Preparation method of polyurethane foam dressing and wound dressing patch

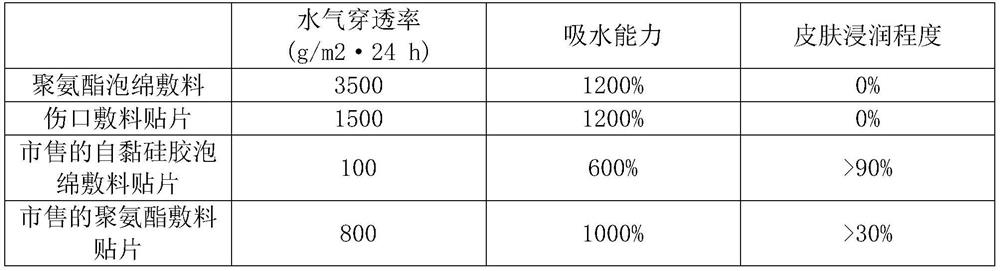

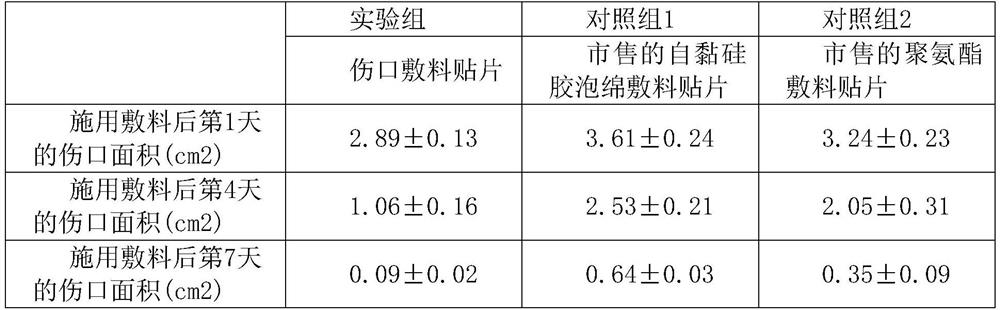

A technology of wound dressing and polyurethane, which is applied in the medical field, can solve the problem of insufficient moisture regulation ability of wounds and normal skin, and achieve the effect of accelerating the healing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] The preparation method of polyurethane foam dressing, comprises the steps:

[0021] Step A: mixing and stirring the hydrophobic polyol with a molar ratio of 1:3 to 1:8 and the hydrophilic diisocyanate, and reacting to obtain a prepolymer containing 3 to 6 isocyanate groups;

[0022] Step B: the prepolymer obtained in step A, hydrophilic polyether polyol, foaming agent, end-capping agent, strengthening agent and catalyst are 1:(0.5-2):(0.2-0.8) in molar ratio :(0.2-0.8):(0.2-0.8) Mix and stir, react to form polyurethane foam dressing.

[0023] On the basis of the above, the hydrophobic polyol is prepared by the following steps:

[0024] Step a1: mixing and stirring the branched trihydric alcohol with a molar ratio of 1:2 to 1:5 and the first diisocyanate to obtain a triisocyanate intermediate;

[0025] The branched trihydric alcohol can be 1,1,1-trimethylolpropane (trimethylolpropane), triethanolamine, glycerin, 1,2,6-hexanetriol, 1,2,4-butanetriol, Polyoxyethyl glyce...

Embodiment 1

[0037] Step a1: In a closed nitrogen environment, mix 1,1,1-trimethylolpropane (TMP) and hexamethylene diisocyanate (HDI) at a molar ratio of 1:3, and add 0.05wt% Triethylenediamine (triethylenediamine, TEDA) (with the total weight of TMP and HDI as 100wt%) was used as a catalyst, stirred and reacted at 80°C for 90min, and the presence of the NCO characteristic peak at 2270cm-1 was monitored by FT-IR. To obtain triisocyanate intermediates;

[0038] Step a2: In a closed nitrogen environment, mix the triisocyanate intermediate with polypropylene glycol triol (PPG4000triol) at a molar ratio of 1:3, and add 0.05wt% TEDA (based on the total of the triisocyanate and PPG triol) Weight is 100wt%) as catalyzer, stirred and reacted 90min in 80 ℃, utilized FT-IR to monitor the disappearance of the NCO characteristic peak at 2270cm-1 place, to obtain the hydrophobic hexahydric alcohol containing polypropylene glycol;

[0039] Step b: In a closed nitrogen environment, mix polyethylene gly...

Embodiment 2

[0044]Step a1: In an airtight nitrogen atmosphere, mix triethanolamine and methylene dicyclohexyl diisocyanate (H12MDI) at a molar ratio of 1:4, and add 0.05wt% triethylenediamine (triethylenediamine , TEDA) (with the total weight of TMP and HDI as 100wt%) as a catalyst, stirred and reacted at 70°C for 100min, and used FT-IR to monitor the presence of the NCO characteristic peak at 2270cm-1 to obtain a triisocyanate intermediate ;

[0045] Step a2: In a closed nitrogen environment, mix the triisocyanate intermediate with poly(tetramethylene ether)glycol triol] at a molar ratio of 1:2, and add 0.05wt %TEDA (with the total weight of the triisocyanate and PPG triol as 100wt%) was used as a catalyst, stirred and reacted at 70°C for 100min, and used FT-IR to monitor the disappearance of the NCO characteristic peak at 2270cm-1 to obtain poly Hydrophobic hexaol of propylene glycol;

[0046] Step b: In an airtight nitrogen environment, mix polyethylene glycol (PEG 1000diol) with met...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com