pebble and boulder stratums with non-uniform hardness. The method includes the four steps of grooving of the softpebble and boulder stratum, drilling of vertical drill holes, soil grasping grooving of the hard pebble and boulder stratum and underground diaphragm wall construction. After the soft pebble and boulder stratum is excavated, grooving work is carried out directly through a grooving machine, the multiple stretching vertical drill holes are drilled in a grooving position, and the vertical drill holes stretch along the whole depth of an underground diaphragm wall foundation trench in the hard pebble and boulder stratum. The vertical drill holes are formed in the position of a grab bucket of the grooving machine, the grab bucket can more easily enter the hard pebble and boulder stratum along the vertical drill holes, the grooving speed of an underground diaphragm wall is increased, abrasion ofthe grooving machine is reduced, and the construction cost of the underground diaphragm wall in the specific stratums is reduced; and meanwhile, the grooving machine can be guided to carry out the grooving work through the vertical drill holes, and clearance intrusion of the underground diaphragm wall is reduced.

Owner:BEIJING MUNICIPAL CONSTR

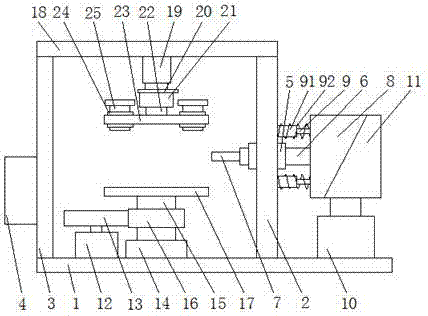

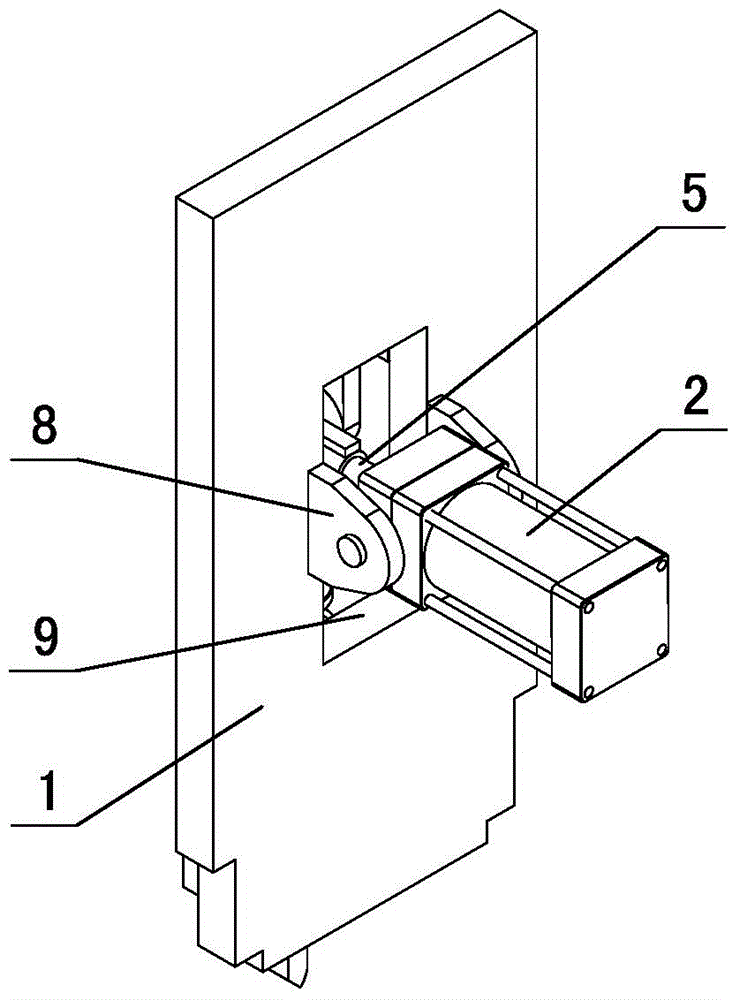

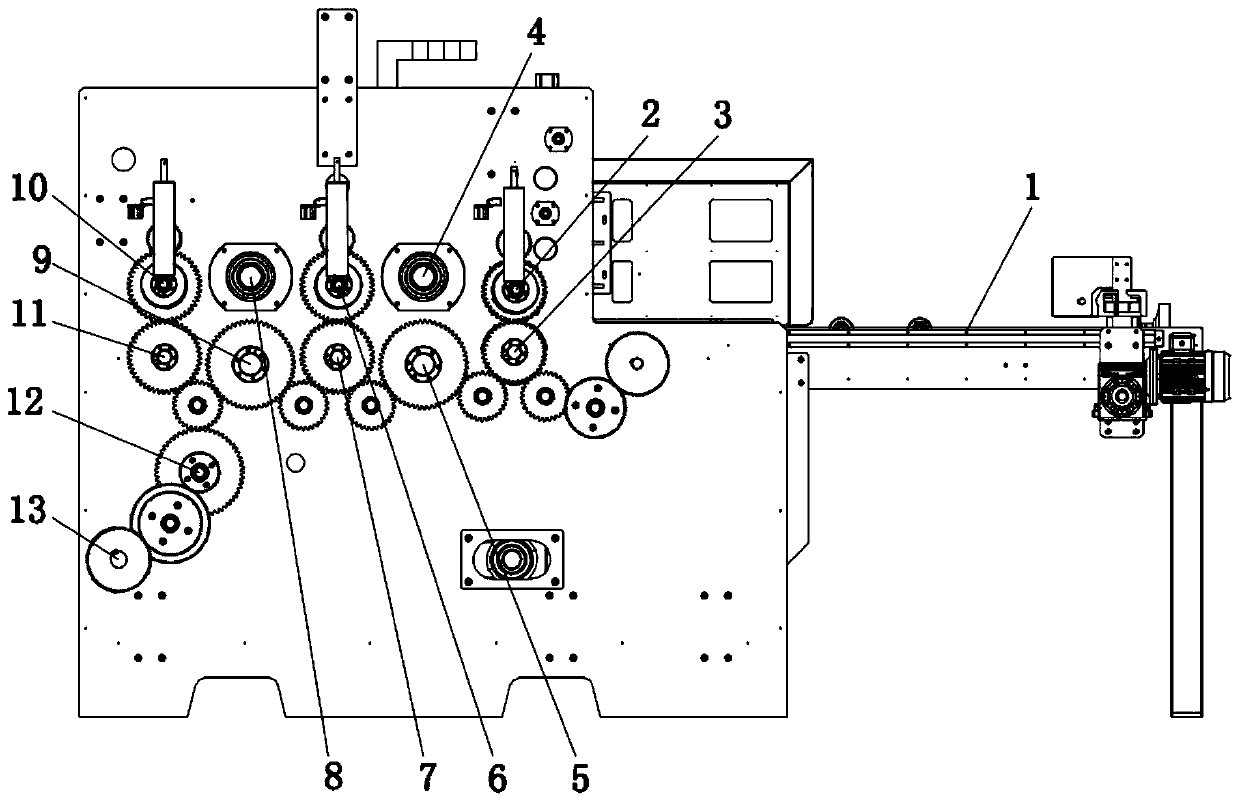

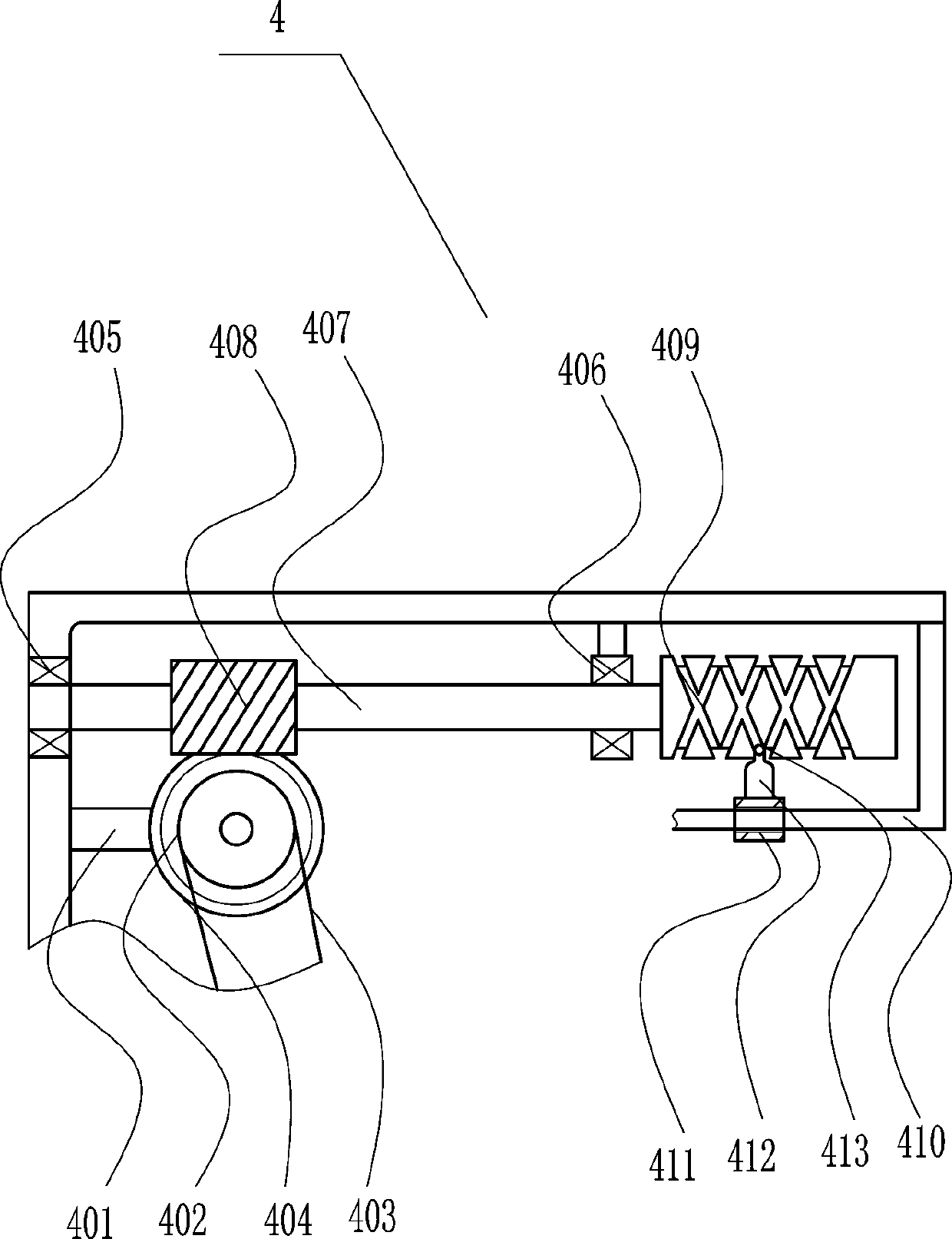

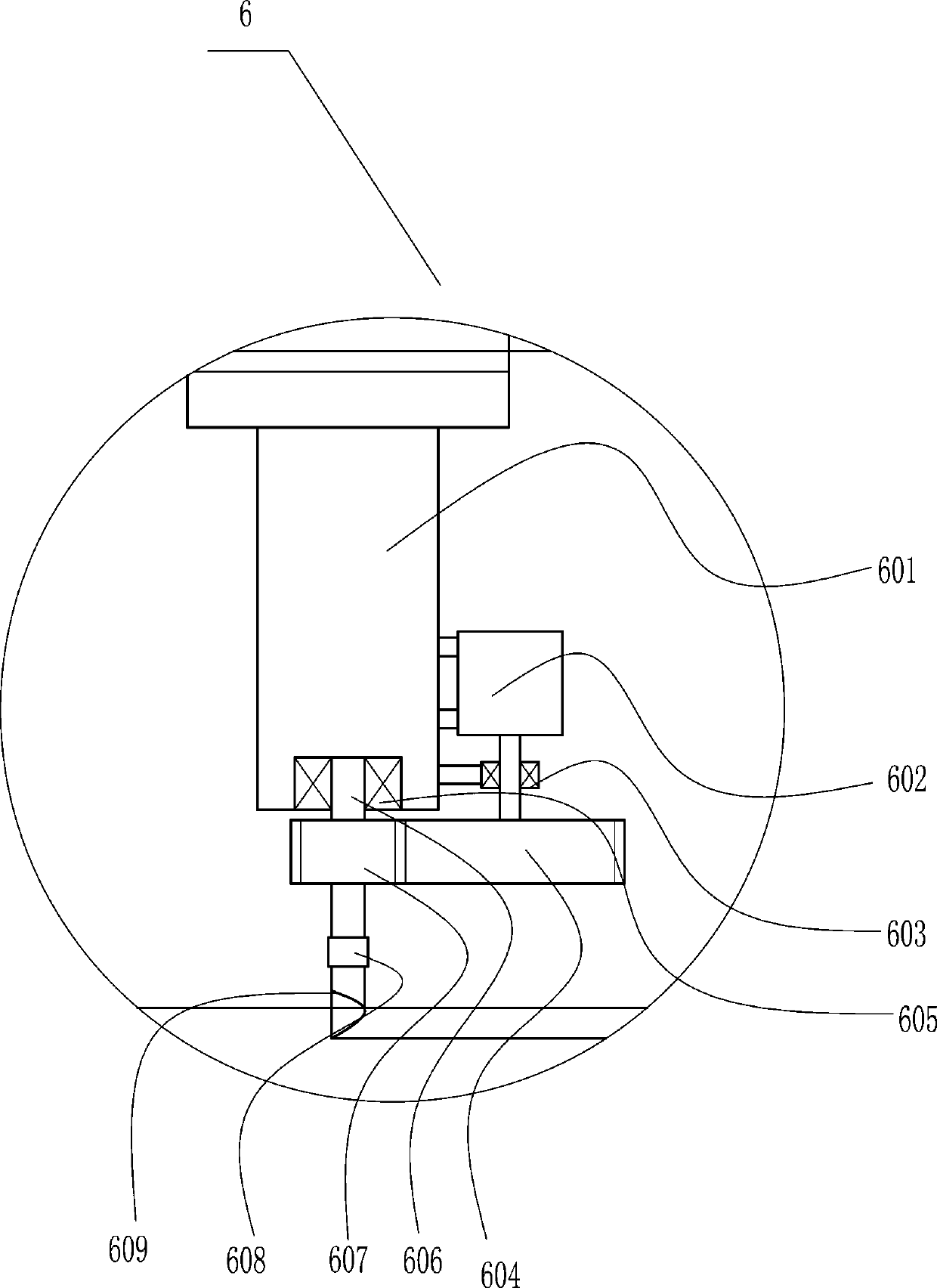

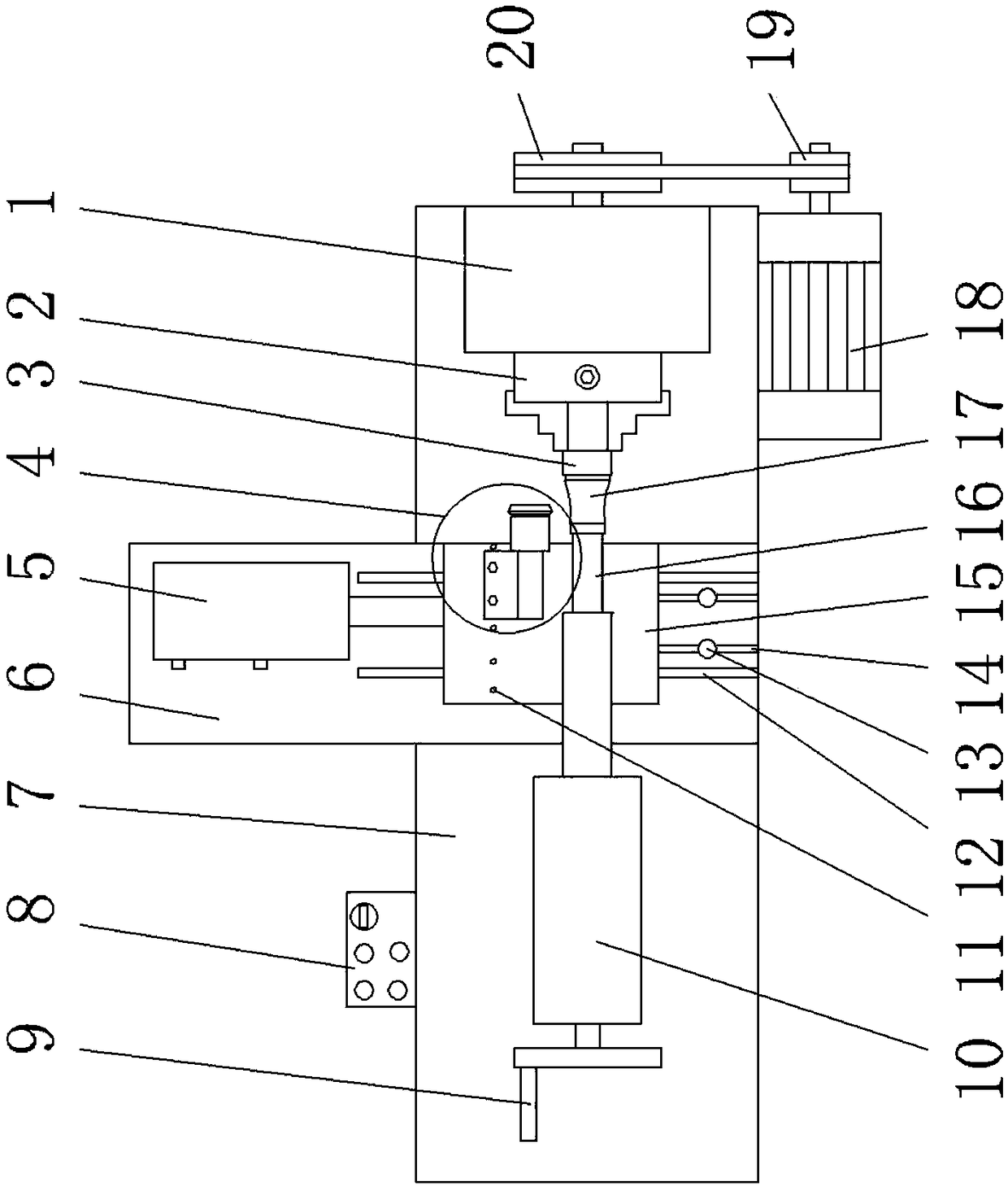

Numerical control groove punching machine and groove punching method thereof

The invention discloses a numerical control groove punching machine and a groove punching method of the numerical control groove punching machine. The numerical control groove punching machine comprises a machine frame, a controller, a groove punching mechanism and a numerical control feeding mechanism, wherein the controller, the groove punching mechanism and the numerical control feeding mechanism are arranged on the machine frame. The numerical control groove punching mechanism comprises a base plate, a double-acting air cylinder and a punching block, wherein the double-acting air cylinder is arranged on the base plate, and the punching block is used for driving an upper die of the groove punching machine to work. A piston rod of the air cylinder is connected with the punching block through a boosting and frequency-increasing mechanism. The boosting and frequency-increasing mechanism comprises an upper boosting arm and a lower boosting arm. The upper end of the upper boosting arm is hinged to the base plate through a hinge base. The lower end of the upper boosting arm, the upper end of the lower boosting arm and the tail end of the piston rod are hinged through the same hinge shaft. The lower end of the lower boosting arm is hinged to the punching block. The numerical control groove punching machine and the groove punching method of the numerical control groove punching machine solve the problems that in the prior art, a grooving machine is high in production cost, low in grooving speed, and the groove depth consistency is poor. The numerical control groove punching machine is low in production cost, high in grooving speed, capable of accurately controlling the groove depth and conducting double-faced grooving, and high in practical value.

Owner:王洪辉

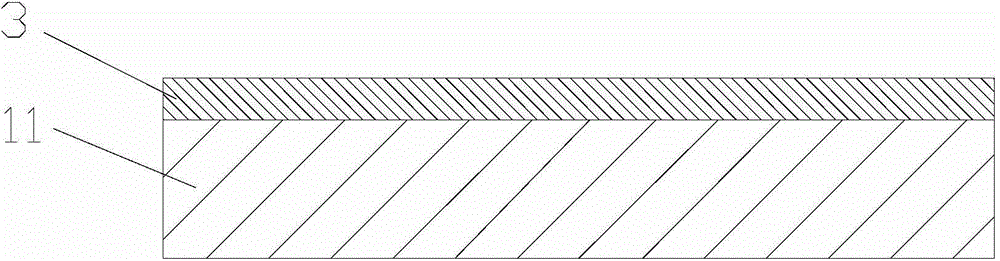

Novel package substrate and manufacturing method thereof

ActiveCN104159396AGood removal effectGrooving speed is fastPrinted circuit detailsPhotodevelopable thick filmEngineeringLaser cutting

The invention provides a manufacturing method of a novel package substrate. A first light-sensitive dry film adheres to a first flame-resistant material plate, then the first light-sensitive dry film is exposed and developed, a prepreg base material adheres to the first flame-resistant material plate at the moment, a second flame-resistant material plate adheres to the prepreg base material, and grooving is carried out. The invention further provides the novel package substrate. The first light-sensitive dry film is located between the first flame-resistant material plate and the prepreg base material after being exposed and developed, so no glue exists between the first flame-resistant material plate and the prepreg base material; thus, laser cutting can be adopted, the grooving speed is increased, waste is convenient and rapid to remove, and production efficiency is improved.

Owner:安捷利美维电子(厦门)有限责任公司

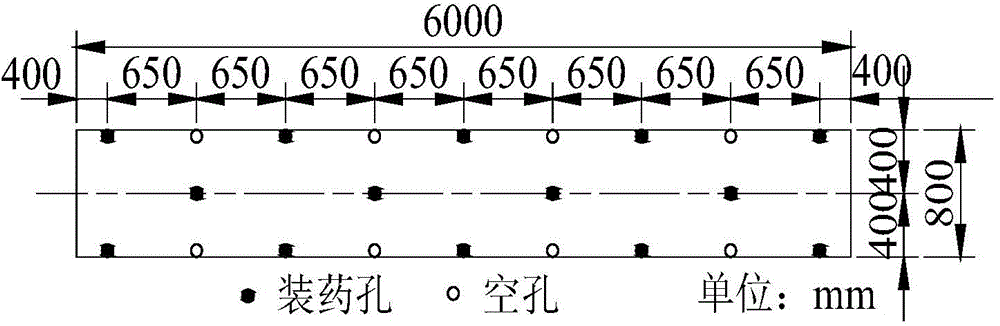

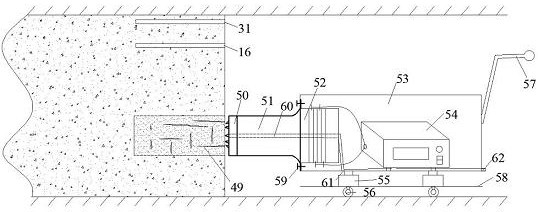

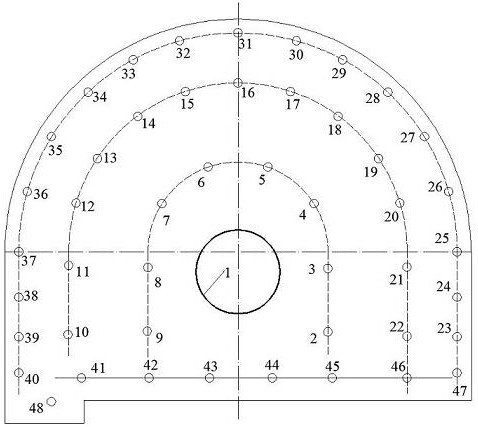

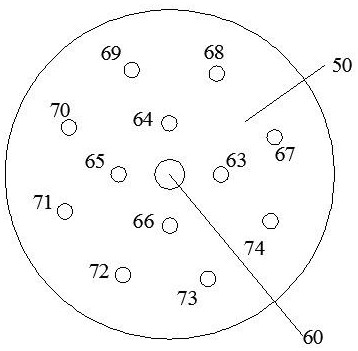

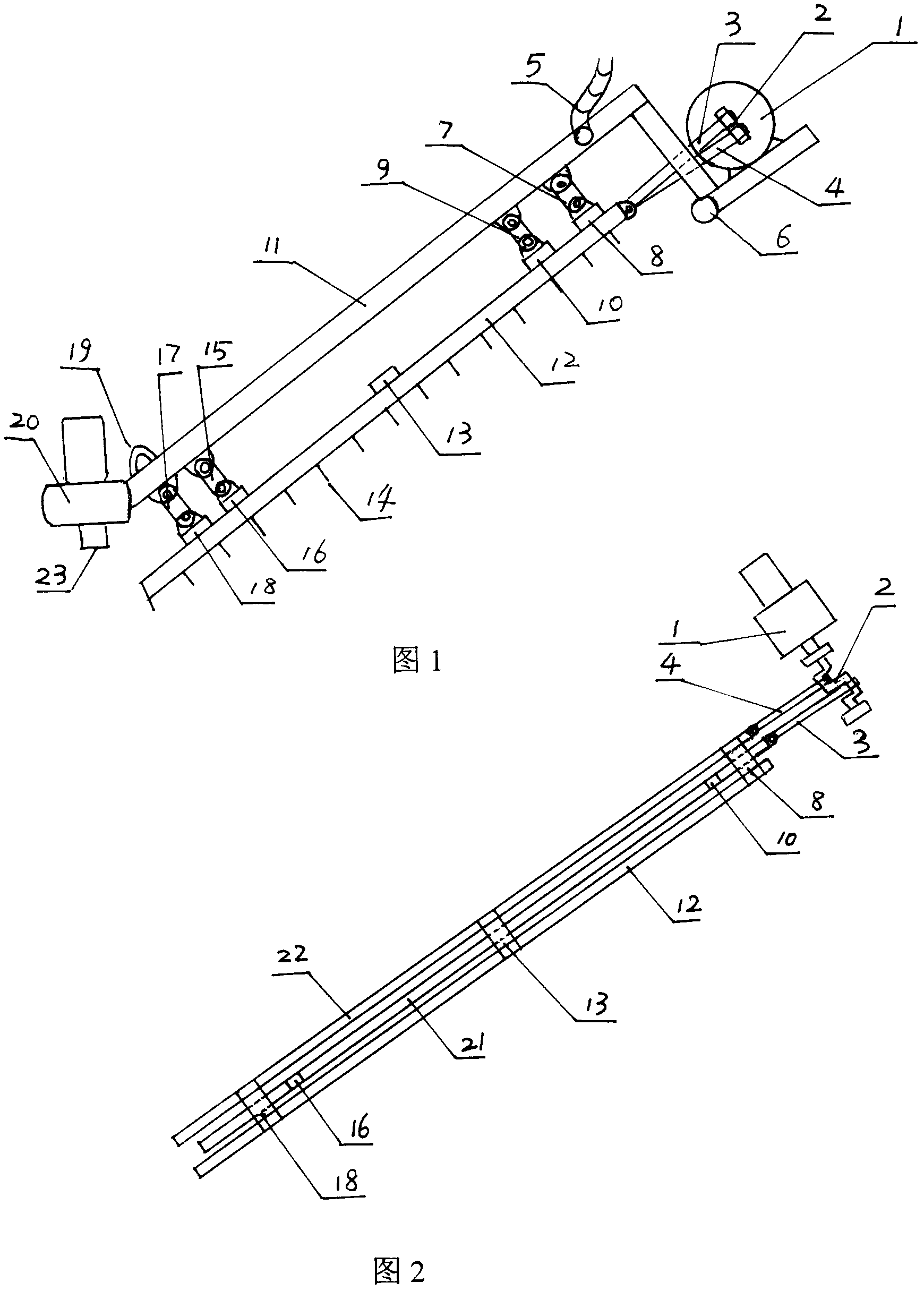

Roadway tunneling efficient rock breaking method based on ultrasonic vibration pre-slotting

ActiveCN112610223AAdjustable powerAdjustable frequencyDisloding machinesBlastingRock engineeringClassical mechanics

The invention belongs to the field of roadway tunneling rock efficient breaking, and particularly relates to a roadway tunneling efficient rock breaking method based on ultrasonic vibration pre-slotting. In order to solve the problem of efficient breaking of hard rock, during hard rock roadway tunneling, the advantages of good ultrasonic directivity, energy concentration and the like are utilized; firstly, ultrasonic vibration equipment is adopted to vibrate and impact a rock mass in a target area, internal cracks are promoted to rapidly expand and rapidly reach breaking, and pre-slotting is achieved; and in combination with optimized arrangement of auxiliary holes and peripheral holes, the efficient breaking of rock is achieved. The method provided by the invention has the advantages that the slotting range and depth can be controlled by adjusting the ultrasonic frequency and power; the time of work procedures such as hole drilling and explosive charging can be effectively reduced; explosives are saved; the tunneling cost is reduced; and the method can be widely applied to rapid tunneling of roadways in hard rock engineering.

Owner:CHINA UNIV OF MINING & TECH

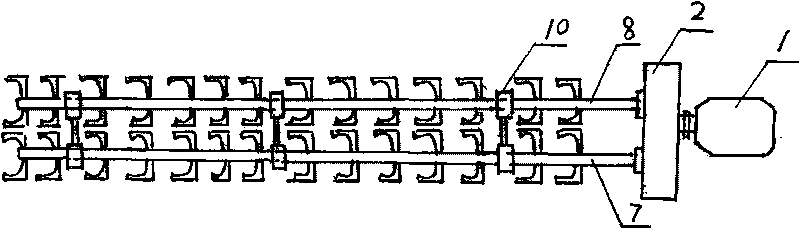

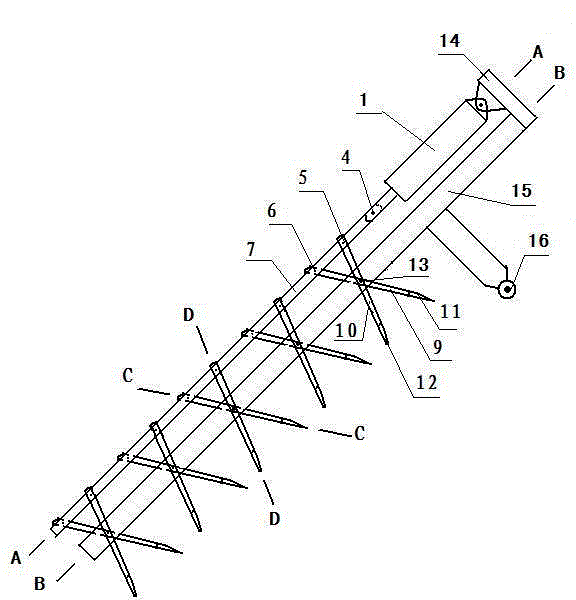

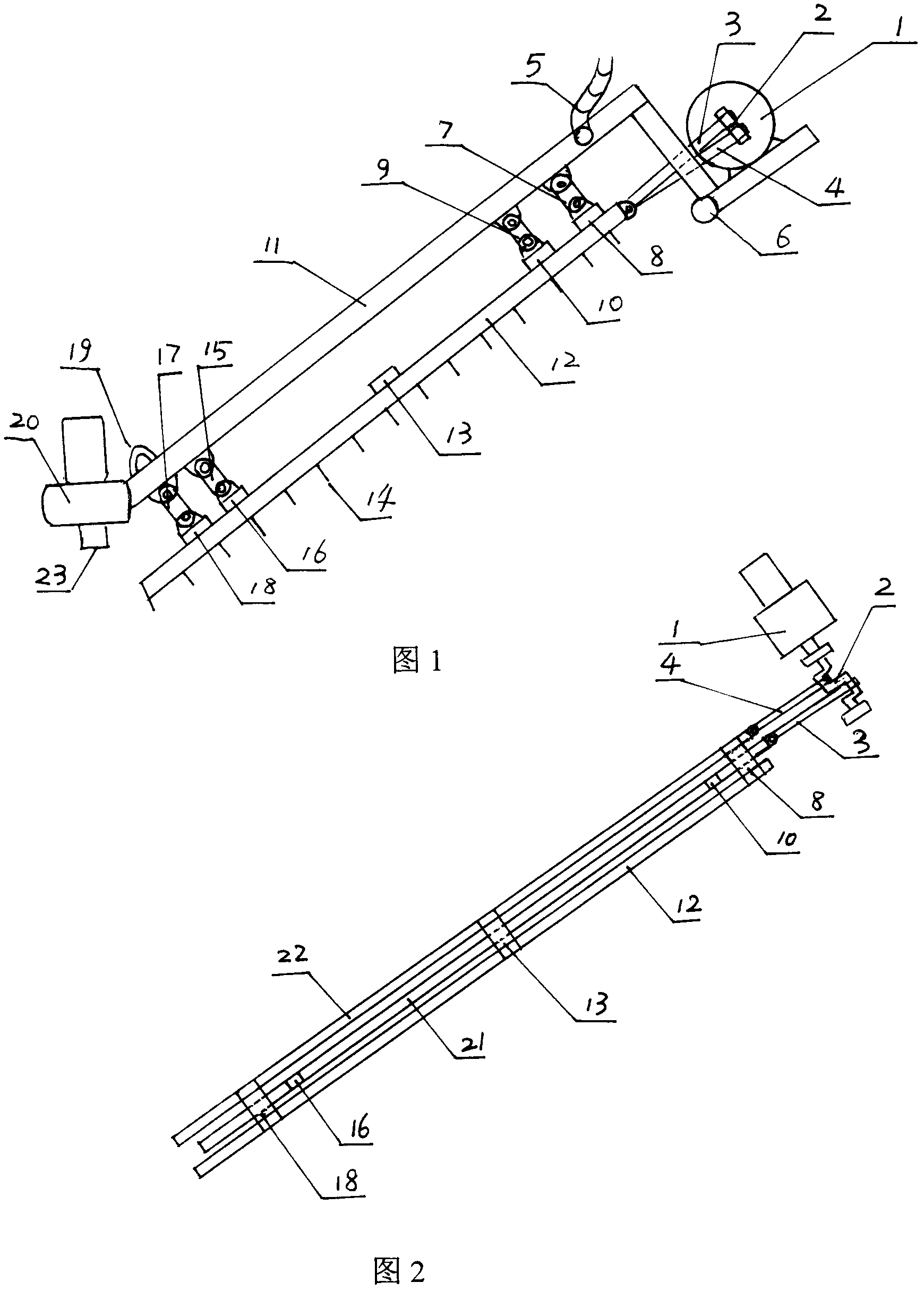

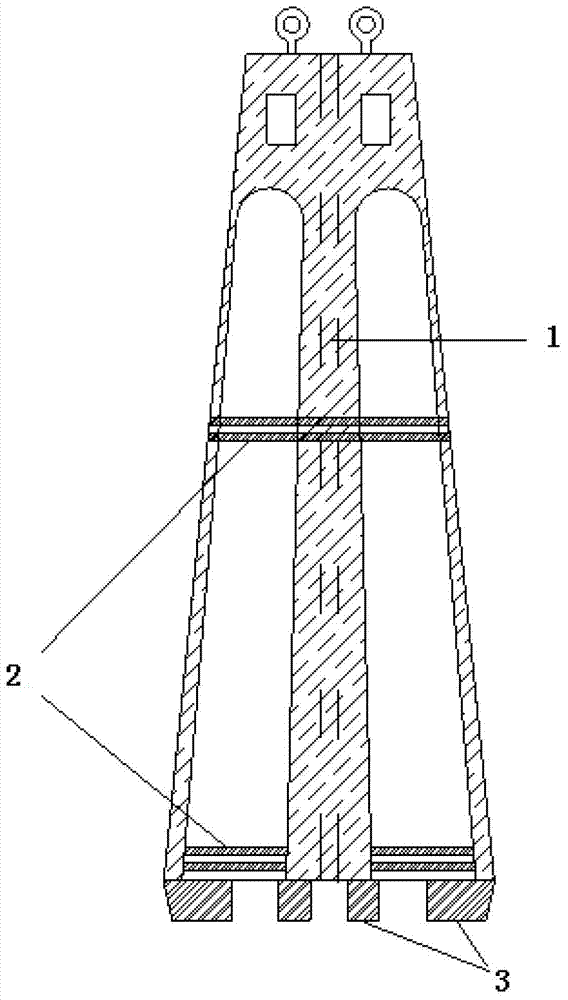

Grooving machine with three saw rods

InactiveCN102561435AGrooving speed is fastSoil-shifting machines/dredgersBulkheads/pilesSlurry wallArchitectural engineering

A grooving machine with three saw rods capable of advancing in clay comprises a supporting shaft and a hoisting lug. The supporting shaft is arranged on the upper portion of the grooving machine, the hoisting lug is disposed on the lower portion of the grooving machine, a sandstone pump is fixed at the lower end of a slurry outlet steel tube, a suction opening is arranged at the bottom end of the sandstone pump, and the upper end of the slurry outlet steel tube is connected with a slurry outlet rubber tube; upper ends of a rocker arm A, a rocker arm B, a rocker arm C and a rocker arm D are connected to the slurry outlet steel tube, the lower end of the rocker arm A is connected to a connector A, the lower end of the rocker arm B is connected to a base, the lower end of the rocker arm C is connected to a base B, the lower end of the rocker arm D is connected to a connector C, the connector A, a connector B and the connector C are respectively used for being connected with upper portions, middles and lower portions of a cutter arbor A and a cutter arbor C, and the base A and the base B are respectively disposed at the upper end and the lower end of a cutter arbor B; the left lower end of a connecting rod A is connected to the right upper end of the cutter arbor C via a pin, the right upper end of the connecting rod A is hinged to a crankshaft, the left lower end of a connecting rod B is connected to the right upper end of the cutter arbor B via a pin, the right upper end of the connecting rod B is hinged to the crankshaft, and the left upper end of the crankshaft is connected to a driving power speed reducer; and a plurality of cutter plates are disposed at the bottom of each of the cutter arbor A, the cutter arbor B and the cutter arbor C. The grooving machine is a special machine tool for building underground continuous walls.

Owner:WATER RESOURCES RES INST OF SHANDONG PROVINCE

Dual-servo dual-shaft corrugated paper high-speed slotting machine

PendingCN110978623AAvoid replacementGrooving speed is fastBox making operationsPaper-makingCardboardFixed bearing

The invention discloses a dual-servo dual-shaft corrugated paper high-speed slotting machine, and relates to the technical field of corrugated paper machining. The machine comprises a feeding mechanism, a lower supporting beam, an upper knife disc and a lower knife disc. The feeding mechanism is fixedly mounted on the rear portion of the lower supporting beam, the two sides of the lower supportingbeam are fixedly provided with a first mounting plate and a second mounting plate correspondingly, and a feeding upper pressing roller, a rear upper knife shaft, a pre-pressing line upper roller, a front upper knife shaft and a main pressing line upper roller are rotatably connected in sequence between the first mounting plate and the second mounting plate from back to front. Slotting speed is high, a first fixed bearing and a second fixed bearing are arranged, copper block replacement by the machine is avoided, control by two independent servo motors is achieved, suspension is achieved, acceleration to a synchronous main shaft is achieved, the paperboard width that is the length between a front groove and a rear groove is not limited, generality is good, five cutter discs are arranged, and the slotting machine can slot a furniture box beside common cartons.

Owner:深圳市万德数字科技有限公司

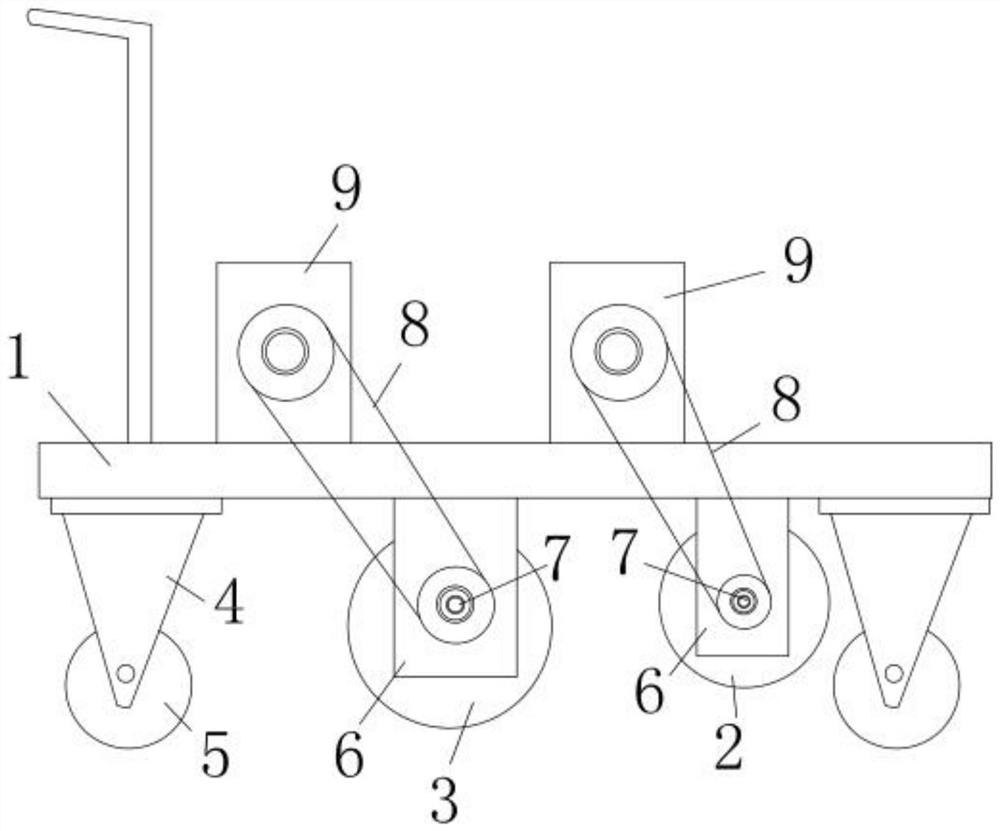

An automatic unloading plank slotting device

ActiveCN108162101BGrooving speed is fastEasy to operateStationary drilling machinesWood mortising machinesCamMechanical engineering

The invention relates to a slotting device, particularly to a wood slotting device capable of achieving automatic discharge, and provides the wood slotting device capable of achieving automatic discharge, which utilizes machinery to replace manual work. The wood slotting device capable of achieving automatic discharge provided to solve the technical problem comprises a rack, a driving device, a conveying device, a cam device, a discharge device, and the like, wherein the driving device is arranged on the rack; the conveying device is arranged on the right side of the driving device; the cam device is arranged above the driving device; the discharge device is arranged below the cam device; a slotting device is arranged below the cam device; and a switch device is arranged below the right side of the discharge device. According to the wood slotting device, an automatic slotting function is achieved, an automatic conveying function is achieved, and the wood slotting device has the characteristics that the slotting speed is high, operation is convenient, manufacturing is simple, manufacturing cost is low, popularization is facilitated, and the like.

Owner:成都千川门窗有限公司

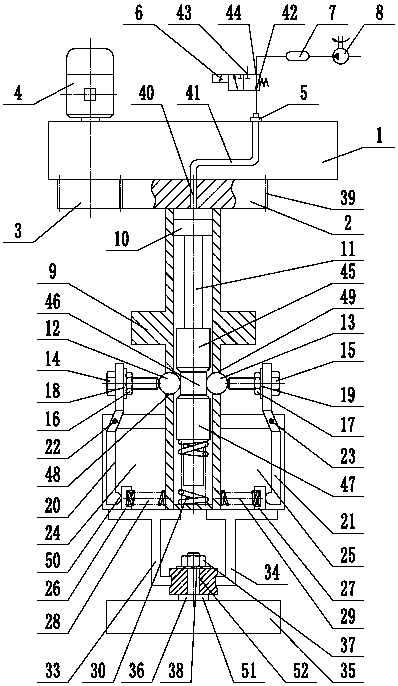

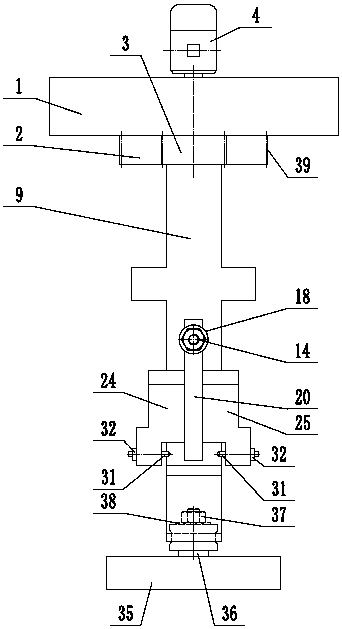

Rotary grooving device for rubber ring

InactiveCN108015838ARealize groovingHigh degree of engagementMetal working apparatusRubber ringGear wheel

The invention provides a rotary grooving device for a rubber ring and belongs to the technical field of rubber ring processing. The rotary grooving device comprises a bearing sleeve, a left steel balland a right steel ball. An outer gear is arranged on the outer side of a rotary disc. A drive gear is engaged with the outer gear. The upper end of a drive shaft is coaxially fixed to the lower end of a piston. The middle end of a left swing rod is hinged to a left support through a left swing rod pin shaft. The middle end of a right swing rod is hinged to a right support through a right swing rod pin shaft. A left grooving seat is arranged on the left support through a guide pin in a left-right sliding manner. A right grooving seat is arranged on the right support through a guide pin in a left-right sliding manner. A left bearing bolt is attached to the left steel ball under the effect of a left return spring, and a right bearing bolt is attached to the right steel ball under the effectof a right return spring. The rubber ring is mounted on a centering rod and is locked through a locking nut. By the adoption of the rotary grooving device for the rubber ring, the rubber ring can be clamped stably, rotary grooving of the rubber ring can be achieved as well, the grooving speed is high, and efficiency is high.

Owner:TONGXIANG GREENCITY FLOCKING

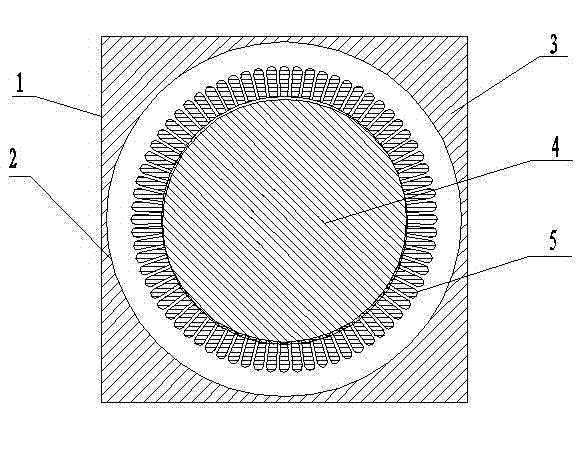

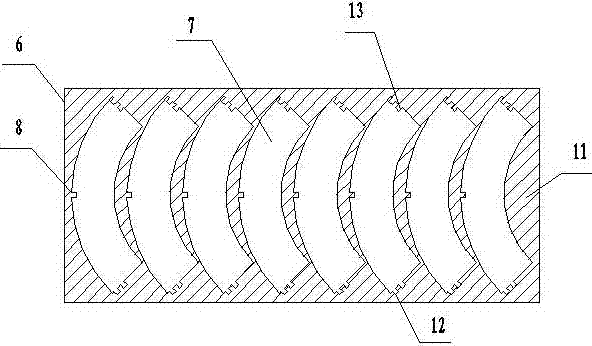

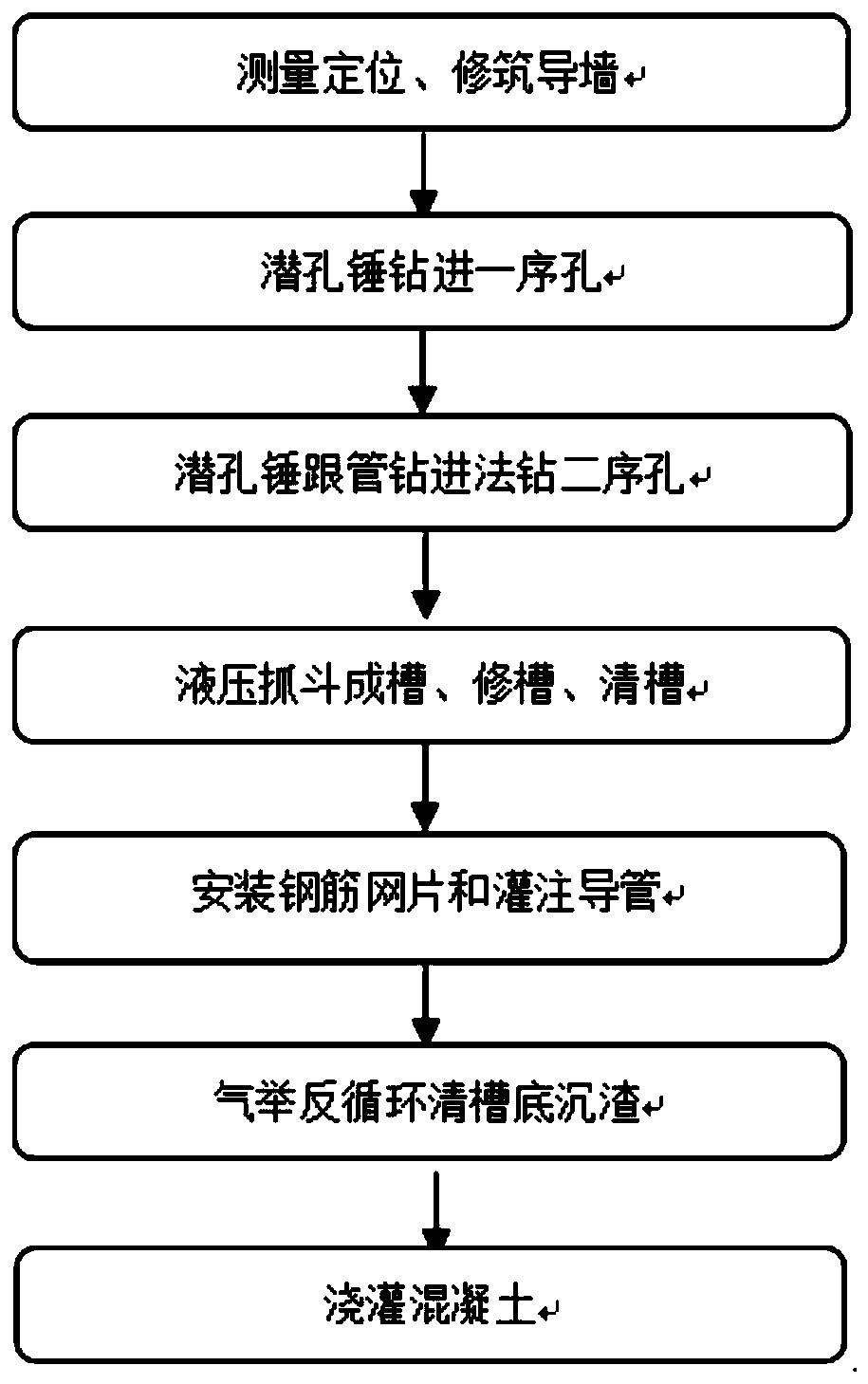

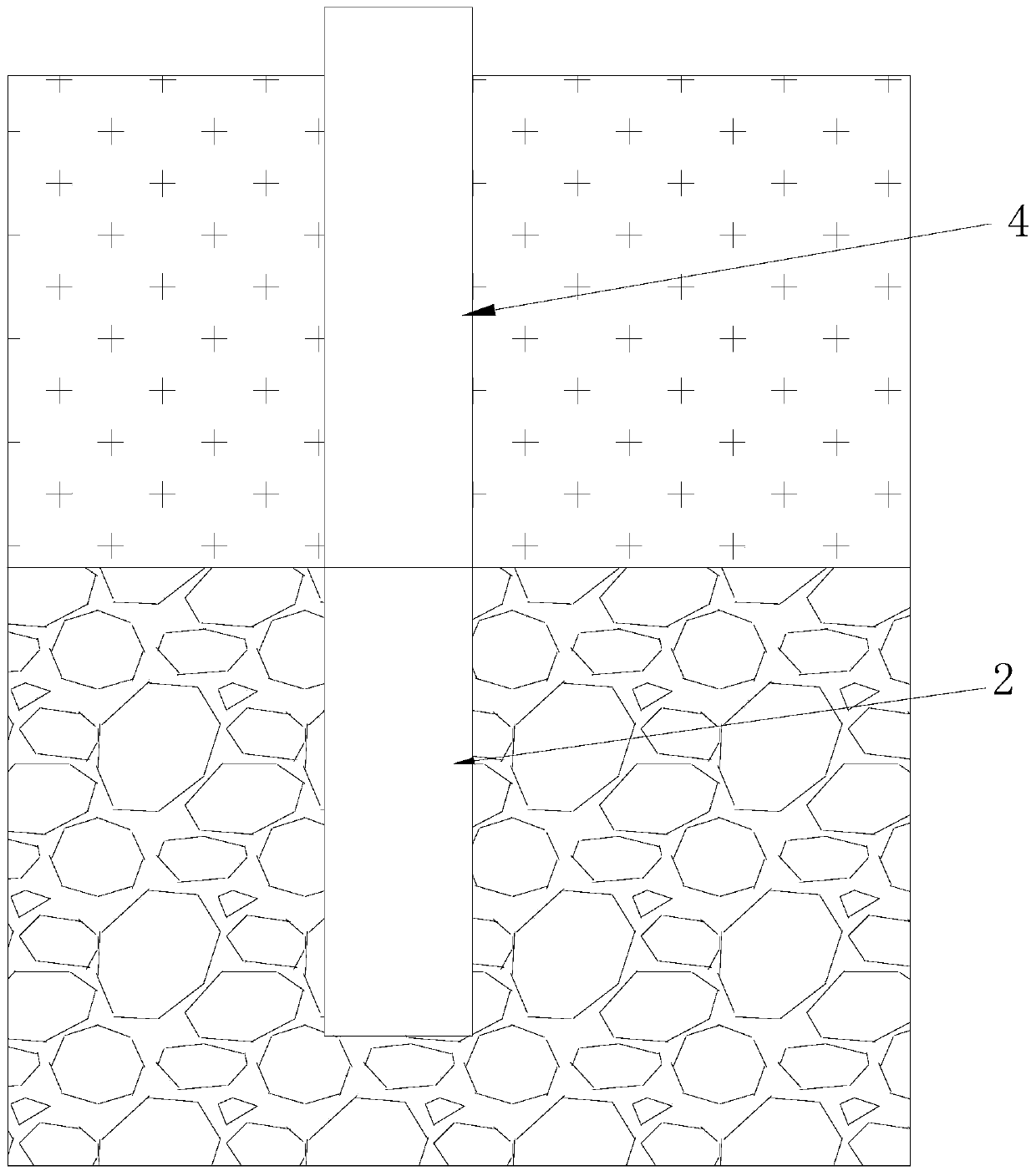

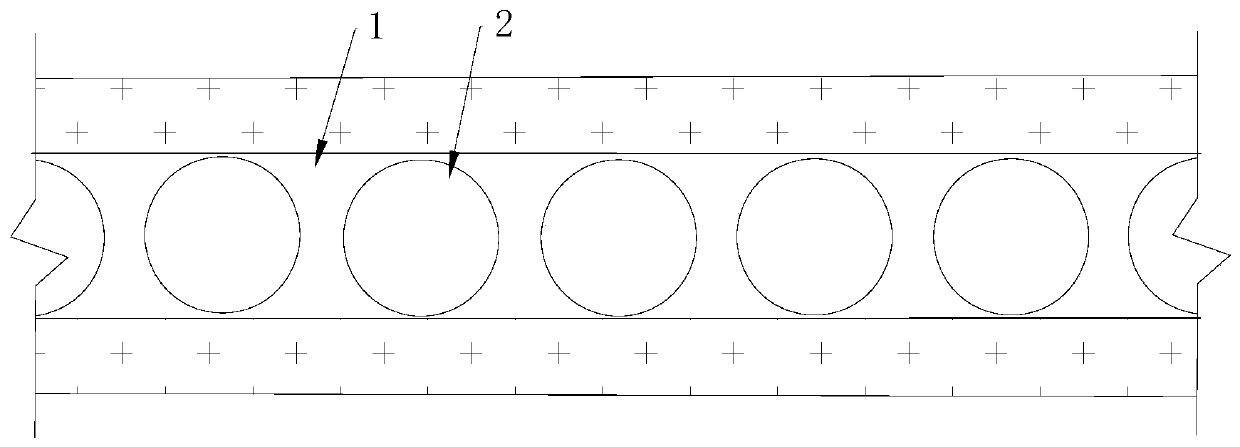

Deep thick hard rock underground continuous wall grooving construction method and structure

InactiveCN111364446AGrooving speed is fastReduce processing operationsReciprocating drilling machinesDirectional drillingSlurry wallMesh reinforcement

The invention relates to the technical field of underground continuous wall grooving, in particular to a deep thick hard rock underground continuous wall grooving construction method. The method comprises the following steps of first, measuring, positioning and constructing a guide wall; second, performing wall protection on a soil layer at the upper part by adopting a wall protective sleeve first, then drilling into the wall protective sleeve by adopting a down-the-hole hammer, drilling into a rock layer to a designed elevation, repeating the steps above, and drilling a plurality of first guide holes which are arranged adjacently; third, drilling a second guide hole between adjacent two first guide holes by adopting a down-the-hole hammer with pipe drilling method, and communicating the second guide hole with the adjacent two first guide holes to form a groove; fourth, trimming the groove and cleaning the groove by adopting a hydraulic grabbing bucket; fifth, mounting reinforcing meshpieces and grouting a guide pipe; and sixth, grouting concrete. The construction method disclosed by the invention is high in hole guiding speed; moreover, a hole is not required to be trimmed by adopting an impact plane set-hammer after the hole is guided; processes are reduced; and the construction efficiency is higher.

Owner:SHENZHEN GONGKAN GEOTECHN GRP +1

Safe and efficient grooving machine

The invention discloses a safe and efficient grooving machine. The safe and efficient grooving machine comprises a workbench. Supporting legs are correspondingly arranged at the bottom of the workbench. The workbench is of a hollow closed frame structure. A plurality of saw grooves penetrating the upper surface of the workbench are correspondingly formed in the upper surface of the workbench. Topbeams are correspondingly arranged above the saw grooves. Top air cylinders are correspondingly arranged on the tops of the top beams. Output shafts of the top air cylinders face the saw grooves. A plurality of horizontal air cylinder fixing bases are correspondingly arranged on the upper surface of the workbench. Output shafts of the horizontal air cylinders are opposite to material fixing columns. A motor moving air cylinder motor is correspondingly arranged in the workbench and correspondingly drives a grooving saw blade. The upper end of the grooving saw blade is correspondingly inserted in the saw grooves. The motor can move front and back, the grooving saw blade can be adjusted in an up-down lifting manner according to the needed grooving depth, the grooving saw blade can be replacedaccording to the grooving width, and one-time grooving forming can be conveniently and rapidly conducted.

Owner:厦门致尊科技有限公司

High-efficiency groove-forming construction method for underground diaphragm wall in slightly weathered granite

The invention provides an efficient grooving construction method for an underground diaphragm wall in micro-weathered granite. The method specifically comprises the following steps: 1, geologically surveying the construction site; 2, determining the rock breaking method; 3, determining blasting parameters; 4, drilling holes from a sand layer to the surface of a rock layer, and unearthing; 5, distinguishing a rock sample, and then determining and drilling to reach intermediately-weathered granite; 5, feeding a PVC (Polyvinyl Chloride) pipe for protecting a blasting lead; 7, drilling hole in the rock layer until reaching depth 1m more than the design burial depth; 8, feeding explosive and blasting. With the adoption of the efficient grooving construction method for the underground diaphragm wall in the micro-weathered granite, the defects and shortcomings like difficult construction in the micro-weathered granite or slow construction progress, and poor grooving quality of the existing construction method of covering sand the micro-weathered granite can be overcome; the efficient, high-precision and deep-rock-embedding grooving construction in the micro-weathered granite is realized; the method has a good effect and fast to groove.

Owner:CHINA RAILWAY 16 BUREAU GRP BEIJING METRO ENG CONSTR +2

Grooving machine

InactiveCN108356362AImprove satisfactionGrooving speed is fastFeeding apparatusLarge fixed membersDrive wheelEngineering

The invention discloses a grooving machine and relates to the technical field of machining equipment of check valve seats. The grooving machine comprises a base. A spindle box is arranged at one end of the base. A tailstock is arranged at the other end of the base. A chuck is arranged at the end, close to the tailstock, of the spindle box. A motor is arranged on the side, close to the spindle box,of the base. A drive wheel is arranged on the motor. A driven wheel is arranged at the other end of the spindle box. An ejecting rod is arranged at the end, close to the spindle box, of the tailstock. A hand wheel is arranged at the other end of the tailstock. A workbench is arranged on the portion, between the spindle box and the tailstock, of the base. An air cylinder and a feeding mechanism are arranged on the workbench in sequence. A grooving mechanism is arranged on the feeding mechanism. Control buttons are arranged on one side of the base. According to the grooving machine, the designof full automatic machining is adopted, workers only need to press the control buttons, and time and labor are saved; the device is high in grooving speed, and the working efficiency is improved; thegrooving precision is high, the product quality is stable, and the customer satisfaction is high; and the device is simple in structure and convenient to maintain.

Owner:安徽德隆机械制造有限公司

Shear type slotting machine

InactiveCN102979122BGrooving speed is fastSoil-shifting machines/dredgersSlurry wallPetroleum engineering

The invention relates to a shear type slotting machine for underground continuous wall slotting. A support shaft is fixedly arranged on a support rod, the upper end of a telescopic oil cylinder A is hinged with a baffle plate, an output shaft at the lower end of the telescopic oil cylinder A is hinged with a transmission rod A through a pin shaft A, the upper end of a telescopic oil cylinder B is hinged with a baffle plate, an output shaft at the lower end of the telescopic oil cylinder B is hinged with a transmission rod B through a pin shaft B, the transmission rod A is provided with pin shafts C at certain interval, the upper end of each cutter arm A is hinged on the transmission rod A by the pin shafts C, the transmission rod B is provided with pin shafts D at certain interval, the upper end of each cutter arm B is hinged on the transmission rod B by the pin shafts D, the lower end of each cutter arm A is provided with cutter teeth A, and the lower end of each cutter arm B is provided with cutter teeth B.

Owner:梅州市广宇建筑工程有限公司

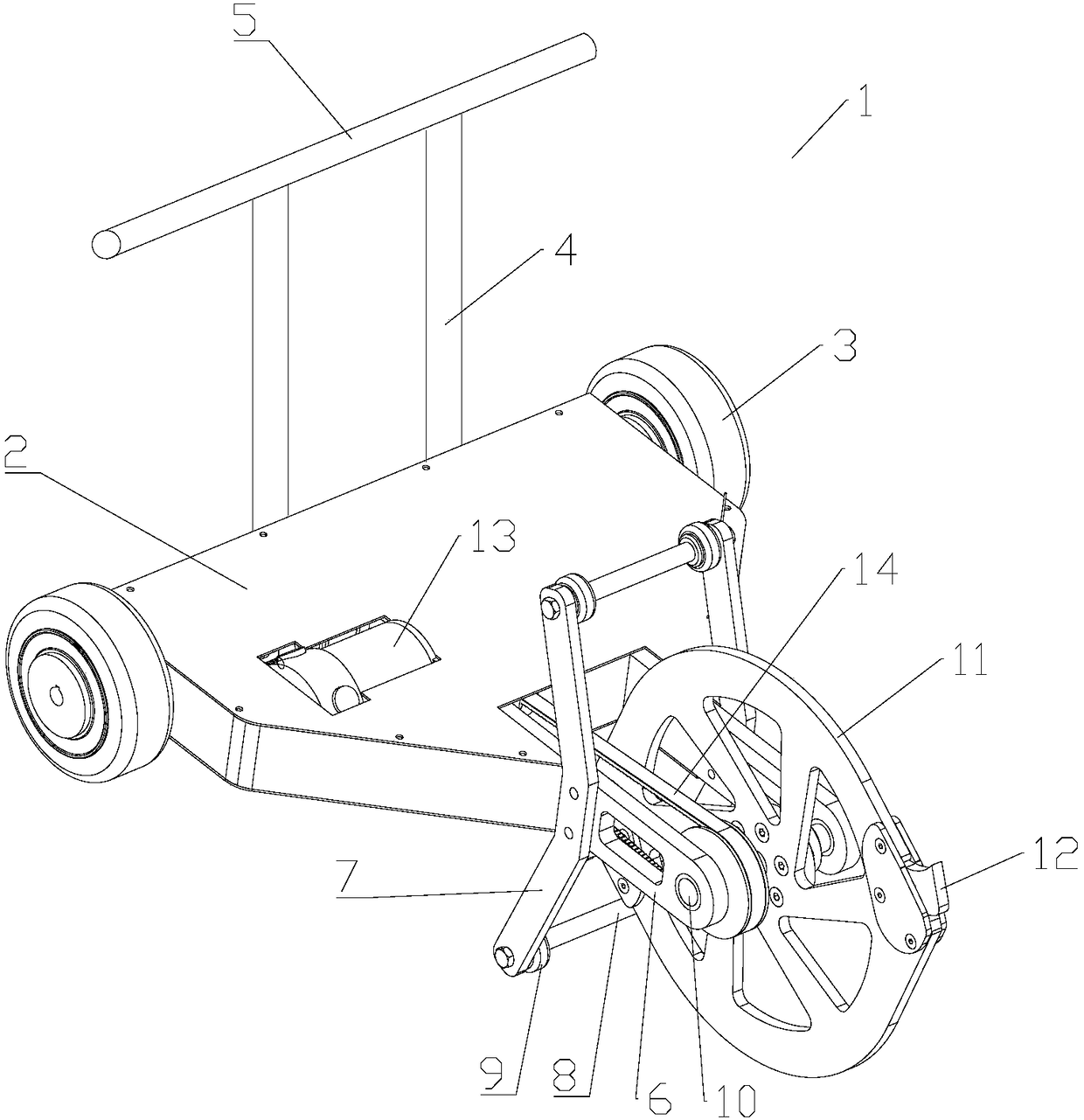

Electric grooving device for grooving surface of large ice block

The invention discloses an electric grooving device for grooving the surface of a large ice block. A pair of rear wheels are arranged on a base plate. A pair of vertical rods are arranged in the rearof the base plate. A hand push rod is connected between the top ends of the vertical rods. A pair of extension rods are arranged in the front of the base plate. A rotary shaft is connected between theextension rods. A front wheel is connected with the rotary shaft. A plurality of scrapers are arranged on the outer edge of the front wheel. A supporting rod is fixedly connected with the rod body ofeach extension rod. A transverse rod is fixedly connected with each of the two ends of each supporting rod. A pair of rolling wheels are arranged on each transverse rod. A driving motor is arranged in the base plate. The driving motor and the front wheel are connected through a transmission belt. The electric grooving device is like a trolley according to the integral structure, and when the electric grooving device is in use, the driving motor is started up, the front wheel is driven to rotate by the driving motor so that the scrapers on the outer edge of the front wheel are driven to rotateat a high speed, the grooving device can form deep grooves in the surface of an ice block by advancing on the ice body, the grooving speed is high, and formed groove bodies are neat and attractive.

Owner:FOCUSUN REFRIGERATION JIANGSU

Grooving machine cutter

InactiveCN112502004AReduce the workload of slottingGrooving speed is fastRoads maintainenceStructural engineeringMachine

The invention relates to the technical field of road equipment, in particular to a grooving machine cutter which structurally comprises a movable frame, a downward rotary cutter is arranged on the movable frame, and the rotary cutter comprises a first rotary cutter set and a second rotary cutter set which are sequentially arranged in the advancing direction of the movable frame. The rotary bladeson the first rotary knife set and the rotary knives on the second rotary knife set are located on the same plane, the axis of the first rotary knife set and the axis of the second rotary knife set areboth perpendicular to the plane where the rotary knives are located, and the rotary knives of the first rotary knife set are the same in size and coaxial. All the rotary cutters of the second rotarycutter set are the same in size and coaxial, the lowest point of the rotary cutters of the first rotary cutter set is higher than the lowest point of the rotary cutters of the second rotary cutter set, and therefore the bottom face can be rapidly and evenly slotted.

Owner:安庆市红雨农业发展有限公司

Grooving machine with three saw rods

InactiveCN102561435BGrooving speed is fastSoil-shifting machines/dredgersBulkheads/pilesSlurry wallArchitectural engineering

Owner:WATER RESOURCES RES INST OF SHANDONG PROVINCE

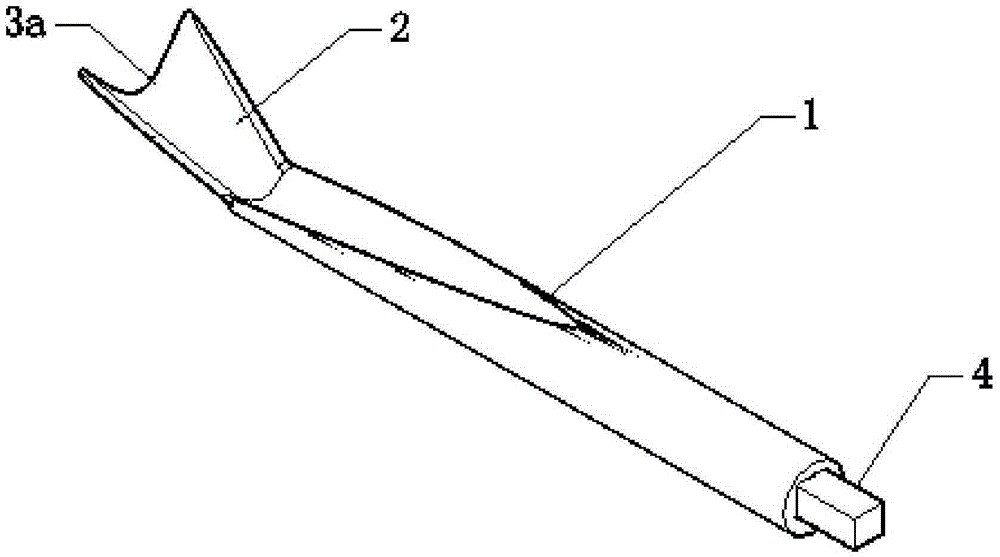

Grooving tool

InactiveCN105350751AImprove construction efficiencyGrooving speed is fastBuilding constructionsTool bitChisel

The invention discloses a grooving tool which comprises a handle rod and a corresponding tool bit. The tool bit comprises a groove type chisel head connected to the handle rod, and the groove type chisel head is bent towards one side by one angle relative to the axis of the handle rod. The grooving tool is simple and reasonable in structure, convenient to use and high in construction efficiency and construction quality, and the influence on and the damage degree of constructed objects are small.

Owner:张建平

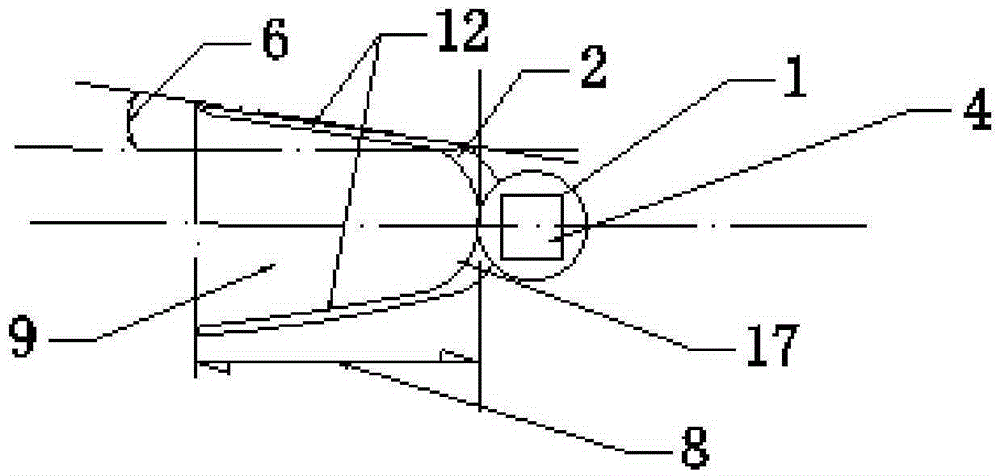

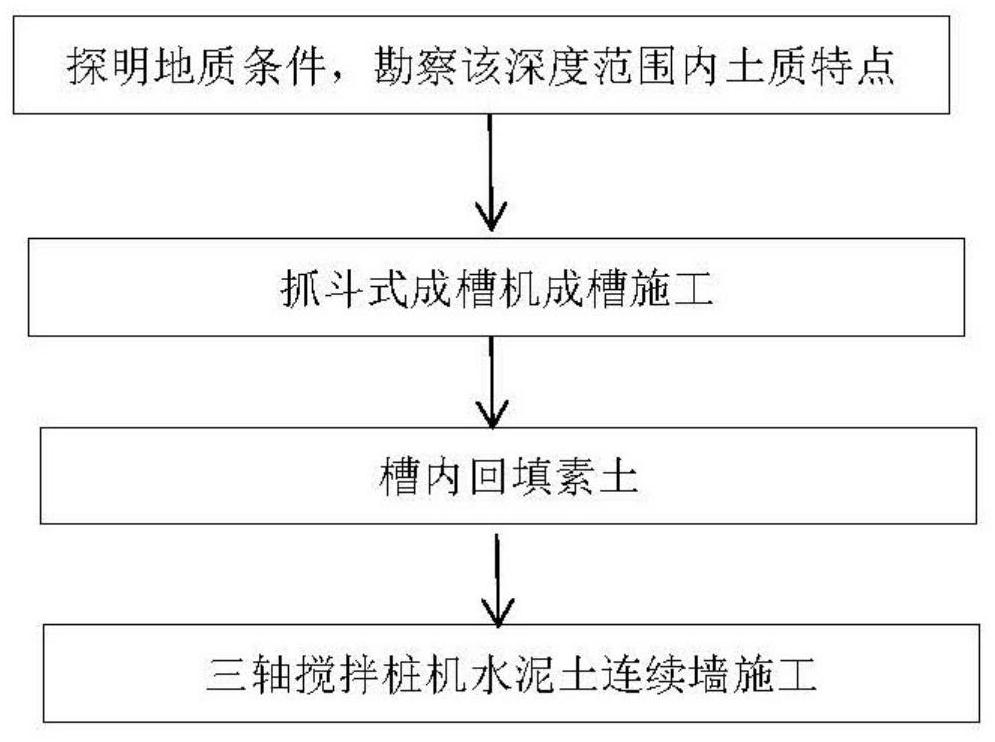

Pebble stratum waterproof curtain construction method

PendingCN113174983AGrooving speed is fastReduce mechanical wearFoundation engineeringSoil characteristicsArchitectural engineering

The invention provides a pebble stratum waterproof curtain construction method. The method comprises the following steps of S1, ascertaining geological conditions, investigating soil characteristics in a depth range, and determining whether a gravel pebble layer with relatively large thickness exists or not; S2, performing grooving through a grab bucket type grooving machine; S3, back-filling the groove with plain soil; and S4, performing stirring by a three-shaft stirring pile machine, and performing grouting to form a wall. According to the method, construction is conducted by multiple equipment together, respective advantages of the equipment are fully utilized, machine abrasion is reduced, construction difficulty is lowered, the construction period is effectively shortened, construction efficiency and construction quality are improved, and cost is saved.

Owner:南京东大岩土工程勘察设计研究院有限公司

Effective trenching construction method for underground diaphragm wall in slightly weathered limestone overlying sandy soil

ActiveCN103437341BGood hammering effectGood construction performanceArtificial islandsSoil-shifting machines/dredgersSlurry wallBULK ACTIVE INGREDIENT

Owner:CHINA RAILWAY 16 BUREAU GRP BEIJING METRO ENG CONSTR +1

Shear type slotting machine

InactiveCN102979122AGrooving speed is fastSoil-shifting machines/dredgersSlurry wallPetroleum engineering

The invention relates to a shear type slotting machine for underground continuous wall slotting. A support shaft is fixedly arranged on a support rod, the upper end of a telescopic oil cylinder A is hinged with a baffle plate, an output shaft at the lower end of the telescopic oil cylinder A is hinged with a transmission rod A through a pin shaft A, the upper end of a telescopic oil cylinder B is hinged with a baffle plate, an output shaft at the lower end of the telescopic oil cylinder B is hinged with a transmission rod B through a pin shaft B, the transmission rod A is provided with pin shafts C at certain interval, the upper end of each cutter arm A is hinged on the transmission rod A by the pin shafts C, the transmission rod B is provided with pin shafts D at certain interval, the upper end of each cutter arm B is hinged on the transmission rod B by the pin shafts D, the lower end of each cutter arm A is provided with cutter teeth A, and the lower end of each cutter arm B is provided with cutter teeth B.

Owner:梅州市广宇建筑工程有限公司

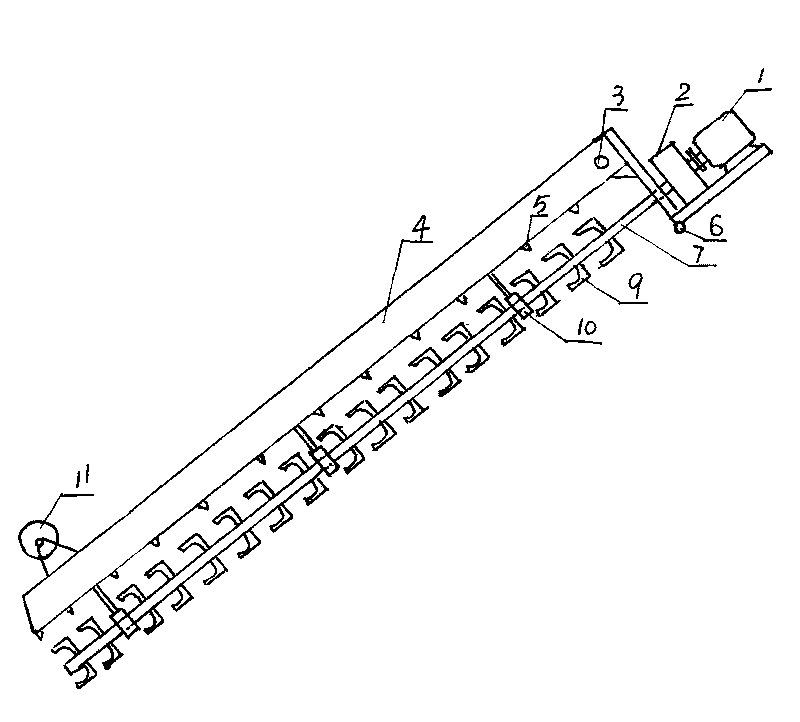

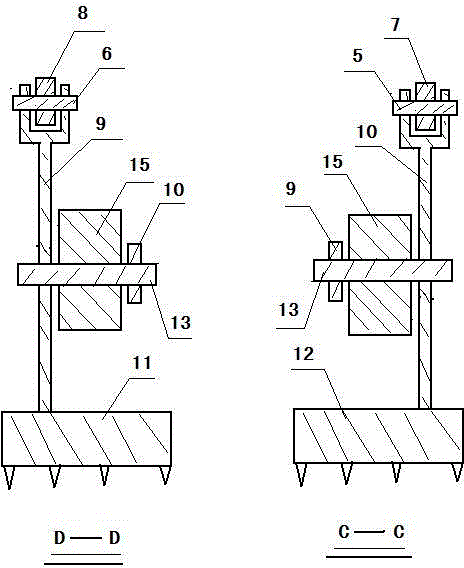

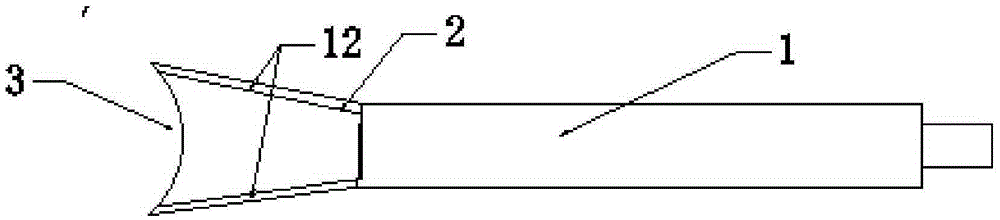

Trenching machine with multiple drilling heads

InactiveCN102619245AGrooving speed is fastNo flushSoil-shifting machines/dredgersSlurry wallEngineering

A trenching machine with multiple drilling heads comprises a panel, a support and a hydraulic oil cylinder, wherein the panel is arranged on the upper portion of the trenching machine, the support is arranged at the lower end of the panel, the hydraulic oil cylinder which is arranged at the right side of the panel is fixed on the panel, an output shaft of the oil cylinder penetrates through the panel and is hinged with the upper end of a pulling rod, the upper end of a main rod is fixed with the panel, a plurality of cutter arbors are provided according to sizes of grooving depths, a hinged support A is arranged on the upper portion of each of the cutter arbors, a hinged support B is arranged on the middle portion of each of the cutter arbors, a water spray nozzle is arranged at the lower end of each of the cutter arbors, two sides of each of the water spray nozzles are respectively provided with a cutter tooth, outermost ends of the two cutter teeth are respectively provided with an edge cutter, the uppermost end of each of the cutter arbors is provided with two branches, branches on the upper portions of two cutter arbors which are adjacent to each other are connected through a connection hose, the hinged support A on the upper portion of each of the cutter arbors are hinged with the pulling rod through a hinged shaft A, and the hinged support B on the middle portion of each of the cutter arbors is hinged with the main rod through a hinged shaft B. The trenching machine with multiple drilling heads is a special machine tool for constructing diaphragm walls.

Owner:张永忠

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com