Grooving machine with three saw rods

A technology of slotting machine and saw rod, which is applied in the direction of earth mover/excavator, construction, sheet pile wall, etc., and can solve the problems of not being able to slot and difficult slotting machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

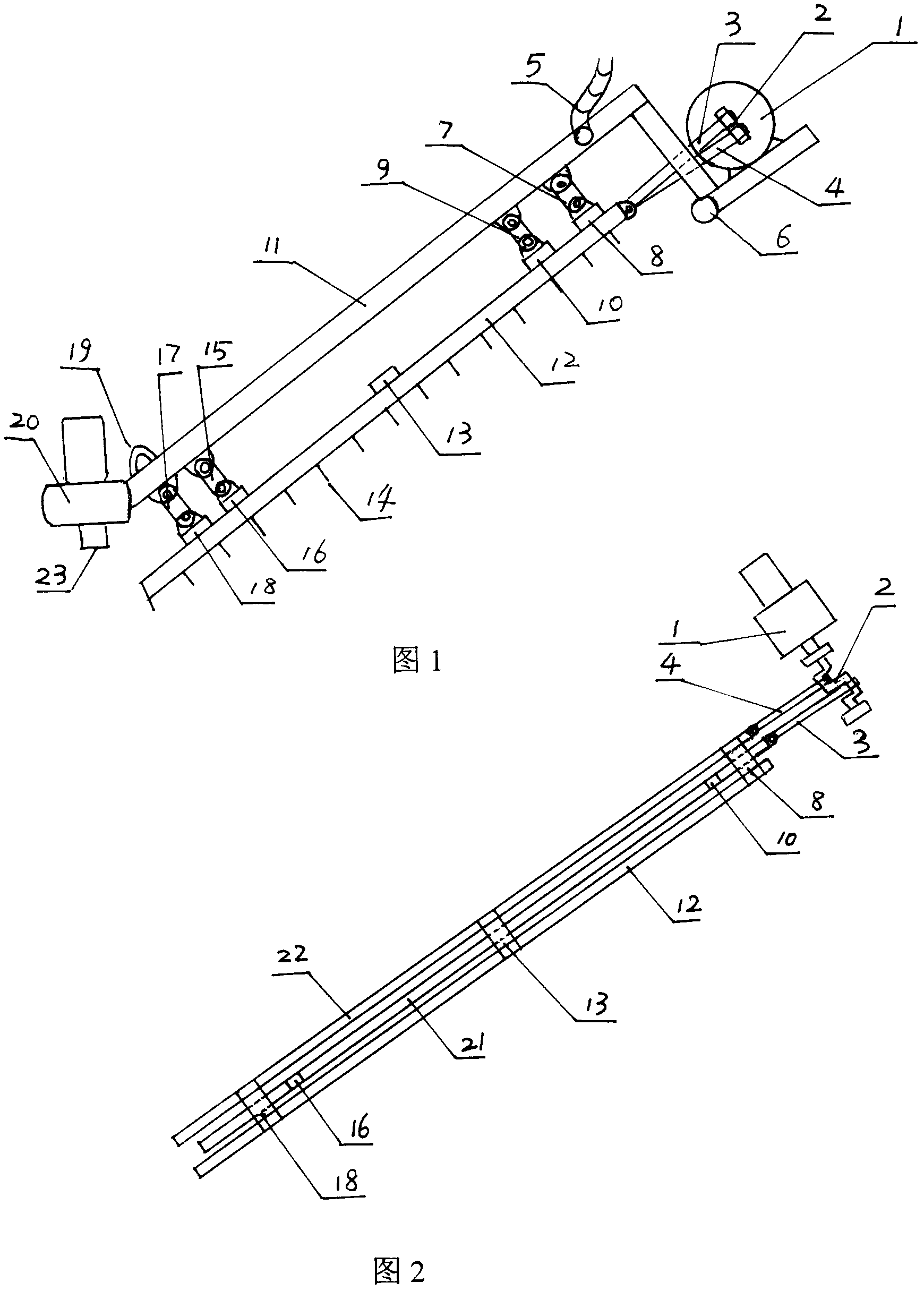

[0012] Accompanying drawing is a kind of concrete embodiment of the present invention, and this embodiment comprises the supporting shaft 6 of slotting machine upper part, the lifting lug 19 of lower part, and the gravel pump is fixed on the lower end of the slurry steel pipe 11, and the bottom end of the gravel pump is provided with There is a suction port 23, and the upper end of the pulping steel pipe is connected with the pulping rubber hose 5; the upper ends of the rocker arm A7, the rocker arm B9, the rocker arm C15, and the rocker arm D17 are all connected to the pulping steel pipe 11, and the lower end of the rocker arm A7 is connected to the connection A8, and the rocker arm The lower end of B9 is connected to the base 10, the lower end of the rocker arm C15 is connected to the base B16, the lower end of the rocker arm D17 is connected to the connection C18, the connection A8, the connection B13, and the connection C18 are respectively used to connect the upper, middle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com