Research on bonding performance of steel-polyvinyl alcohol hybrid fiber reinforced ECC and FRP ribs

A technology of polyethylene fiber and polyvinyl alcohol, which is applied in the field of building materials, can solve the problems of large shrinkage, hollowing in the gap, and loose connection of board seams, etc., and achieves good bond strength and compressive strength, and bond strength and Higher compressive strength, better water retention and adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

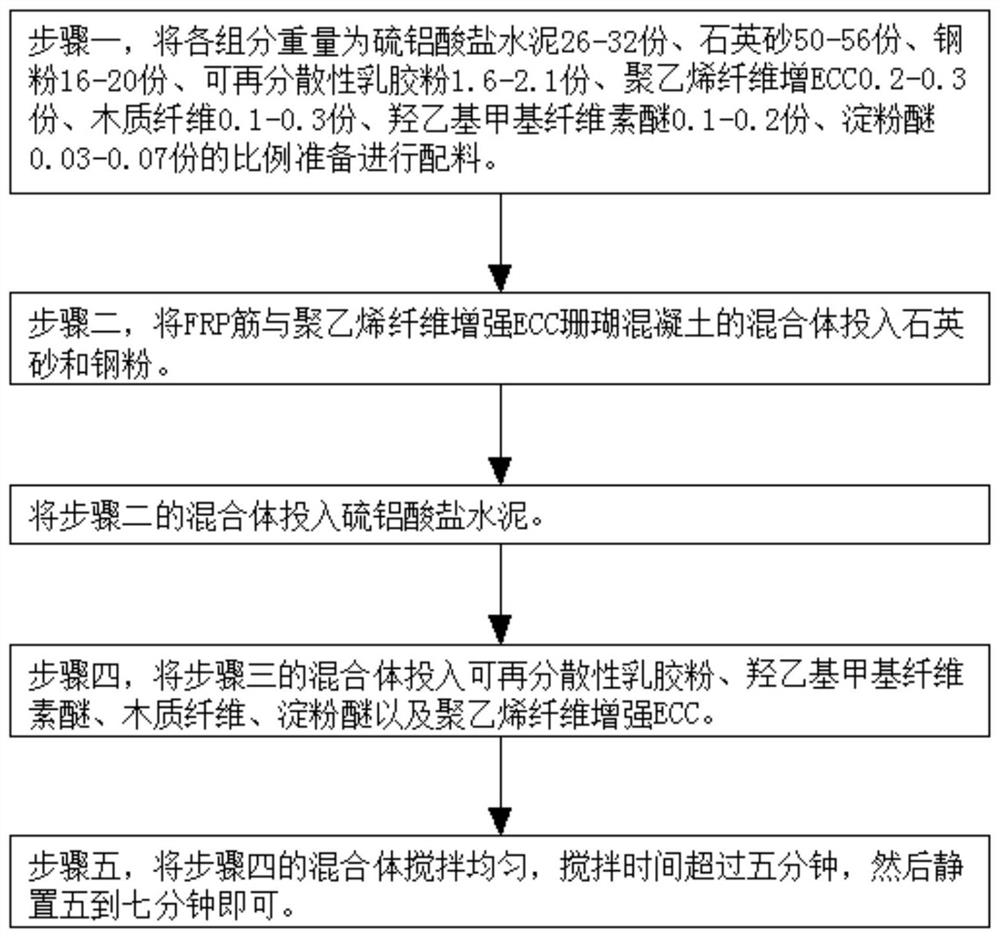

[0020] Specific embodiment one, please refer to figure 1 .

[0021] The invention provides a technical solution:

[0022] Research on the bonding properties of steel-polyvinyl alcohol hybrid fiber reinforced ECC and FRP bars, the required material components are:

[0023] Sulphoaluminate cement, quartz sand, redispersible latex powder, hydroxyethyl methyl cellulose ether, wood fiber, starch ether, polyethylene fiber reinforced ECC and steel powder, wherein the weight of each component is sulphoaluminate 28 parts of cement, 56 parts of quartz sand, 16 parts of steel powder, 2.1 parts of redispersible latex powder, 0.3 parts of polyethylene fiber reinforced ECC, 0.3 parts of wood fiber, 0.2 parts of hydroxyethyl methyl cellulose ether, starch ether 0.03 copies;

[0024] The specific steps of the research are as follows:

[0025] Step 1, the weight of each component is 28 parts of sulfoaluminate cement, 56 parts of quartz sand, 16 parts of steel powder, 2.1 parts of redispers...

specific Embodiment 2

[0031] Specific embodiment two, please refer to figure 1 .

[0032] The invention provides a technical solution:

[0033] Research on the bonding properties of steel-polyvinyl alcohol hybrid fiber reinforced ECC and FRP bars, the required material components are:

[0034] The components required for it are:

[0035] Sulphoaluminate cement, quartz sand, redispersible latex powder, hydroxyethyl methyl cellulose ether, wood fiber, starch ether, polyethylene fiber reinforced ECC and steel powder, wherein the weight of each component is sulphoaluminate 32 parts of cement, 48 parts of quartz sand, 20 parts of steel powder, 1.6 parts of redispersible latex powder, 0.2 parts of polyethylene fiber reinforced ECC, 0.1 part of wood fiber, 0.1 part of hydroxyethyl methyl cellulose ether, starch ether 0.07 copies;

[0036] The specific steps of the research are as follows:

[0037] Step 1, the weight of each component is 32 parts of sulfoaluminate cement, 48 parts of quartz sand, 20 p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com