High-strength antibacterial environment-friendly water-permeable brick and preparation method thereof

A permeable brick, high-strength technology, applied in the direction of ceramic products, clay products, other household appliances, etc., can solve the problems of permeable brick aperture blockage, affect the water permeability of permeable bricks and other problems, achieve the adjustment of mechanical strength enhancement, easy promotion and use, sustainable long time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

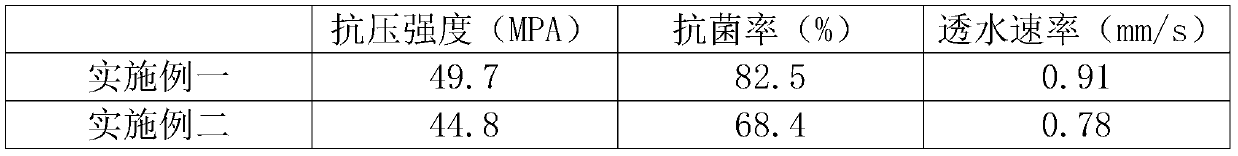

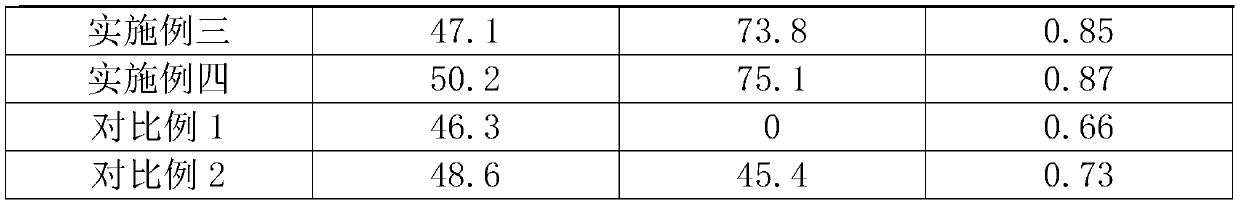

Examples

Embodiment 1

[0025] The high-strength antibacterial and environmentally friendly permeable bricks include 80 parts by weight of polymer fiber porous concrete, 60 parts of construction waste, 10 parts of hollow microspheres, 5 parts of nano-titanium dioxide, 3 parts of nano-silica, 3 parts of nano-tourmaline, 4 parts of modified activated carbon, 1 part of modified graphene oxide, 4 parts of zirconia fiber and 6 parts of antibacterial agent.

[0026] The antibacterial agent comprises the following raw materials in mass percentage: 3 parts of cellulose acetate microspheres, 1 part of carboxymethyl chitosan, 2 parts of (4-carboxyphenylethynyl) trimethylsilane, 1-butyl-3-methylsilane 2 parts of imidazole p-toluenesulfonate ionic liquid, 1 part of styrene-based cation exchange resin.

[0027] The manufacturing method of this embodiment includes the following steps:

[0028] A, polymer fiber porous concrete, construction waste residue, hollow microspheres, and nano tourmaline are mixed and then...

Embodiment 2

[0034] The components of high-strength antibacterial and environmentally friendly permeable bricks include 100 parts by weight of polymer fiber porous concrete, 40 parts of construction waste, 20 parts of hollow microspheres, 3 parts of nano-titanium dioxide, 5 parts of nano-silica, 8 parts of nano-tourmaline, 4 parts of modified activated carbon, 3 parts of modified graphene oxide, 6 parts of zirconia fiber and 2 parts of antibacterial agent.

[0035] The antibacterial agent comprises the following raw materials in mass percentage: 2.5 parts of cellulose acetate microspheres, 1.5 parts of carboxymethyl chitosan, 2 parts of (4-carboxyphenylethynyl) trimethylsilane, 1-butyl-3-methylsilane 2 parts of imidazole p-toluenesulfonate ionic liquid, 2 parts of styrene-based cation exchange resin.

[0036] The manufacturing method of this embodiment includes the following steps:

[0037] A, polymer fiber porous concrete, construction waste residue, hollow microspheres, and nano tourmal...

Embodiment 3

[0043] The components of high-strength antibacterial and environmentally friendly permeable bricks include 85 parts by weight of polymer fiber porous concrete, 45 parts of construction waste, 12 parts of hollow microspheres, 4 parts of nano-titanium dioxide, 3 parts of nano-silica, 4 parts of nano-tourmaline, 2 parts of modified activated carbon, 1 part of modified graphene oxide, 3 parts of zirconia fiber and 3 parts of antibacterial agent.

[0044] The antibacterial agent comprises the following raw materials in mass percentage: 4 parts of cellulose acetate microspheres, 2 parts of carboxymethyl chitosan, 1 part of (4-carboxyphenylethynyl) trimethylsilane, 1-butyl-3-methylsilane 1.5 parts of imidazole-p-toluenesulfonate ionic liquid, and 1.5 parts of styrene-based cation exchange resin.

[0045] The manufacturing method of this embodiment includes the following steps:

[0046]A, polymer fiber porous concrete, construction waste residue, hollow microspheres, and nano tourmal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com