Dual-phase magnetic nano-composite scaffold material and preparation method thereof

A technology of magnetic nano and composite scaffolds, applied in the field of biomedical composite materials, to achieve the effects of facilitating adhesion growth and vascularization, reducing toxicity, and improving biomechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Step 1: Dissolve 18.18g of PLGA in 100ml of 1,4-dioxane and stir evenly in a water bath at 60°C to obtain a homogeneous solution of the first PLGA and 1,4-dioxane;

[0048] Step 2, weigh 1.82g of Col-I powder and add it to the homogeneous solution of the first PLGA and 1,4-dioxane obtained in step 1, ultrasonically oscillate for 20 hours, and electromagnetically stir for 16 hours to obtain a concentration of 20% by mass. Cartilage phase scaffold solution;

[0049] Step 3: Dissolve 16.66g of PLGA in 100ml of 1,4-dioxane and stir evenly in a water bath at 60°C to obtain a homogeneous solution of the second PLGA and 1,4-dioxane;

[0050] Step 4, weigh 1.67g n-HA and 1.67g magnetic nanoparticles Fe respectively 2 o 3 Add the second PLGA and 1,4-dioxane obtained in step 3 into the homogeneous solution, ultrasonically oscillate for 20 minutes, and electromagnetically stir for 16 hours to obtain a mass percentage concentration of 20% and put it into the bone phase scaffold s...

Embodiment 2

[0054] Step 1: Dissolve 18.18g of PLGA in 100ml of 1,4-dioxane and stir evenly in a water bath at 50°C to obtain a homogeneous solution of the first PLGA and 1,4-dioxane;

[0055] Step 2, weigh 1.82g of Col-I powder and add it to the homogeneous solution of the first PLGA and 1,4-dioxane obtained in step 1, ultrasonically oscillate for 10 hours, and electromagnetically stir for 12 hours to obtain a mass percent concentration of 20%. Cartilage phase scaffold solution;

[0056] Step 3, weigh 16.66g of PLGA and dissolve it in 100ml of 1,4-dioxane, and stir evenly in a water bath at 50°C to obtain a homogeneous solution of the second PLGA and 1,4-dioxane;

[0057] Step 4, weigh 1.67g n-HA and 1.67g magnetic nanoparticles Fe respectively 2 o 3 , adding the second PLGA and 1,4-dioxane obtained in step 3 into the homogeneous solution, ultrasonically oscillating for 10 minutes, and electromagnetically stirring for 12 hours to obtain a mass percentage concentration of 20% and put it ...

Embodiment 3

[0061] Step 1, weigh 18.18g of PLGA and dissolve it in 100ml of 1,4-dioxane, and stir evenly in a water bath at 70°C to obtain the first homogeneous solution of PLGA and 1,4-dioxane;

[0062] Step 2, weigh 1.82g of Col-I powder, add it to the homogeneous solution of the first PLGA and 1,4-dioxane obtained in step 1, ultrasonically oscillate for 30 hours, and electromagnetically stir for 24 hours to obtain a concentration of 20% by mass The cartilage phase scaffold solution;

[0063] Step 3, weigh 16.66g of PLLA and dissolve it in 100ml of 1,4-dioxane, and stir evenly in a water bath at 70°C to obtain a homogeneous solution of the second PLGA and 1,4-dioxane;

[0064] Step 4, weigh 1.67g n-HA and 1.67g magnetic nanoparticles Fe respectively 2 o 3 Add the second PLGA and 1,4-dioxane obtained in step 3 into the homogeneous solution, ultrasonically oscillate for 30 minutes, and electromagnetically stir for 24 hours to obtain a mass percentage concentration of 20% and put it into...

PUM

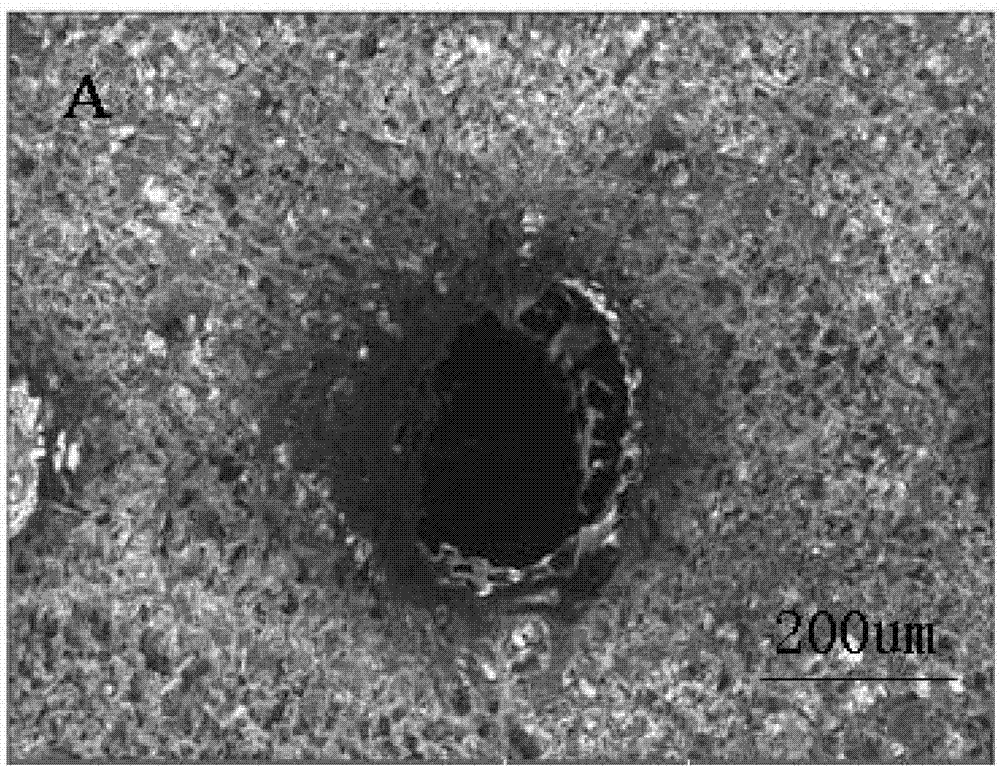

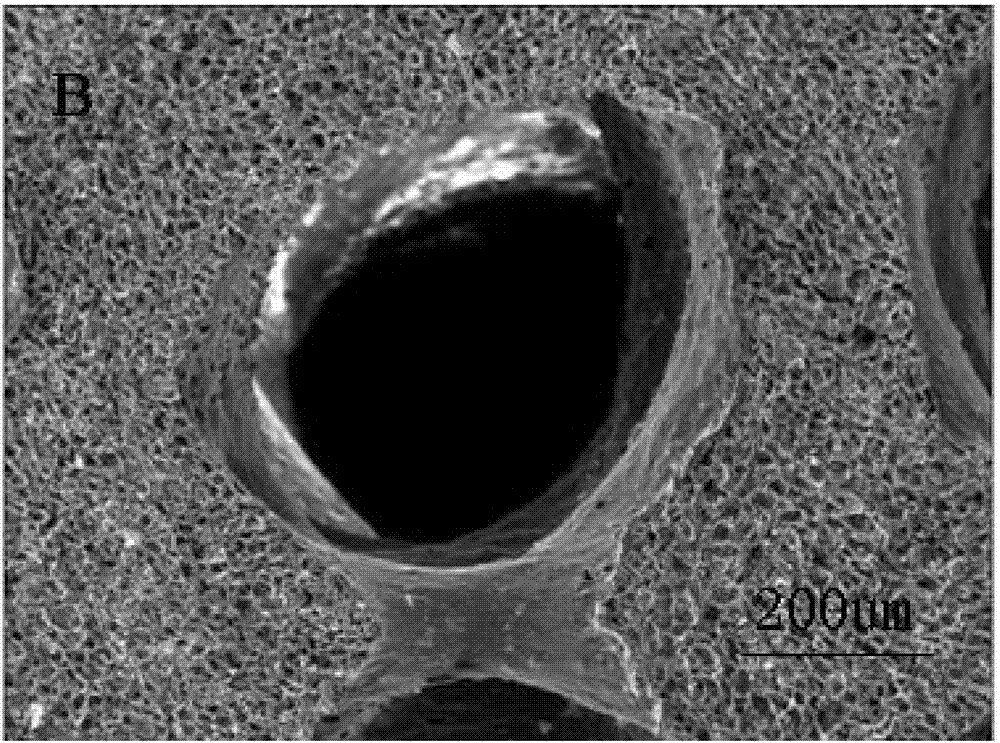

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com