Pebble stratum waterproof curtain construction method

A water-stop curtain and construction method technology, applied in the direction of infrastructure engineering, construction, etc., can solve the problems of not being able to give full play to the maximum advantages of equipment, slow construction progress, and large equipment consumption, so as to improve construction efficiency, construction quality, and groove formation speed Fast, less mechanical wear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solution of the present invention will be explained more clearly and completely through the description of preferred embodiments of the present invention in conjunction with the accompanying drawings.

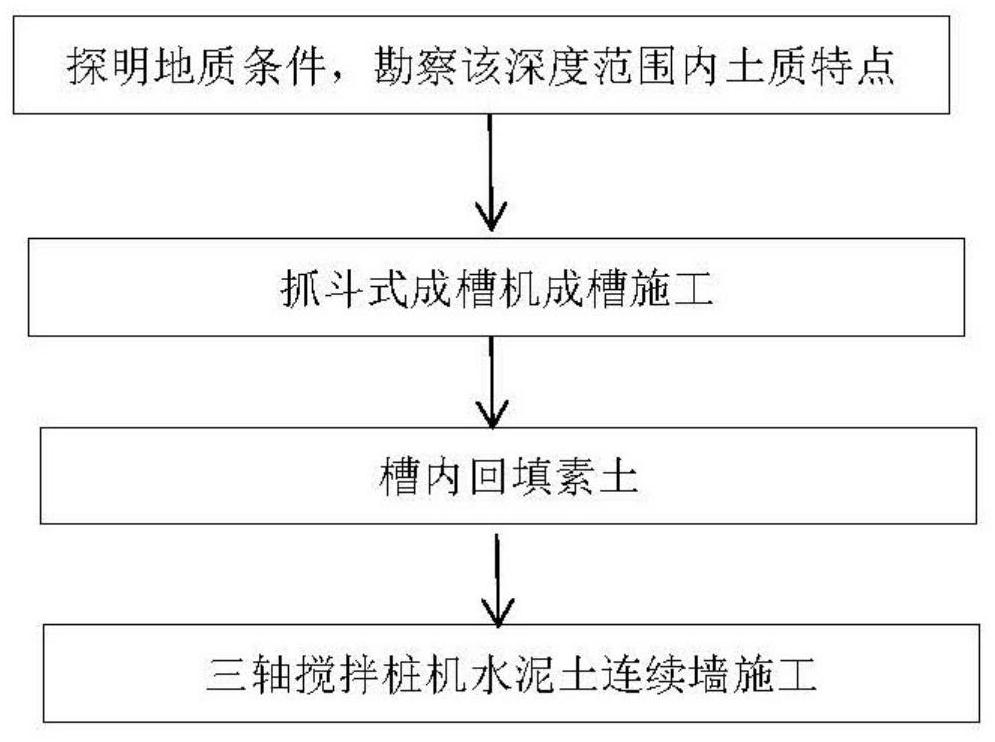

[0022] Such as figure 1 As shown, a kind of pebble formation waterproof curtain construction method of the preferred embodiment of the present invention comprises the following steps:

[0023] S1: Ascertain the geological conditions, investigate the soil characteristics within the depth range, and determine whether there is a thicker gravel and pebble layer; if there is a thicker gravel and pebble layer, go to step S2 and use a grab-type groove forming machine In trenching construction, if there is no thick gravel and pebble layer, and the main soil layer is soft soil, silt, or sandy soil, proceed to step S4.

[0024] S2: Groove construction by grab-type grooving machine, the grooving speed is controlled during the grooving process, the grooving depth is n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com