Patents

Literature

42results about How to "Good compressive strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Combined polyol for polyisocyanurate foam

The polyol composition for polyisocyanurate foam consists of: polyester polyols based on aromatic acid anhydride 40-70 wt%; polyethylene / propylene oxide polyether polyols based on fatty amine, fatty diamine or fatty polyamine 0-10 wt%; compound containing active hydrogen atom 0-25 wt%, liquid organic fire retardant 14-25 wt%, water 1-3 wt%, catalyst 2-4.5 wt%, and supplementary material and / or additives 2-5 wt%. The hard foam prepared through one-step process has homogeneous and fine cells, and has the excellent performances in electric insulation, light weight, sound isolation, chemical corrosion resistance, etc. similar to those of PUR foam as well as pressure strength, size stability, heat insulation, flame resistance, low burning smoke amount, etc. superior to PUR foam. The present invention may be used in heat insulating material and sandwiched composite material with relatively high temperature requirement.

Owner:COVESTRO DEUTSCHLAND AG

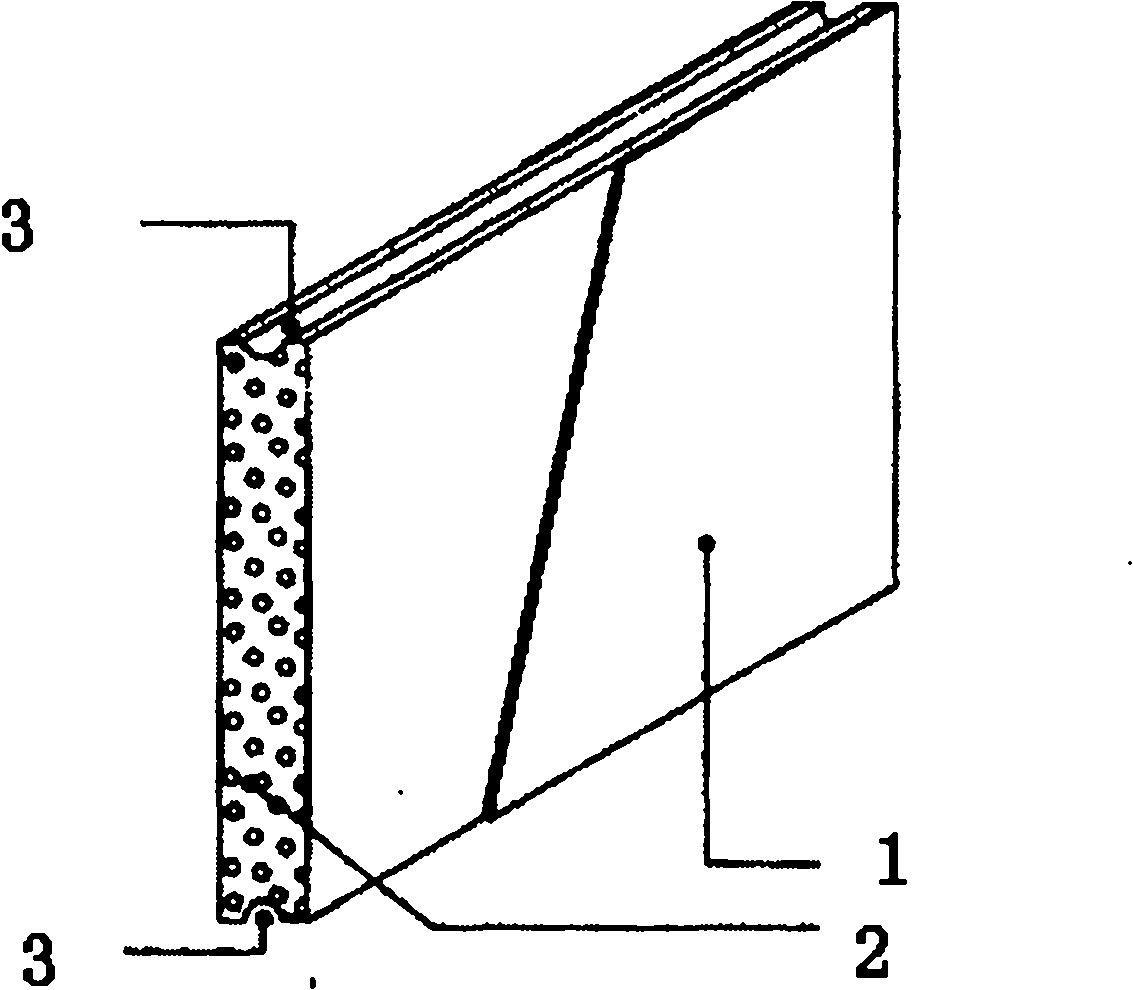

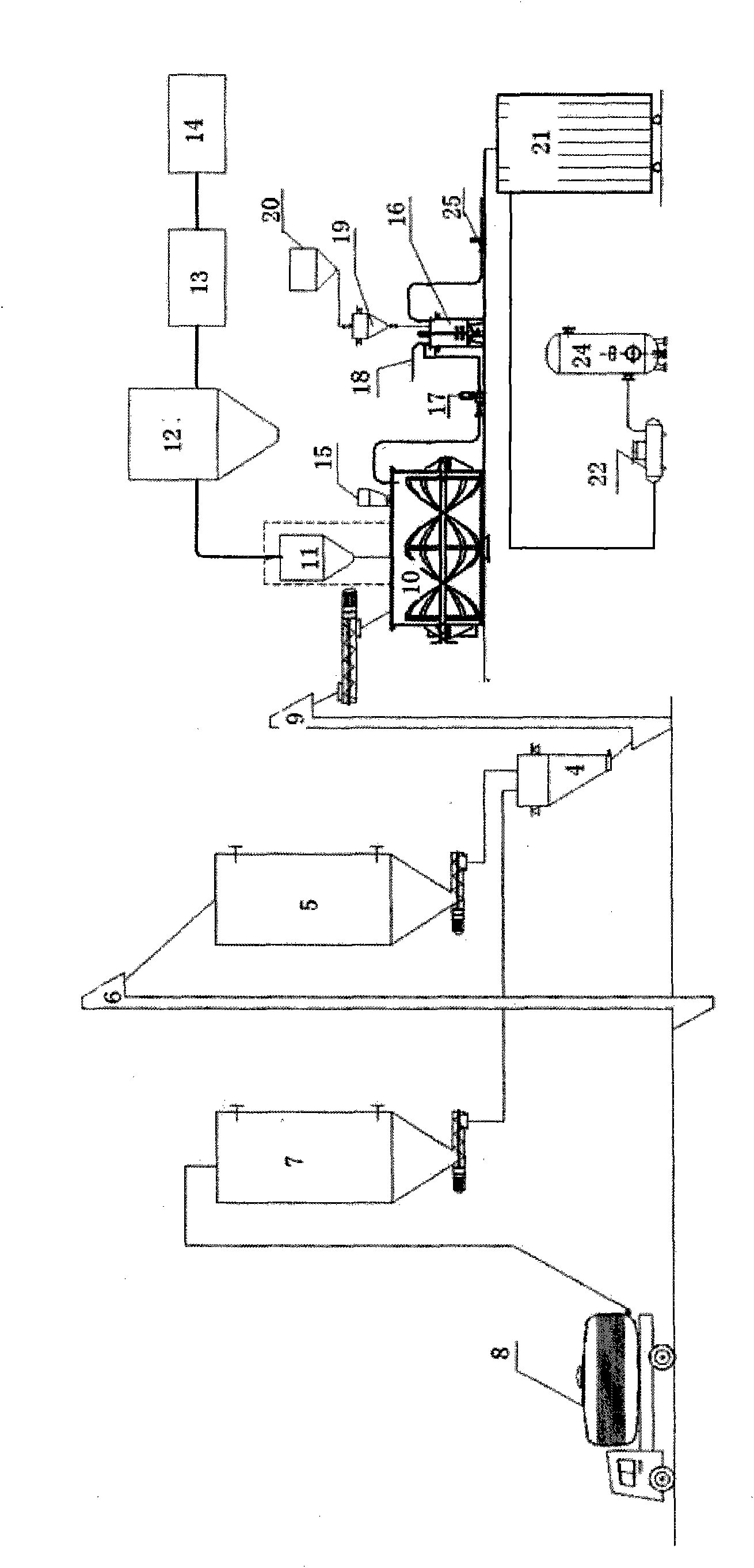

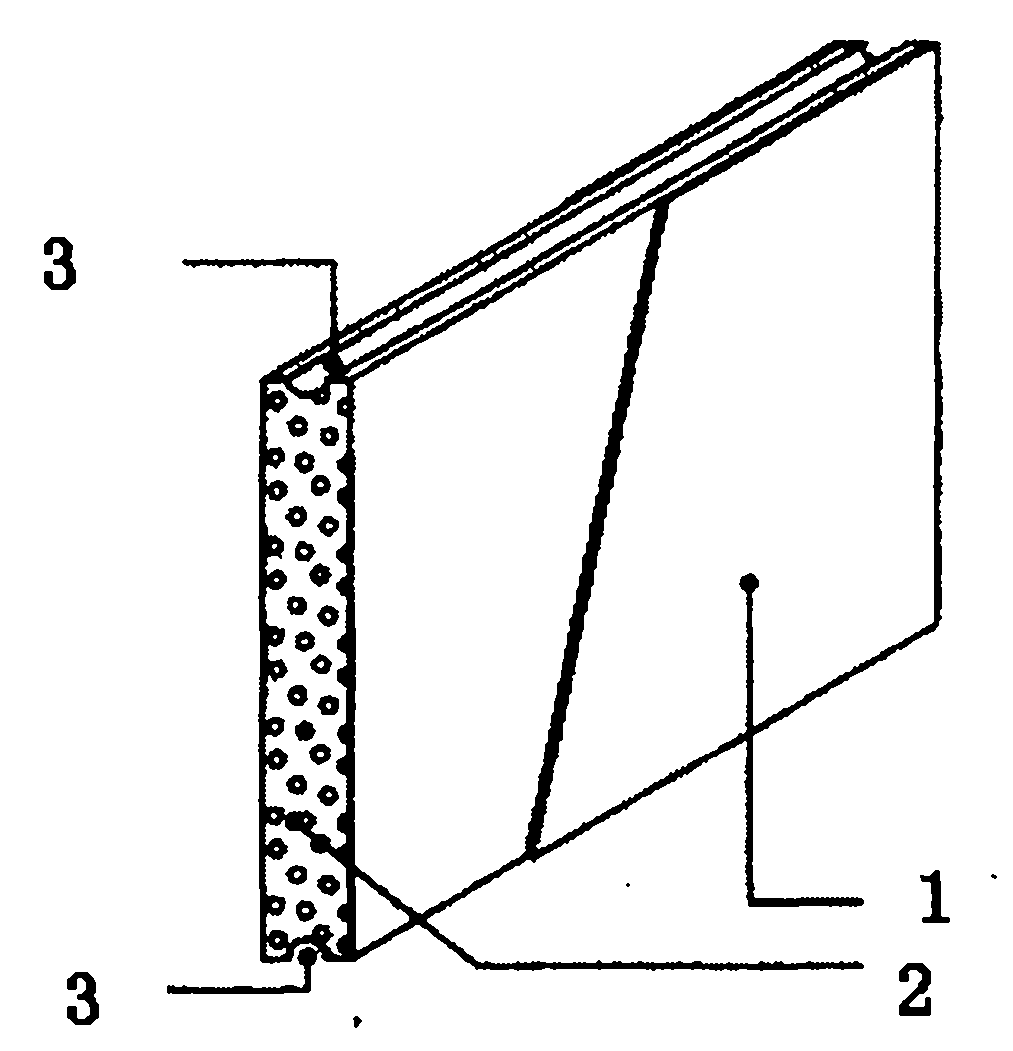

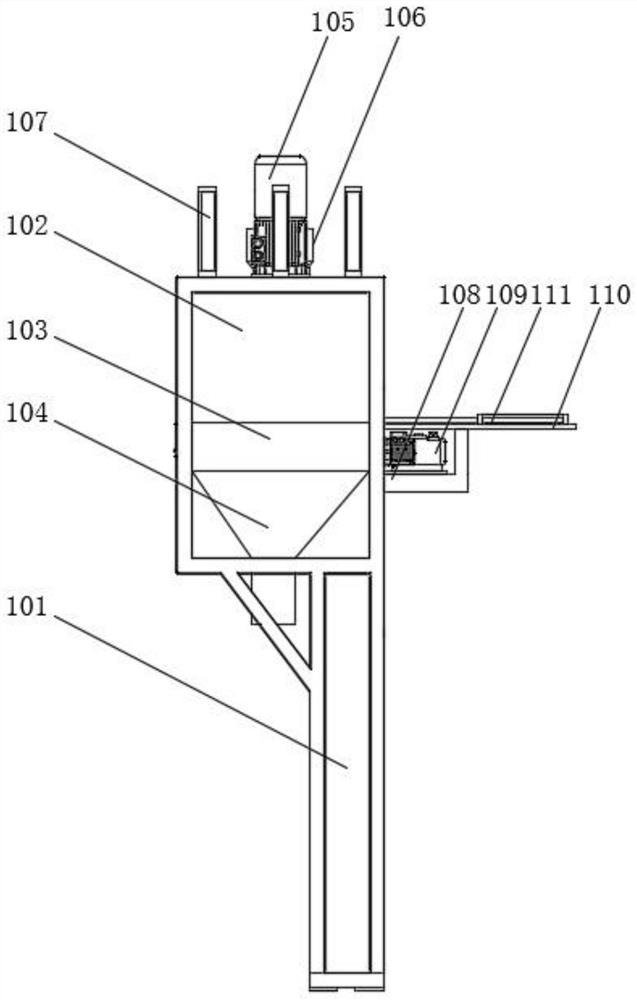

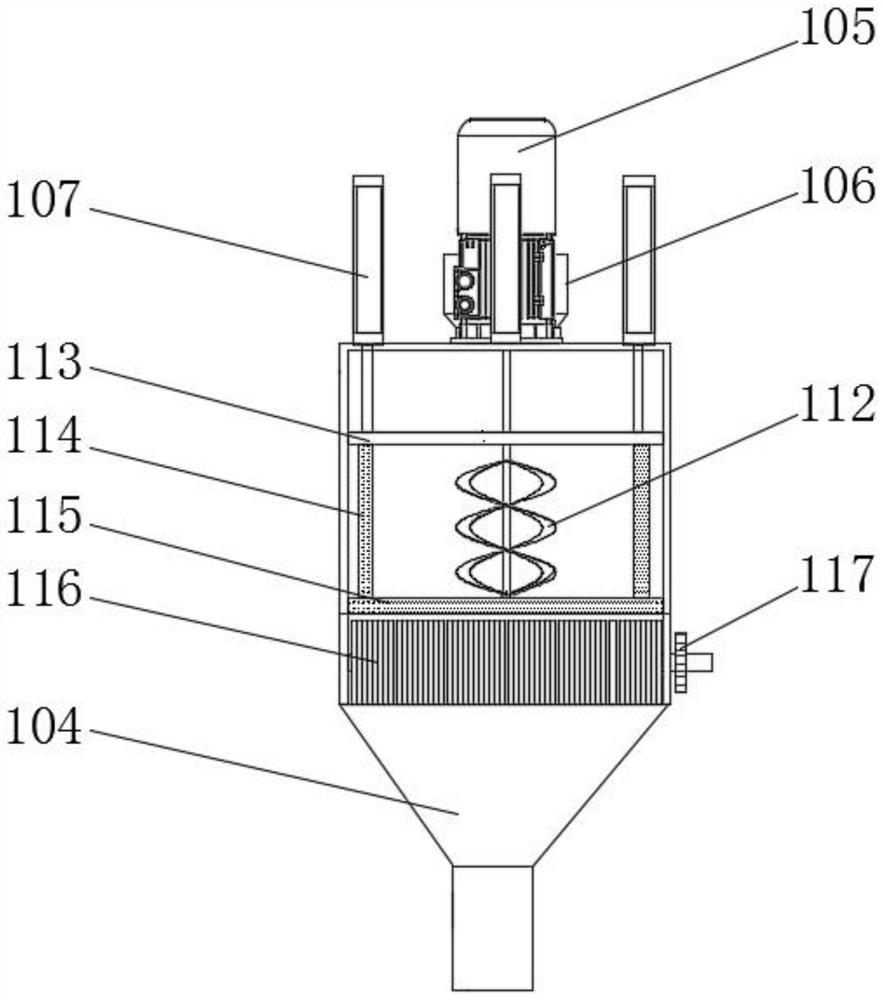

Energy-saving, low-carbon and heat-insulation composite wallboard, and production method and equipment thereof

The invention provides an energy-saving, low-carbon and heat-insulation composite wallboard, and a production method and production equipment thereof. The energy-saving, low-carbon and heat-insulation composite wallboard is characterized by consisting of two surface boards and a core board arranged between the two surface boards, wherein the core board is prepared from polystyrene foamed plastics, fly ash, cement, sand, admixture and water. The invention also provides the production method and production equipment of the energy-saving, low-carbon and heat-insulation composite wallboard. The energy-saving, low-carbon and heat-insulation composite wallboard has the advantages of light weight, thin body, impact resistance, compression resistance, heat preservation, heat insulation, water proofing, fire proofing, sound insulation, shock proofing, explosion absorption, easy cutting, slotting, no need of plastering, fast dry operation, labor saving and the like.

Owner:上海康尼建材科技有限公司

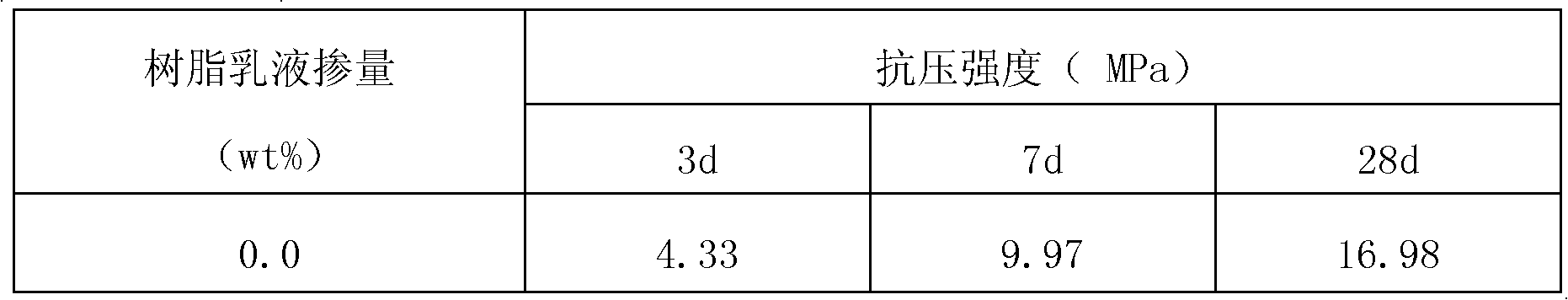

Fly ash-based inorganic polymer composite cementitious material and preparation method thereof

InactiveCN101792275AEfficient circular economyNo waste dischargeSolid waste managementCement productionAcrylic resinFlexural strength

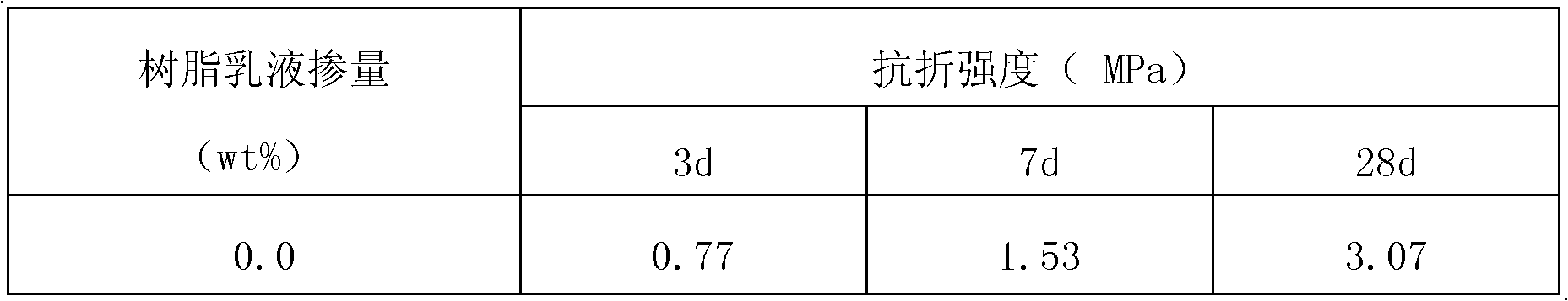

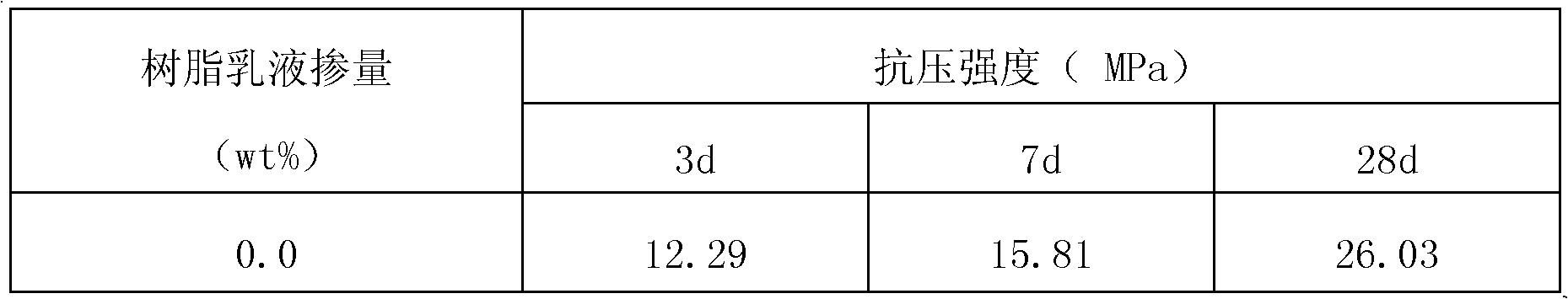

The invention relates to a fly ash-based inorganic polymer composite cementitious material and a preparation method thereof, and the fly ash-based inorganic polymer composite cementitious material comprises the following raw materials: 1350g of fly ash, 150g of silicon powder, 225 or 300g of sodium silicate and 307 or 264g of water (water + crystal water in Na2SiO29H2O: fly ash and silicon powder is equal to 0.29), wherein the doping amount of butyl acrylate-acrylic resin emulsion is 0.5%-3% of the weight of the fly ash and the silicon powder. The fly ash-based inorganic polymer composite cementitious material is prepared by using the sodium silicate for exciting the binary complex fly ash and the silicon powder at room temperature or doping the butyl acrylate-acrylic resin emulsion into the binary complex fly ash and the silicon powder excited by the sodium silicate at the room temperature. The optimal compressive strength at the age of 28 days is improved by 10.43MPa in comparison with a binary complex fly ash-based inorganic polymer, and the flexural strength at the age of 28 days is improved by 2.52MPa. The doping of the butyl acrylate-acrylic resin emulsion can significantly improve the compressive strength and the flexural strength of the fly ash-based inorganic polymer composite cementitious material; and the preparation process is carried out under normal temperature and normal pressure and has the advantages of zero emission, greenness and environmental protection.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

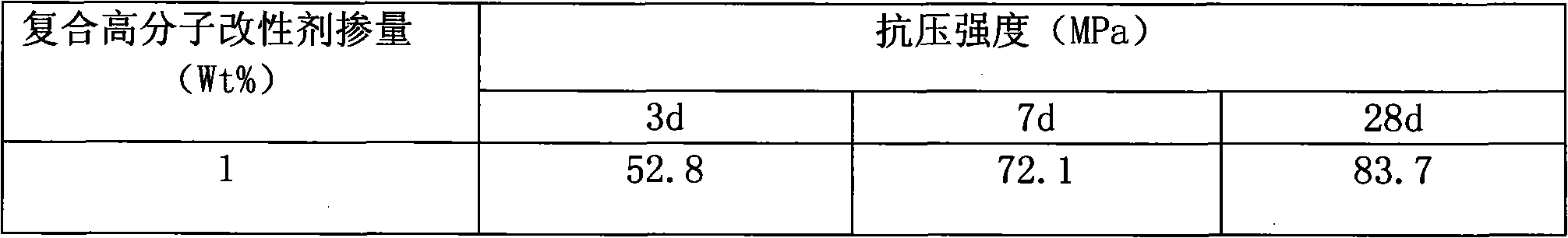

Kaolin-slag base geological polymer compound cementing material with enhanced composite organic macromolecule and preparation method thereof

InactiveCN101560068AIncrease profitEfficient use ofSolid waste managementCement productionPolyvinyl acetateKaolin clay

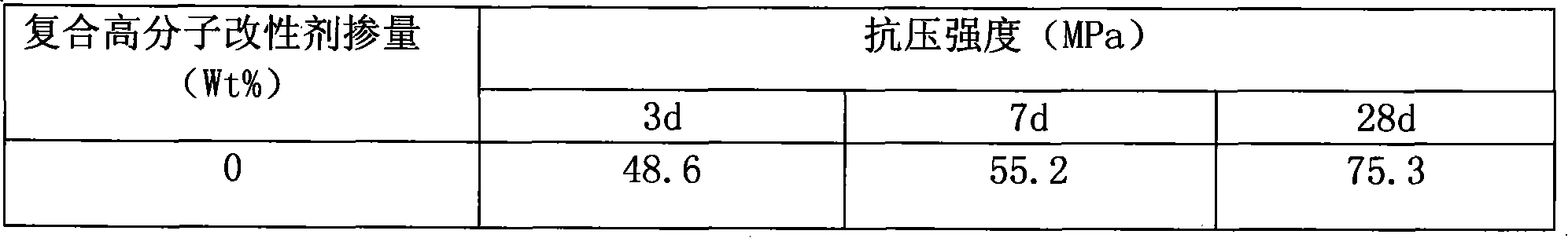

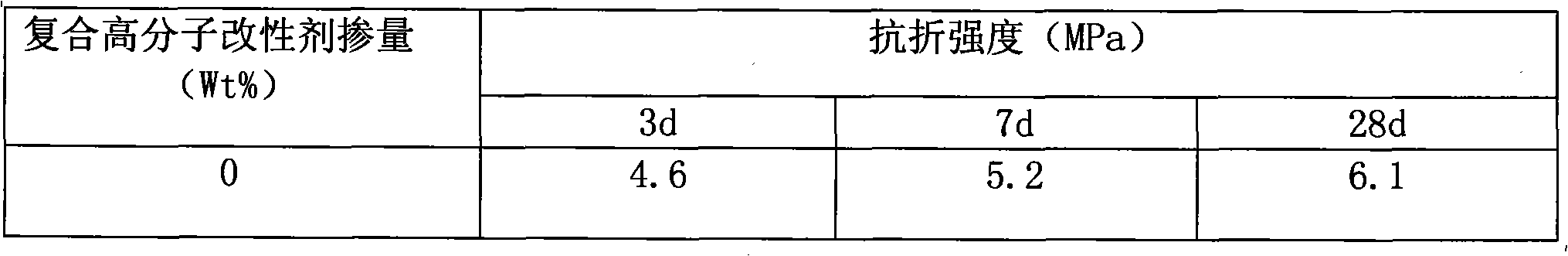

The invention discloses a kaolin-slag base geological polymer compound cementing material with enhanced composite organic macromolecule and a preparation method thereof. The prepared compound cementing material is generated by adding binary composite organic macromolecule polyvinyl acetate emulsion powder and polyacrylate resin emulsion into binary composite kaolin and slag under stimulation of sodium silicate. Adding quantity of the binary composite organic macromolecule polyvinyl acetate emulsion powder and polyacrylate resin emulsion is based on quantity of the binary composite kaolin and slag; the adding quantity of the binary composite organic macromolecule polyvinyl acetate emulsion powder and polyacrylate resin emulsion is 1%-15% of the quantity of the binary composite kaolin and slag; adding quantity of the sodium silicate is 15% of the quantity of the binary composite kaolin and slag; and water cement ratio is 0.36. The preparation process is free of three waste discharge and heating that the preparation process is environment-friendly. The kaolin-slag base geological polymer compound cementing material with enhanced composite organic macromolecule solves key technical problems of inorganic geological polymer cementing material, such as inefficient flexibility and bad long-term compression strength.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

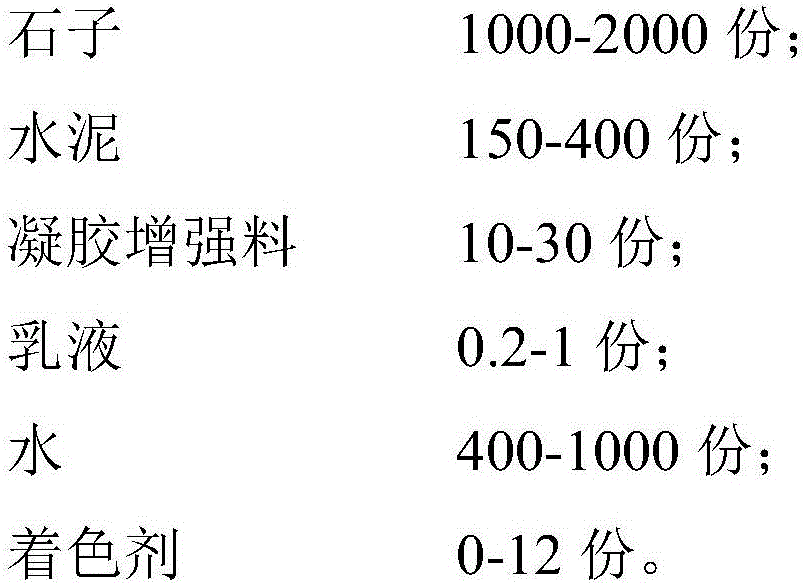

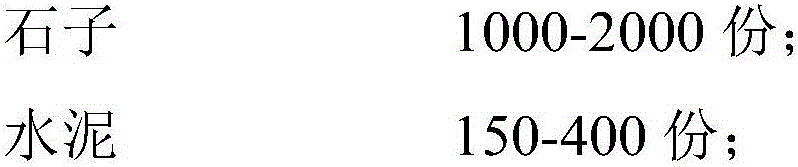

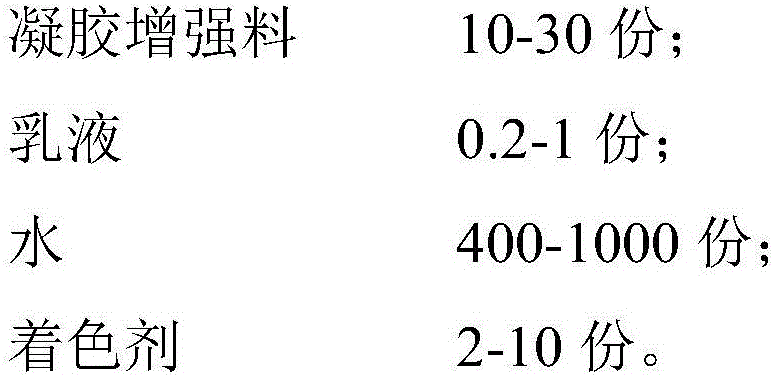

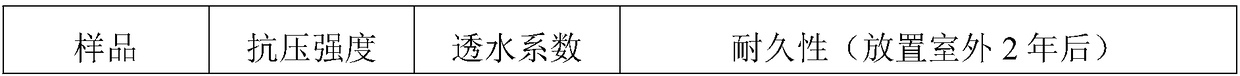

Long-life permeable concrete and production method thereof

InactiveCN106348691AGood compressive strengthGood permeability coefficientFreeze thaw resistanceEmulsion

The invention discloses long-life permeable concrete and a production method thereof; the long-life permeable concrete is produced from, by weight, 1000-2000 parts of gravel, 150-400 parts of cement, 10-30 parts of gel reinforcing material, 0.2-1 part of emulsion, 400-1000 parts of water, and 0-12 parts of a colorant. The long-life permeable concrete provided herein has good compressive strength and high permeation coefficient, can meet the need of various projects for concrete permeability, is helpful for maintaining ecological balance and implementing sustainable development, is good in decoration effect, easy to maintain, high in freeze-thaw resistance, high in radiating property and high in bearing capacity, enables urban ecological environment to be effectively improved, is highly ecologically friendly and has a long life up to 8 years and longer.

Owner:唐山安信混凝土有限公司

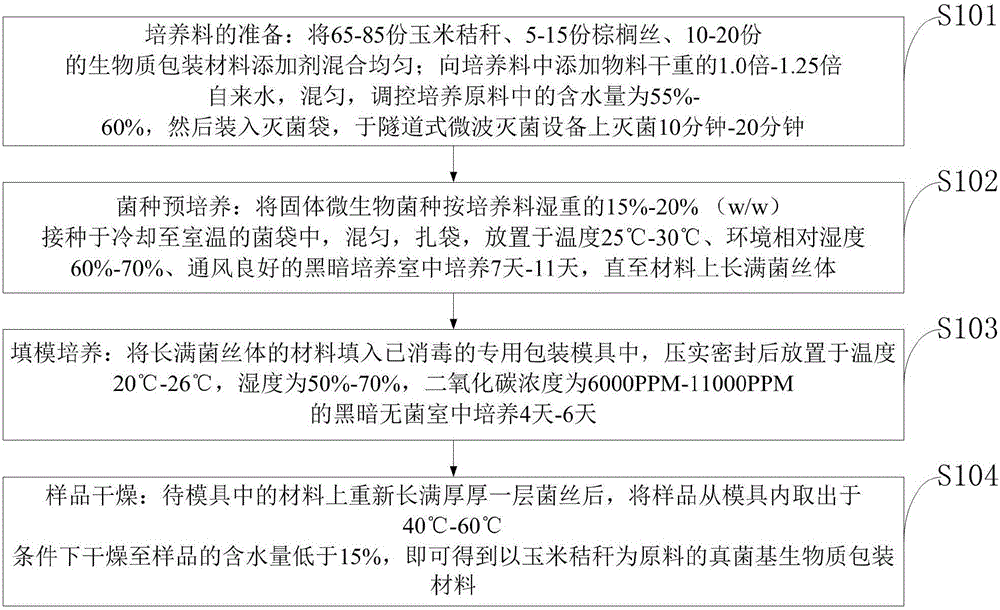

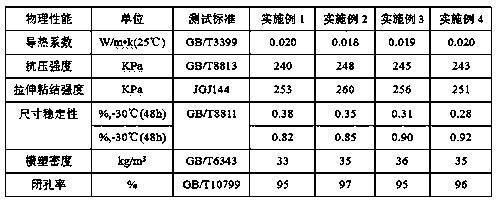

Fungus-based biomass packaging material taking maize straw as main materials and preparation method thereof

InactiveCN106633990AReduce manufacturing costReduce energy consumptionFungiPack materialMechanical property

The invention relates to a fungus-based biomass packaging material taking maize straw as main materials and a preparation method thereof. The biomass packaging material comprises the maize straw, palm threads and biomass packaging material additives, wherein the biomass packaging material additives comprise the following components in parts by mass: 60 parts of rice bran, 8 parts of maize flour, 8 parts of soybean meal, 6 parts of flour, 10 parts of quick lime and 8 parts of gypsum powder. The preparation method comprises the following steps: preparing a culture material; pre-culturing strains; filling mold and culturing; and drying samples. The preparation method is simple in production process and low in production cost; the prepared biomass packaging material is environmentally friendly and ecological, has excellent biodegradable property and excellent mechanical property, is capable of effectively reducing environmental pollution, and is an ideal environment-friendly packaging material.

Owner:SHENZHEN ZEQINGYUAN TECH DEV SERVICE CO LTD

Polyurethane rigid foam

The invention relates to a foam material, and discloses polyurethane rigid foam. A heat preservation material is prepared by mixing and foaming the following raw materials in parts by weight: 70 to 100 parts of isocyanate, 40 to 80 parts of polyether glycol I, 10 to 30 parts of polyether glycol II, 3 to 6 parts of expanded vermiculite, 5 to 8 parts of nanosilicon dioxide, 10 to 20 parts of a foaming agent, 1 to 5 parts of a catalyst, and 1 to 5 parts of 3-[poly(ethylene glycol-copolymerized-propylene glycol) mono methyl ether] chloropropyltrialkoxysilane, wherein the polyether glycol I is lignin polyether glycol; the polyether glycol II is polyether glycol polymerized by modified sunflower seed oil serving as a starting agent and epoxypropane serving as a polymeric monomer. The heat preservation material is higher in compressive strength, tensile strength and impact strength, and meanwhile, phenomena of deformation, bulging, ridging and even cracking of a water tank are avoided.

Owner:GUANGXI JISHUN ENERGY TECH

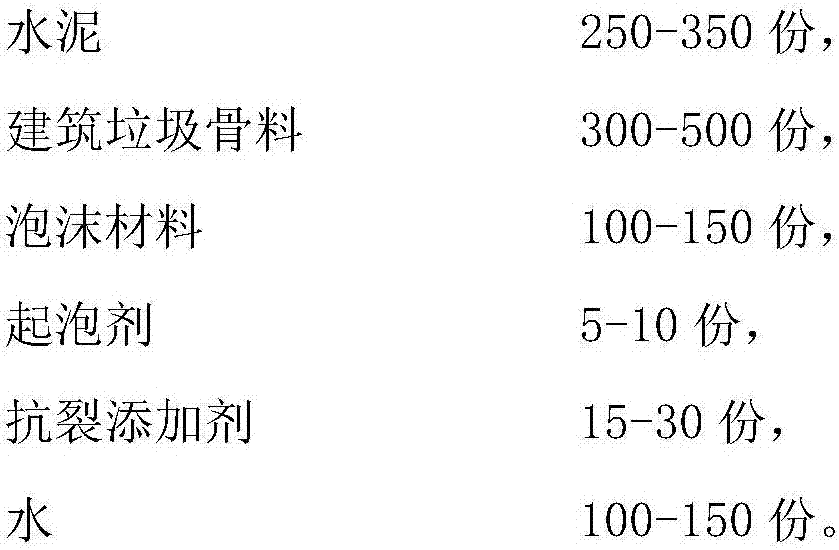

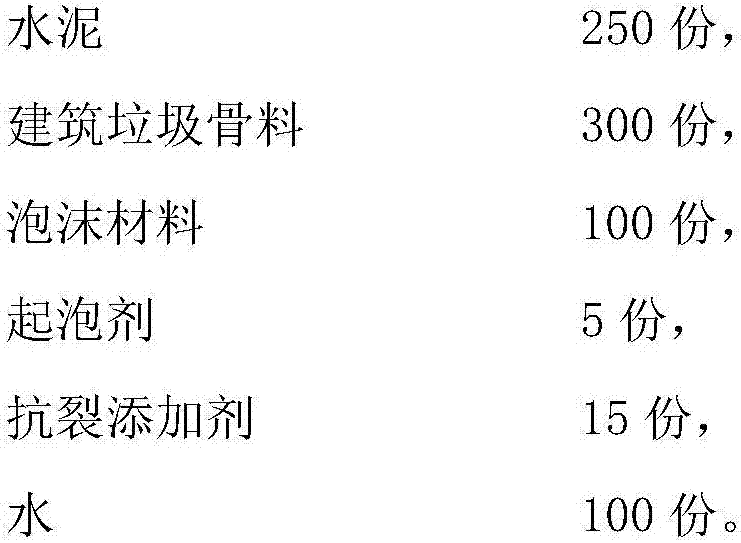

Concrete and preparation method thereof

InactiveCN107140896AGood compressive strengthStable compressive strengthCeramicwareWater resistanceConstruction aggregate

The invention provides concrete and a preparation method thereof. The concrete comprises, by weight, 250 to 350 parts of cement, 300 to 500 parts of a building waste aggregate, 100 to 150 parts of a foaming material, 5 to 10 parts of a foaming agent, 15 to 30 parts of an anti-cracking additive and 100 to 150 parts of water. The preparation method solves the environmental pollution problems caused by construction wastes and reasonably reduces the cost of the concrete. The prepared concrete has good compression resistance, shearing resistance and water resistance, greatly enhances the crack resistance and impermeability of the concrete and greatly prolongs the waterproofing period of buildings.

Owner:HEFEI YAKELI NEW BUILDING MATERIAL CO LTD

High-strength waterproof concrete building material

InactiveCN110128078AChange in hydrophilicity and compressive strength differenceGood compressive strengthBuilding materialCalcium carbonate

The invention relates to a high-strength waterproof concrete building material. The material comprises the following components in parts by weight: 5-15 parts of a waterproof agent, 1000-1200 parts ofgravel, 600-700 parts of sand, 250-350 parts of Portland cement, 60-80 parts of fly ash, 150-170 parts of water, and 60-80 parts of nano-calcium carbonate. The waterproof agent and nano-calcium carbonate with different particle sizes are added in the material, and thus the characteristics of poor hydrophilicity and compressive strength of ordinary building materials are changed, the material hasgood compressive strength, and has anti-permeability, waterproof and hydrophobic functions, the construction is simplified, the construction period is shortened, the construction cost is reduced, andthe service life of the building material is improved.

Owner:济南市坤鹏技术开发中心

Adhesive special for sand aerated concrete boards and preparation method of adhesive

The invention discloses an adhesive special for sand aerated concrete boards and a preparation method of the adhesive. The adhesive comprises, by weight percentage, 25-30% of Portland cement, 50-58% of quartz sand, 15-20% of sand aerated concrete board waste, 1.5-2.0% of redispersible latex powder, 0.1-0.3% of hydroxypropyl methyl cellulose ether, 0.1-0.3% of wood fibers, 0.04-0.08% of starch ether and 0.1-0.2% of polypropylene fibers. The adhesive is good in water-retaining property and adhesive property, small in shrinkage ratio, high in crack resistance and less prone to interface crack generation, the recycled sand aerated concrete board waste is used as the raw material, and consistency with the color of a wall after filling is achieved.

Owner:SHAANXI NITYA NEW MATERIALS TECH CO LTD

Refractory material based on polycrystalline alumina

InactiveUS20050150430A1Good thermal stabilityGood compressive strengthAluminium compoundsCeramicwarePorosityCorundum

The invention concerns a refactory material based on corundum treated by electrofusion consisting of beads of diameter ranging between 50 μm and 5 mm, having a total pore ratio ranging between 10 and 50 % of the volume of the beads, the sealed porosity representing from 80 to 98% of the total porosity. The inventive material is in particular designed for spray-applied refractory concrete.

Owner:PEM ABRASIFS REFRACTAIRES

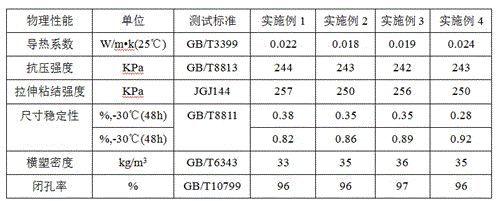

Foamed concrete and preparation method thereof

InactiveCN110759687AGood compressive strengthStable compressive strengthCeramicwareWeather resistanceFlame resistance

The invention discloses foamed concrete and a preparation method thereof. The foamed concrete comprises the following raw materials in parts by weight: 160-200 parts of cement, 60-140 parts of ore powder, 60-130 parts of fly ash, 120-210 parts of water, 80-140 parts of a foam material, 12-25 parts of a binder, 10-20 parts of a foaming agent, 10-20 parts of a dispersant and 60-90 parts of coated wollastonite powder, wherein the coated wollastonite powder is prepared by the following steps: firstly, performing ball mill dispersion treatment on a raw material, namely wollastonite powder, with alcohol for 4-6 hours, drying obtained slurry, and sintering the dried slurry for 2-3 hours at 420-480 DEG C. As gaps in the surface of the foamed concrete is bonded by using a waterproof adhesive, heatconduction of the foamed concrete is prevented, then the heat conductivity of the foamed concrete is improved, the flame retardancy and compressive strength can be greatly improved, the shock resistance, the sound insulation and the weather resistance of a finished product, namely a foamed concrete product, can be improved to a certain extent, and the reliability and the practicability of the product can be improved.

Owner:滁州市富邦新型建材有限公司

Method for manufacturing hollow gold ornaments

InactiveCN107028305AGood compressive strengthEasy to assembleJewelleryElectroforming processesThree dimensional shapeNanotechnology

The invention discloses a method for manufacturing hollow gold ornaments. Compared with traditional casting and oil pressing methods, the method has the advantages that the weight of gold ornaments manufactured with the method is reduced by two thirds, the size of manufactured gold ornaments is larger, and a three-dimensional shape can be obtained. Gold ornaments manufactured with the method have excellent compressive strength, can be assembled, worn and used conveniently and have a longer service life, and the gold ornament repair cost is reduced.

Owner:陈哲

Rigid foam polyurethane thermal insulation material

The invention relates to a thermal insulation material and discloses a rigid foam polyurethane thermal insulation material. The thermal insulation material is prepared by mixing and foaming the following raw materials in parts by weight: 70-100 parts of isocyanate, 40-80 parts of polyether polyol I, 10-30 parts of polyether polyol II, 3-6 parts of expanded vermiculite, 5-8 parts of nano silicon dioxide, 10-20 parts of foaming agent, 1-5 parts of catalyst and 1-5 parts of 3-[polyethylene glycol methyl ether]propyl trialkoxy silane, wherein the polyether polyol I is lignin polyether polyol; and the polyether polyol II is polyether polyol polymerized by taking modified peanut oil as an initiator and epoxy propane as a polymerization monomer. The thermal insulation material has high compressive strength, tensile strength and impact strength and avoids the phenomena of deformation, bulging, barring and even cracking of a water tank.

Owner:GUANGXI JISHUN ENERGY TECH

Arenaceous quartz adglutinate bricks and fabrication technology thereof

The invention discloses a quartz sand baked brick and a manufacture process thereof, which belongs to the brick used in building materials. The ingredients of the invention consist of quartz sand, clay and fly ash. The manufacture process of the quartz sand baked brick is as follows: the ingredients are weighted according to the material mixture ratios and are mixed evenly, then water is added to the mixture for blending and stirring evenly; the mixture is shaped by mould pressing or vibrating squeeze, then is baked and put into a brick kiln to sinter, and then end product of the invention can be obtained. Being baked by taking the quartz sand as the raw material, the quartz sand baked brick can take place of the bricks taking the clay as the material, thus decreasing destructin of the earth. At the same time, the quartz sand baked brick has the performance of the clay baked end brick and has the advantages of high pressive strength, good heat-insulating performance, resistance to elements, good hydroscopic property, no deformation, low price, etc.

Owner:黄凯宏

Carbon fiber reinforced water permeable concrete and preparation method thereof

The invention relates to carbon fiber reinforced water permeable concrete and a preparation method thereof. The technical problems that water permeable concrete in the prior art has low compressive strength, poor durability, a poor water permeation effect and a short service life. According to the provided carbon fiber reinforced water permeable concrete and the preparation method thereof, the concrete is prepared from, by weight, 130-170 parts of cement, 20-30 parts of steel slag, 15-22 parts of magnesium oxide, 13-15 parts of calcium oxide, 16-30 parts of coal gangue, 15-30 parts of fly ash,2-6 parts of epoxy acrylate resin, 2-2.5 parts of polypropylene fiber, 10-30 parts of chopped carbon fiber, 40-60 parts of gravel, 20-30 parts of coarse sand, 0.5-0.8 part of lithium carbonate, 2-5 parts of nonionic surfactant and 170-182 parts of water; at the same time, the preparation method of the concrete is also provided. The carbon fiber reinforced water permeable concrete and the preparation method thereof are widely used in the technical field of road materials.

Owner:威海南海碳材料科技研究院有限公司

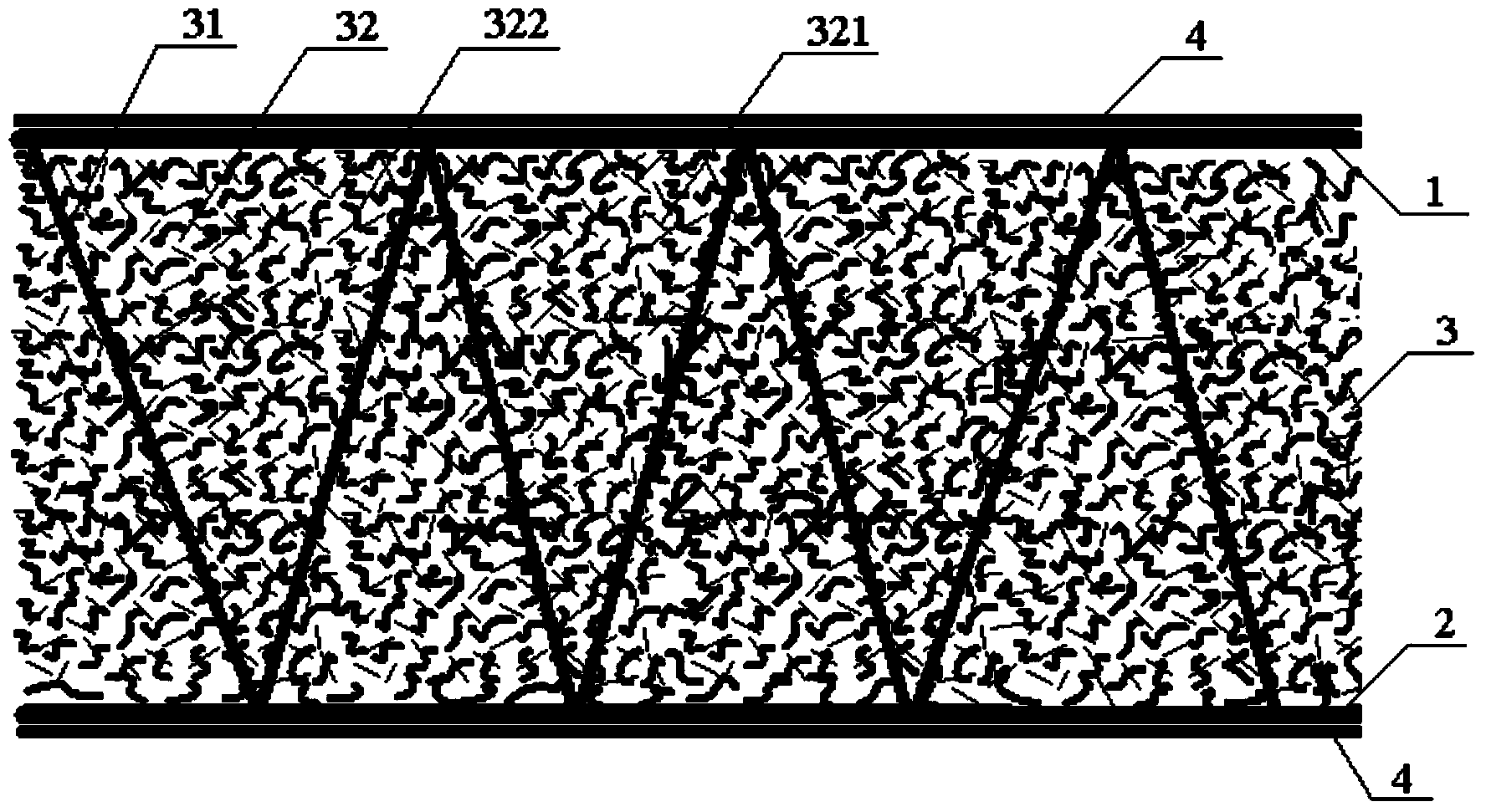

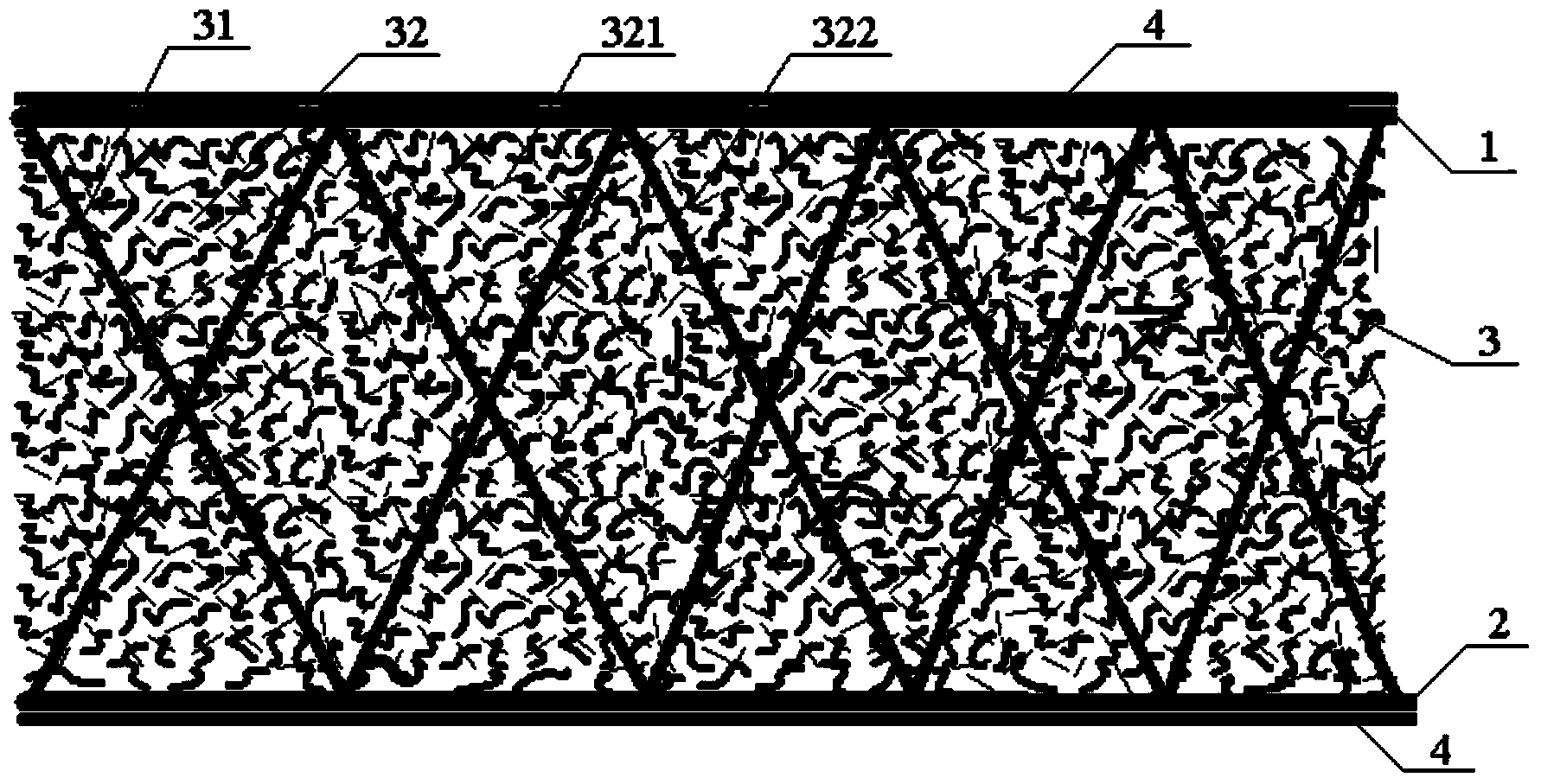

Reinforced heat-insulation three-dimensional fabric

Disclosed reinforced heat-insulation three-dimensional fabric comprises an upper surface layer, a lower surface layer and an intermediate layer arranged between the upper surface layer and the lower surface layer, wherein the intermediate layer comprises spacing fibers and silica aerogel dopped with whisker or / and reinforced short fiber, and multiple intervals formed by arrange of the spacing fibers are filled with the silica aerogel. The three-dimensional fabric provided by the invention not only has good fire resistance, heat resistance and heat insulation performance, but also has good compressive strength, bending strength and tensile strength, is capable of satisfying the application requirements in the fields of fire fighting, industrial heat insulation and the like, and has practicality.

Owner:SHANGHAI UNIV OF ENG SCI

Inorganic foam fire preventing and extinguishing material as well as preparation method and application thereof

ActiveCN114470603AReduce surface tension differencePrevent bustSolid waste managementFire extinguisherCompressive resistanceFoaming agent

The invention relates to an inorganic foam fire preventing and extinguishing material and a preparation method and application thereof, the inorganic foam fire preventing and extinguishing material comprises a component A, a component B and a component C. The component A comprises cement, fly ash, an anionic surfactant and water; the component B comprises a foaming agent, a thickening agent, a foam stabilizer and water; the component C comprises an accelerator, a water reducing agent and water; the mass ratio of the component A to the component B to the component C is (10-50): (0.1-4): (1-5). The raw materials are prepared into the component A, the component B and the component C which are stored independently, and then the three components are mixed to prepare the fire preventing and extinguishing material. The invention further provides a preparation method and application of the inorganic foam fire preventing and extinguishing material, on one hand, the technological process is changed, on the other hand, the formula of the inorganic foam fire preventing and extinguishing material is reasonably constructed, the breaking degree of foam in the mixing process is reduced, and the material high in compressive strength and good in leaking stoppage fire preventing and extinguishing effect is prepared.

Owner:CCTEG CHINA COAL RES INST

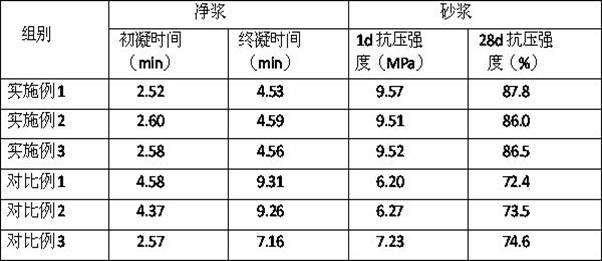

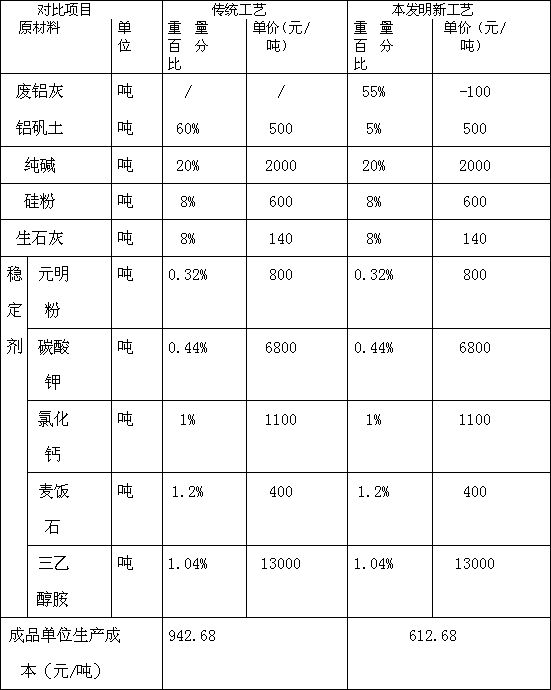

Concrete accelerator and preparation method thereof

InactiveCN111704379AShort initial and final setting timesGood compressive strengthSodium carbonateChemistry

The invention discloses a concrete accelerator and a preparation method thereof. The concrete accelerator comprises the following components in parts by weight: 50-60 parts of waste aluminum ash, 3-8parts by weight of bauxite, 15-25 parts by weight of sodium carbonate, 6-10 parts by weight of silicon powder, 6-10 parts by weight of quick lime and 2-6 parts by weight of a stabilizer. The preparation method of the concrete accelerator comprises the following steps: accurately weighing the raw components in proportion, and conveying a formed mixture to a rotary kiln through a conveying system for roasting. According to the invention, shorter initial setting time and final setting time are obtained through a unique formula; better compressive strength is realized; the waste aluminum ash is adopted in the formula, so waste utilization can be reasonably carried out; in the preparation process, waste gas, waste water and waste smoke are avoided; and in the preparation method, a rotary kiln is adopted for roasting the mixed raw materials, a kiln temperature is easy to control, and a unique roasting process is selected, so the performance of the concrete accelerator can be effectively improved.

Owner:四川省绿辉环保科技有限公司

Baking-free brick with air purifying function

InactiveCN106348702AGood compressive strengthHigh compressive strengthCeramic shaping apparatusAir cleaningRiver sand

The invention discloses a baking-free brick with an air purifying function and a preparation method of the baking-free brick, and relates to the technical field of baking-free bricks. The baking-free brick with the air purifying function comprises the following components: a mixture A and a mixture B, wherein the mixture A comprises the following components in parts by weight: river sand 70-85 parts, slag 40-60 parts, quick lime 30-40 parts, cement 10-15 parts, silica powder 5-8 parts, nano aluminium oxide 5-8 parts, clay 5-8 parts, ethanolamine 1-2 parts, waterglass 1-2 parts, and an early strength agent 1-2 parts; the grain size distribution of the river sand is 2-3 mu m 30wt%; the grain size of the nano aluminium oxide is 30-60 nm; and the mixture B comprises the following components in parts by weight: water 40-60 parts, acetic acid 8-9 parts, urea 20-30 parts, an emulsifying agent 3-3.5 parts, propylene carbonate 7-8 parts, melamine 3-3.5 parts, dicyandiamide 2-2.5 parts, polyacrylamide 0.03-0.05 part, and ethylacetoacetate 0.05-0.07 part.

Owner:明光市凯旋新型建材厂

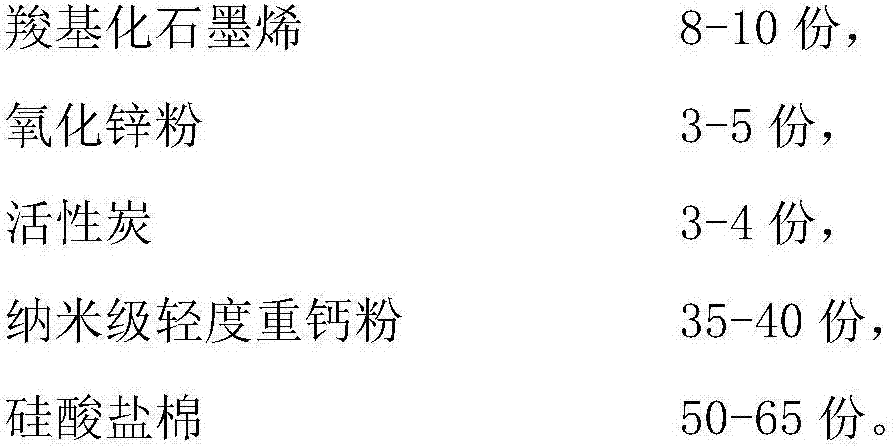

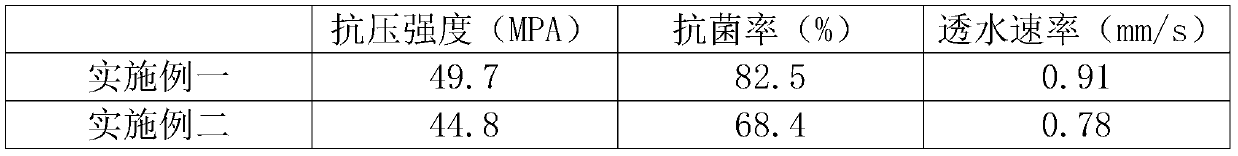

High-strength antibacterial environment-friendly water-permeable brick and preparation method thereof

InactiveCN110156488AEasy to makeGood compressive strengthCeramic materials productionCeramicwareActivated carbonCorrosion

The invention discloses a high-strength antibacterial environment-friendly water-permeable brick and a preparation method thereof. The water-permeable brick comprises the following components in partsby weight: 80-100 parts of polymer fiber porous concrete, 40-60 parts of building waste residues, 10-20 parts of hollow microbeads, 3-9 parts of nano titanium dioxide, 2-6 parts of nano silicon dioxide, 3-10 parts of nano tourmaline, 2-4 parts of modified activated carbon, 1-3 parts of modified graphene oxide, 2-8 parts of zirconia fibers and 2-6 parts of an antibacterial agent. According to thehigh-strength antibacterial environment-friendly water-permeable brick disclosed by the invention, an antibacterial agent taking carboxymethyl chitosan as a main component is added, so that the water-permeable brick has a balanced sterilization effect, damage to the environmental is small, and the lasting time of the sterilization effect is long. The water-permeable brick is simple in preparationmethod, has the advantages of excellent compressive strength, wear resistance and corrosion resistance and high strength, is not easily damaged, and has the advantages of adsorbing pollutants in waterand inhibiting and resisting bacteria. Environmental protection performance is good, and popularization and use are convenient.

Owner:柳州柳晶环保科技有限公司

Solar energy storage ceramic material with high energy storage density

PendingCN112457023AGood compressive strengthStrong thermal shock resistanceCeramicwareSodium silicateSilicon nitride

The invention discloses a solar energy storage ceramic material with high energy storage density. The solar energy storage ceramic material is prepared from the following components in parts by weight: 60-80 parts of silicon nitride, 30-45 parts of boron nitride, 15-25 parts of boron carbide, 5-15 parts of titanium silicide, 5-12 parts of aluminum oxide, 2-7 parts of sodium silicate, 3-10 parts ofmagnesium oxide and 1-5 parts of lanthanum oxide, wherein all the components are powder with the average particle size of 10-50nm; silicon nitride, boron nitride and boron nitride are adopted as basematerials, so that the ceramic material has the advantages of being good in compressive strength and high in thermal shock resistance; and meanwhile, titanium silicide, aluminum oxide, sodium silicate, magnesium oxide and lanthanum oxide are added as additives, and especially a small amount of lanthanum oxide is added, so that the energy storage density of the ceramic material can be remarkably improved. The energy storage density of the solar energy storage ceramic material with high energy storage density can reach 1000 kJ / g or above.

Owner:湖州浩通电子科技有限公司

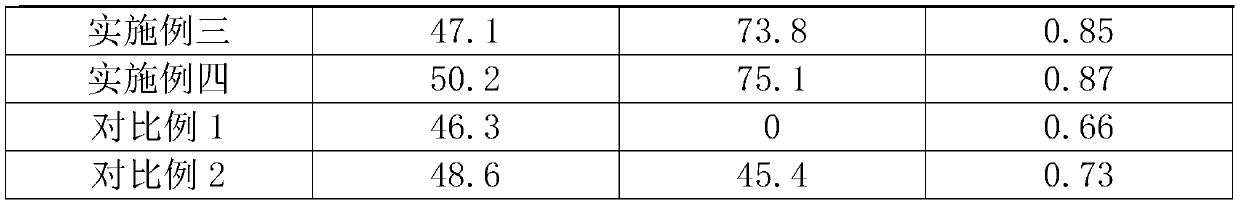

Insulation board and manufacturing method thereof

The invention discloses an insulation board which is prepared from the following raw materials in parts by weight: 25 to 33 parts of slag powder, 20 to 28 parts of sawdust, 18 to 26 parts of straw fiber, 10 to 18 parts of adhesive, 15 to 23 parts of polystyrene resin, 22 to 30 parts of foaming agent, 8 to 16 parts of antioxidant, 5 to 13 parts of stabilizer, 1 to 5 parts of fire retardant and 5 to 13 parts of catalyst. Further, the insulation board comprises the following raw materials in parts by weight: 25 parts of slag powder, 20 parts of sawdust, 18 parts of straw fibers, 10 parts of an adhesive, 15 parts of polystyrene resin, 22 parts of a foaming agent, 8 parts of an antioxidant, 5 parts of a stabilizer, 1 part of a fireproof agent and 5 parts of a catalyst. The prepared heat insulation board is good in heat transfer coefficient, fireproof performance, specific gravity, compressive strength and breaking strength and has low heat conductivity so that better heat insulation performance is guaranteed, and the insulation board has excellent toughness and rigidity.

Owner:上海望实建筑工程有限公司

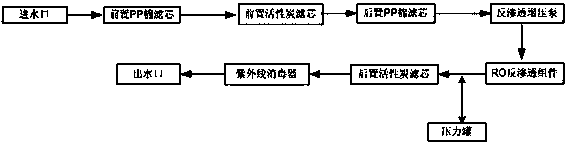

Powder dropping preventive water dispenser with polypropylene (PP) film activated carbon filter elements

InactiveCN103663604AGood compressive strengthGood anti-pollution performanceMultistage water/sewage treatmentWater/sewage treatment by sorptionActivated carbonPolypropylene

The invention provides a powder dropping preventive water dispenser with polypropylene (PP) film activated carbon filter elements. The water dispenser comprises a front PP cotton filter element, a front-end activated carbon filter element, a rear PP cotton filter element, an RO (reverse osmosis) booster pump, an RO component, a rear-end activated carbon filter element, an ultraviolet sterilizer and a water outlet which are connected in sequence, wherein the front PP cotton filter element and the rear PP cotton filter element comprise a first PP cotton filter layer and a second PP cotton filter layer which are arranged in sequence in the water flow direction, the pore diameter of each PP cotton filter layer is reduced gradually in the water flow direction, the pore diameter of the first PP cotton filter layer is larger than that of the second PP cotton filter layer and is 4.5 mu m, and the pore diameter of the second PP cotton filter layer is 1.5 mu m; and the front-end activated carbon filter element and the rear-end activated carbon filter element comprise a cylindrical hollow filter casing, a water inlet and the water outlet are formed in two ends of the filter casing respectively, a cylindrical filter screen is arranged in the filter casing and is closely attached to the inner wall of the filter casing, and an activated carbon film is arranged in the filter screen.

Owner:CHENGDU JETCOM TECH

Heat insulation building composite material and preparation method thereof

InactiveCN106995288AGood insulation performanceGood compressive strengthBarium metaphosphateCalendic acid

The invention discloses a heat insulation building composite material and a preparation method thereof. The heat insulation building composite material is prepared from the following components in parts by weight: 30 to 45 parts of building waste powder, 6 to 8 parts of sodium mercaptobenzothiazole, 5 to 8 parts of methyl acetoacetate, 6 to 10 parts of disodium dihydrogen pyrophosphate, 2 to 6 parts of waterborne polyurethane, 5 to 8 parts of barium metaphosphate, 2 to 5 parts of calendic acid, 7 to 16 parts of illite, 8 to 15 parts of gangue, 5 to 8 parts of fluorocarbon alcohol, 0.5 to 1 part of glycyrrhetinic acid monoglucuronide, 0.5 to 1 part of lignin, and 0.1 to 1 part of water reducing agent. The heat insulation building composite material has the advantages that the heat insulation property is good, the compressive strength and neutral salt mist-resistant property are good, the weight of the heat insulation building material is light, and the requirement of modern buildings is well met; by using the building waste as the raw material, better energy-saving and environment-friendly effects are realized.

Owner:HEFEI ZHIHUI LONGTUTENG INTPROP CO LTD

Nickel-iron slag self-insulating autoclaved brick and preparation method thereof

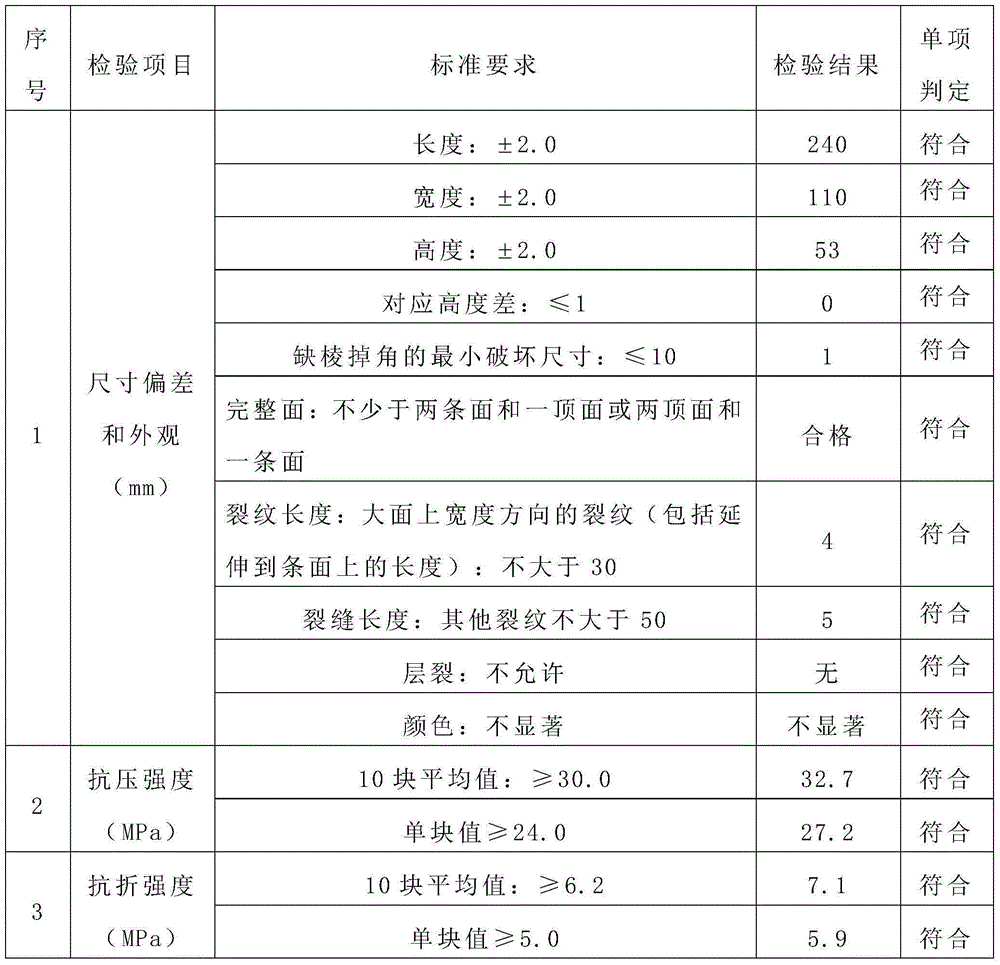

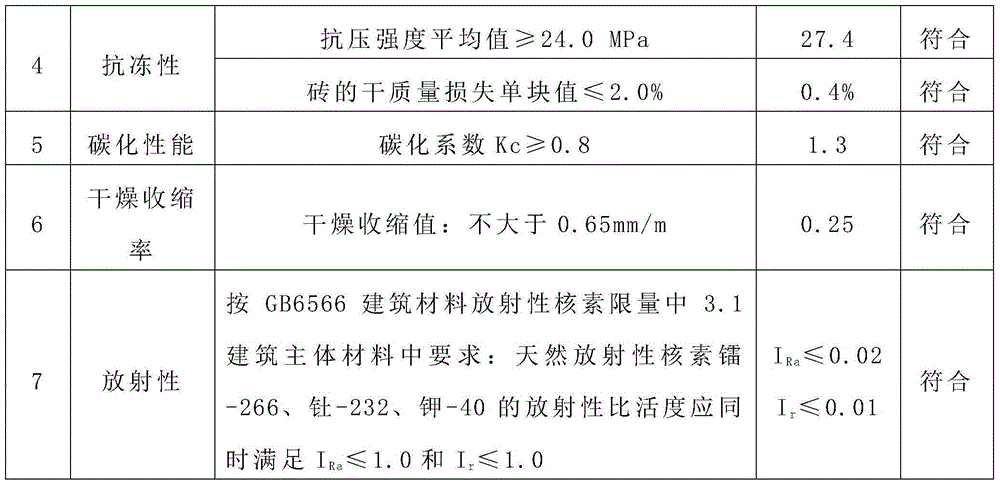

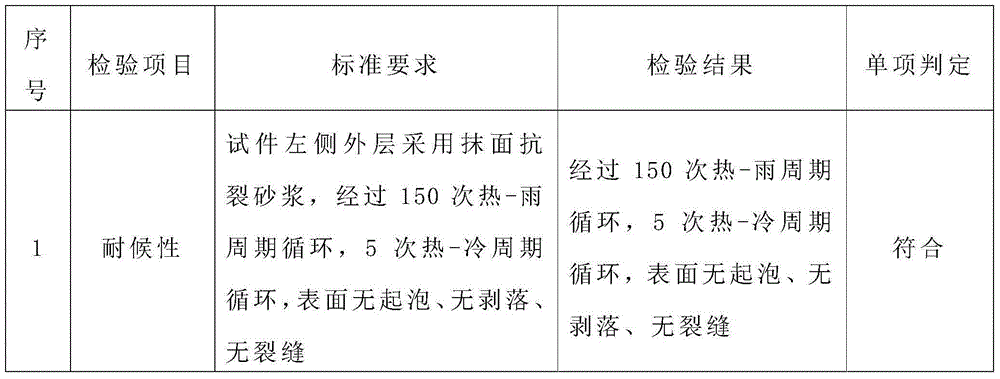

The invention relates to a nickel-iron slag self-heat preservation autoclaved brick and a preparation method for the same. The nickel-iron slag self-heat preservation autoclaved brick comprises nickel-iron slag and a calcium material, wherein the calcium material is preferably carbide slag; the nickel-iron slag comprises powdery nickel-iron slag and granular nickel-iron slag. The nickel-iron slag self-heat preservation autoclaved brick has a low heat transfer coefficient, strong compressive strength and high freezing resistance; the strength grade can reach MU30; the appearance quality and dimensional deviation of the nickel-iron slag self-heat preservation autoclaved brick are consistent with standards; the surface of the self-heat preservation autoclaved brick is detected to be free of bubbling, stripping and cracks by virtue of weather resistance tests; in addition, the aims of treating wastes with wastes and turning the wastes into wealth can be fulfilled, pollution caused by the nickel-iron slag can be reduced, and the ecological environment can be optimized; high added value can be obtained with low cost, so that the self-heat preservation autoclaved brick has great economic and social benefits.

Owner:SHANDONG WEIYE NEW BUILDING MATERIAL

Preparation method of waste brick aggregate

InactiveCN112194398AHigh compressive strengthGood compressive strengthSolid waste managementPoly ethyleneEnvironmental engineering

The invention provides a preparation method of waste brick aggregate, which comprises the following steps of crushing waste bricks, screening out waste brick particles with the particle size of 2-20 mm, and treating the waste brick particles with polyvinylpyrrolidone to prepare the waste brick aggregate. By means of the method, the prepared waste brick aggregate has higher compressive strength.

Owner:北京联绿技术集团有限公司

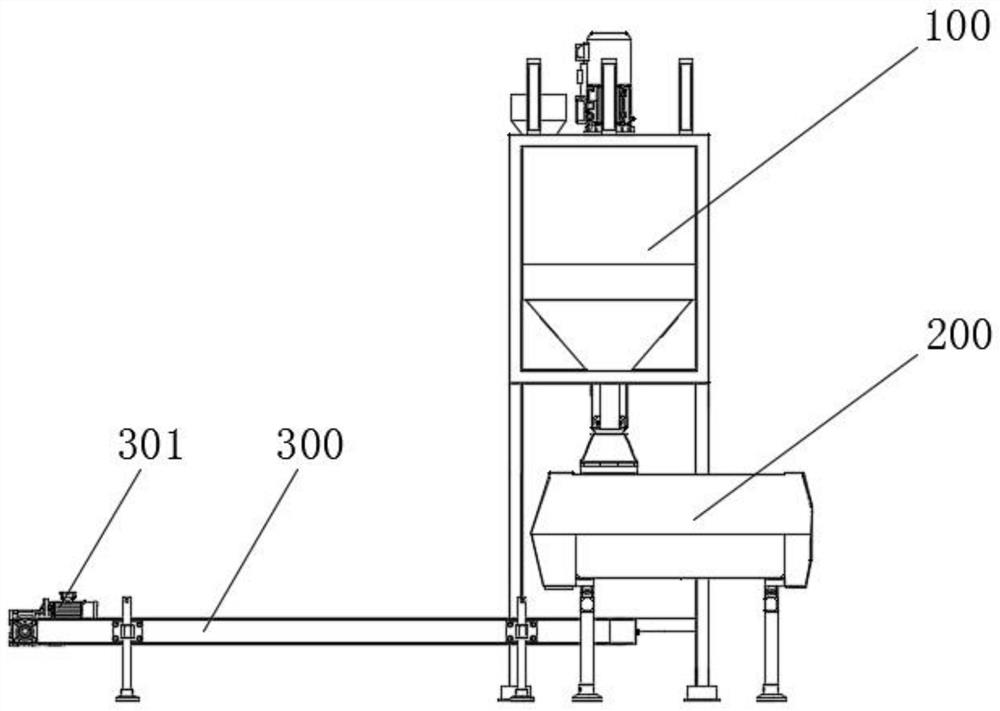

Fiber reinforced concrete and preparation method thereof

InactiveCN112266208AGood compressive strengthImprove fracture toughnessRiver sandFibre reinforcement

The invention discloses fiber-reinforced concrete and a preparation method thereof. Carbon fibers, brucite fibers, glass fibers, epoxy resin, acrylate emulsion, a dispersing agent, diatomite and rubber powder are used to prepare a reinforced fiber material by using reinforced fiber production equipment; and then cement, fly ash, mineral powder, water, gravels, river sand, a water reducing agent and the reinforced fiber material are uniformly mixed to prepare the fiber reinforced concrete. The fiber reinforced concrete has excellent compressive strength and flexural strength; and according to the reinforced fiber production equipment, raw materials are stirred evenly through a powder making mechanism and then dried, then the raw materials are smashed into powder, the smashed powder is screened through a screening mechanism according to the particle size, the powder with the small particle size is selected to be used for preparing concrete, reinforced fiber materials are evenly dispersedin the concrete, thus the effect of the reinforced fiber material is fully exerted, and the prepared concrete is further good in mechanical property and high in quality.

Owner:何国辉

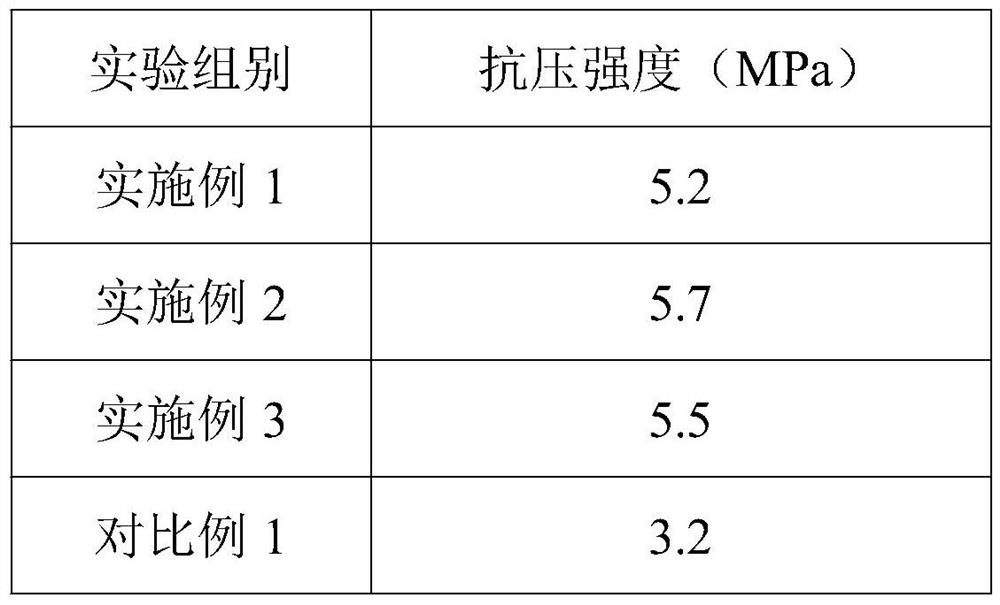

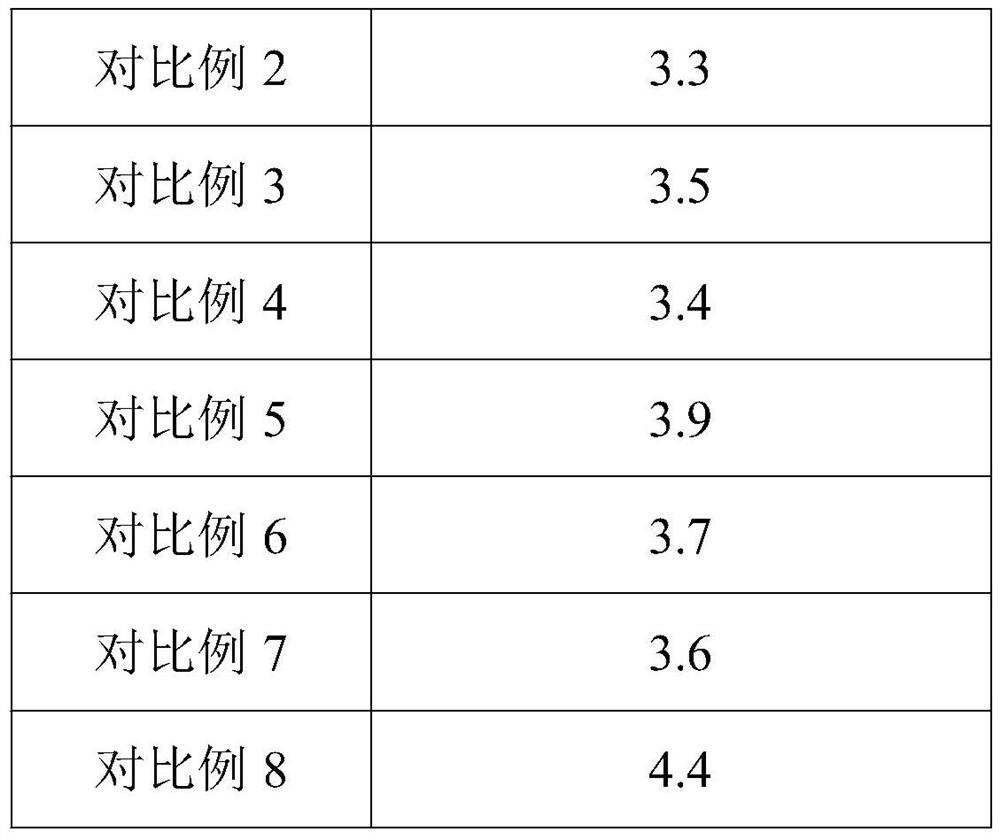

High-performance core material, preparation method and application of high-performance core material in preparation of polyphenyl granule light partition board

PendingCN114605116AGood compressive strengthHigh strengthConstruction materialWallsMaleic anhydrideAcetylacetone

The invention discloses a high-performance core material, which is prepared from the following raw materials: cement, coal ash, polystyrene particles, sand, resorcinol, maleic anhydride, zeolite powder, ethylene phosphate, a foaming agent, a foam stabilizer, hydrogen peroxide, tert-butyl peroxypivalate, trimethylolpropane tri (3-aziridinyl propionate), acetylacetone, 1, 2-cyclohexanediamine, 2, 2, 4, 6-tetramethyl-1, 3-pentanediol, 1, 2, 4-tetramethyl-1, 3-pentanediol, 1, 2, 4-tetramethyl-1, 3, 4-tetramethyl-1, 3, 4-tetramethyl-1, 3, 4-tetramethyl-1, 3, 4-tetramethyl-1, the component A is prepared from 1, 2-di (tert-butylperoxy) butane, octenyl succinic acid modified starch and water; the high-performance core material is prepared through the steps of slurry preparation, foam liquid preparation, raw material mixing and the like. The compressive strength of the polyphenyl granule light partition wall board made of the core material is 5.2 MPa or above, which indicates that the compressive strength of the polyphenyl granule light partition wall board made of the core material is good, and is superior to the technical index that the compressive strength of the light partition wall board is larger than or equal to 3.5 MPa according to the national standard requirement of Lightweight Partition Wall Board for Building (GB / 23451-2009).

Owner:GUANGXI HONGFA BUILDING MATERIALS TECH

Research on bonding performance of steel-polyvinyl alcohol hybrid fiber reinforced ECC and FRP ribs

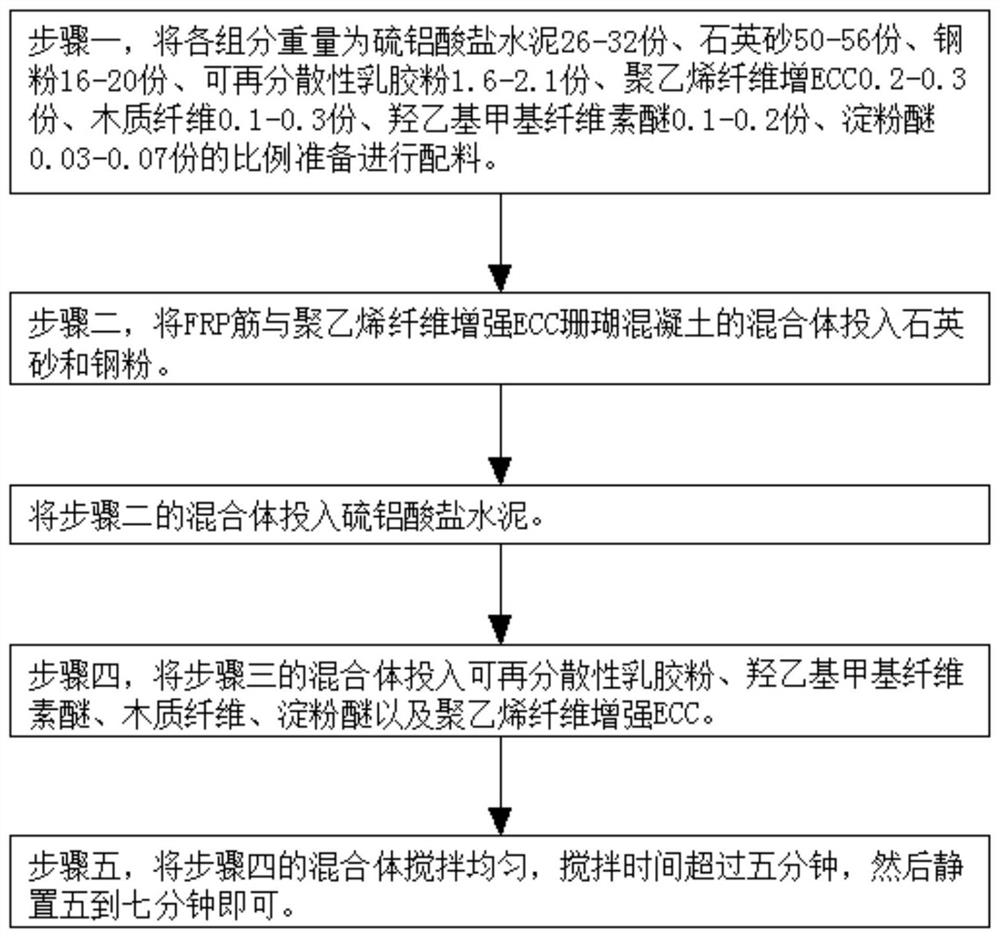

The invention discloses research on bonding performance of steel-polyvinyl alcohol hybrid fiber reinforced ECC and FRP ribs. The research comprises 1) preparing the following components in parts by weight: 26 to 32 parts of sulphoaluminate cement, 50 to 56 parts of quartz sand, 16 to 20 parts of steel powder, 1.6 to 2.1 parts of redispersible latex powder, 0.2 to 0.3 part of polyethylene fiber reinforced ECC, 0.1 to 0.3 part of wood fibers, 0.1 to 0.2 part of hydroxyethyl methyl cellulose ether and 0.03 to 0.07 part of starch ether; 2) adding the quartz sand and the steel powder into a mixture of the FRP ribs and the polyethylene fiber reinforced ECC coral concrete; 3), adding the mixture obtained in the step 2 into the sulphoaluminate cement; 4), adding the mixture obtained in the step 3 into the redispersible latex powder, the hydroxyethyl methyl cellulose ether, the wood fibers, the starch ether and the polyethylene fiber reinforced ECC; and 5), uniformly stirring the mixture obtained in the step 4 for more than five minutes, and then standing for 5-7 minutes.

Owner:WUHAN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com