Numerical control groove punching machine and groove punching method thereof

A grooving machine and grooving technology, applied in the field of stamping processing, can solve the problems of slow grooving speed, inability to precisely control the grooving depth, and high production cost of the grooving machine, and achieve simple structure, high working reliability, and grooving. The effect of deep precise control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

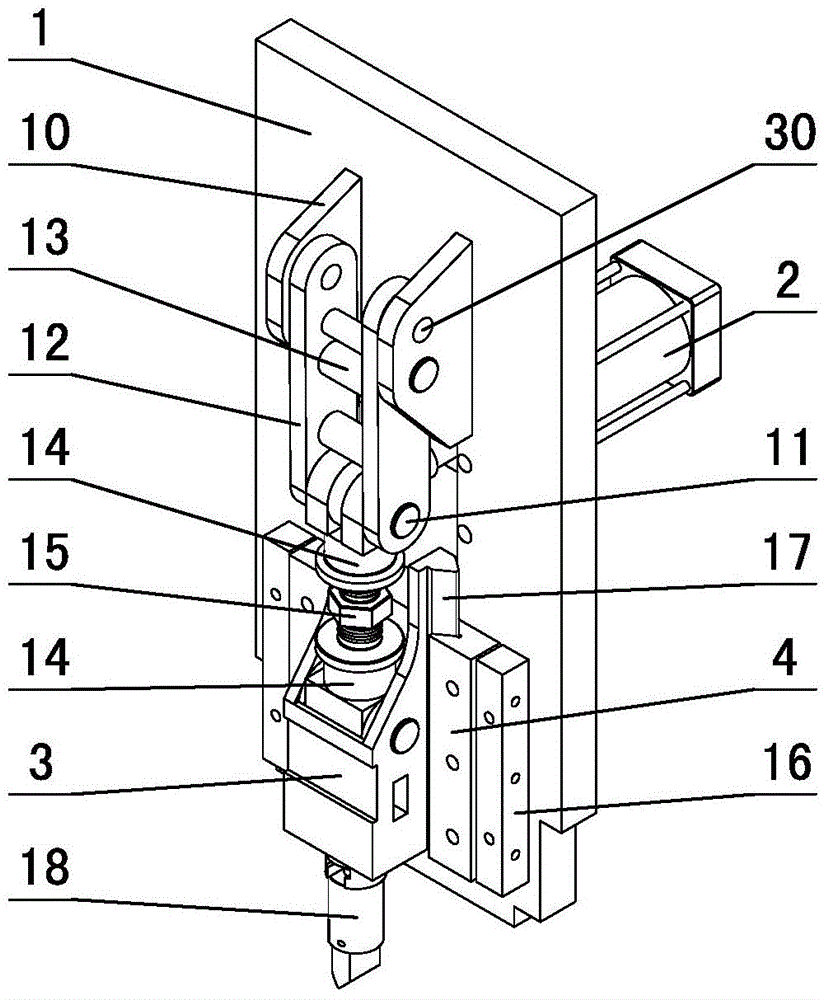

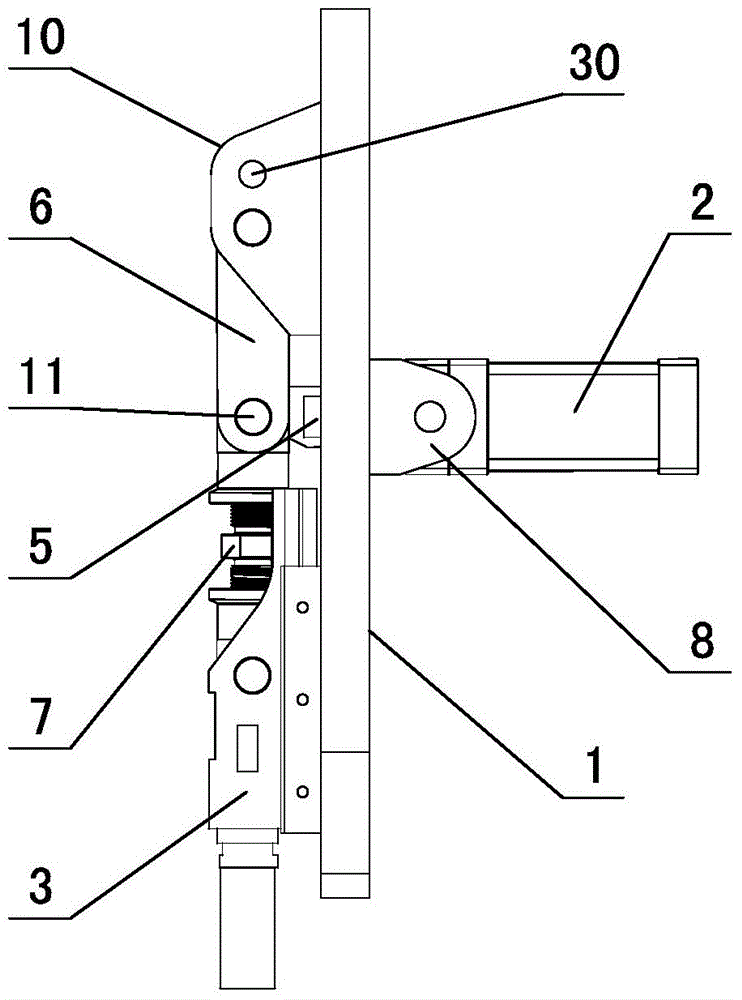

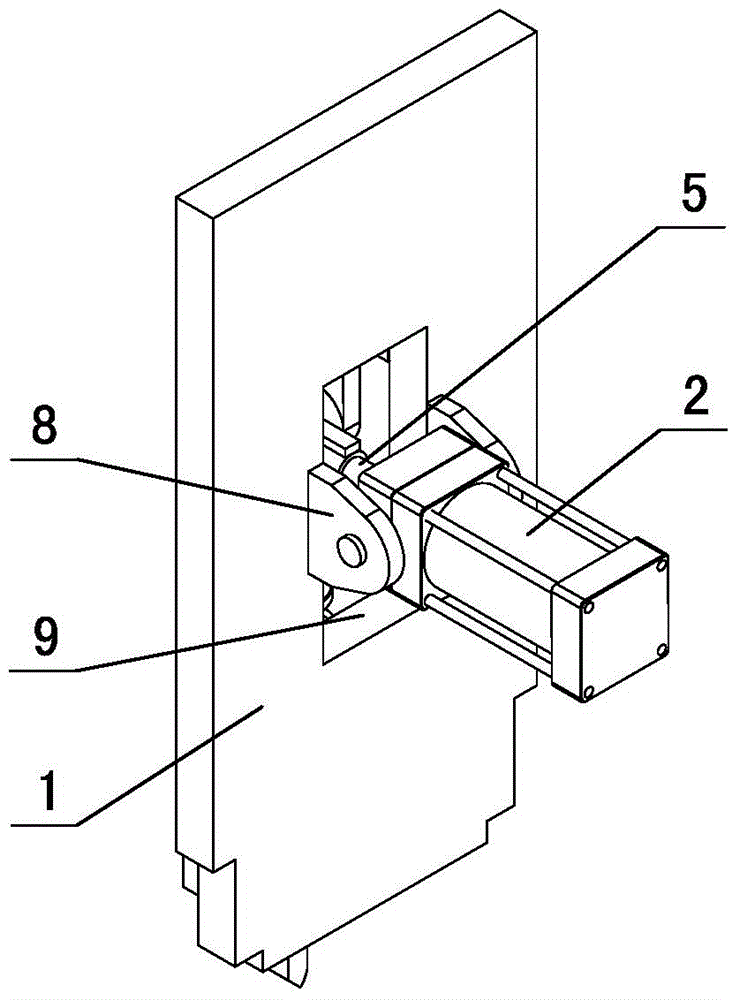

[0040] in such as figure 1 figure 2 image 3 In the shown embodiment 1, a kind of numerical control grooving machine comprises a frame (not shown in the figure) and a controller arranged on the frame, a numerically controlled feeding mechanism and a grooving mechanism, and the described NC grooving mechanism includes The base plate 1 and the double-acting cylinder 2 arranged on the base plate and the stamping block 3 used to drive the upper die of the grooving machine to work, the base plate is provided with a slide rail 4, the stamping block and the slide rail constitute a sliding pair, the cylinder of the cylinder The body is hinged on the base plate, and the piston rod 5 of the cylinder is connected with the stamping block through the booster frequency mechanism. The booster frequency mechanism includes an upper booster arm 6 and a lower booster arm 7. The arm is arranged on one side of the base plate, and the cylinder is hinged to the other side of the base plate throug...

Embodiment 2

[0052] exist Figure 4 Figure 5 In the shown embodiment 2, two grooving mechanisms are provided on the frame, and the two grooving mechanisms are arranged side by side in the moving direction of the feeding mechanism. The stamping block of the first grooving mechanism is provided with a V-shaped indenter 18 , the frame corresponding to the V-shaped indenter is provided with a columnar top block 19; the stamping block of the second groove mechanism is provided with a columnar indenter 20, and the frame corresponding to the columnar indenter is provided with a V-shaped top block 21 , all the other structures are the same as in Example 1.

[0053] The grooving method of the CNC grooving machine in this embodiment is to calculate the stamping positions of the upper surface and the lower surface of the slats that need to be grooved according to different character frame structures, and input them into the controller of the NC grooving machine, and the controller controls the firs...

Embodiment 3

[0055] exist Figure 6 In the shown embodiment 3, a die seat driven by a stepping motor is provided below the stamping block, and the die seat includes an upper die seat and a lower die seat, and several upper dies that can accommodate the upper die are arranged in the cylindrical upper die seat 22. Cavity 23, the upper mold cavity is arranged on the same circumferential surface with the center line of rotation of the mold base as the axis, the cross section of the upper mold cavity is circular, and the upper mold 24 can slide up and down in the upper mold cavity. An upper mold anti-rotation structure and an upper mold return spring are provided between the upper mold cavity; a number of positioning grooves 25 corresponding to the upper mold cavity are provided on the outer peripheral surface of the upper mold base, and a positioning groove 25 corresponding to the upper mold cavity is provided on the base plate. Scalable positioning plate 26, when the telescopic positioning pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com