Dry type ground heating plate and dry type ground heating system

A floor heating board, dry type technology, applied to floors, insulation layers, buildings, etc., can solve the problems of cumbersome laying process and inconvenient installation, and achieve the effect of improving heating effect, facilitating laying and increasing heat dissipation area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

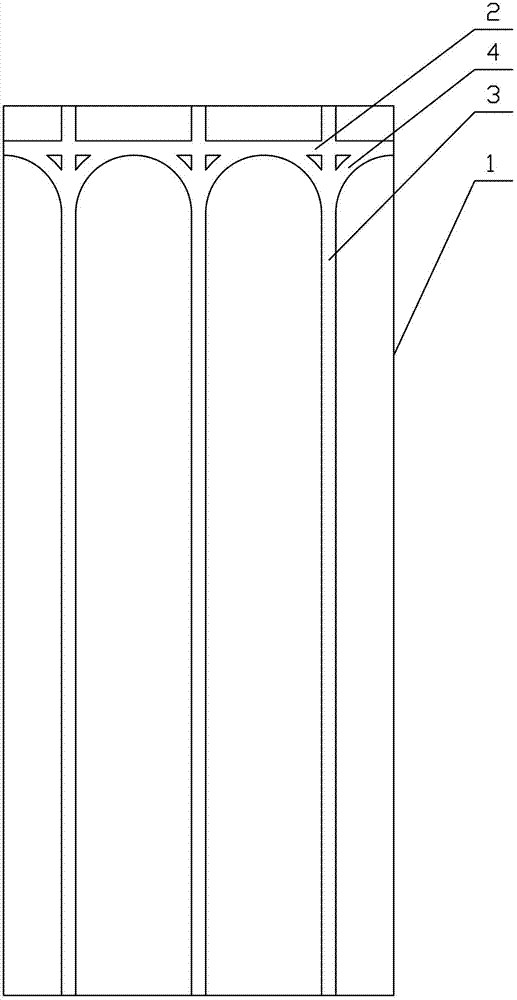

[0044] Such as figure 1 As shown, the dry floor heating panel provided in this embodiment includes a body 1, and at least one transverse groove 2 and at least one longitudinal groove 3 are formed on the upper surface of the body 1; the transverse groove 2 and the longitudinal groove 3 intersect vertically, and the transverse groove 2 communicates with the longitudinal groove 3; an arc groove 4 is also provided, one end of the arc groove 4 communicates with the transverse groove 2, and the other end of the arc groove 4 communicates with the longitudinal groove 3; and the arc groove 4 communicates with the transverse groove 2, The longitudinal grooves 3 are all tangential.

[0045] Specifically, in the dry floor heating panel provided in this embodiment, one transverse groove 2 and three longitudinal grooves 3 are formed on the body 1 .

[0046] When installing, you only need to place the floor heating pipe in the longitudinal groove 3 first, then lay the floor heating pipe alo...

Embodiment 2

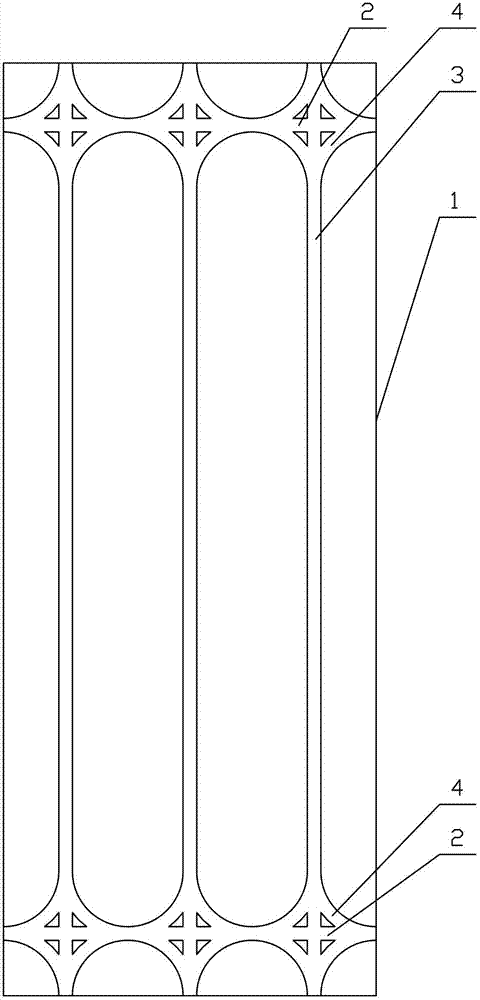

[0051] Such as figure 2 As shown, the dry floor heating panel provided in this embodiment includes a body 1, and two transverse grooves 2 and three longitudinal grooves 3 are formed on the upper surface of the body 1; the transverse grooves 2 and the longitudinal grooves 3 intersect vertically, and the transverse grooves 2 It communicates with the longitudinal groove 3; it is also provided with an arc groove 4, one end of the arc groove 4 communicates with the transverse groove 2, and the other end of the arc groove 4 communicates with the longitudinal groove 3; and the arc groove 4 communicates with the transverse groove 2, the longitudinal groove Slots 3 are all tangent.

[0052] Its specific laying process and beneficial effects are the same as or similar to the dry floor heating panel provided in Embodiment 1, and will not be repeated here.

Embodiment 3

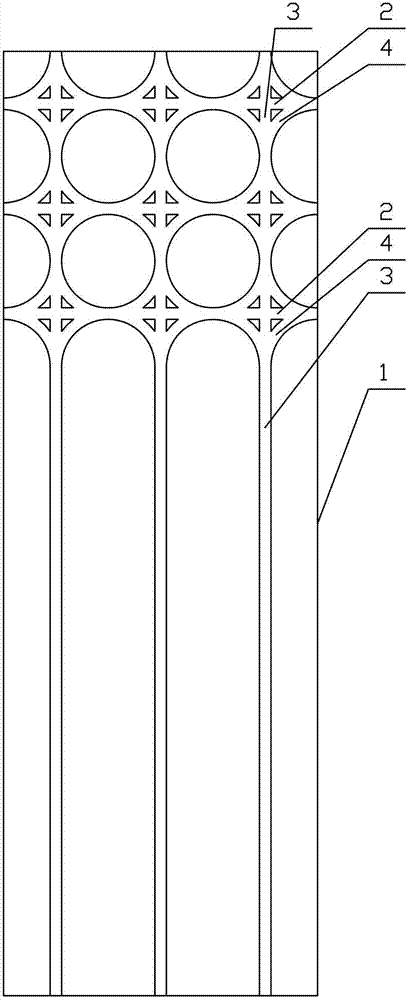

[0054] Such as image 3 As shown, the dry floor heating panel provided in this embodiment includes a body 1, and three transverse grooves 2 and three longitudinal grooves 3 are formed on the upper surface of the body 1; and the longitudinal grooves 3 are parallel to each other and evenly distributed on the body 1; The grooves 2 are parallel to each other; the transverse groove 2 and the longitudinal groove 3 are vertically intersected, and the transverse groove 2 and the longitudinal groove 3 are connected; an arc groove 4 is also provided, and one end of the arc groove 4 communicates with the transverse groove 2, and the arc groove 4 The other end communicates with the longitudinal groove 3; and the arc groove 4 is tangent to the transverse groove 2 and the longitudinal groove 3.

[0055] Its specific laying process and beneficial effects are the same as or similar to the dry floor heating panel provided in Embodiment 1, and will not be repeated here, and only the differences...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com