Patents

Literature

108results about How to "Easy slotting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

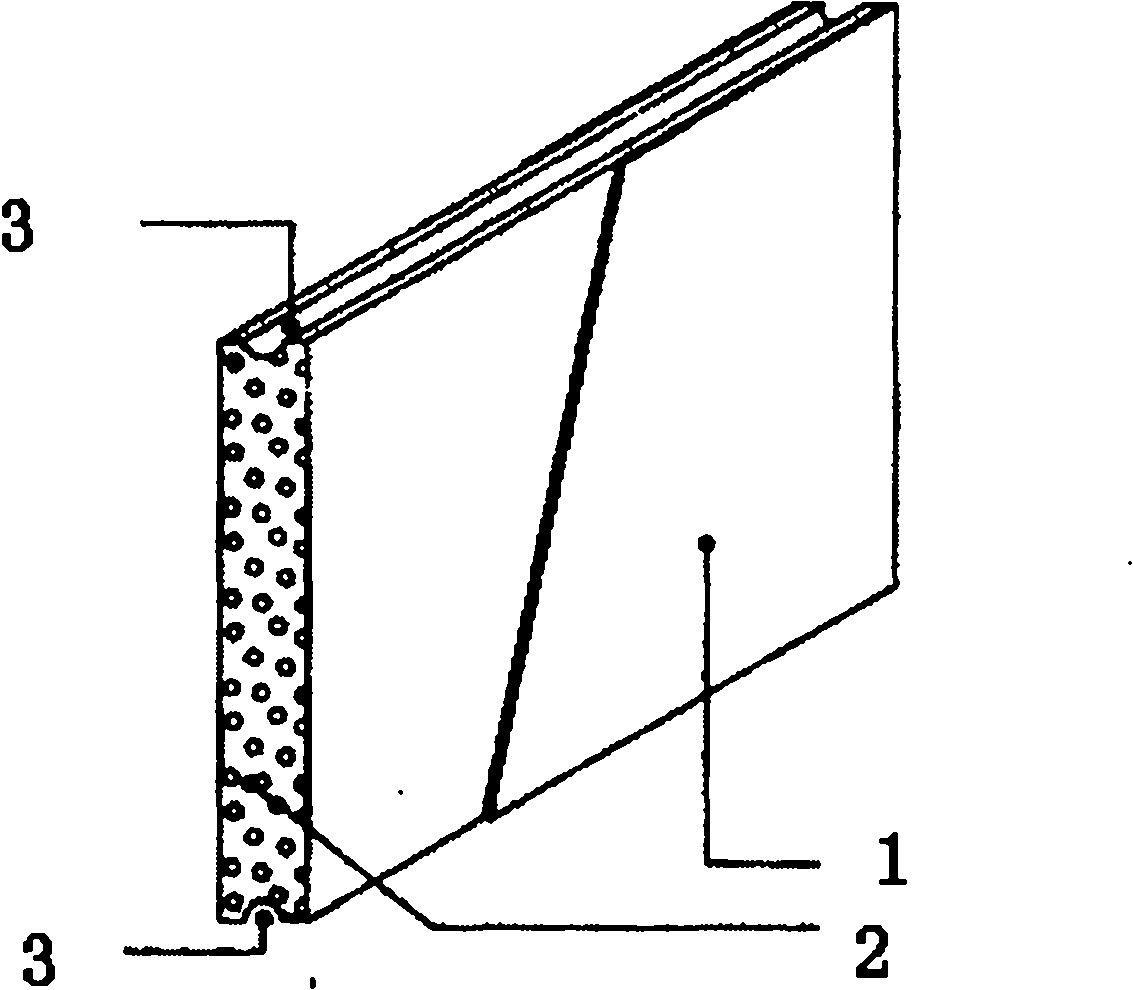

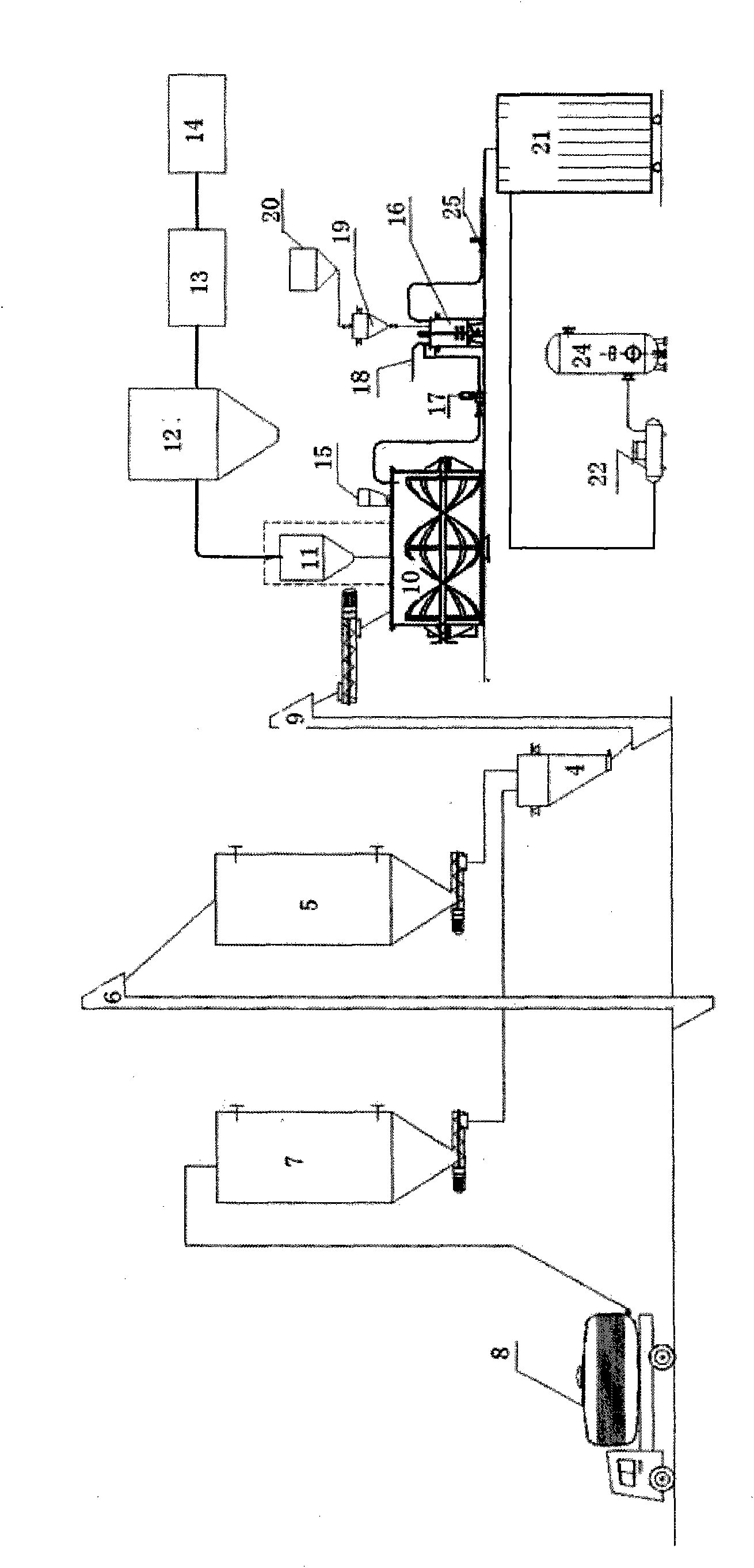

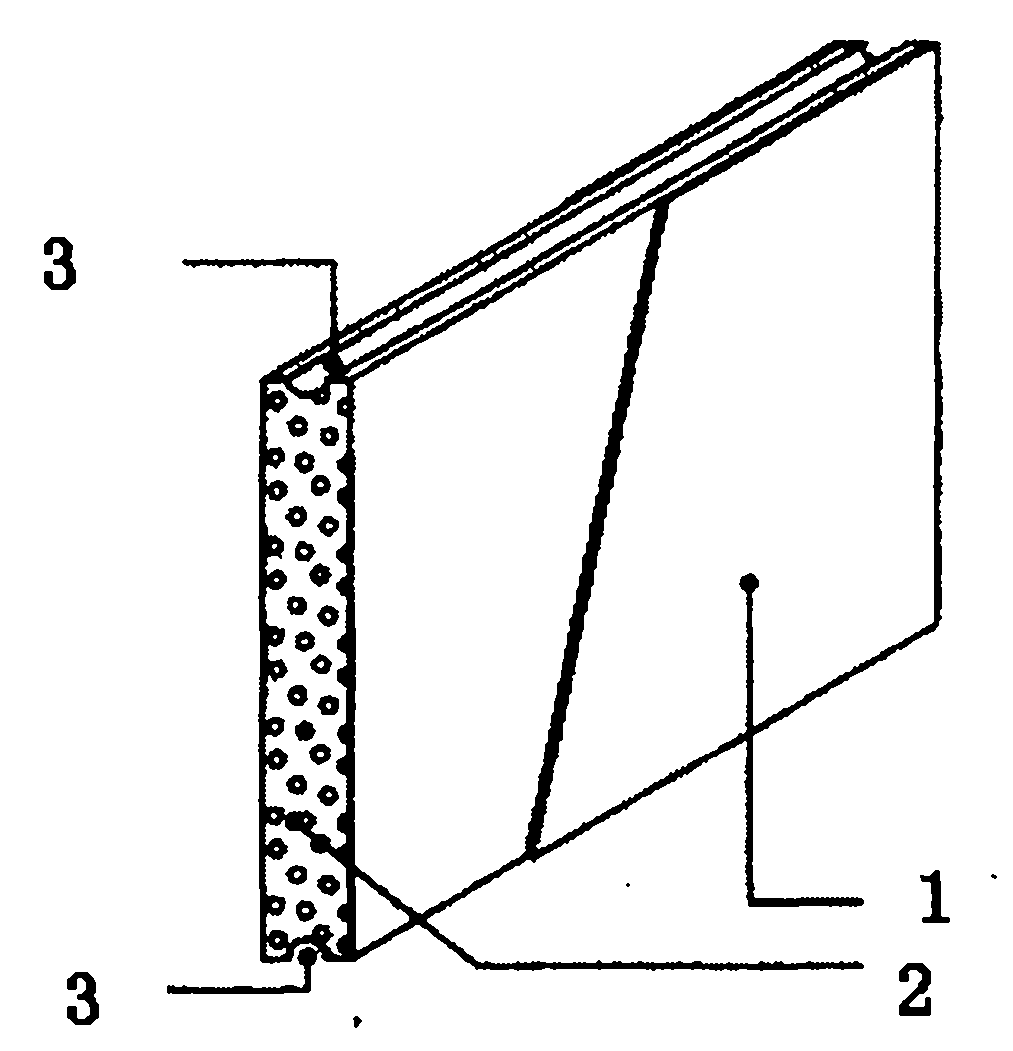

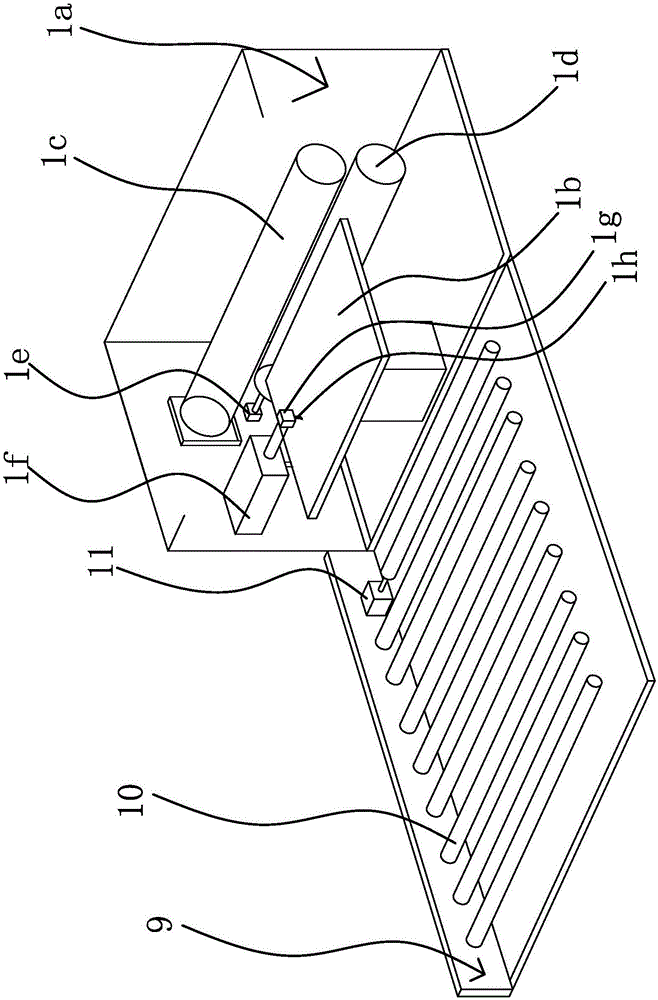

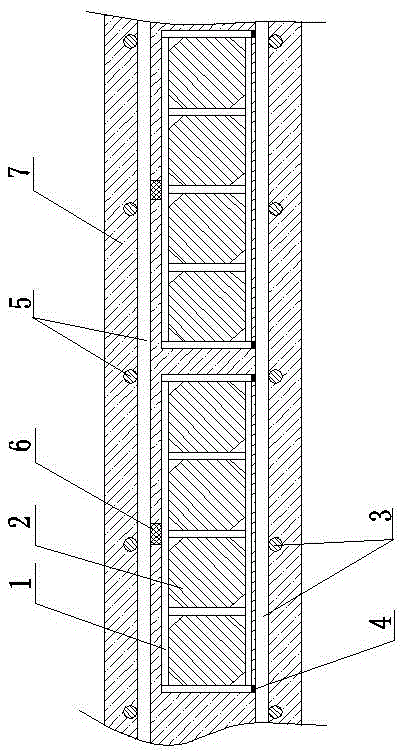

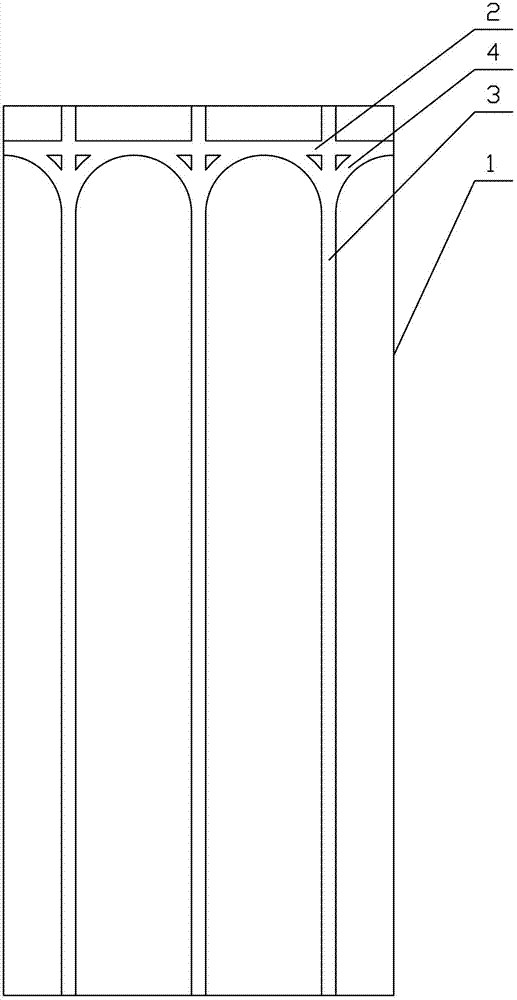

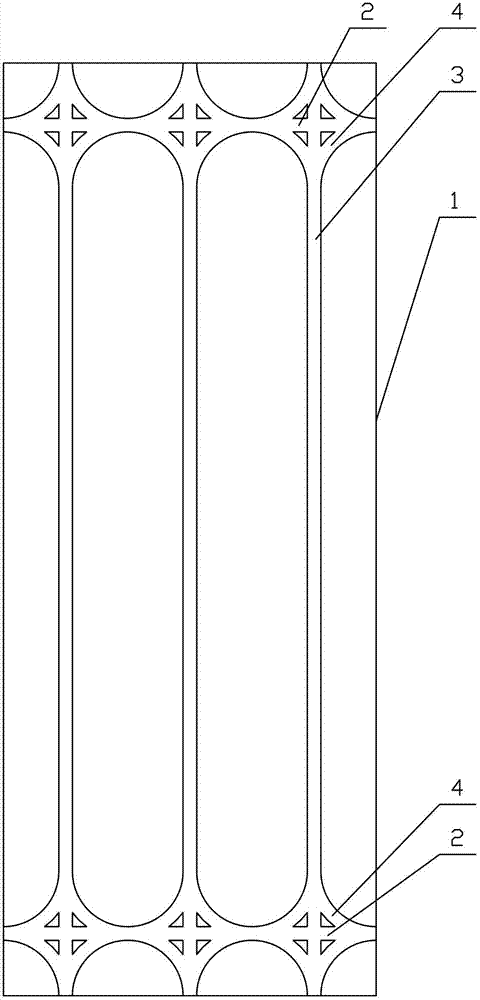

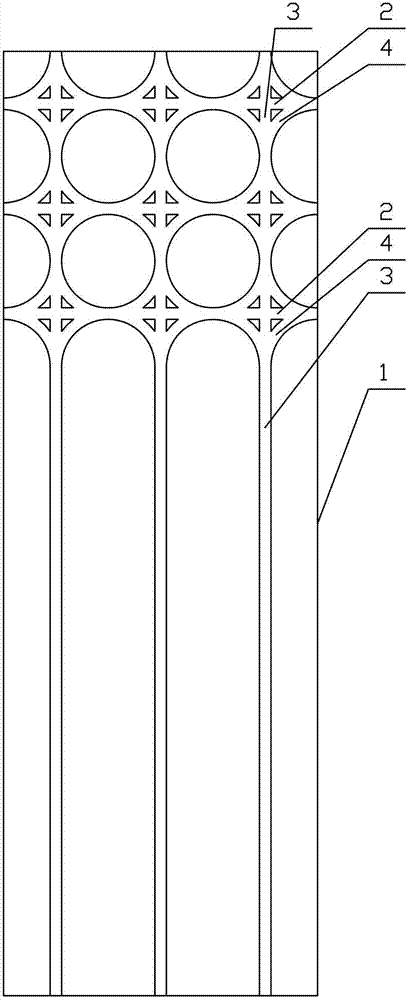

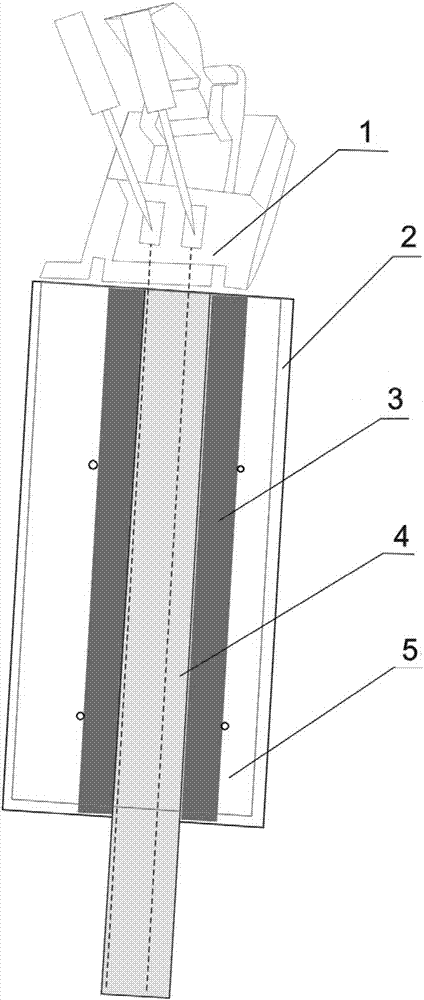

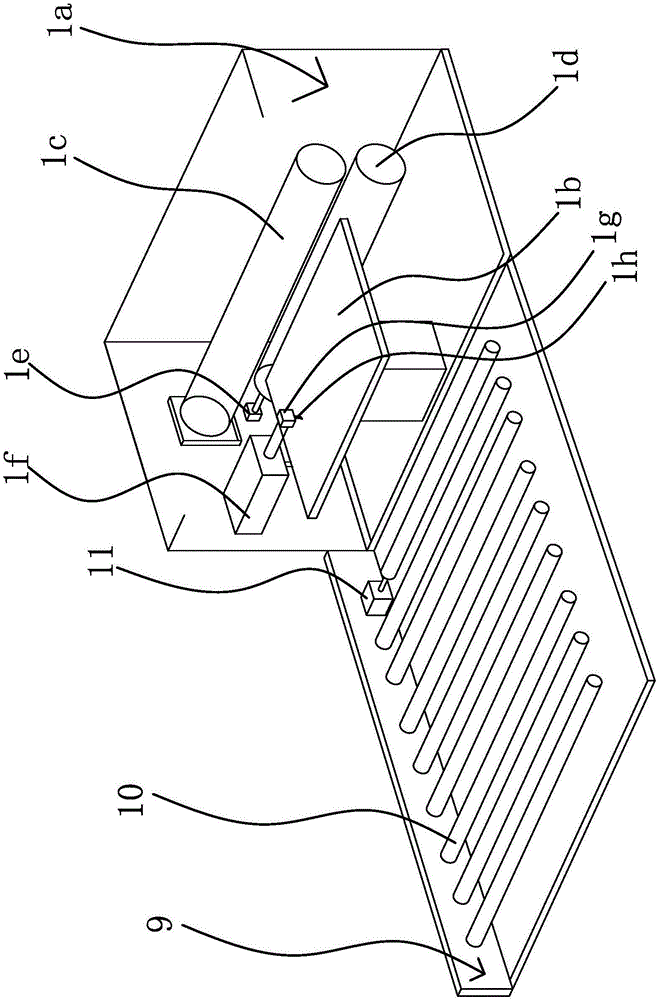

Energy-saving, low-carbon and heat-insulation composite wallboard, and production method and equipment thereof

The invention provides an energy-saving, low-carbon and heat-insulation composite wallboard, and a production method and production equipment thereof. The energy-saving, low-carbon and heat-insulation composite wallboard is characterized by consisting of two surface boards and a core board arranged between the two surface boards, wherein the core board is prepared from polystyrene foamed plastics, fly ash, cement, sand, admixture and water. The invention also provides the production method and production equipment of the energy-saving, low-carbon and heat-insulation composite wallboard. The energy-saving, low-carbon and heat-insulation composite wallboard has the advantages of light weight, thin body, impact resistance, compression resistance, heat preservation, heat insulation, water proofing, fire proofing, sound insulation, shock proofing, explosion absorption, easy cutting, slotting, no need of plastering, fast dry operation, labor saving and the like.

Owner:上海康尼建材科技有限公司

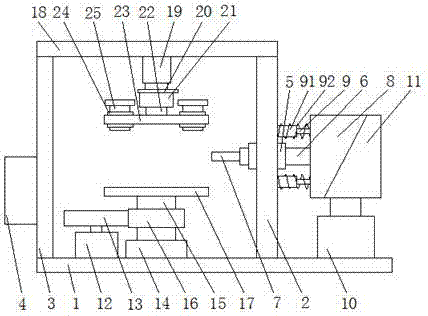

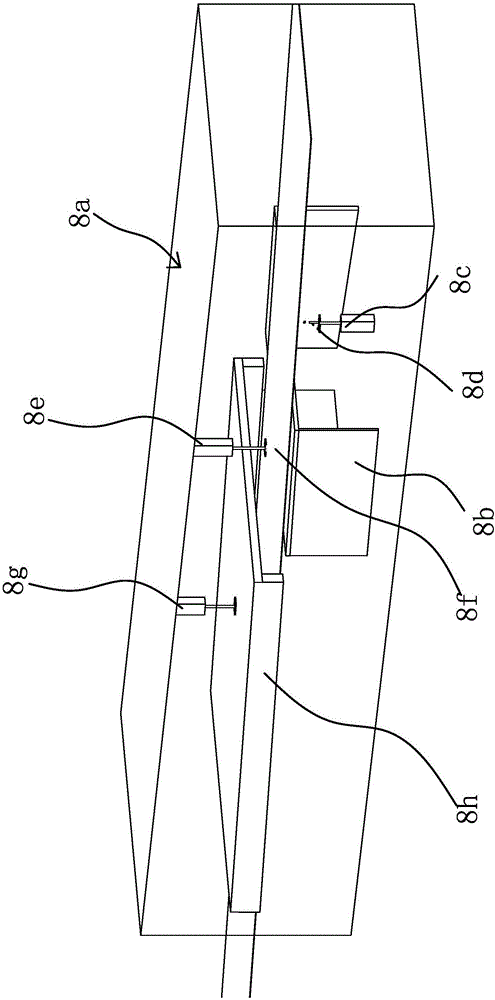

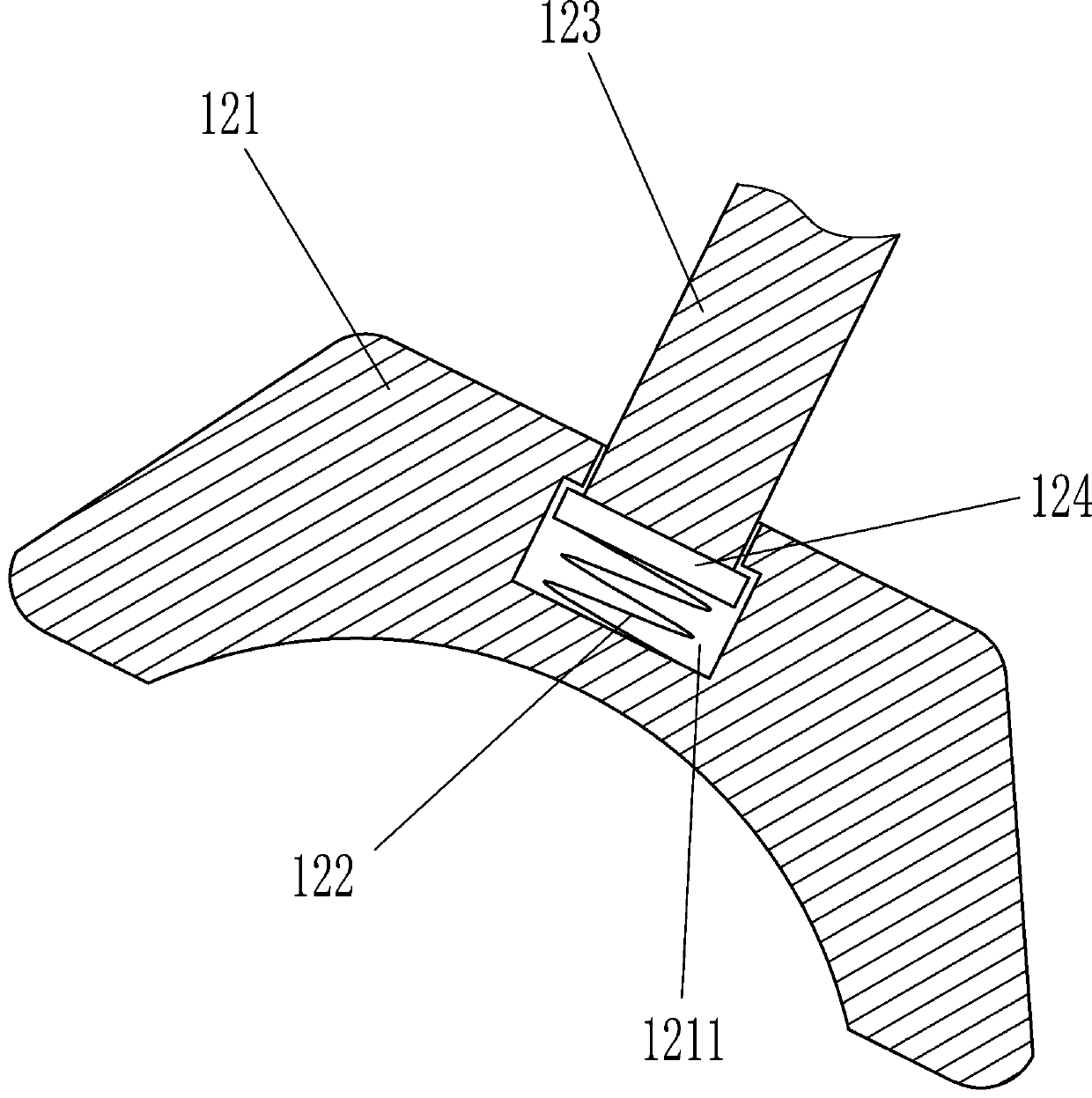

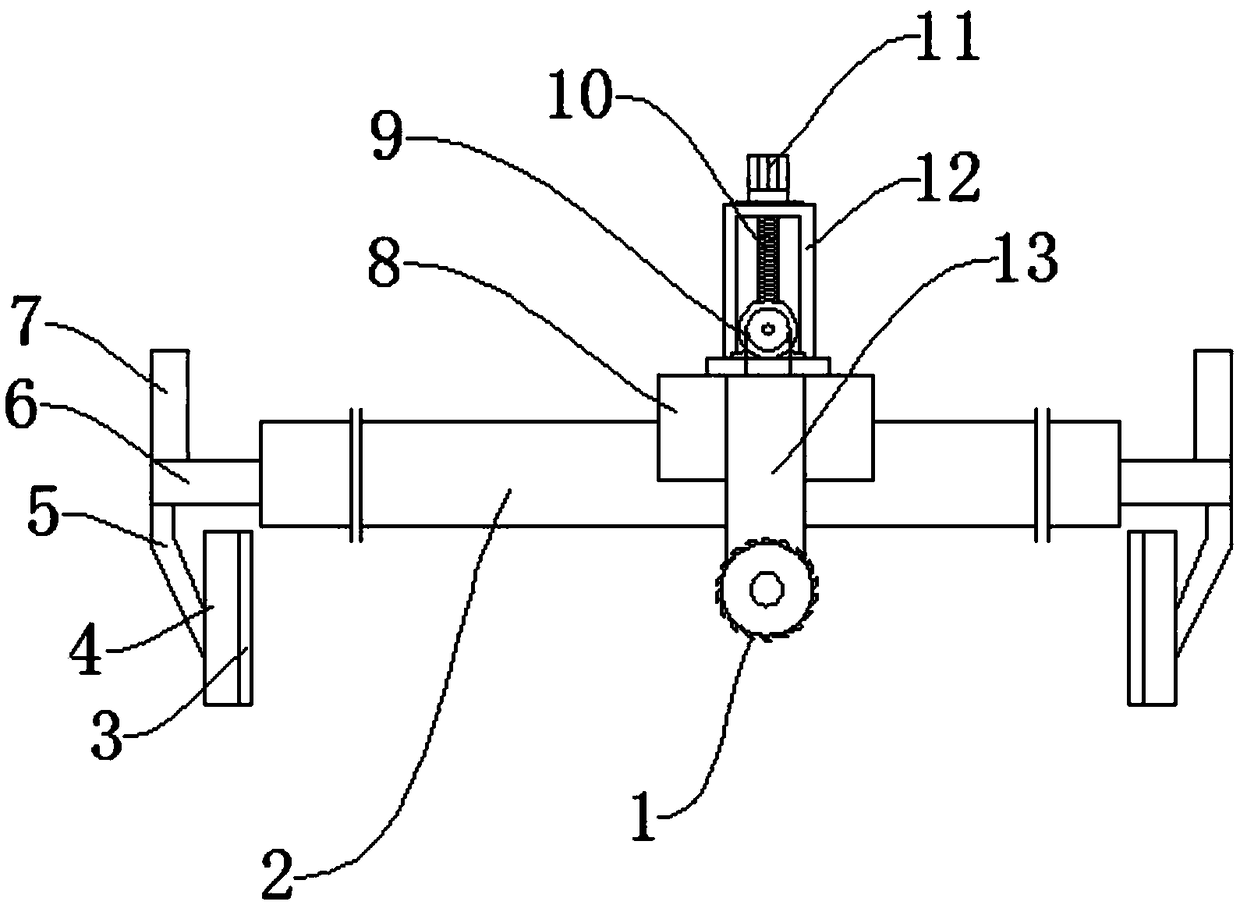

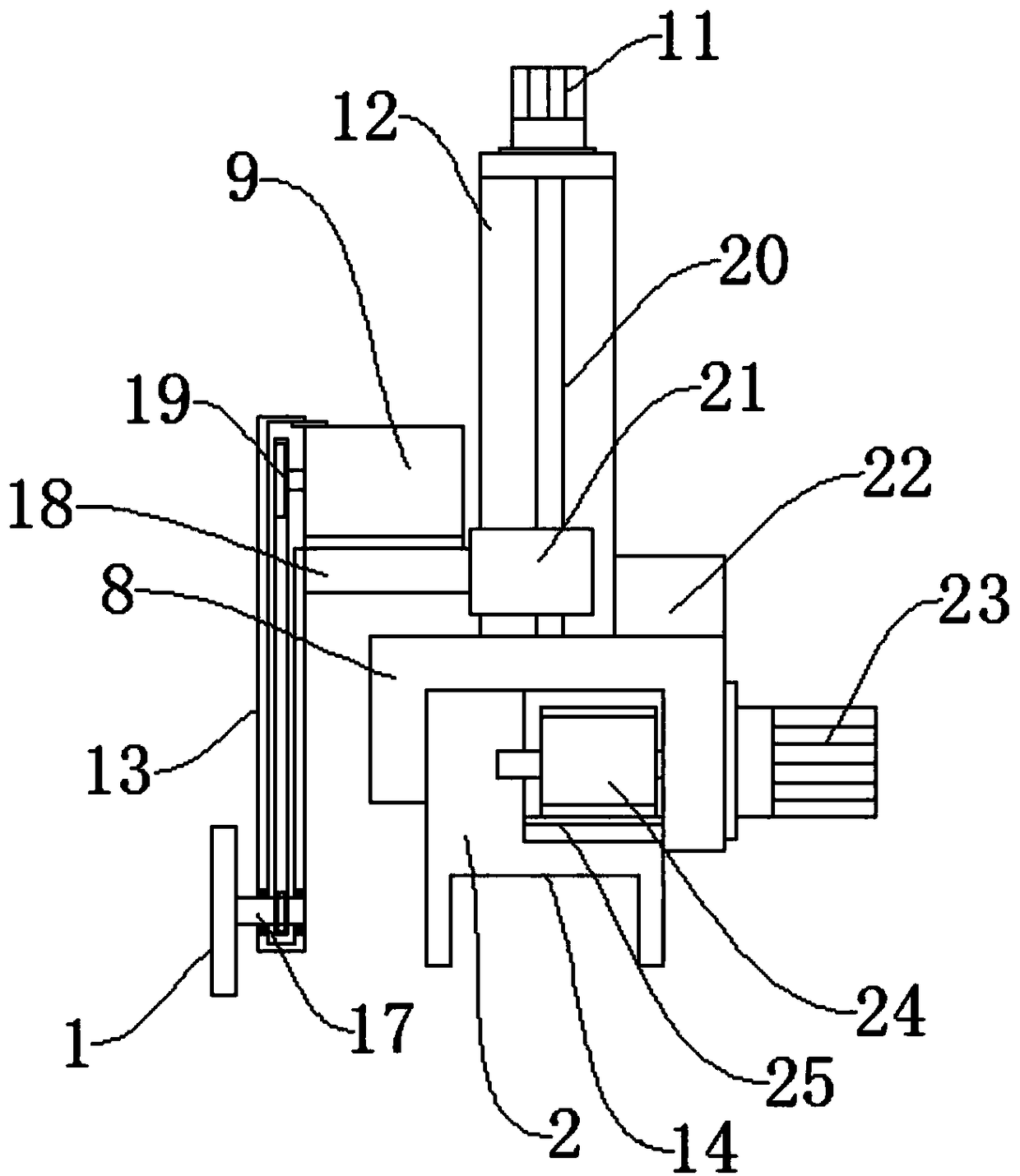

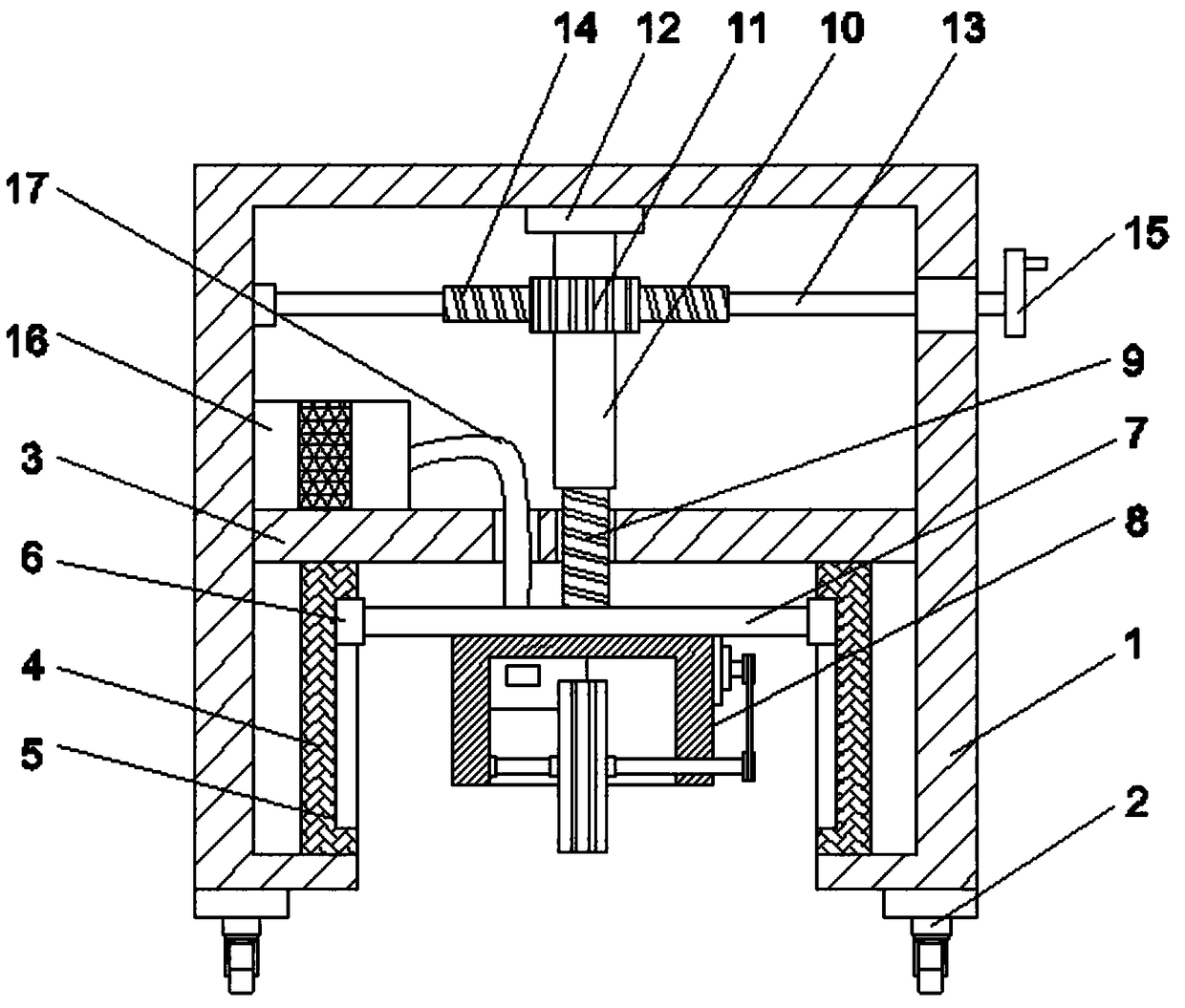

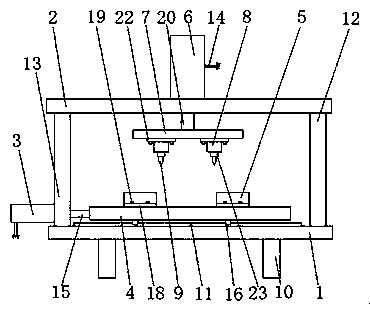

Side face slotting device for cylindrical wood

InactiveCN107379150AImprove production efficiencyEasy slottingWood mortising machinesWood slotting machinesChiselEngineering

The invention discloses a side face slotting device for cylindrical wood. The side face slotting device for cylindrical wood comprises a base plate. The upper surface of the base plate is provided with a first fixing plate and a second fixing plate. The left side face of the second fixing plate is provided with a control panel. The right side face of the first fixing plate is connected with a sliding sleeve in a clamped manner. According to the side face slotting device for the cylindrical wood, the wood is placed on a supporting plate, a second electric push rod extends to tightly press the wood, secondary tight pressing and fixation are conducted on the wood through bolts and nuts, a motor is controlled to rotate, the supporting plate is made to drive the wood to rotate, the first electric push rod is controlled to extend, a second pressing block presses a first pressing block to move leftwards, a sliding rod is made to move leftwards in the sliding sleeve, and then a chisel makes contact with the wood; through control over the extending height of the first electric push rod, the leftward movement distance of the chisel is controlled, so that the slotting depth of the wood is controlled. The side face slotting device for the cylindrical wood is convenient to control and rapid in slotting and improves the manufacturing efficiency of wood products.

Owner:扬州市大悦信息科技有限公司

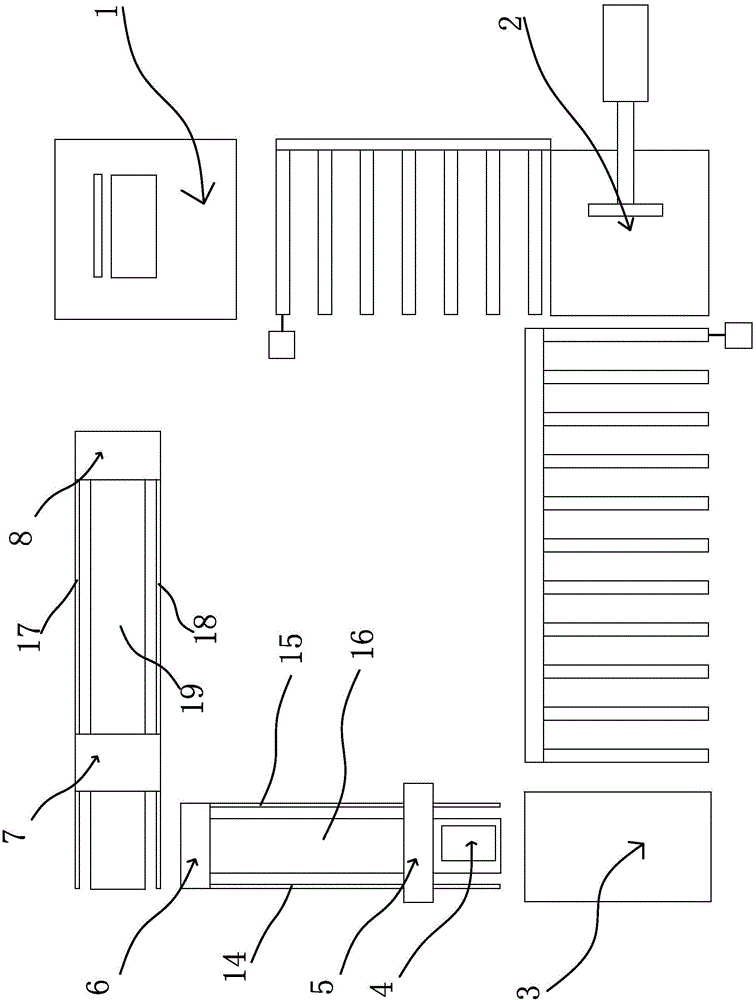

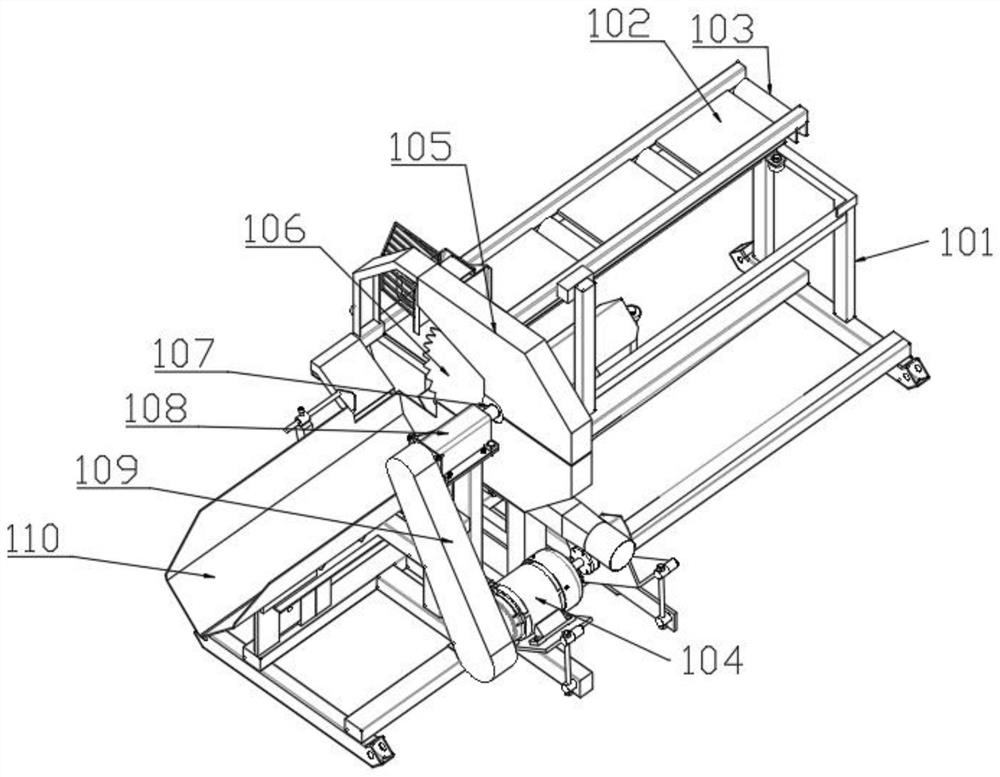

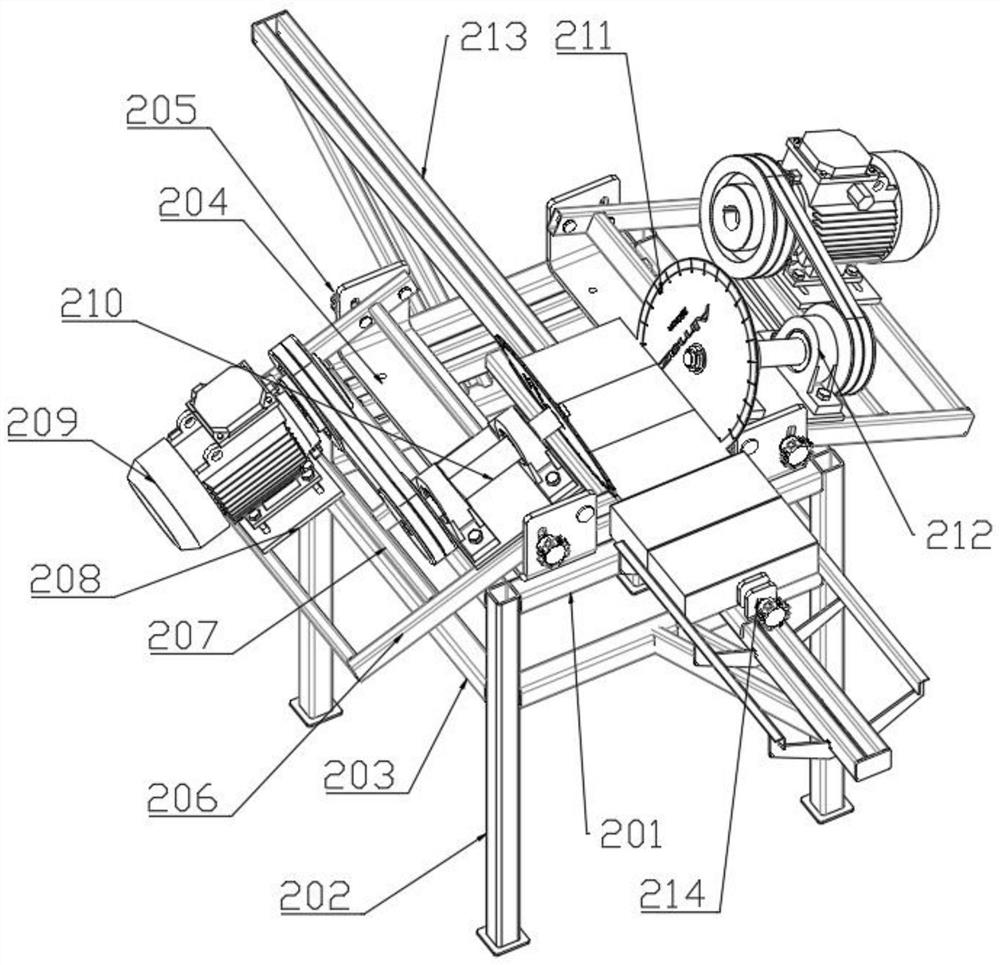

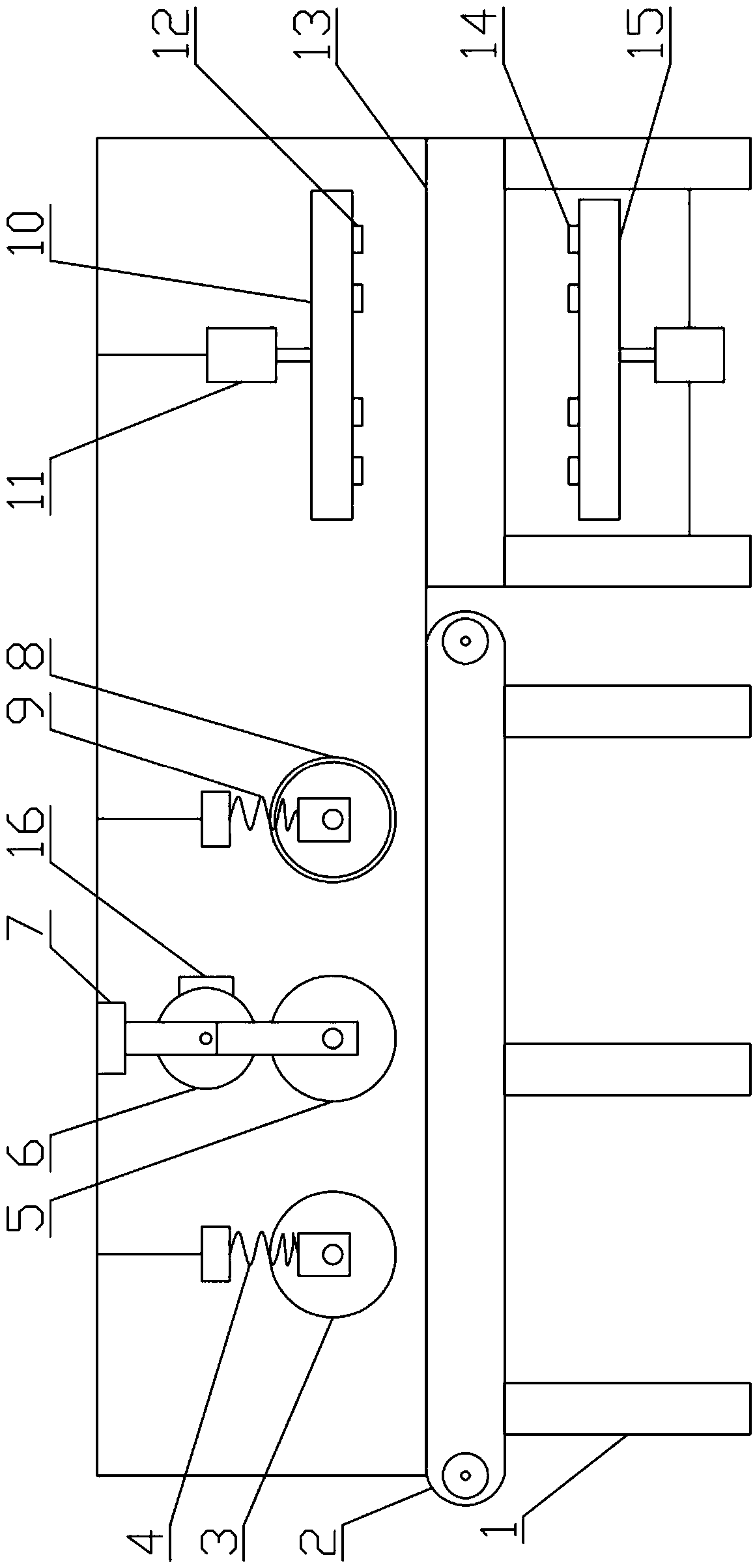

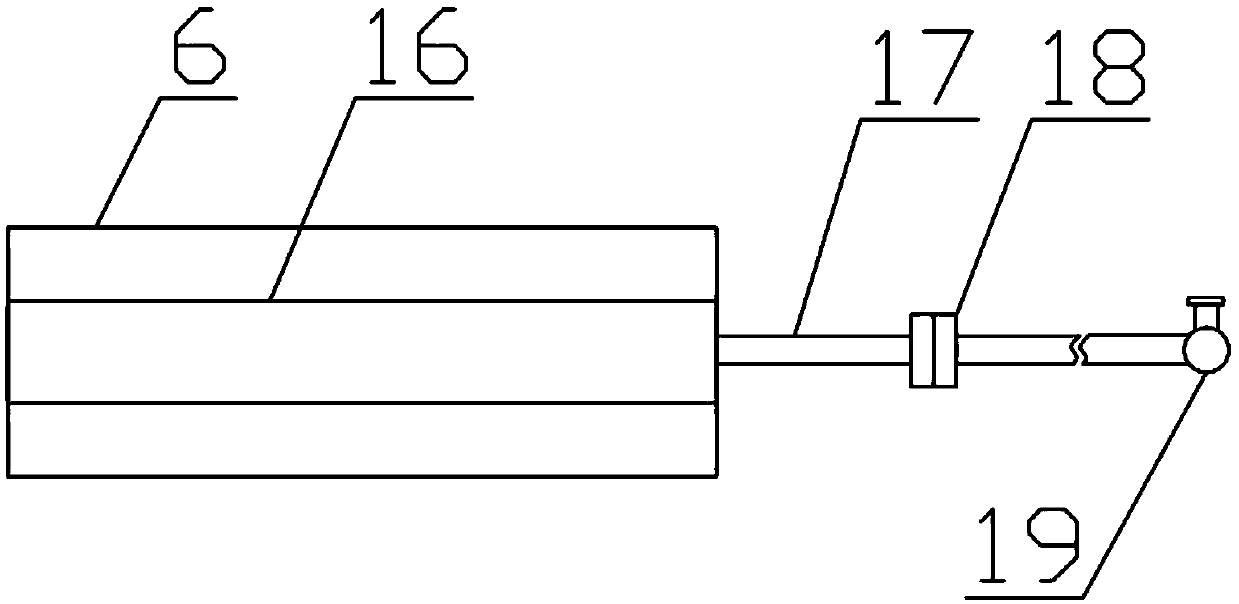

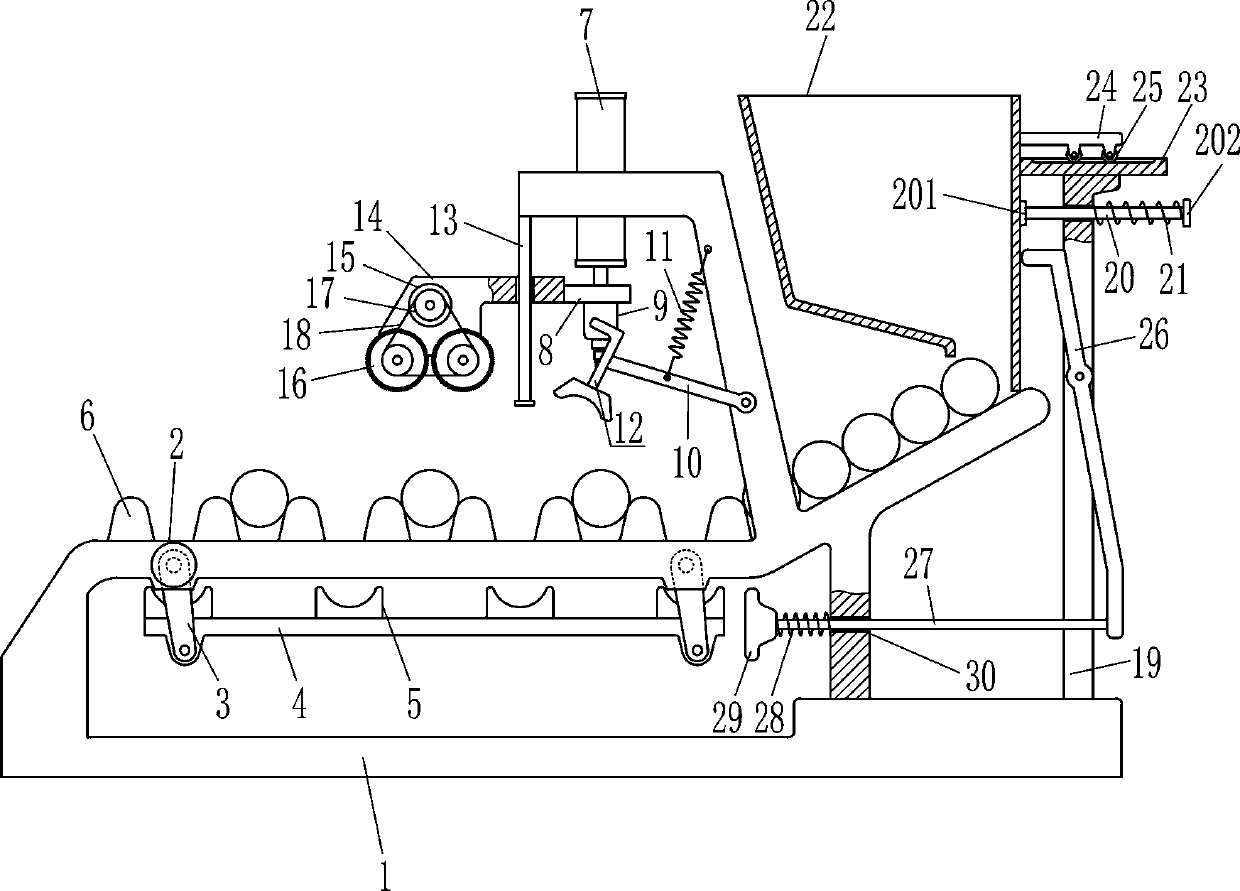

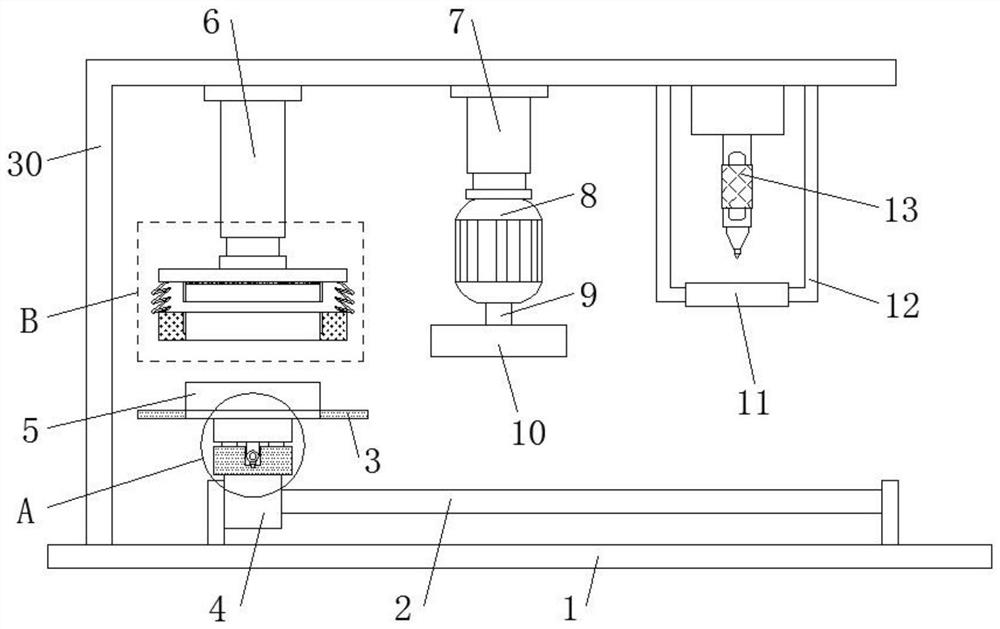

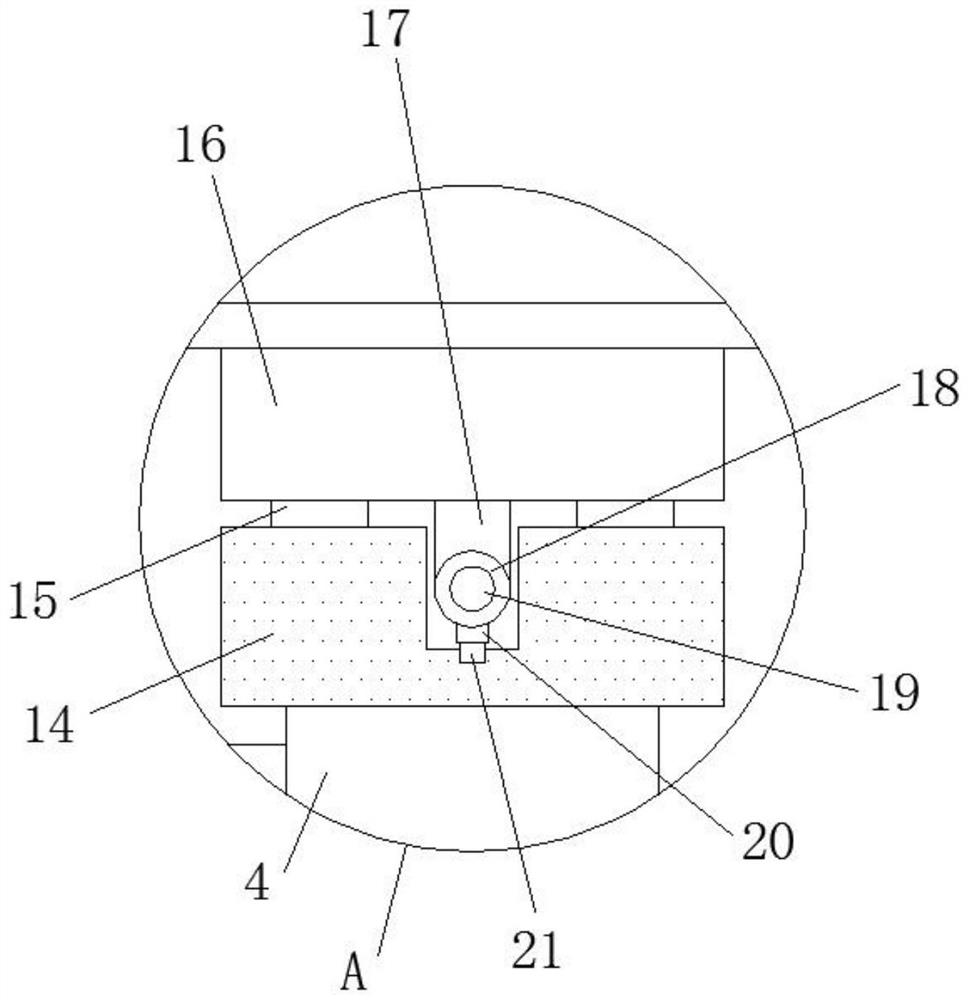

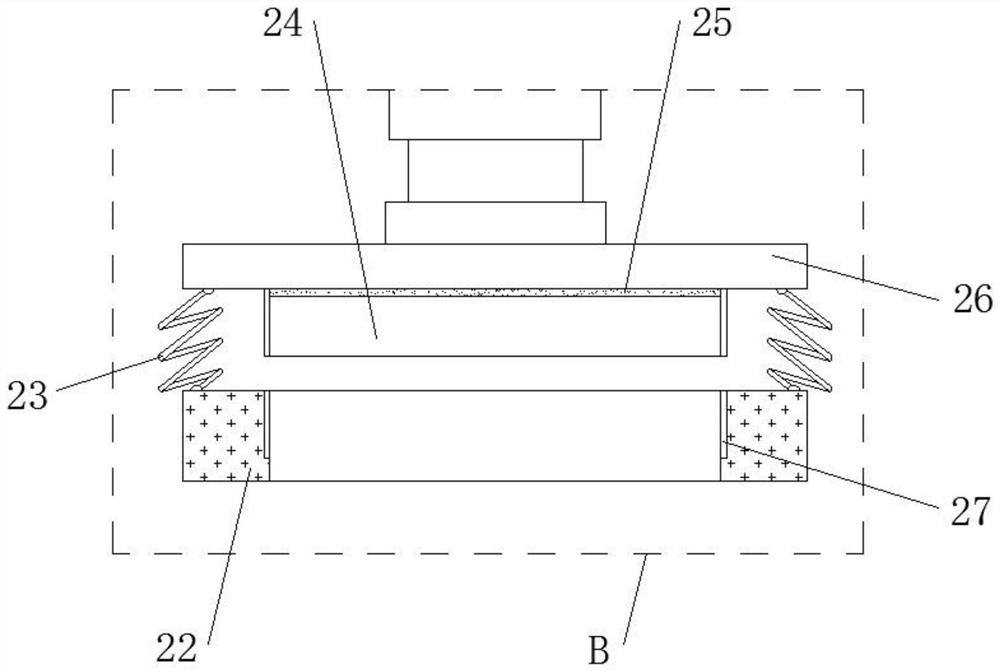

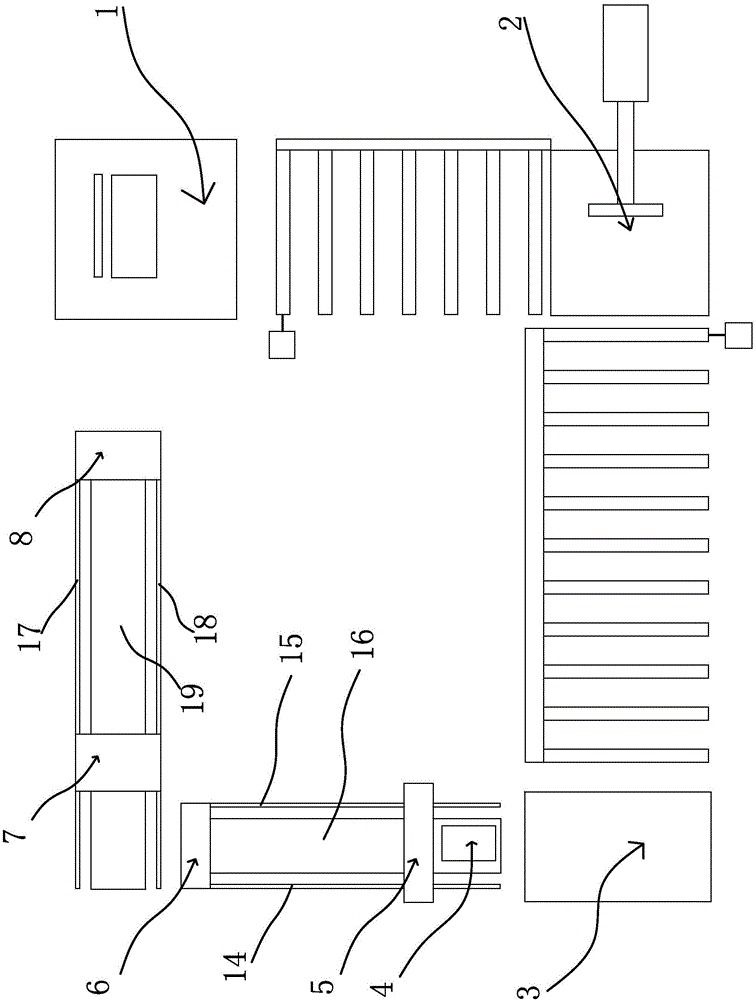

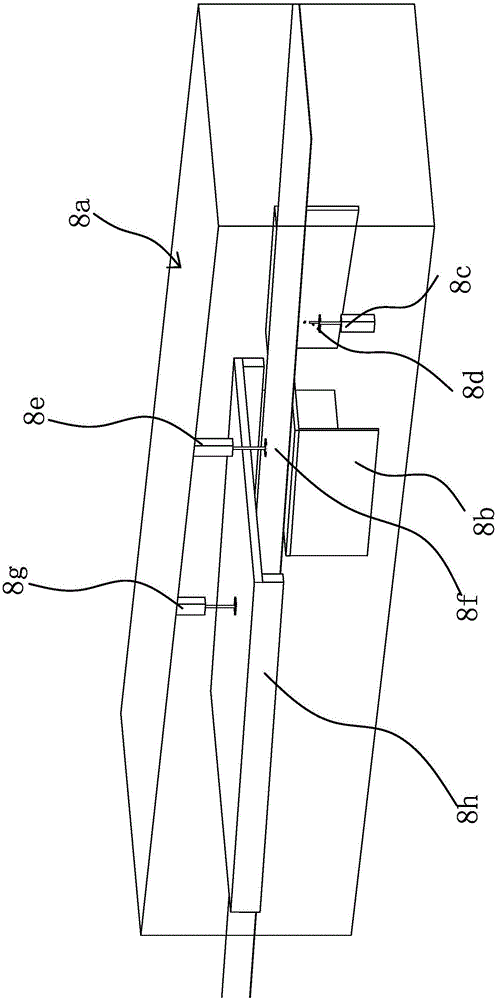

Processing equipment for lock latch type PVC floors

ActiveCN106272584AReduce manual cutting timeImprove work efficiencyMetal working apparatusEngineeringMechanical engineering

The invention provides processing equipment for lock latch type PVC floors, and solves the problem in the prior art that integral processing of the lock latch type PVC floor cannot be realized. The processing equipment for the lock latch type PVC floors comprises a machine frame, a cutting mechanism capable of cutting a PVC plate into the plurality of PVC floors comprises a cutting cabin, a cutting table, an upper clamping roll and a lower clamping roll and is arranged at one end of the machine frame, wherein both the cutting cabin and the cutting table are fixed on the machine frame; the upper clamping roll and the lower clamping roll are arranged on the machine frame; a mounting seat is fixed at the end part of a piston rod for pushing an air cylinder, and a cutting knife is fixed on the mounting seat; a plurality of conveying rolls I are arranged at the outlets of the cutting table, and a conversion mechanism capable of converting the PVC floors is arranged at the outlets of the conveying rolls I; a plurality of conveying rolls II are arranged at the outlet of the conversion mechanism, and an overturn mechanism is arranged at the outlets of the conveying rolls II; a slotting device for slotting the PVC floors is arranged on the rear side of the overturn mechanism. The processing equipment provided by the invention has the advantage that the advantage that the integral process of the lock latch type PVC floors is realized.

Owner:浙江海象新材料股份有限公司

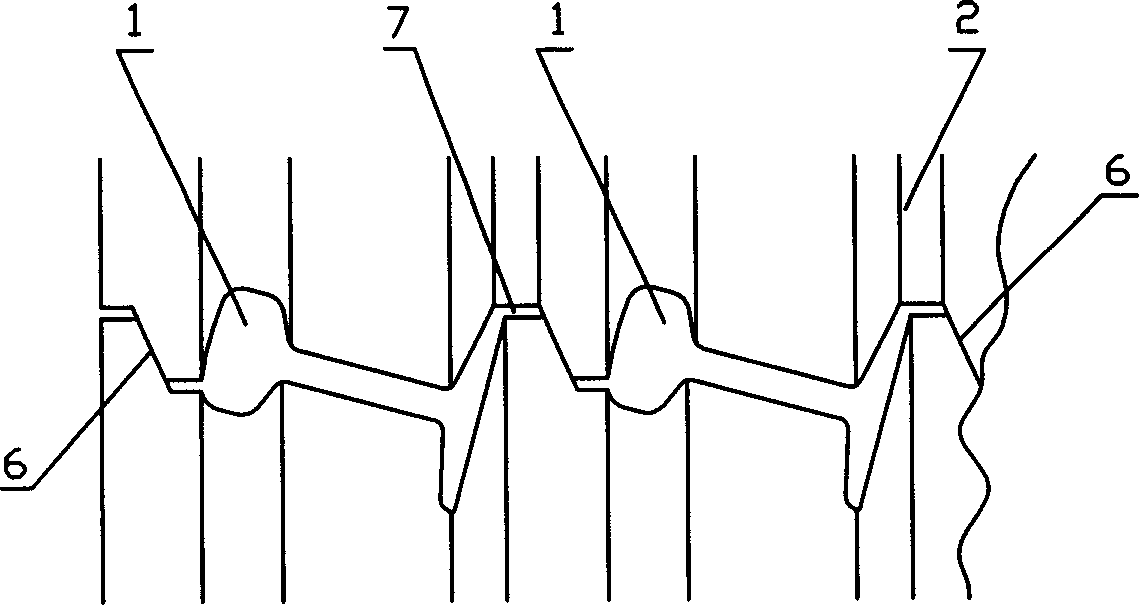

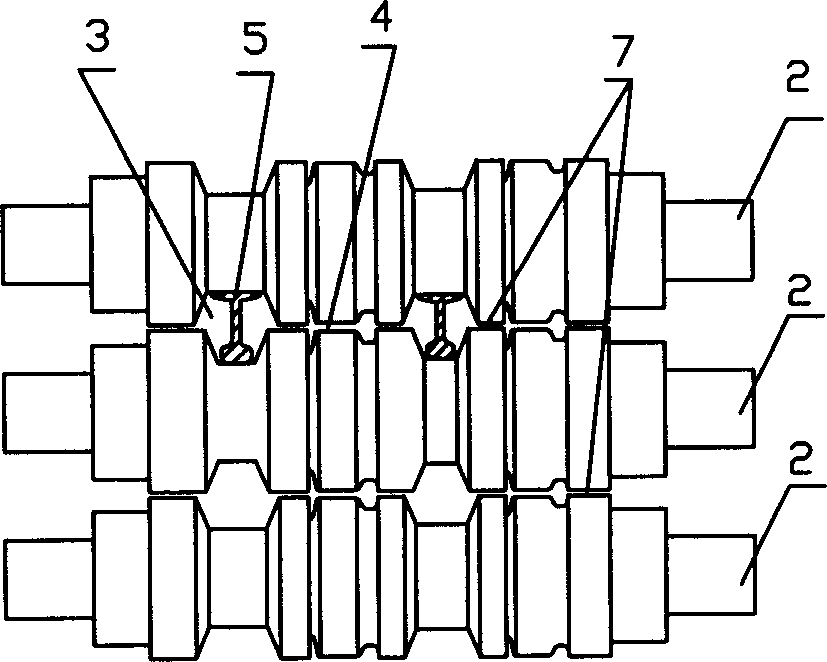

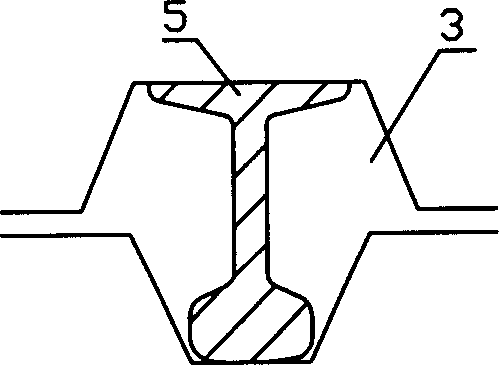

Process for rolling large-scale rails into miniature type rails and rollers therefor

InactiveCN1546247ALow powerLow running costRollsMetal rolling arrangementsEngineeringMechanical engineering

Owner:周燕雄 +1

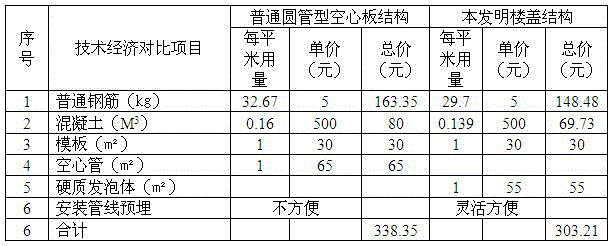

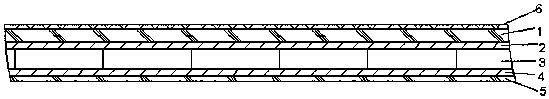

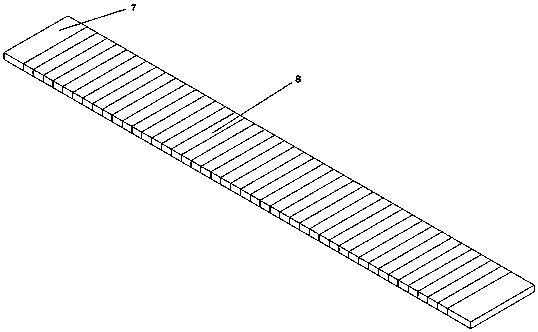

Construction method for light tube non-prestress hollow floor system

A construction method for a light tube non-prestress hollow floor system relates to the technical field of building construction. The method comprises procedures of foam composite plate manufacturing, template supporting and arranging and lower-layer stress rib binding, wire tube laying, reinforcing steel bar split head arranging, foam composite plate fixing, upper frame stud binding and concrete casting. The floor system is high in hollowness, and low in water absorption, and has superior heat insulation performance, and the construction method can lower floor system cost, facilitates subsequent ornament construction, and is comparatively suitable for two-way plates and prestress structures.

Owner:江苏扬州建工建设集团有限公司

Solid wood composite cork floor and making method thereof

InactiveCN107816193AAvoid deformationSolution to short lifeWood veneer joiningConstructions elementsSolid woodEngineering

The invention belongs to the technical field of wood floor, relates to a solid wood composite floor, and particularly relates to a solid wood composite cork floor and a making method thereof. The solid wood composite cork floor disclosed by the invention sequentially comprises a coating layer, an upper cork composite layer, an upper balancing layer, a middle layer, a lower balancing layer and a lower cork layer, wherein a solid wood composite material layer is arranged between the upper and lower cork layers, the lower surface of the coating layer is laminated to the upper surface of the uppercork layer, the lower surface of the upper cork layer is laminated to the upper surface of the upper balancing layer, the lower surface of the upper balancing layer is laminated to the upper surfaceof the middle layer, the lower surface of the middle layer is laminated to the upper surface of the lower balancing layer, and the lower balancing layer is laminated to the upper surface of the lowercork layer. The invention also discloses a making method of the floor. The invention solves the characteristic of easy deformation of solid wood, overcomes relatively poor mechanical property of cork,adopts a gluing manner of two times of assembly, and effectively solves the problems of poor quality and poor gluing property caused by deformation, lamination dislocation and compression performancedifference of different layers.

Owner:DAYA JIANGSU FLOOR

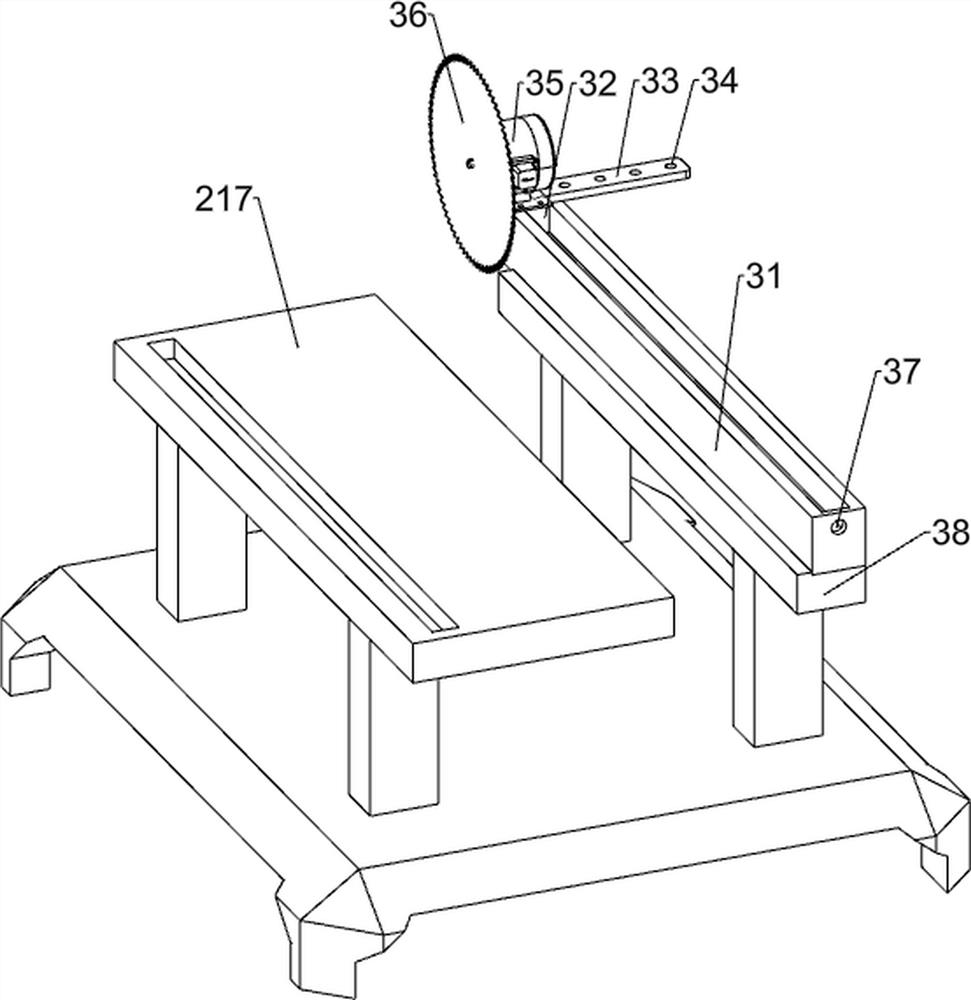

Bending forming process for V-shaped groove wood veneer

ActiveCN113103393AEasy to handleEasy to transportEdge grinding machinesWood treatment detailsWood veneerPulp and paper industry

The invention discloses a bending forming process for a V-shaped groove wood veneer, and relates to the technical field of basic processes. The method comprises the following steps that firstly, wood is processed, and processed wood is placed on a log cutting machine to be processed; secondly, wood slicing is conducted, specifically, the processed wood is placed on a slicing machine to be processed and sliced; thirdly, burr cleaning is conducted, specifically, the sliced wood is placed on a grinding machine to be processed and ground; fourthly, wood board cutting is conducted, specifically, the processed wood board is placed on a multi-functional wood planer, and the wood board is cut into sections and roughly planed through the multi-functional wood planer; and fifthly, polishing and grinding are conducted, specifically, the wood board obtained after section cutting is polished and ground, and the wood veneer is formed by the wood board. Through the arrangement of the log cutting machine, the unprocessed wood can be processed, and subsequent treatment of the device on the wood is facilitated.

Owner:DONGGUAN ZHONGJIN FURNITURE CO LTD

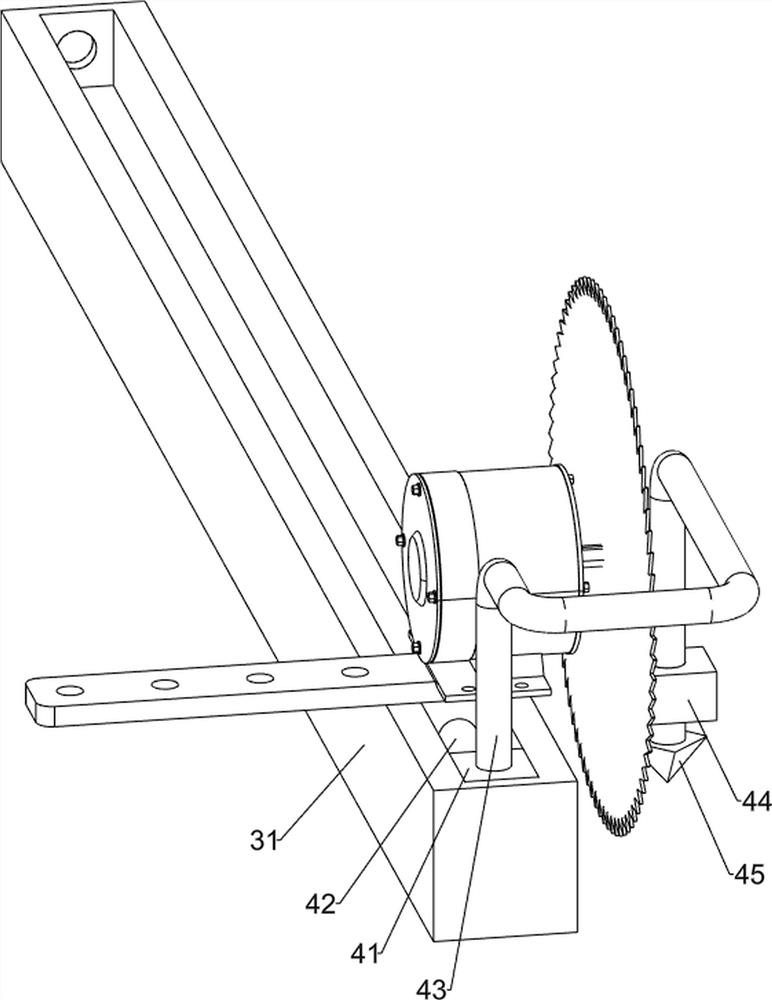

Wood cutting equipment for woodworking

InactiveCN112571547AEasy slottingEasy to cutProfiling/shaping machinesBark-zones/chip/dust/waste removalAgricultural engineeringWood cutting

The invention relates to cutting equipment, in particular to wood cutting equipment for woodworking. According to the wood cutting equipment for woodworking, raw material waste is not likely to be caused, and manual fixing of workers is not needed during cutting. According to the technical scheme, the wood cutting equipment for woodworking comprises a mounting frame, a clamping mechanism and a cutting mechanism; and the mounting frame is sued for supporting the whole equipment, the clamping mechanism is arranged on one side of the top of the mounting frame, and the cutting mechanism is arranged on the other side of the top of the mounting frame. Through the clamping mechanism, the worker can clamp wood of different lengths, then through the cutting mechanism, a cutting wheel can cut the wood, and through a grooving mechanism and a lifting mechanism, the worker can better groove and cut the wood.

Owner:刘钰

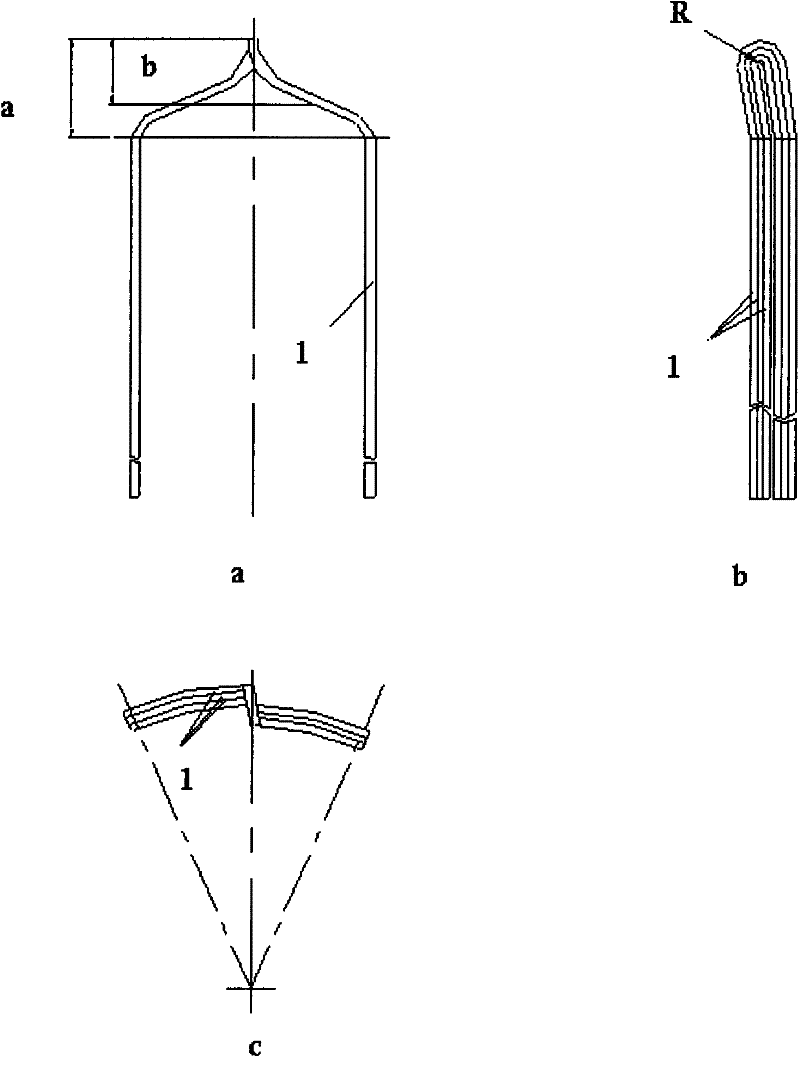

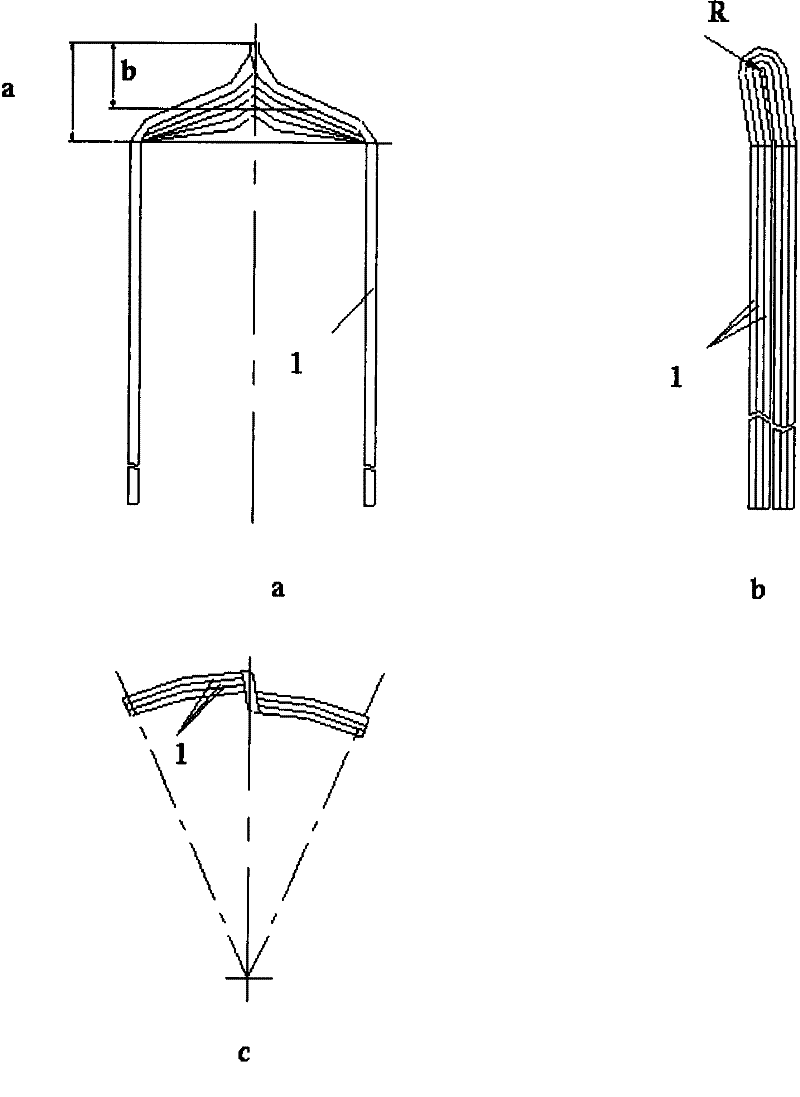

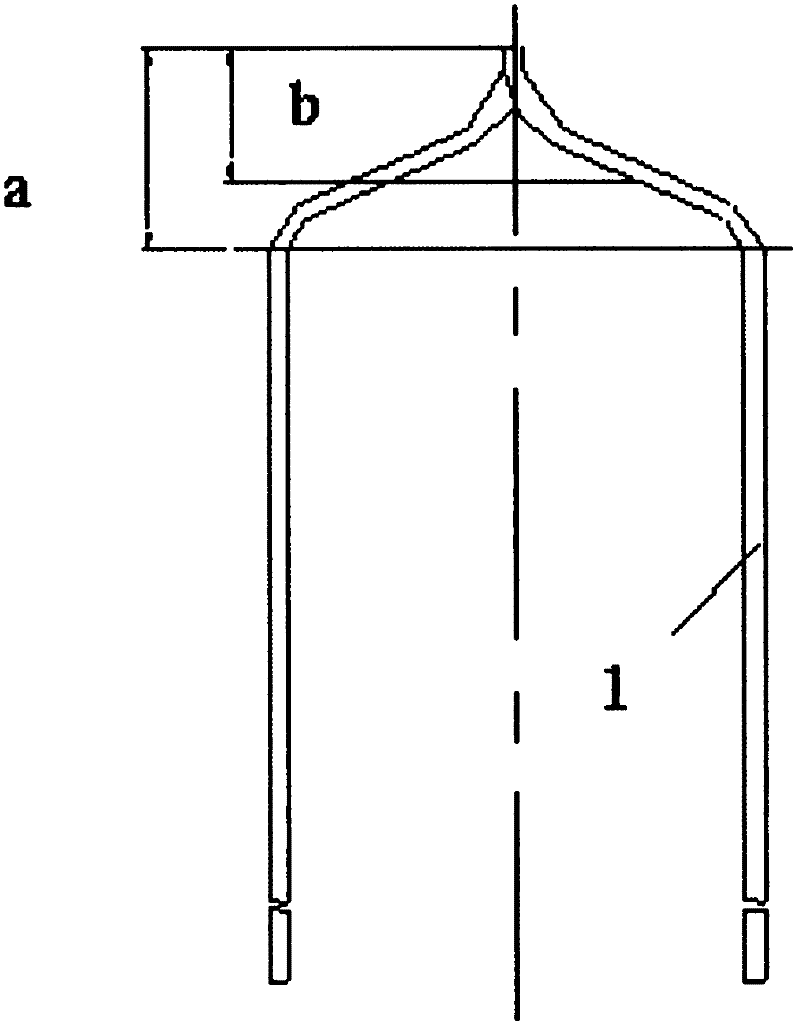

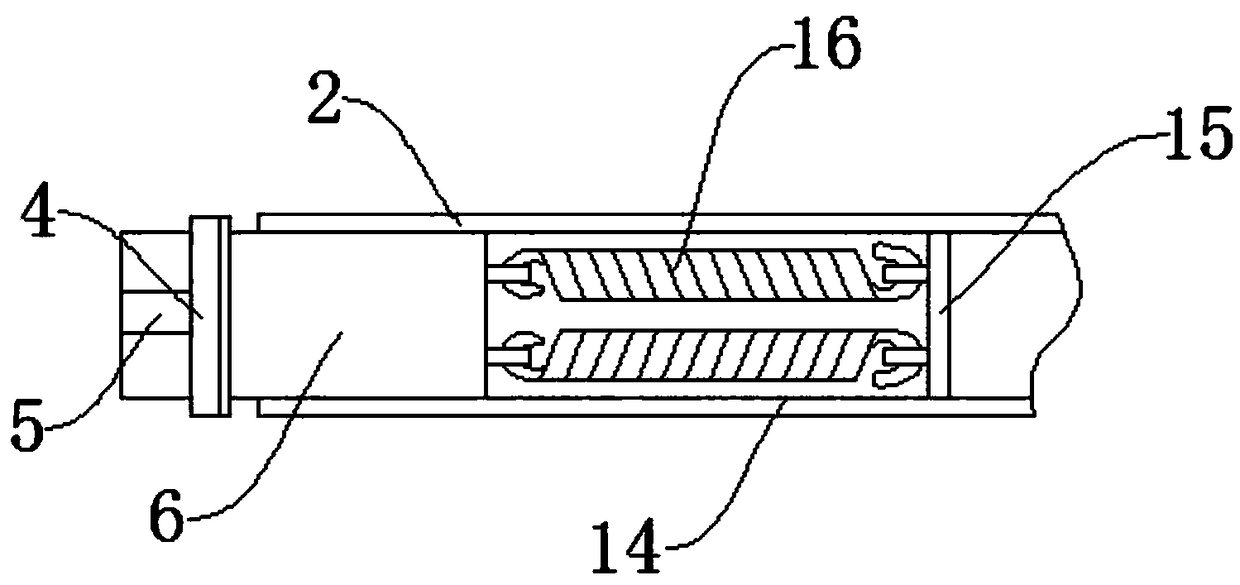

A method for forming multi-conductor parallel winding components

InactiveCN102299593AImprove insulation performanceImprove cooling effectManufacturing dynamo-electric machinesElectrical conductorEngineering

The invention relates to a forming method of a multi-conductor parallel winding element. The forming method provided by the invention is technically characterized by comprising the following steps: connecting N solid wires in parallel, and overlapping and fixing the middle parts of the solid wires by use of insulating tapes so as to form an integral wire; bending the integral wire into a U shape and dismantling the insulating tapes; and performing 1 / 2 overlapping by taking the bent part of the U shape of the integral wire as a center and performing drawing formation according to winding element chart requirements. The multi-conductor parallel winding element produced by the method provided by the invention has the advantages that the end socket of the element has no conductor separation phenomenon, the integral shape consistency is good and no conductor insulation damage is caused. When the stator / rotor winding of a motor is subjected to wire inserting, the element can be put into a groove easily, the size of a winding head after wire inserting is small, and the end sockets of the element are uniformly arranged in order, so that the insulation damage caused by squeezing and collision among conductors at the winding head of the motor winding being subject to wire inserting can be avoided, the turn-to-turn short circuit fault of the motor winding can be effectively prevented from being caused, and the insulating property of the motor winding and the heat dissipation performance of the winding head are improved.

Owner:SHAANXI AVIATION ELECTRICAL

Carton grooving device with carton bursting prevention function and grooving method

A carton grooving device with a carton bursting prevention function comprises a machine frame. A conveying belt which is used for conveying carton boards is arranged on the machine frame. A humidifying mechanism which is used for humidifying the carton boards is arranged above the conveying belt. A grooving mechanism which is used for grooving the carton boards is arranged at the tail end of the conveying belt. The humidifying mechanism comprises a humidifying wheel and a water feeding wheel. The humidifying wheel is installed above the conveying belt, and the water feeding wheel is installedover the humidifying wheel. A water feeding sponge strip is installed on the water feeding wheel. The distance between the humidifying wheel and the conveying belt is smaller than or equal to the thickness of each carton board, and the distance between the water feeding wheel and the humidifying wheel is smaller than the thickness of the water feeding sponge strip. The carton grooving device withthe carton bursting prevention function is reasonable in design and convenient to use. The carton boards are humidified and then grooved, the phenomenon that when the carton boards are grooved, the carton boards burst is effectively avoided, and therefore the reject ratio of cartons is greatly reduced, and normal production of the cartons is guaranteed.

Owner:连云港市振扬纸品有限公司

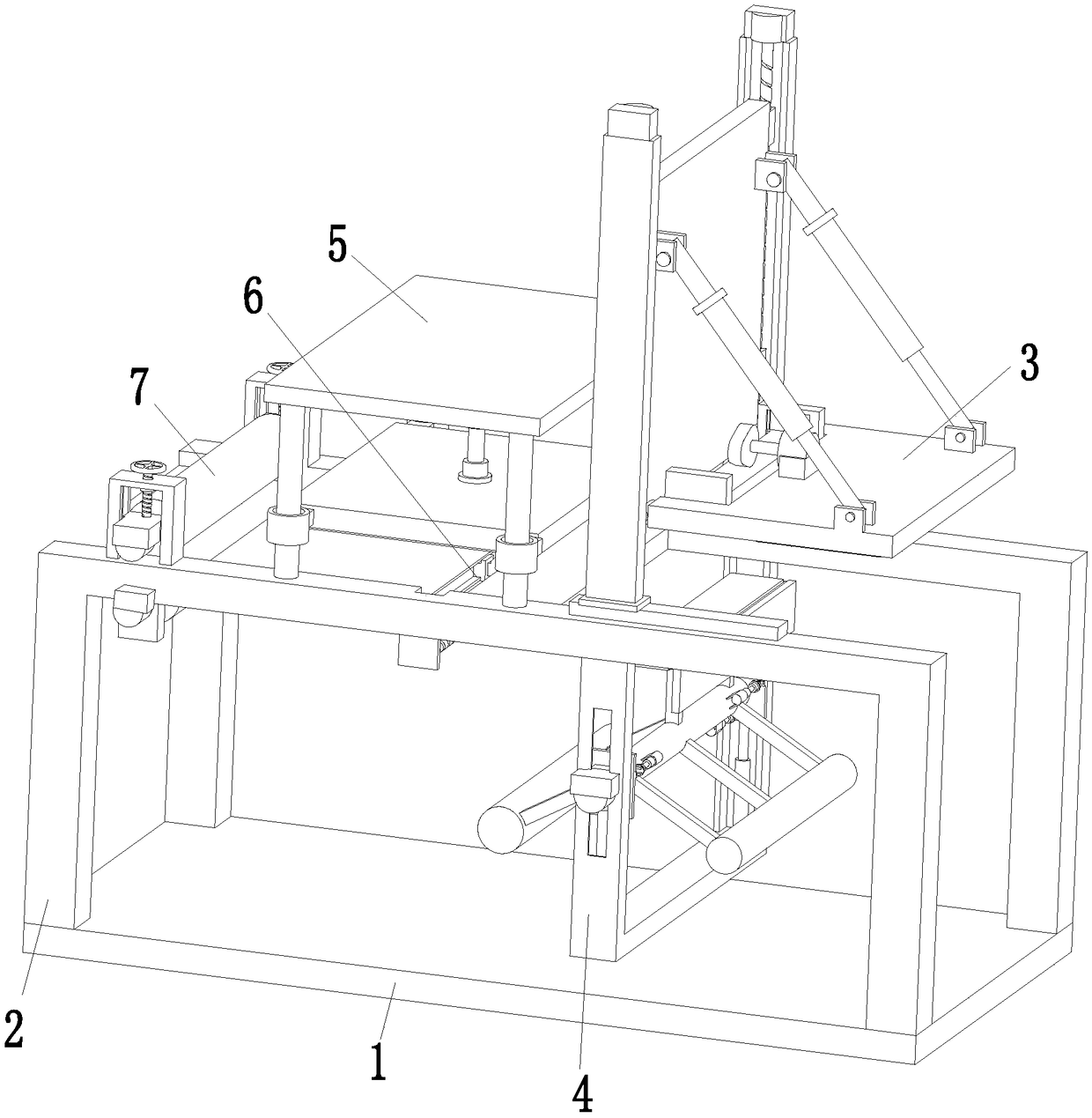

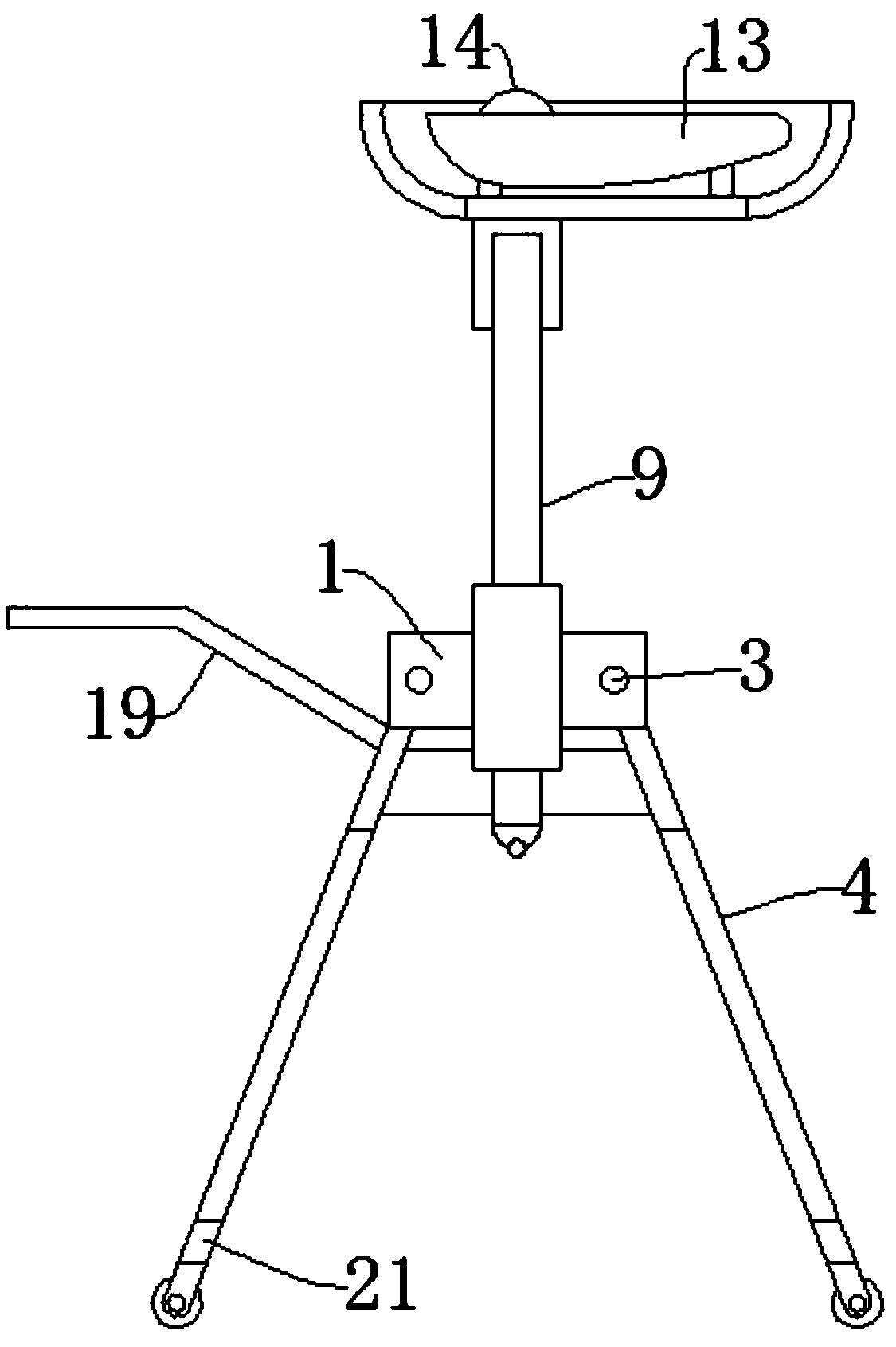

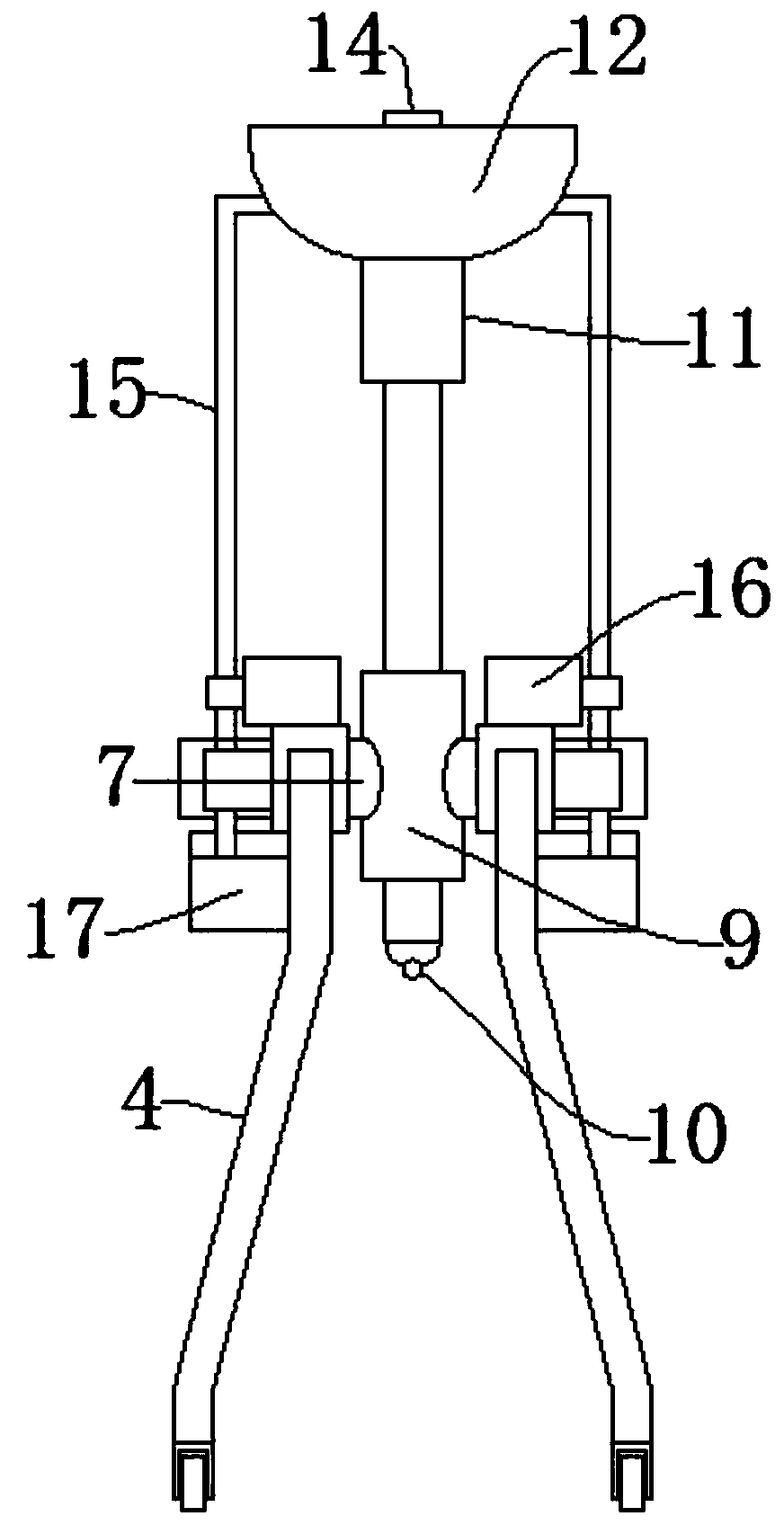

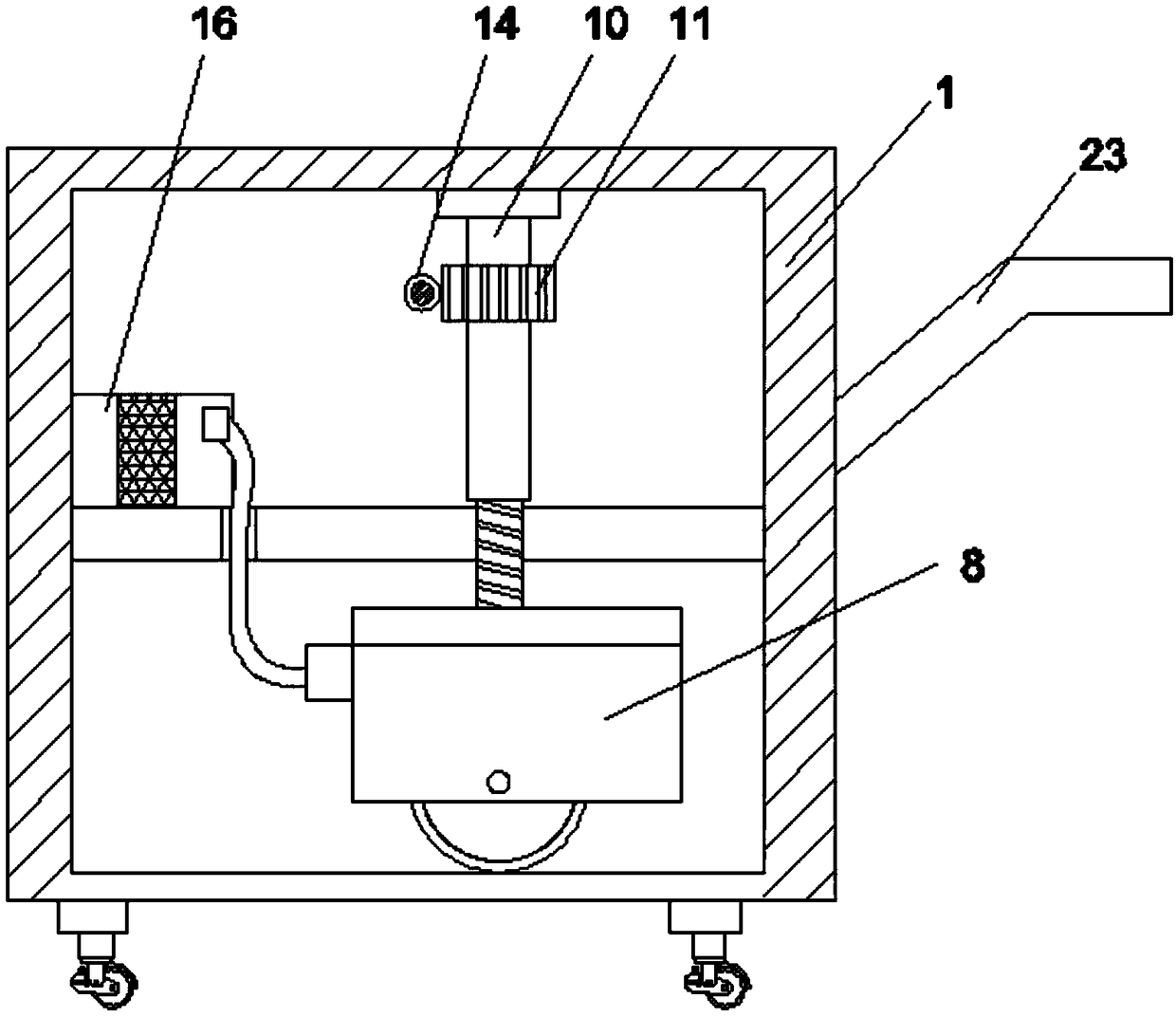

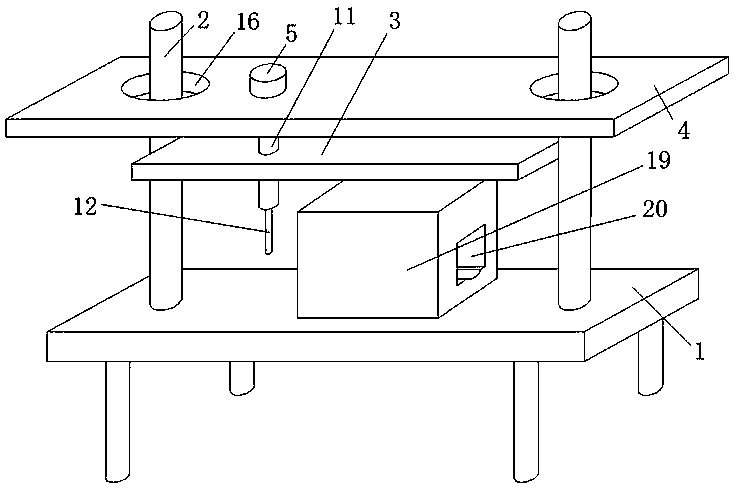

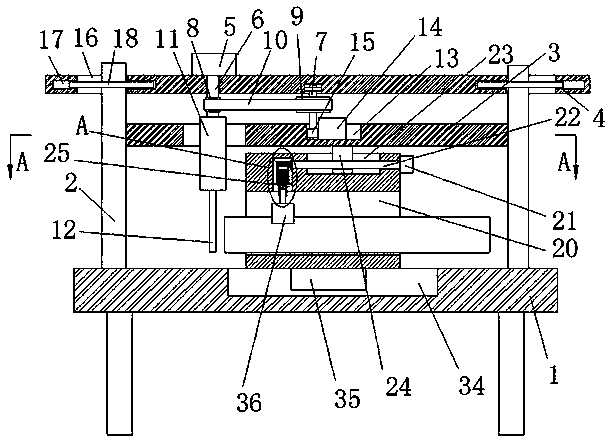

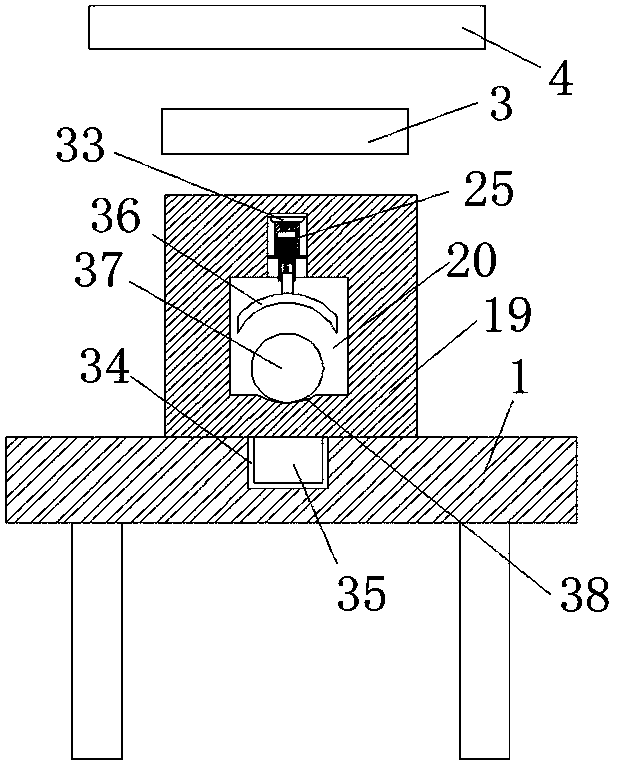

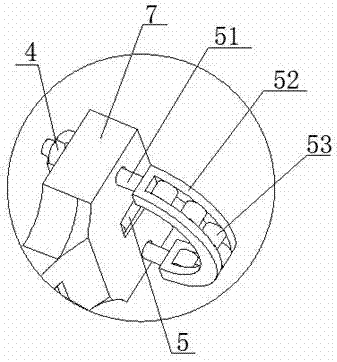

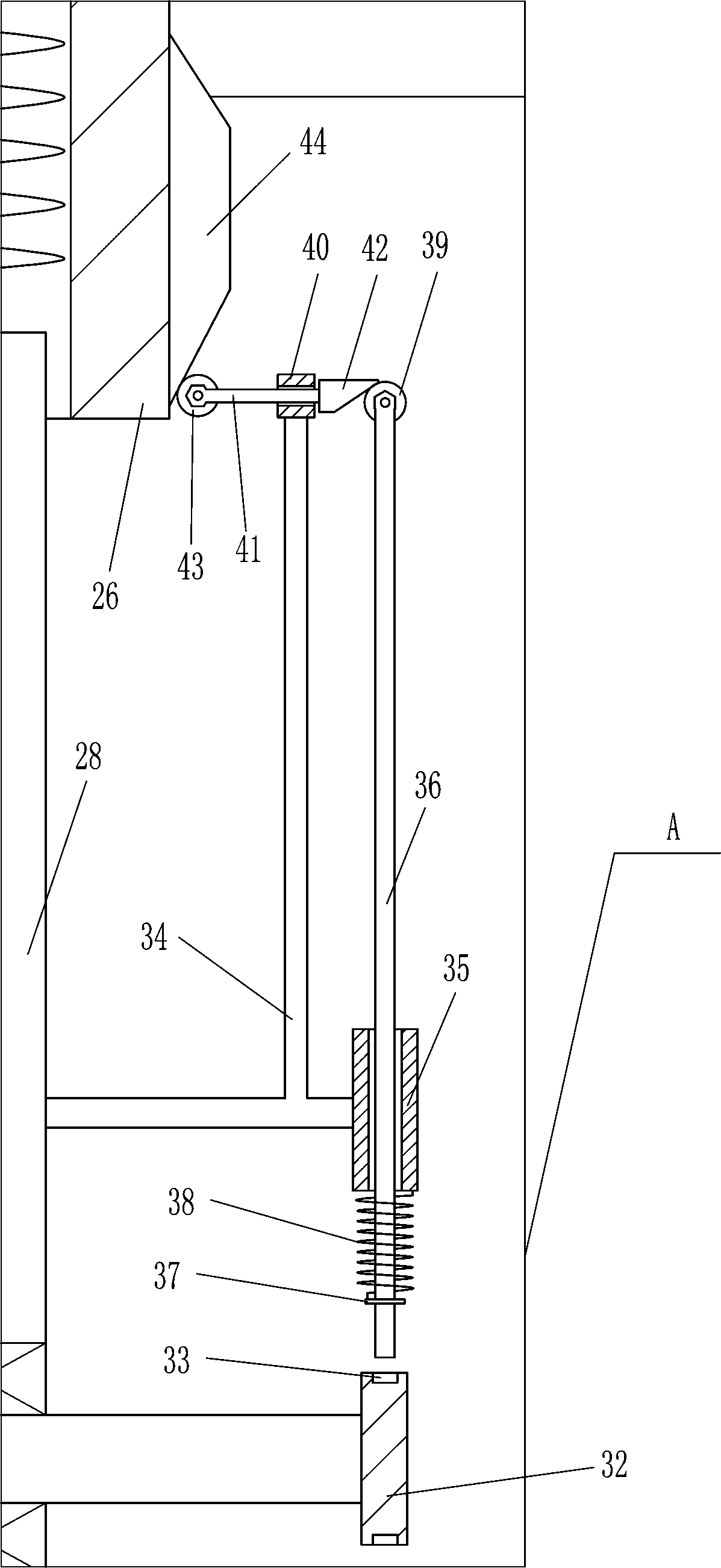

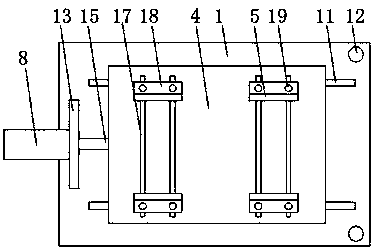

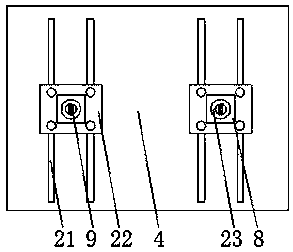

Log slotting device

InactiveCN109591126AFalling smoothlyEasy slottingWood mortising machinesWood slotting machinesEngineeringDrill

The invention relates to a slotting device, in particular to a log slotting device, and aims at providing a log slotting device capable of reducing labor intensity and preventing wood thorns from being stabbed into hands. According to the technical scheme, the log slotting device comprises a rack, a first motor, first oscillating rods, a bracket and the like. The left portion of the front side face of the rack is provided with the first motor capable of driving the first oscillating rods to rotate. The first oscillating rods are rotationally connected to the left side and the right side of thelower portion of the rear side face in the rack, and the rear end of an output shaft of the first motor penetrates through the front wall of the rack. A pressing device can be used for fixing log sothat a user can conveniently slot the log through an electric drill, accordingly, the user does not need to hold the electric drill for log slotting, and the labor intensity of the user can be lowered. Friction wheels can rotate and make contact with the log for grinding, and therefore the situation that when the user carries the log, the wood thorns on the log are stabbed into the hands of the user, and inconvenience is brought to people during log carrying is avoided.

Owner:肖勇斌

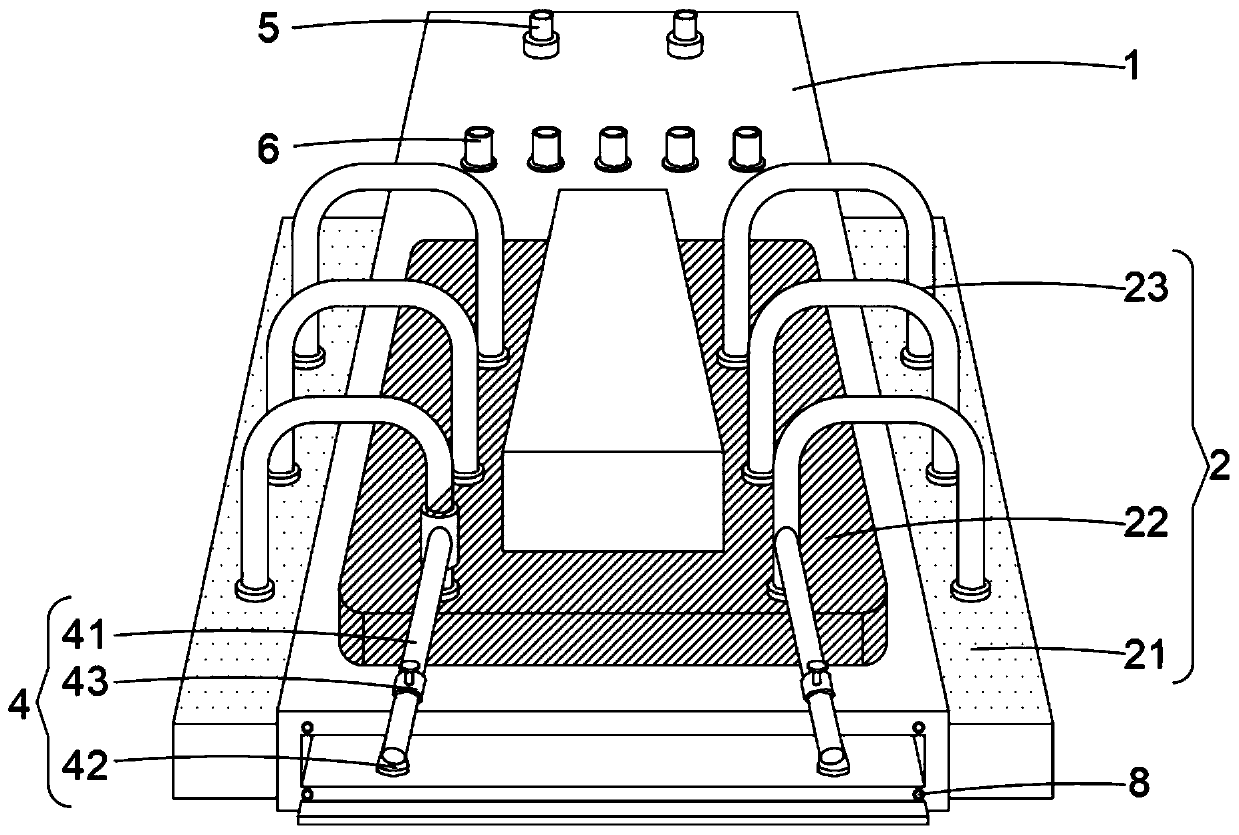

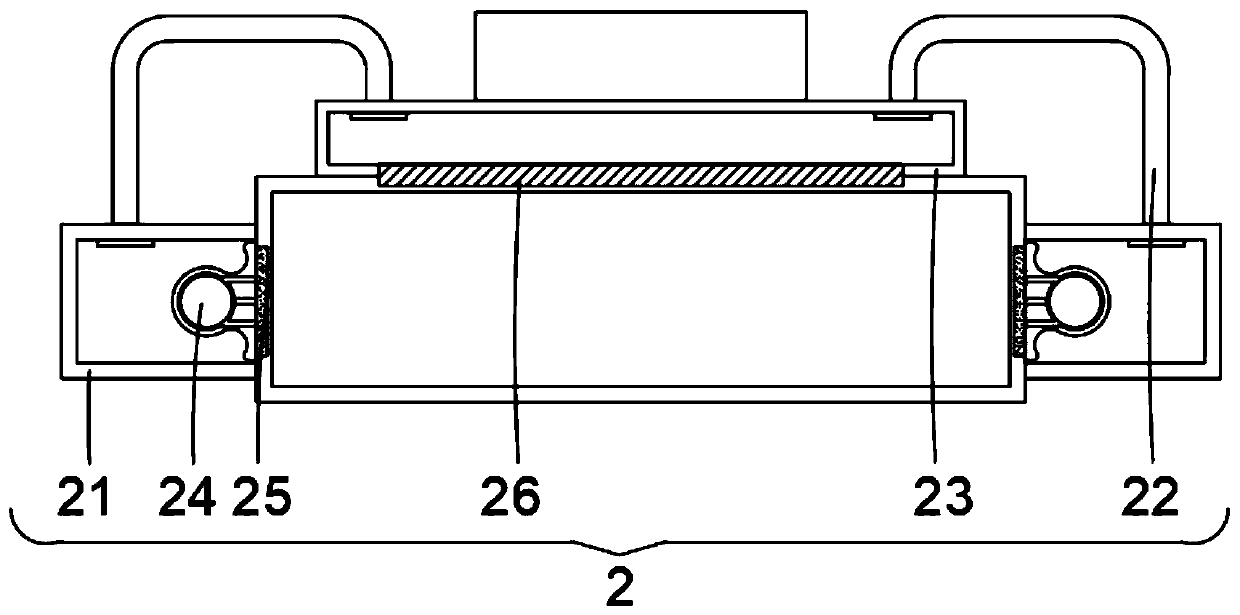

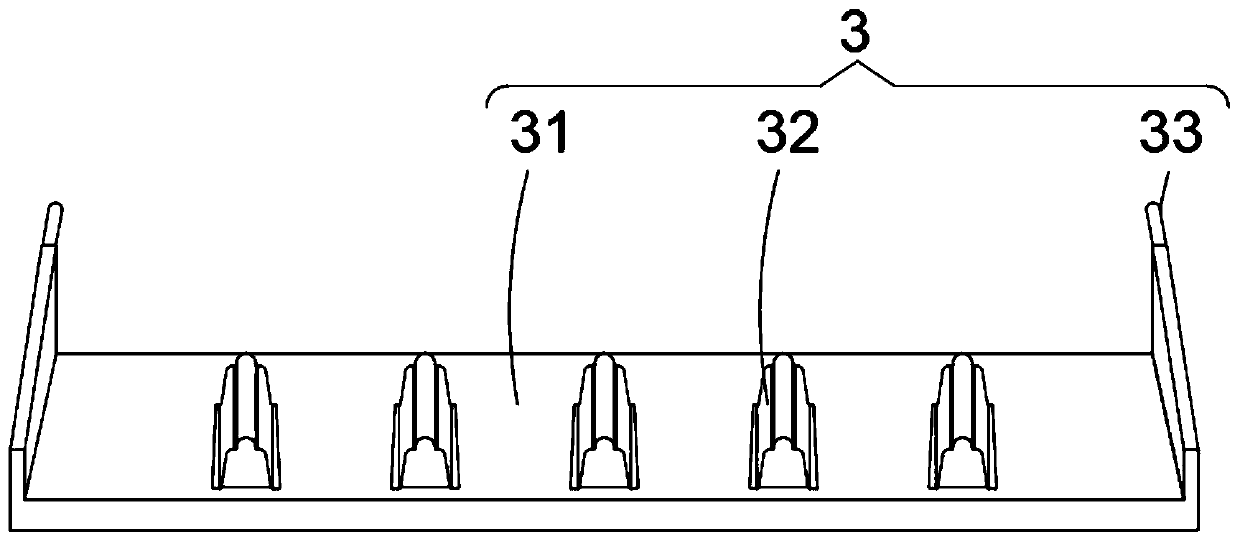

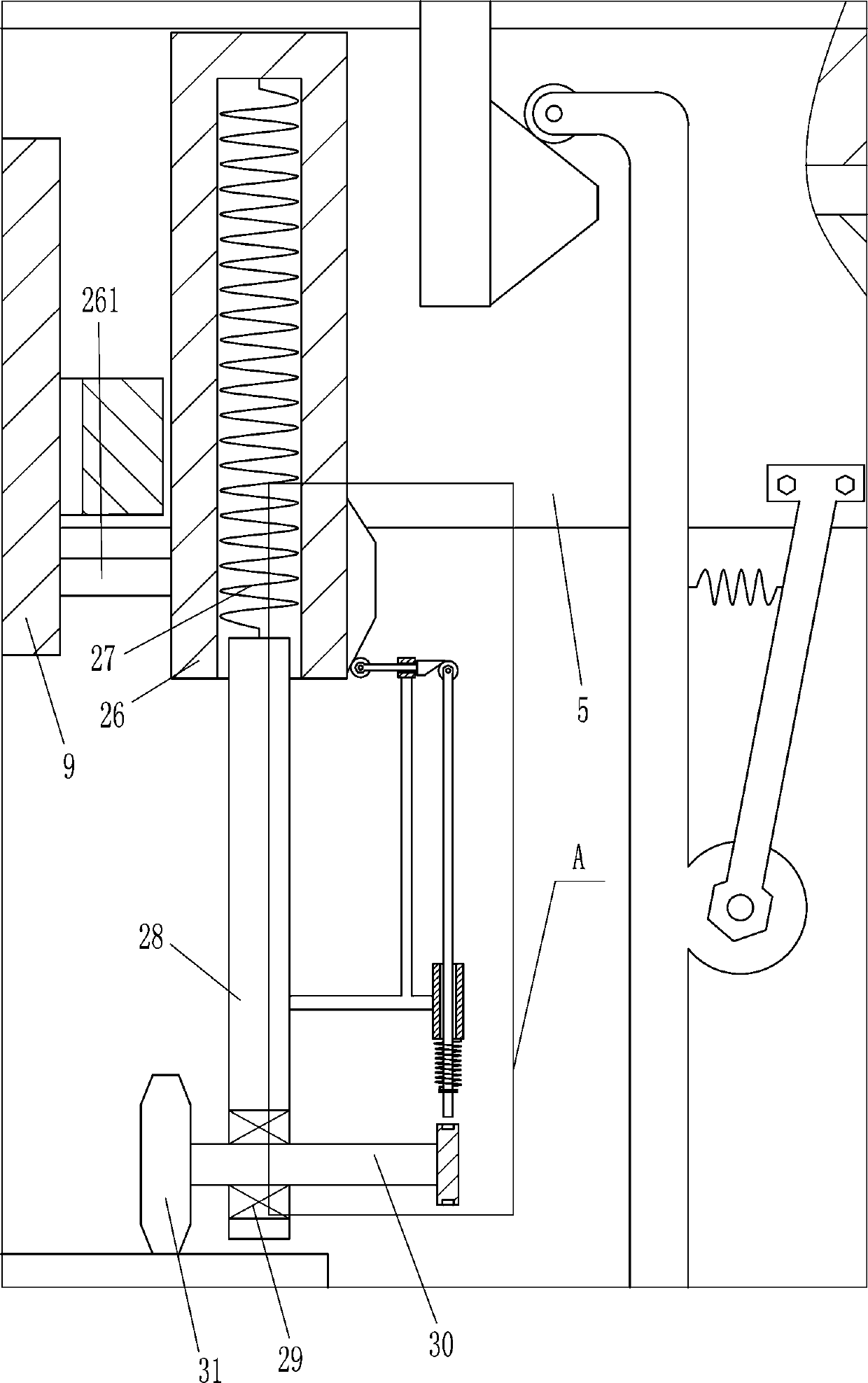

Intelligent bending machine for aluminum-plastic panel

The invention relates to an intelligent bending machine for an aluminum-plastic panel. The intelligent bending machine comprises a bottom plate, two U-shaped supporting frames, a bending device, a diedevice, a pressing device, a slotting device and a feeding device. The two U-shaped supporting frames are installed at the upper end of the bottom plate, the bending device is installed at the rightupper ends of the U-shaped supporting frames, the die device is installed at the right lower ends of the U-shaped supporting frames, the slotting device is installed in the middles of the U-shaped supporting frames, the pressing device is installed at the upper end of the slotting device, and the feeding device is installed at the left ends of the U-shaped supporting frames. By means of the intelligent bending machine, the problems that at present, aluminum-plastic panels are conveyed manually in the bending process of the aluminum-plastic panels, the manual conveying efficiency is low, the slotting depth can not be controlled in manual slotting, the manual bending effect is poor, the bending precision is low, the aluminum-plastic panels can not be accurately bent to have needed angles, arcs are not likely to be formed when arc bending is carried out on the aluminum-plastic panels, dies are not convenient to change and the like are solved.

Owner:安徽坤源铝业有限公司

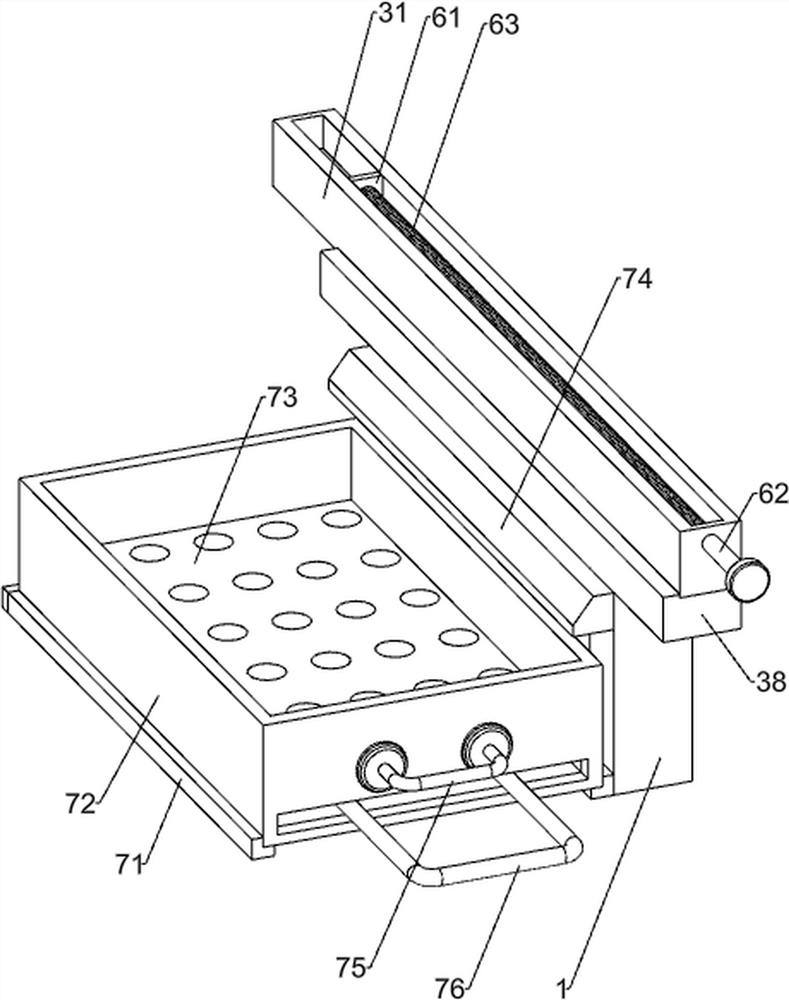

Device and process for packaging UVC LED chip on wafer

ActiveCN111640695AEasy to GrindQuick cutSolid-state devicesSemiconductor/solid-state device manufacturingWaferStructural engineering

The invention discloses a device and process for packaging a UVC LED chip on a wafer. Directed at the problem that a wafer line is prone to being damaged, the invention puts forward the following scheme that: the device comprises a bottom plate and an L-shaped frame, the L-shaped frame is fixed to the outer wall of the top of the bottom plate through bolts, the L-shaped frame is inverted, an electric sliding rail is fixed to the outer wall of the top of the bottom plate through bolts, a sliding block is slidably connected to the outer wall of one side of the electric sliding rail, a supportingplatform mechanism is arranged on the outer wall of the top of the sliding block, a first electric telescopic rod is fixed to one side of the inner wall of the top of the L-shaped frame through bolts, a film covering mechanism is arranged at one end of an extension rod of the first electric telescopic rod, and a second electric telescopic rod is fixed to a position, close to the first electric telescopic rod, of the inner wall of the top of the L-shaped frame. According to the invention, a paster and a wafer are rapidly laminated and cut, and the surface of the wafer is completely covered after the paster and the wafer are laminated, thereby facilitating the subsequent wafer grinding, avoiding the damage of a wafer line, and facilitating the slotting and packaging of the wafer.

Owner:SHENZHEN CHANGFANG GRP CO LTD

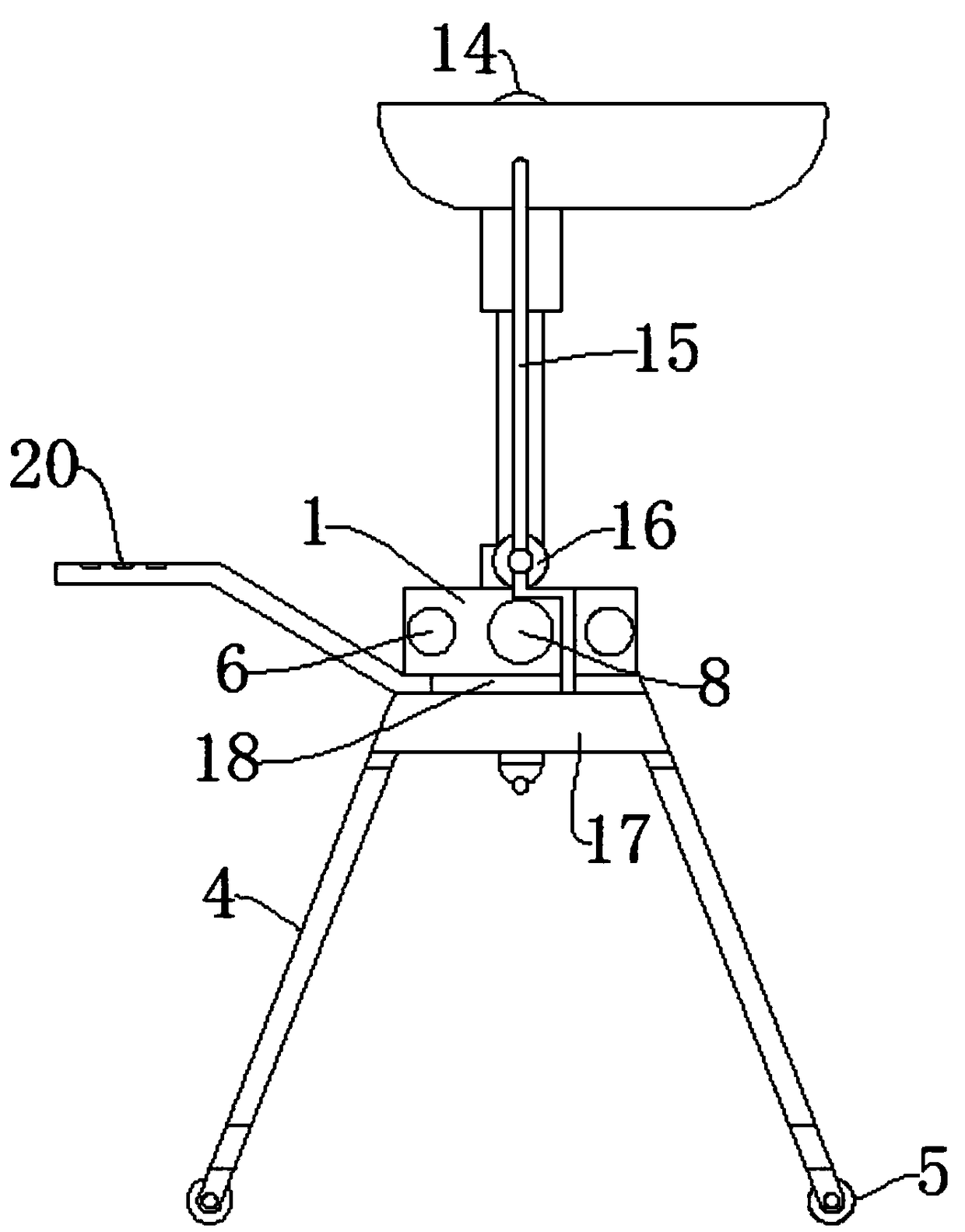

Hydroelectric slotting machine for indoor decoration

ActiveCN108972909ASave yourself the hassle of underliningImprove practicalityWorking accessoriesStone-like material working toolsEngineeringFuselage

The invention discloses a hydroelectric slotting machine for indoor decoration. The hydroelectric slotting machine comprises an electric-hydraulic pusher and is characterized in that two axles are symmetrically mounted on the front side and the back side of the body of the electric-hydraulic pusher, a mounting plate is mounted at one end of each axle in a rolling manner, mounting grooves are arranged in two ends of the lower surface of each mounting plate, mounting shafts are mounted in the mounting grooves in a rolling manner, support legs are fixedly mounted to the mounting shaft, and universal wheels are hinged to the lower ends of the support legs; stepping motors are fixedly mounted on the front sides of the mounting plates, and the output shafts of the stepping motors are fixedly connected with one ends of the mounting shafts; gear motors are fixedly mounted on the front sides of the mounting plates, and the output shafts of the gear motors are fixedly connected with one ends ofthe axles. The hydroelectric slotting machine has the advantages that wall top slotting can be performed by marking the floor, trouble caused by wall top marking is avoided, time and labor can be saved, and good practicality is achieved.

Owner:山东腾圣市政工程有限公司

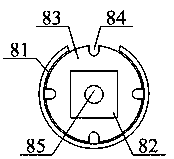

Dry type ground heating plate and dry type ground heating system

The invention provides a dry type ground heating plate. The plate comprises a body, wherein an arc slot, at least one transverse slot and at least one longitudinal slot are formed on the upper surface of the body, transverse slots and longitudinal slots are intersected vertically and are communicated, one end of the arc slot is communicated with transverse slots, the other end of the arc slot is communicated with longitudinal slots, the arc slot is tangential to transverse slots and longitudinal slots, and the arc slot, transverse slots and longitudinal slots are formed on the upper surface of the body in advance. During usage, a ground heating tube is coiled in the arc slot, transverse slots and longitudinal slots, the installation can be completed, and the paving and the installation are facilitated. The invention also provides a dry type ground heating system. The paving and the installation are facilitated.

Owner:马占荣

Slotting device for producing antistatic aramid composite floor and method of using slotting device

InactiveCN109203133ASimple structureEasy to fixWood mortising machinesWood slotting machinesHobbingEngineering

The invention discloses a slotting device for producing an antistatic aramid composite floor and a method of using the slotting device. The slotting device comprises a slotting knife and a base, wherein a lower mounting groove is formed inside the lower end of the base, an inner fixing plate is disposed in the lower mounting groove, a return spring is disposed on one side of the inner fixing plate, and a sliding block is disposed on one side of the return spring. A handle is disposed above the outer end of the sliding block, a support arm is disposed below the outer end of the sliding block, and a side splint is disposed at an end of the support arm. An anti-slip mat is disposed on a side of the side splint, and a rack is disposed above the base. A gear hobbing is disposed above the rack,a horizontal moving seat is disposed above the gear hobbing, and a horizontal moving motor is disposed on one side of the horizontal moving seat. The beneficial effects include that 1. the structure is simple, the installation and fixing are convenient, and the transportation and use are convenient; 2. the slotting depth and length can be precisely controlled through control by a servo motor, andslotting at different positions on the floor is convenient.

Owner:鑫材泰克(天津)复合材料有限公司

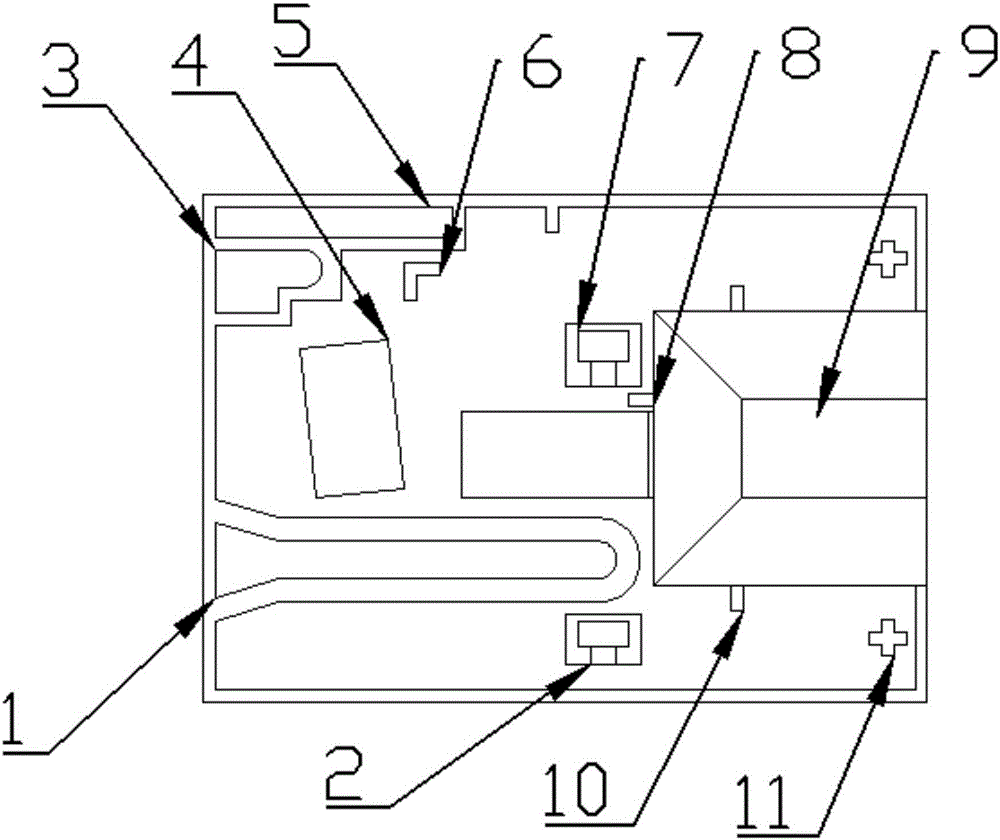

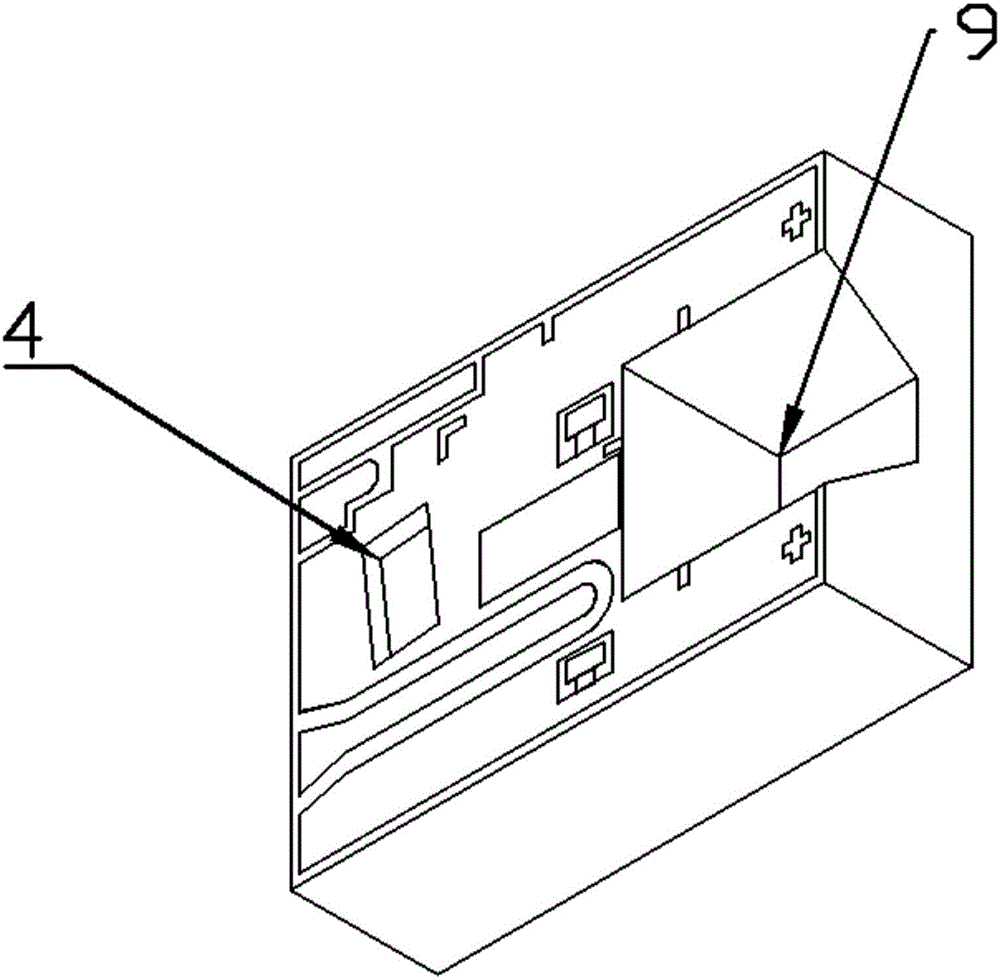

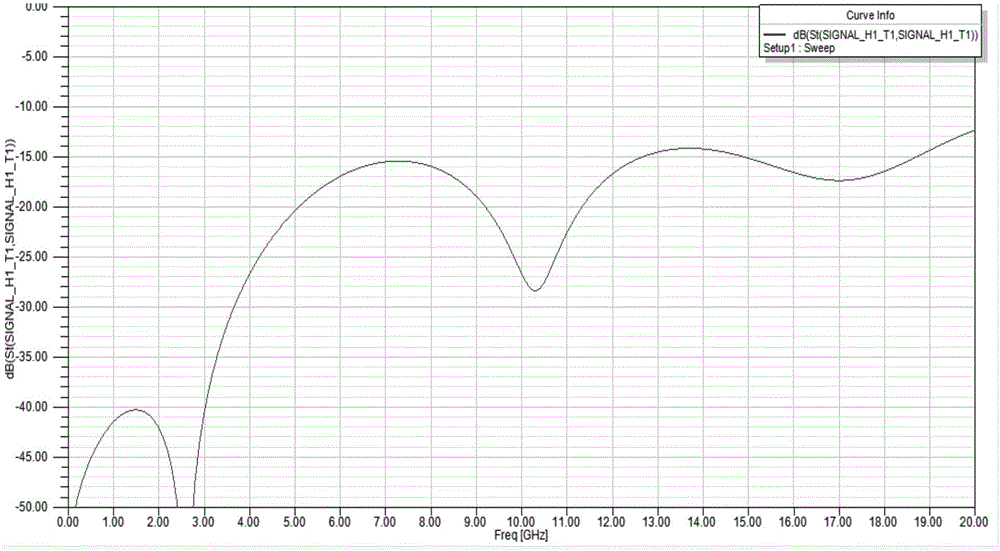

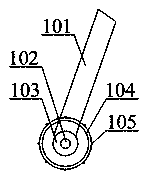

10G miniaturized EML laser heat sink

InactiveCN106785889AGood thermal conductivityHigh precision photolithographyLaser detailsSemiconductor laser structural detailsHeat sinkTransmission line

The invention relates to the field of optical devices, in particular to a design of a 10G miniaturized EML laser heat sink. The invention provides the 10G miniaturized EML laser heat sink, which comprises a silicon substrate, wherein a backlight monitoring assembly placement groove, a V-shaped notch, a bonding pad, a high-frequency transmission line and a thin-film circuit are arranged in / on the silicon substrate; the backlight monitoring assembly placement groove is positioned in a rear position of a laser chip; the V-shaped notch is used for holding a lens, and is positioned in a right ahead position of the laser chip; the bonding pad is used as a preserved bonding pad for gold wire binding; the thin-film circuit is used for regulating the high-frequency performance of the laser chip. The design of the laser heat sink has the advantages that on the basis of guaranteeing the total electric performance of the laser, the existing EML laser heat sink is optimized; a process encapsulation platform is favorably simplified; the attaching mounting work procedure with multiple materials and complicated process is simplified; the design belongs to a heat sink design scheme with the advantages of exquisite and ingenious structure, obvious effect, simple process and low cost.

Owner:DALIAN CANGLONG OPTOELECTRONICS TECH

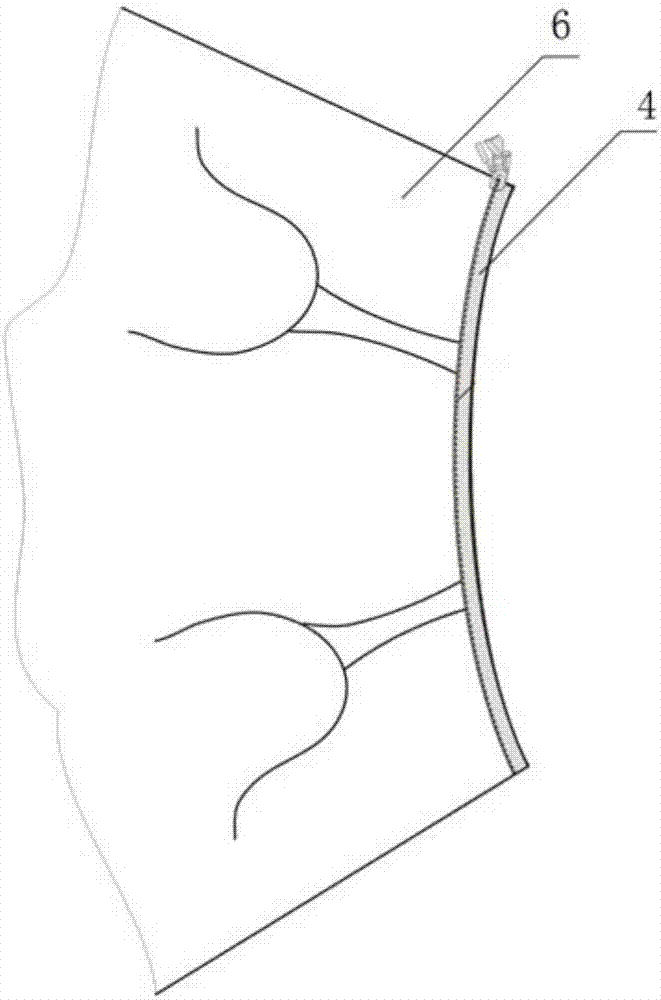

Template pull tube device for adhering woven tape to rear neckline

The invention relates to a template pull tube device for adhering a woven tape to a rear neckline. The template pull tube device is arranged at the lower portion of a needle head of a double-needle machine and comprises a bottom layer plate, a face layer plate and a middle interlayer arranged between the bottom layer plate and the face layer plate, wherein the middle interlayer is provided with a positioning groove for the woven tape to be placed, the positioning groove is equal to the woven tape in width, the woven tape is put in the positioning groove in work, a rear neckline cut-part is put at the upper portion of the face layer plate, and the woven tape is sewed and adhered to the lower portion of the rear neckline cut-part through the needle head of the double-needle machine. Compared with the prior art, the middle interlayer is made of a foam material, the cost is low, grooving is convenient, convenience is brought to woven tape placement, the bottom layer plate and the face layer plate are glass plates, are transparent and visual, facilitate observation of the situation of the woven band in the positioning groove and can be adjusted in time, the woven band is freely pulled in the positioning groove, does not easily produce tensile deformation, is completely matched with the rear neckline and is not easily sewed crooked, and accordingly the product quality is ensured.

Owner:劲霸男装(上海)有限公司

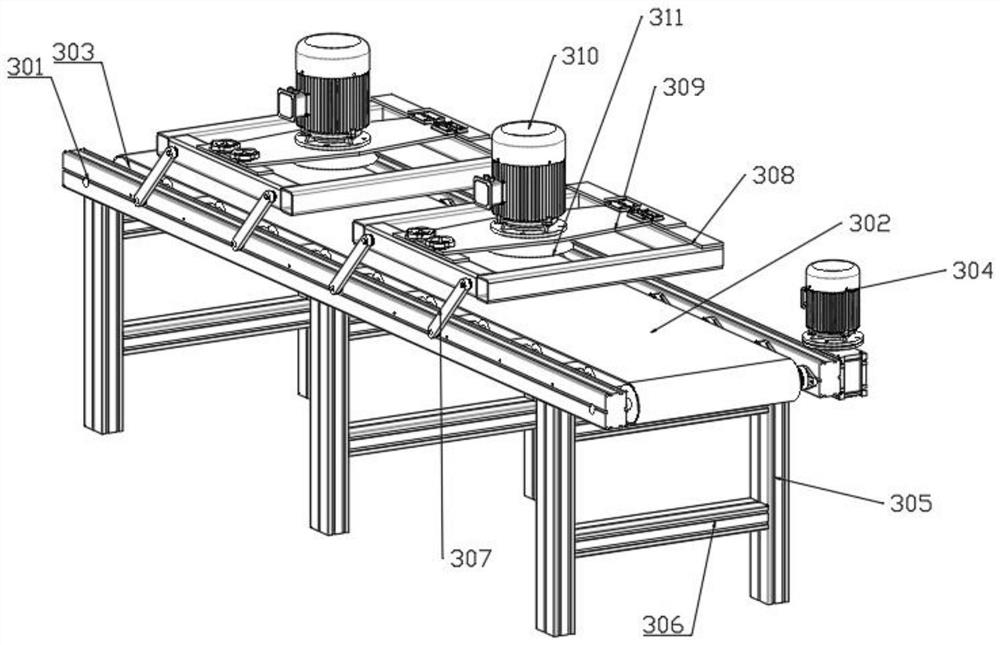

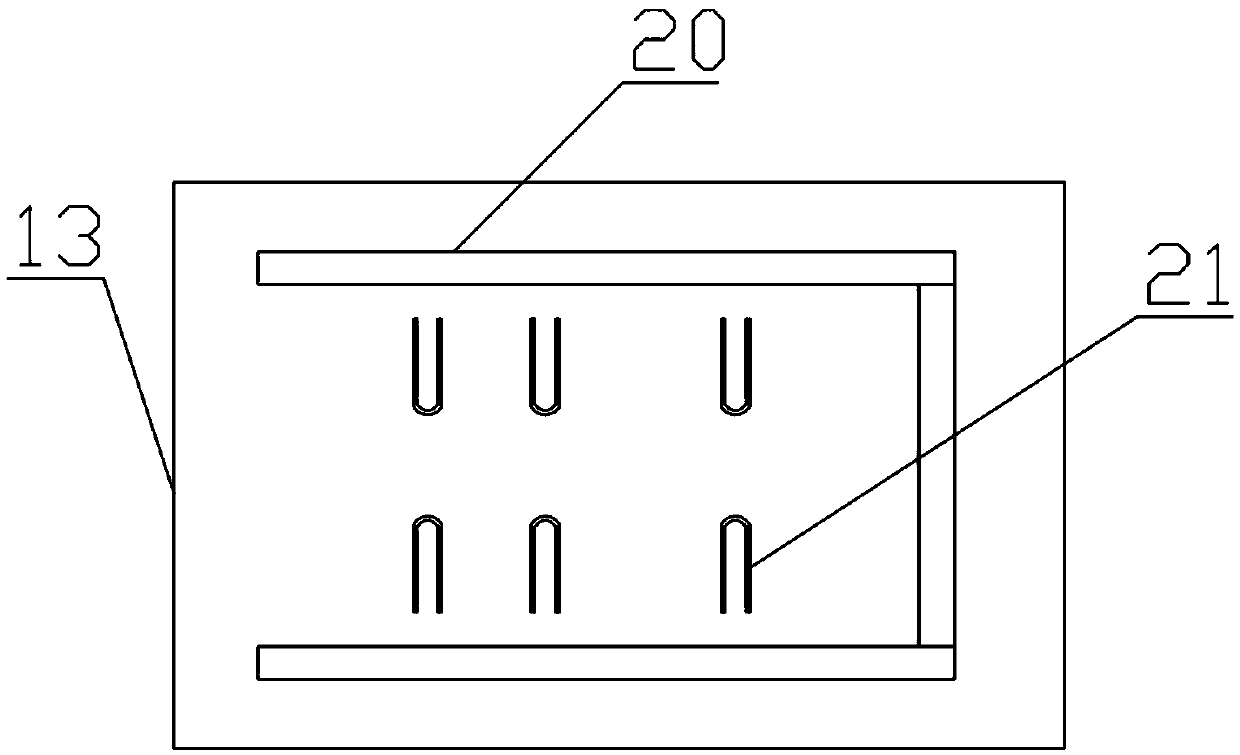

Latch PVC floor grooving device

ActiveCN106313162AEasy slottingHigh precisionDirt cleaningMetal working apparatusEngineeringMechanical engineering

The invention provides a latch PVC floor grooving device, and solves the problem of inaccurate grooving in the prior art. The latch PVC floor grooving device comprises a frame; a side correcting mechanism capable of vertically straightening a PVC floor is arranged at one end of the frame; the side correcting mechanism includes a guide rail 1 and a guide rail 2 fixed on the frame in parallel; a conveying belt 1 capable of driving the PVC floor to forwards move is arranged between the guide rail 1 and the guide rail 2; a side pressing structure capable of pressing the PVC floor on the conveying belt 1 for conveying is arranged above the guide rail 1; side grooving mechanisms capable of grooving side parts of the PVC floor are arranged at the end parts of the guide rail 1 and the guide rail 2; an end positioning mechanism capable of transversely straightening the PVC floor is arranged at the other end of the frame; the end positioning mechanism includes a guide rail 3 and a guide rail 4 fixed on the frame in parallel; and end grooving mechanisms capable of grooving end parts of the PVC floor are arranged at the end parts of the guide rail 3 and the guide rail 4. The latch PVC floor grooving device has the advantage of precise grooving.

Owner:浙江海象新材料股份有限公司

Base surface slotting device for building construction with dustproof function

InactiveCN109267464AEasy to cutEasy to transportRoads maintainenceDrive shaftArchitectural engineering

The invention discloses a base surface slotting device for building construction with dustproof function, including the equipment framework, Support plate and cutting device, a left and a right side of that equipment frame are provide with a runner, a support plate is arranged in that middle part of the equipment frame, a fixing plate is arranged at the low end of the supporting plate, the lower end of the fixing plate is fixedly connected with the bottom end of the equipment frame, a sliding groove is arranged on the inner side of the two fixing plates, a sliding block is arranged on the inner side of the sliding groove, and the sliding block is slidably connected with the sliding groove. In accordance with that present invention, a swing turntable rotate that worm by driving the drive shaft, the worm meshing gear rotates to interact with the screw rod, so that the screw rod drives down the support frame, lowers the cutting device, makes the cutter contact with the grooved base surface, facilitates the grooving of the building base surface, and the cutter adopts a wide-blade cutter to directly groove the cut base surface, and at the same time, the grooving depth is controlled by adjusting the height of the cutting device.

Owner:高立伟

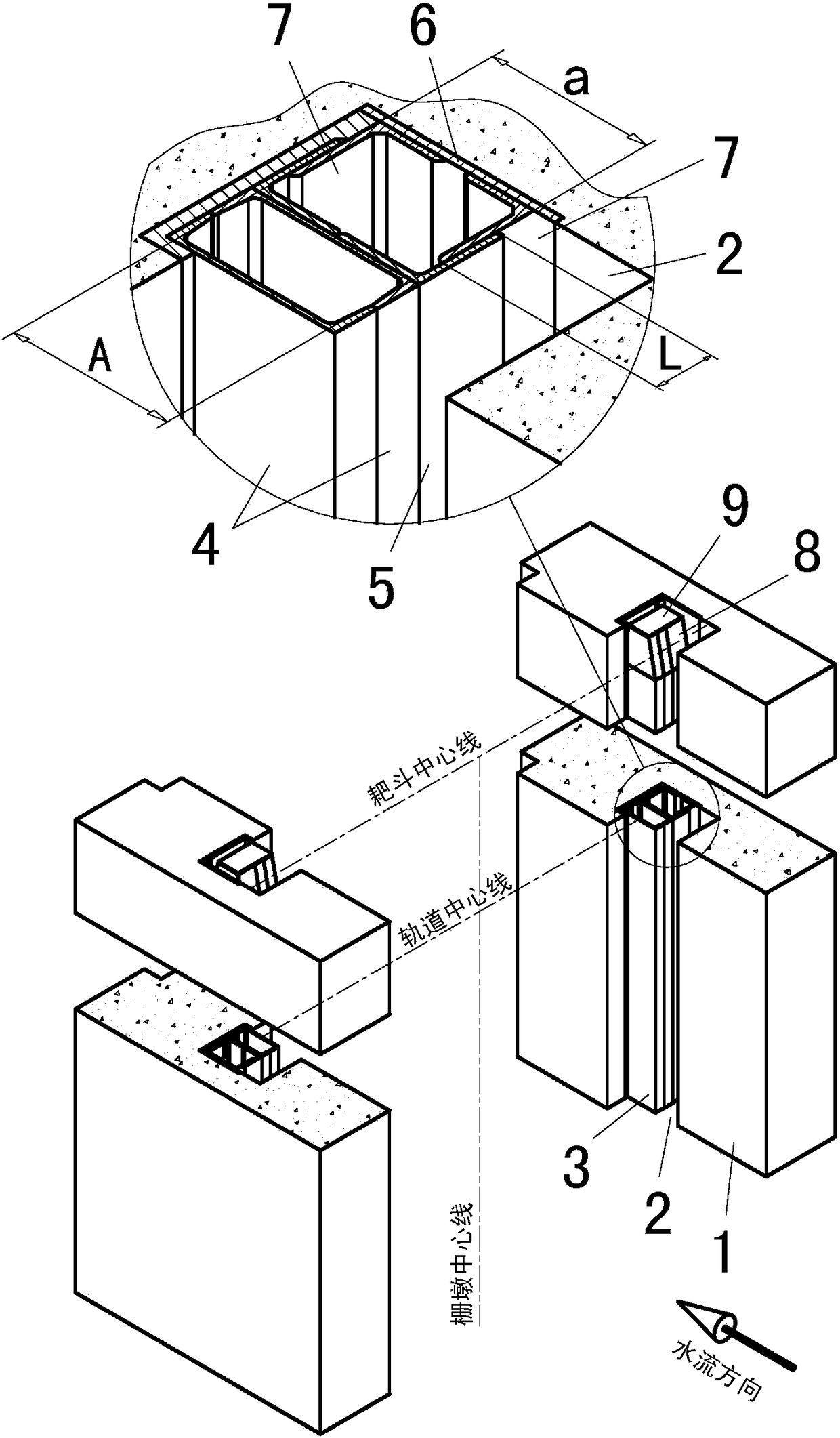

Improvement method and improved structure of decontaminating scraper pan rail

InactiveCN108252281AEasy to slotReduce manufacturing difficultyWater cleaningEngineeringInstallation Error

The invention discloses an improvement method and an improved structure of a decontaminating scraper pan rail. According to the improvement method and the improved structure disclosed by the invention, a combined rail is used for replacing an i-steel rail which is directly pre-embedded inside a trash rack pier in the prior art; in specific implementation, a bottom steel plate is pre-embedded inside a scraper pan groove of the trash rack pier in a pouring process of the trash rack pier; and then the bottom steel plate and the combined rail which is formed by welding profile steel are welded together. According to the improvement method disclosed by the invention, the profile steel is convenient to buy, simple to manufacture and machine and easy to control in precision and needs not to be manufactured in a factory; and the improvement method can effectively adapt to installation errors of the pre-embedded bottom steel plate, and improves the manufacturing efficiency and the installationefficiency of the decontaminating scraper pan rail.

Owner:CHINA POWER CONSRTUCTION GRP GUIYANG SURVEY & DESIGN INST CO LTD

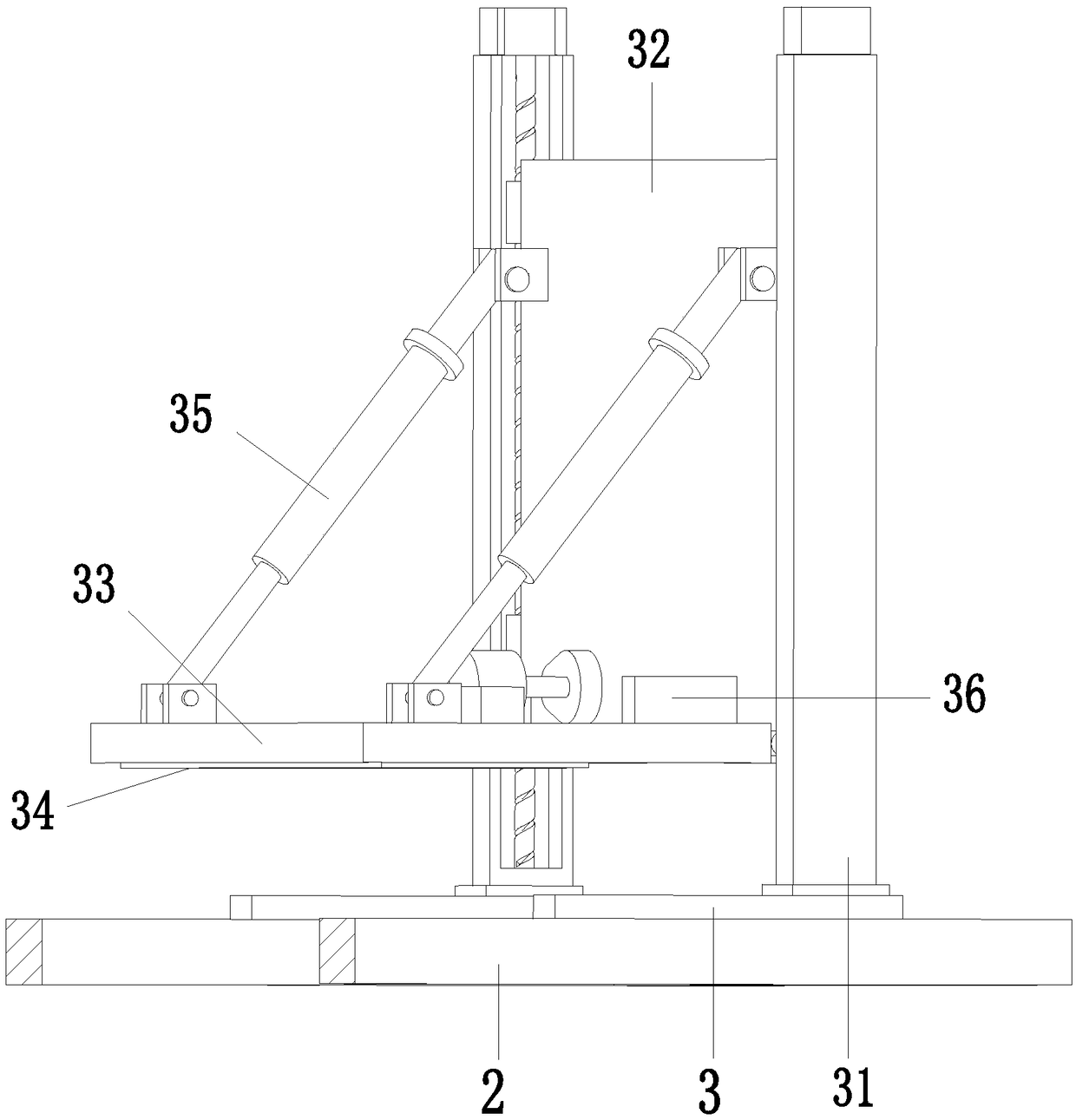

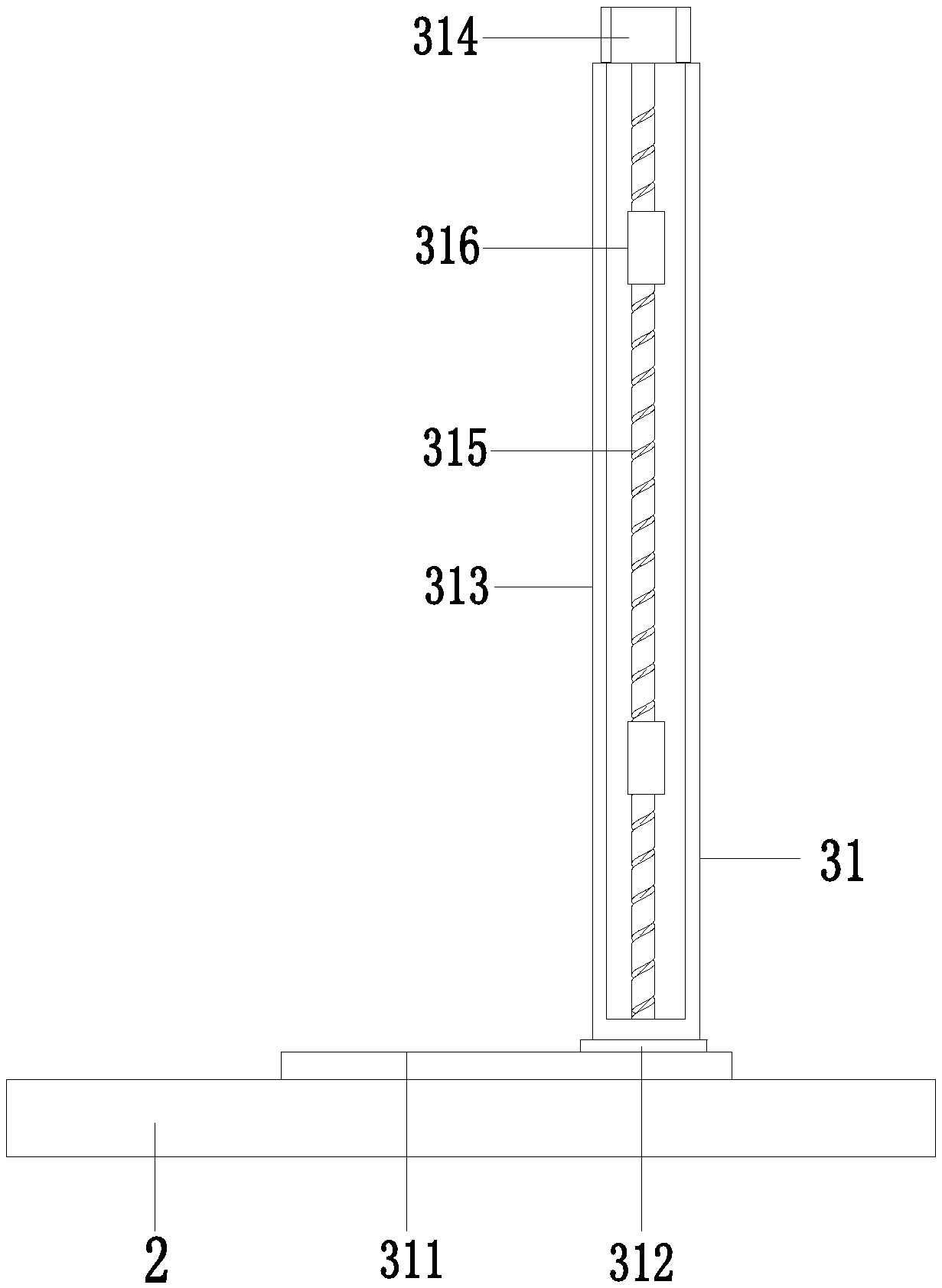

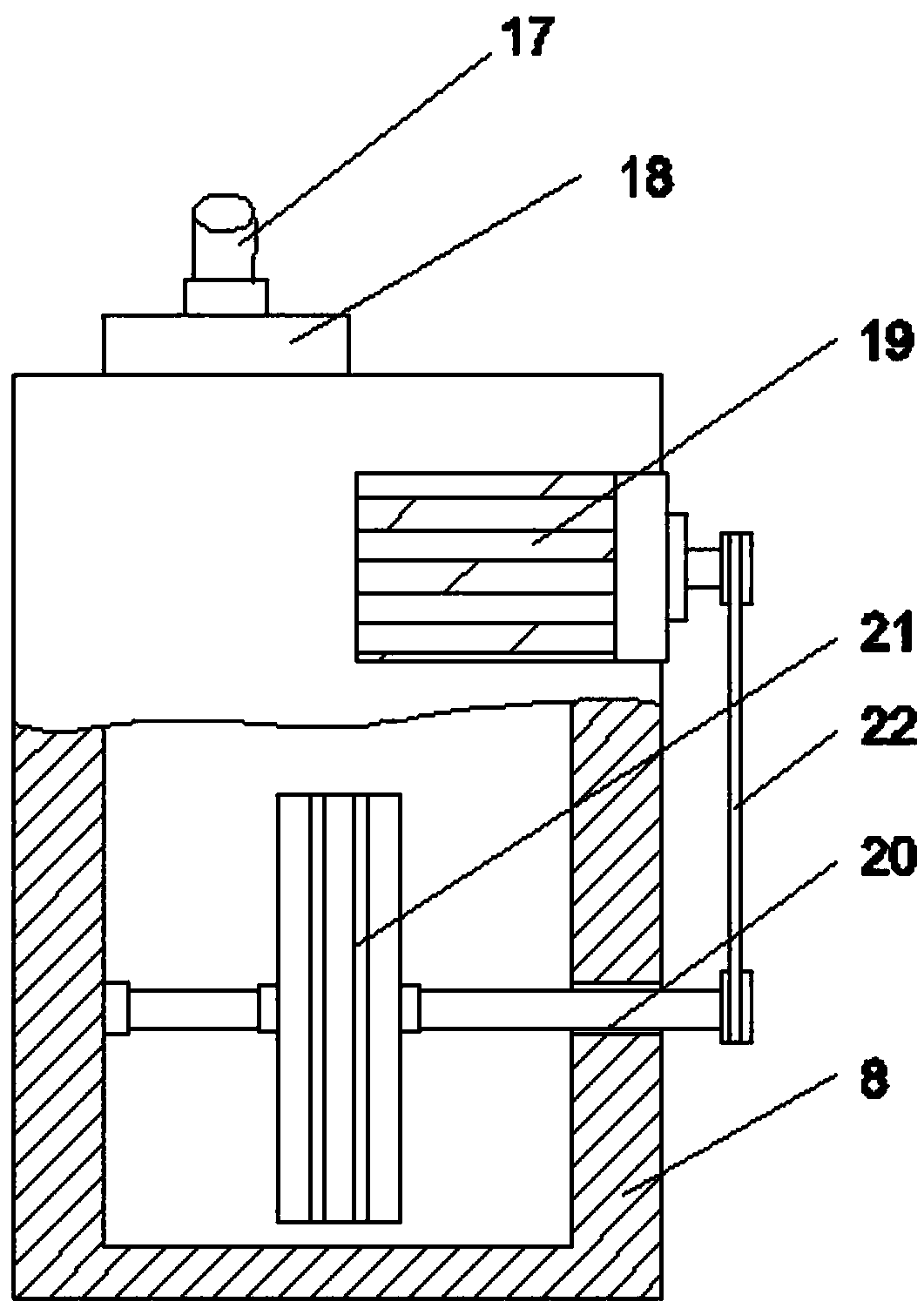

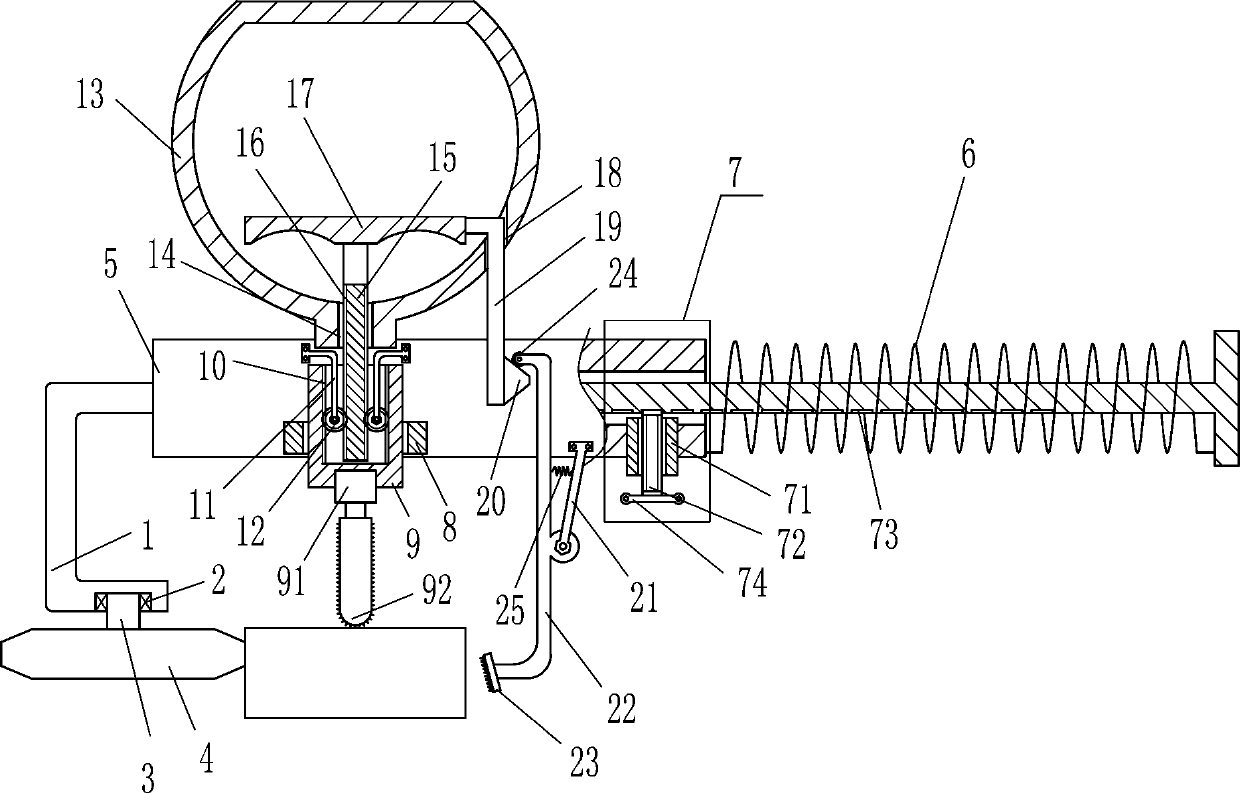

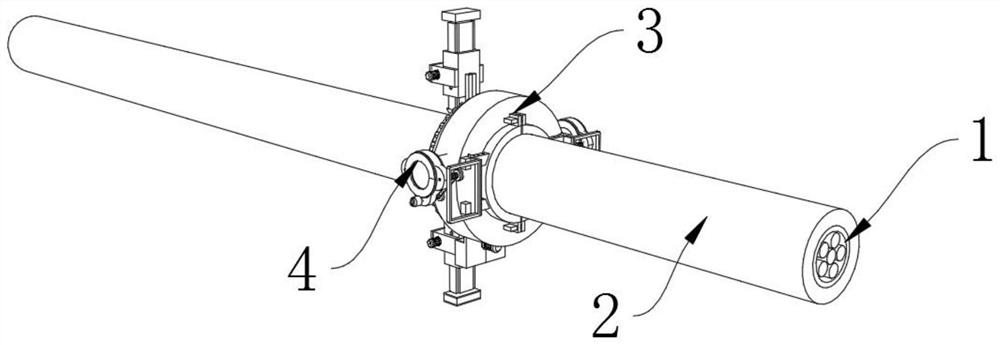

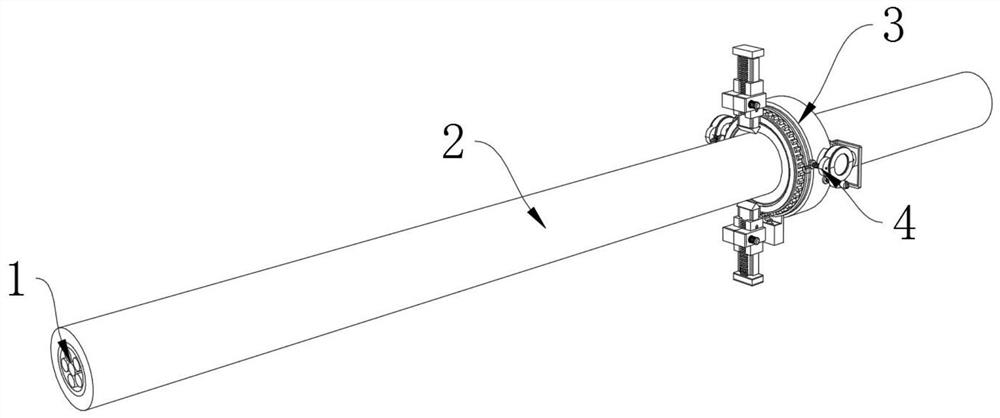

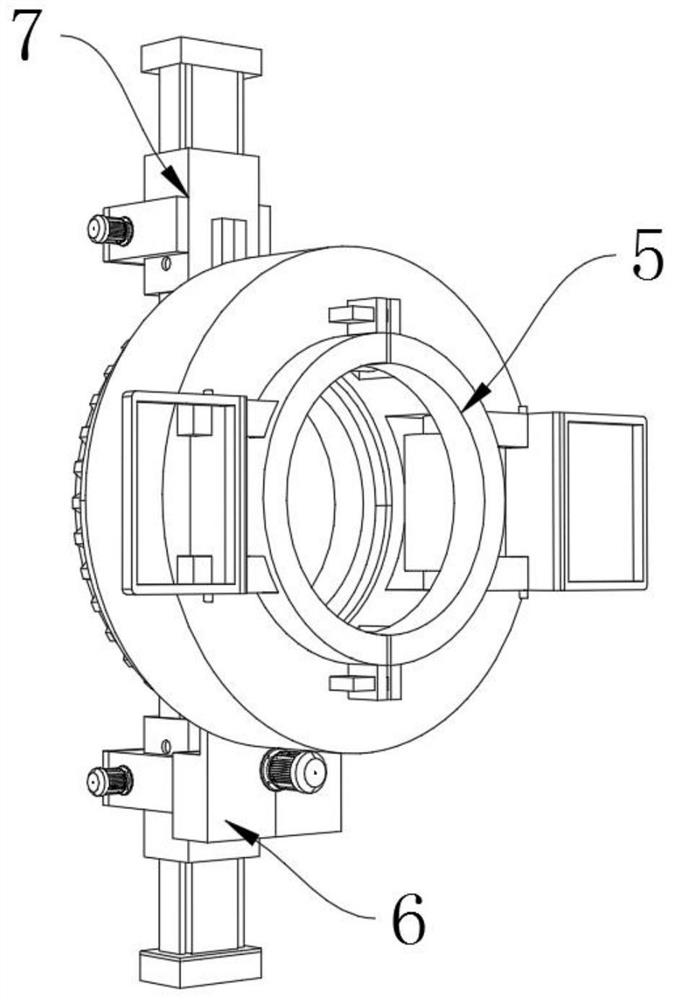

Semi-circular grooving machine for end part of steel pipe

PendingCN110919411AEasy slottingEasy to useFeeding apparatusLarge fixed membersElectric machineMachine

The invention belongs to the field of steel pipe grooving equipment, and particularly relates to a semi-circular grooving machine for the end part of a steel pipe. According to the semi-circular grooving machine, aiming at the problem that semi-circular groove forming is difficult due to the fact that when a semi-circular groove is formed on the end part of the steel pipe, the rotary cutter cannotbe directly used for grooving the steel pipe due to the existing cutter with the too small diameter. The following scheme is now presented, the semi-circular grooving machine comprises a base, wherein two symmetrically arranged supporting rods are fixedly mounted on the top of the base, one side, close to each other, of the two supporting rods is fixedly provided with the same fixing plate, the top ends of the two supporting rods are slidably connected with the same top plate, the top of the top plate is fixedly provided with a first motor, the output shaft of the first motor is fixedly provided with a first rotating rod, the bottom of the top plate is rotatably connected with a second rotating rod, the first rotating rod is in transmission connection with the second rotating rod, and thebottom end of the first rotating rod is fixedly provided with a fixing base. The semi-circular grooving machine is simple in structure and convenient to use, the semi-circular grooving machine can quickly form the semi-circular groove on the steel pipe, and the semi-circular grooving machine is convenient for people to use.

Owner:江西省致能智造产业技术研究有限公司

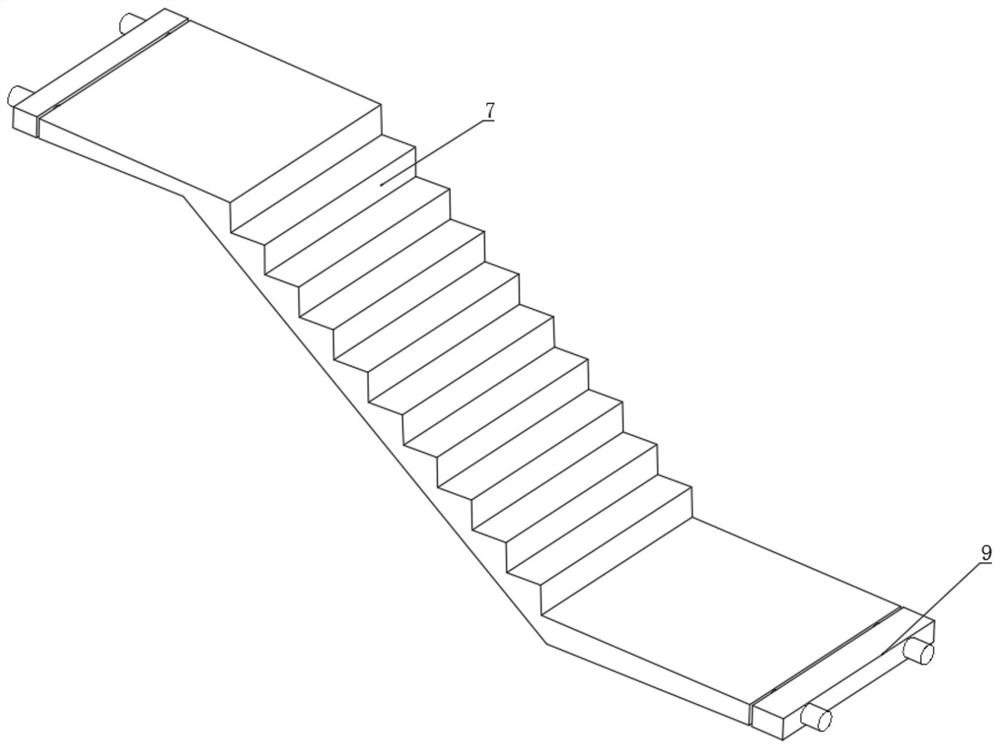

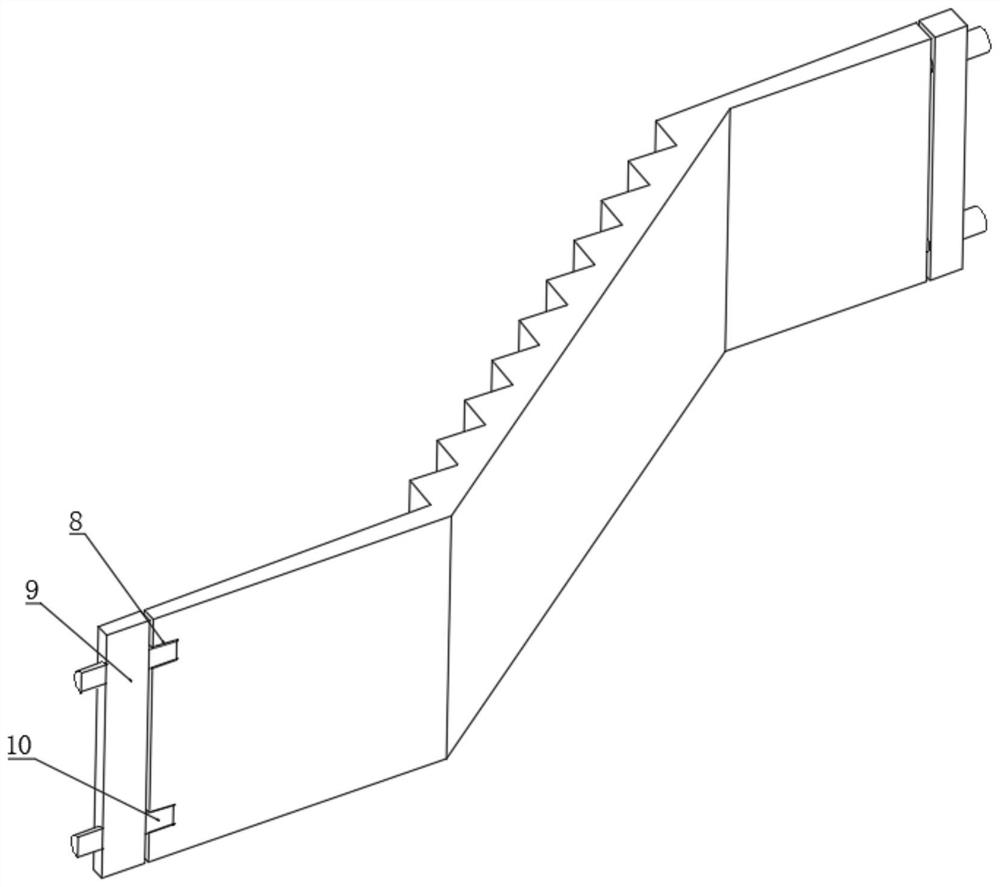

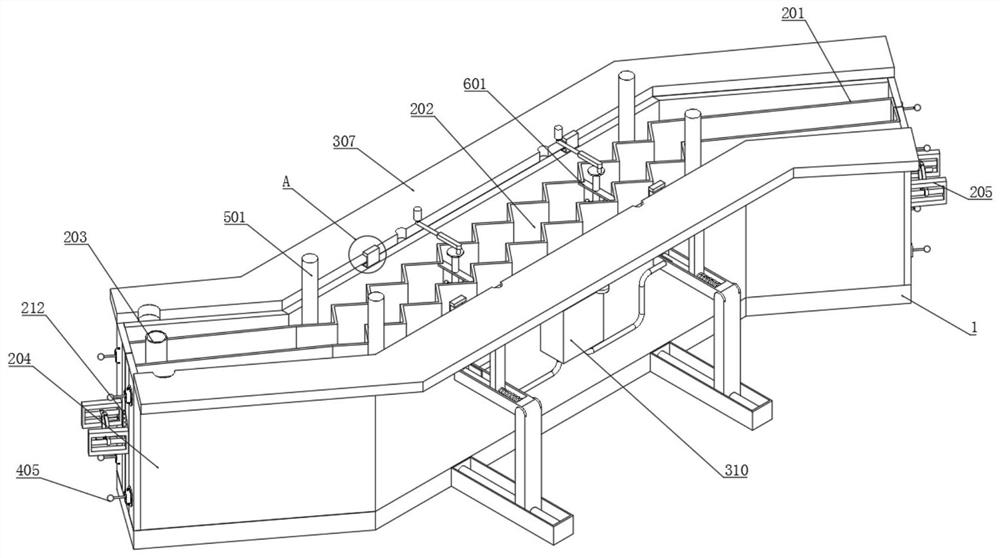

Assembled prefabricated stair and preparation device thereof

ActiveCN113001710AEasy to demouldEasy to disassembleDischarging arrangementMould separation apparatusSlide plateMaterials science

The invention discloses an assembled prefabricated stair and a preparation device thereof. The assembled prefabricated stair comprises a base, wherein a demolding mechanism is arranged in the middle position of the top end of the base, and the demolding mechanism comprises step plates, ventilation cavities, air guide pipes, sliding plates, mounting frames, guide rods, connecting frames, placement grooves, a sliding groove, sliding blocks, ejector rods and sealing films; and the step plates are symmetrically welded to the middle position of the top end of the base, and the ventilation cavities are formed in the opposite ends of the two step plates. According to the assembled prefabricated stair and the preparation device thereof, hot steam can be conveniently injected into the ventilation cavities through the air guide pipes, and therefore, the step plates can be conveniently heated; through the cooperation of the placement grooves and the sliding groove, the sliding blocks can conveniently slide, so that the two mounting frames are conveniently spliced, and the two sliding plates are combined; and meanwhile, through the ejector rods and the sealing films, air is conveniently injected into the ventilation cavities, so that contact parts of concrete and the step plates are separated through thermal expansion and cold contraction, and the inner sides of two stair base bodies are conveniently demolded.

Owner:泰华远大装配式建筑(廊坊)有限公司

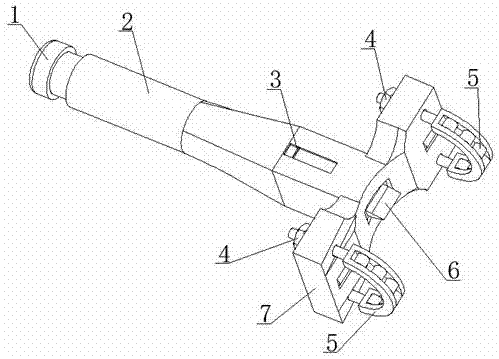

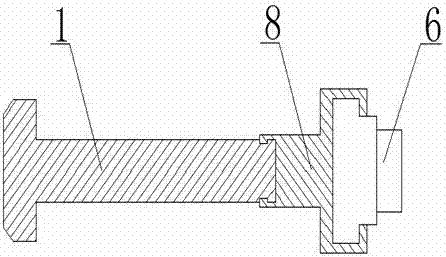

Convenient manual steel pipe slotting tool

InactiveCN107984027AQuick cutEasy to carryTurning machinesArchitectural engineeringMaterial resources

The invention discloses a convenient manual steel pipe slotting tool, which belongs to the technical field of steel pipe processing. The convenient manual steel pipe slotting tool is mainly formed bya handle, chains, a lathe tool and a fixing plate, wherein the fixing plate is symmetrically arranged on the head end of the handle; two symmetrical through holes are formed on the left and the rightof the fixing plate; the two chains are arranged; each chain is symmetrically arranged in the through holes in two ends of the fixing plate; and the lathe tool is arranged in the middle of the fixingplate and is used for cutting a steel pipe. When in use, the steel pipe to be slotted is firstly fixed onto the fixing plate through the chains on the two ends of the fixing plate, and then the handleis rotated, so that the lathe tool can be used for slotting the steel pipe. The convenient manual steel pipe slotting tool provided by the invention has the advantages of convenience in carrying, simplicity in operation, low manufacturing cost, and capabilities of providing convenience for working personnel working in the field to quickly cut the steel pipe, and being beneficial for saving a lotof manpower and material resource cost.

Owner:GUIGANG HOUSHUN INFORMATION TECH CO LTD

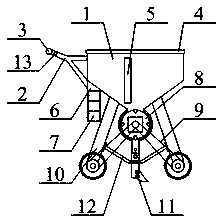

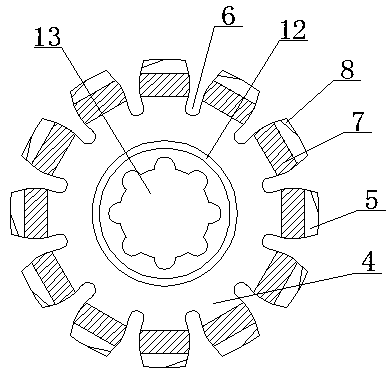

Cotton planting device

PendingCN111034428AImprove the fixed effectSmooth rotationPlantingSeed depositing seeder partsElectric machineryAgricultural engineering

The invention provides a cotton planting device. The cotton planting device comprises a material storage hopper, a Y-shaped support rod, a handle, a dust-proof cover, an observation window, a batterycasing, a rechargeable lithium battery, an electric discharge rack structure, a transmission chain, a side moving rack structure, an adjustable material guide rack structure, an auxiliary fixing rackstructure, and a power switch; the handle is mounted on a left side of the Y-shaped support rod by a bolt; the dust-proof cover is placed on an upper side of the material storage hopper; the battery casing is mounted on a left side of a lower part of the material storage hopper by screws; and the rechargeable lithium battery is mounted on an inner side of the battery casing by screws. According tothe cotton planting device, outer sides of a transmission gear and a driven gear are sleeved with the transmission chain, so that rotation of the driven gear driven by a rotating motor via the transmission gear through the transmission chain is facilitated when the cotton planting device is in operation, thereby facilitating rotation of a moving wheel driven by a rotating rod; and a soil scrapingrack is mounted in an upper part of a right side of an adjustable sleeve by a bolt, so that slotting in the soil during operation of the cotton planting device is facilitated.

Owner:山东钟金燕家纺有限公司

Plastic plate extrusion die

InactiveCN110774555AHeating evenlyReduce processing timeMetal working apparatusHeat conductingPhysics

The invention provides a plastic plate extrusion die. The plastic plate extrusion die comprises a die body which is rotatably connected with a sealing cover plate at a discharge port, a heating mechanism and a grooving mechanism, the heating mechanism is arranged on the die body, the heating mechanism comprises side edge boxes, a top surface box, a gas guide pipe, heating pipes, a first heat conducting plate and a second heat conducting plate, the two side boxes with the same specification are fixedly mounted on the two side walls of the die body correspondingly, the heating pipes are fixedlyinstalled in the two side edge boxes, the top surface box is fixedly installed at the top of the die body, the top surface box is in communication with the side edge boxes on the two sides of the diebody through a plurality of identical gas guide pipes correspondingly, the inner walls of the corresponding die body of the side edge boxes are fixedly embedded with the first heat conducting plate, and the inner wall of the corresponding die body of the top surface box is fixedly embedded with the second heat conducting plate. The plastic plate extrusion die has the advantages of multi-surface heating and convenience in grooving of the bottom of the plastic plate.

Owner:大冶市金玉模具科技有限公司

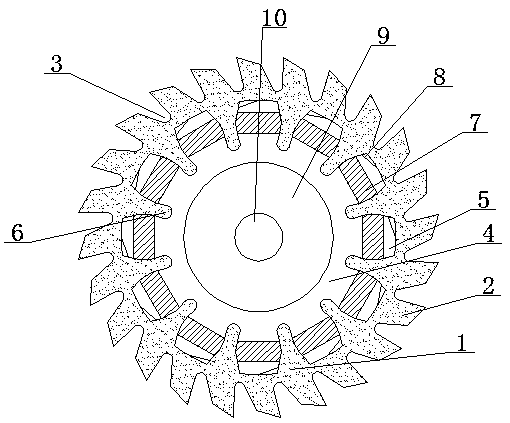

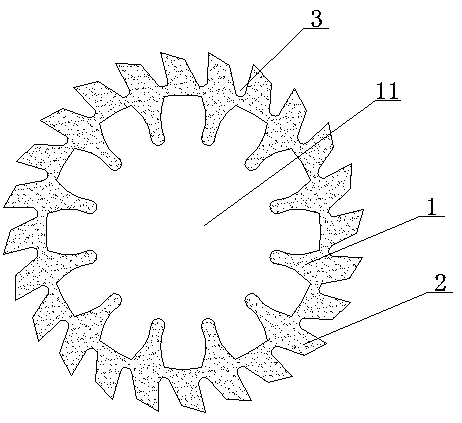

Combined type multifunctional diamond saw blade

InactiveCN109079997AReasonable internal structure designVersatileStone-like material working toolsMachine partsCombined use

The invention discloses a combined type multifunctional diamond saw blade. The combined type multifunctional diamond saw blade comprises a cutting disc and a grooving disc; multiple cutting teeth arearranged on the surface of the cutting disc; a first placing hole is formed in the middle part of the cutting disc; the grooving disc is sleeved in the first placing hole; multiple grooving teeth arearranged on the surface of the grooving disc; a grooving blade is fixedly connected to the surface of each grooving tooth; a grinding disc is fixedly connected to the side surface of each grooving tooth; a second placing hole is formed in the middle part of the grooving disc; and a connecting sleeve is sleeved in the second placing hole. The combined type multifunctional diamond saw blade disclosed by the invention has the advantages that the grinding and the grooving of a machined part are made convenient by arranging grinding discs on the grooving teeth of the grooving disc; as the whole grooving disc is placed in the cutting disc, the cutting of the machined part is made convenient, combined use is realized, and the carrying is convenient; in addition, the cost of the whole combined type diamond saw blade is lower than the costs of three different blades; and moreover, the integrally combined diamond saw blade is more stable, uneasy to fall off and fully-functional.

Owner:JIANGSU SUPER PEAK TOOLS CO LTD

Board grooving machine

ActiveCN110497486AReduce shakingReduce open biasWood mortising machinesWood slotting machinesPulp and paper industry

The invention relates to a grooving machine, in particular to a board grooving machine. The board grooving machine is small in size, low in cost and incapable of partially grooving. The board groovingmachine is characterized by comprising a first support rod, a first bearing, a first rotating shaft, a first roller, a first slide sleeve, a first spring, an adjusting device and the like; the firstsupport rod is movably arranged in the first slide sleeve; and the first bearing is embedded in the bottom of the first support rod. Through arrangement of the adjusting device, the board grooving machine can adapt to multiple boards, so that the application range is wider, and the practicability is higher; the board grooving machine is smaller in size, simple in operation, more convenient to adjust, more economical, suitable for all people and convenient for people to preferably work; and the boards can be fixed through a clamping plate and a first roller, so that people can preferably perform grooving, the partial grooving condition caused by shaking of a grooving wheel is reduced, and the stability of the grooving wheel is improved.

Owner:HEBEI JIRONG FURNITURE

Cable

InactiveCN113345627AEasy to slideImprove work efficiencyInsulated cablesApparatus for removing/armouring cablesEngineeringStructural engineering

The invention discloses a cable, and belongs to the technical field of novel cables. The cable comprises a cable main body and a cable sheath, and the cable sheath is arranged on the outer side of the cable main body; the cable further comprises a convenient-to-adjust following automatic girdling stripping structure and convenient stripping and slotting structures, and the outer side of the cable sheath is slidably connected with the convenient-to-adjust following automatic girdling stripping structure; and the two sides of the convenient-to-adjust follow-up automatic girdling stripping structure are fixedly connected with the convenient stripping and slotting structures. Through the design of the convenient-to-adjust following automatic girdling stripping structure, the device can slide along with the cable conveniently, so that the device is adjusted to move to the two ends of the position needing to be stripped, automatic girdling stripping is carried out on the cable sheath, the working efficiency is greatly improved; and through the design of the convenient stripping and slotting structures, the device can conveniently complete stripping and slotting at the stripping position of the cable, so that the cable sheath at the stripping position can be conveniently slotted, and the cable stripping process is more convenient.

Owner:朱立梅

Grooving device applicable to production of plastic-wood boards

The invention provides a grooving device applicable to production of plastic-wood boards. The grooving device comprises an operating table, a top plate, a first air cylinder, a bearing table, fastening tables, a second air cylinder, an adjusting plate, fixing blocks and grooving columns, and is characterized in that the operating table is disposed on a support; the top plate is disposed on an upright column and an upright plate; the first air cylinder is disposed on the upright plate; the bearing table is provided with sliding blocks and first fixing grooves; first mounting plates are disposedon the fastening plates; the adjusting plate is disposed on a second piston rod; second mounting plates are disposed on the fixing blocks; and the grooving columns are disposed on the fixing blocks through mounting blocks. According to the grooving device applicable to production of the plastic-wood boards, the fixing blocks are arranged to be of a structure that the positions of the fixing blocks can be adjusted on the adjusting plate through the second mounting plates and mounting bolts, the positions, on the adjusting plate, of the fixing blocks are adjusted according to the different grooving positions of the plastic-wood boards, thus the positions of the grooving columns can be adjusted, the different positions of the plastic-wood boards are conveniently grooved, and the grooving quality of the plastic-wood boards is improved.

Owner:芜湖三华包装科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com