Core-shell drug-loaded nano-fiber dressing and preparation method thereof

A drug-loaded nanometer and fiber technology, which is applied in the fields of medical formula, fiber chemical characteristics, medical science, etc., can solve the problem of reduced spinnability of electrospinning solution, so as to facilitate cell adhesion and proliferation, promote wound healing, and promote cell regeneration. The effect of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

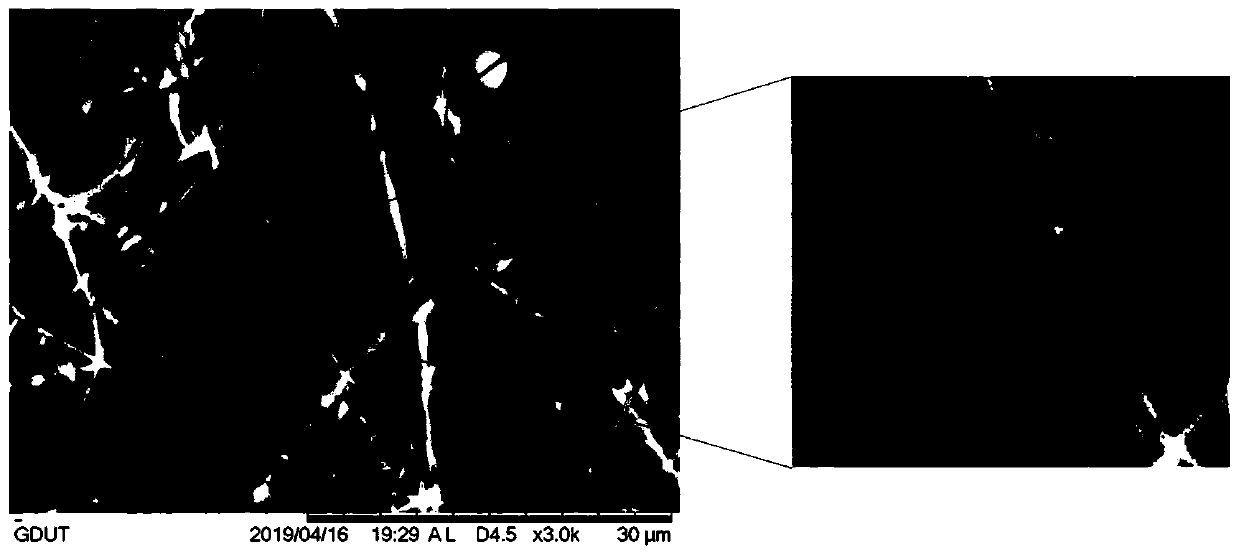

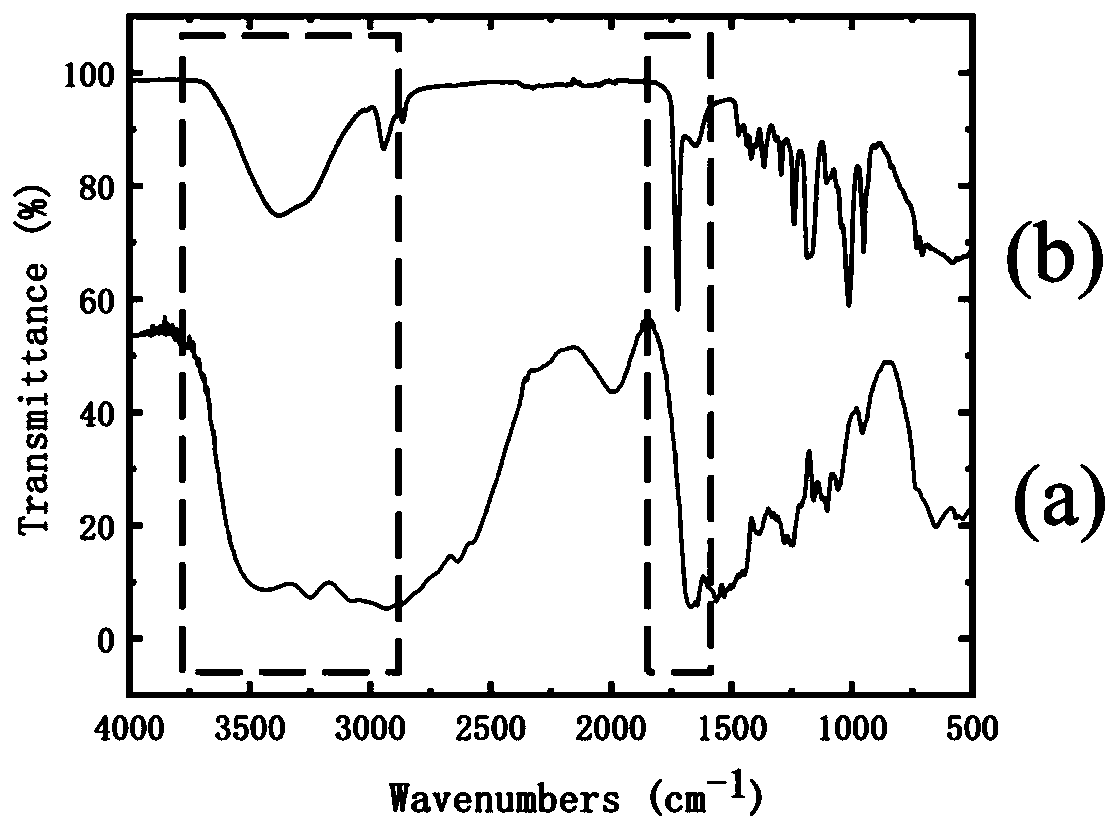

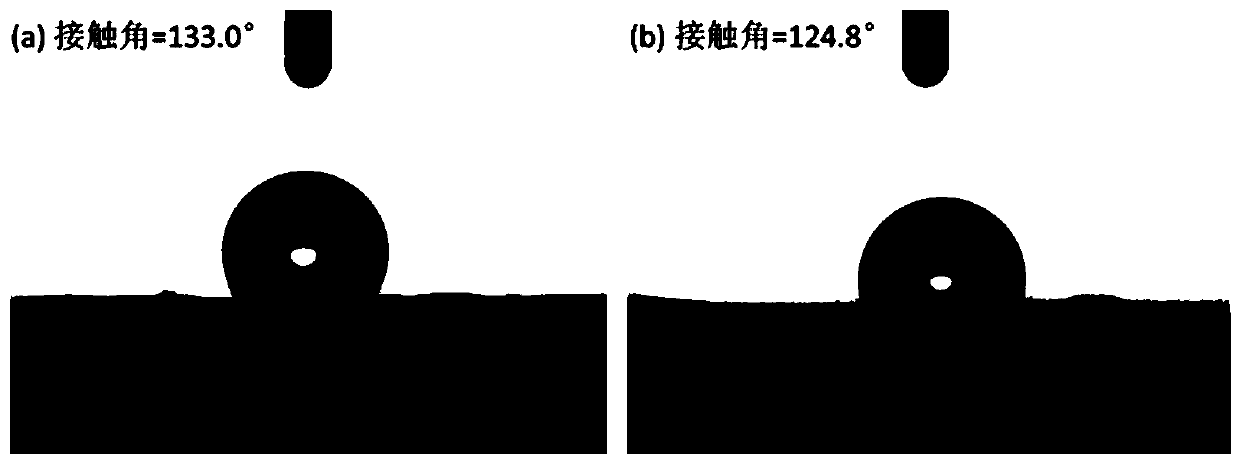

Embodiment 1

[0055] First prepare the inner tube solution: take polyvinyl alcohol particles with a molecular weight of 140,000 and mix them with distilled water. The content of polyvinyl alcohol in the mixed solution is 15% (w / v), and the mixed solution is placed in a round-bottomed flask. Put the mixed solution into a silicone oil bath magnetic stirring pot for stirring to obtain a polyvinyl alcohol solution. The set temperature of the silicone oil bath magnetic stirring pot is 90°C, the stirring time is 3 hours, and the stirring speed is set at 300-500rpm; take 1mL honey into the reagent bottle with a syringe, then add 19mL polyvinyl alcohol solution, and magnetically stir at 400rpm After 12 to 24 hours, fully mix to form a homogeneous solution, that is, the inner tube solution, and the volume fraction of honey in the inner tube solution is 5% (v / v).

[0056] Then prepare the outer tube solution: add ε-polylysine with a molecular weight of 3600-4300 and polycaprolactone with a molecular ...

Embodiment 2

[0067] First prepare the inner tube solution: take polyvinyl alcohol particles with a molecular weight of 140,000 and mix them with distilled water. The content of polyvinyl alcohol in the mixed solution is 15% (w / v), and the mixed solution is placed in a round-bottomed flask. Put the mixed solution into a silicone oil bath magnetic stirring pot for stirring to obtain a polyvinyl alcohol solution. The set temperature of the silicone oil bath magnetic stirring pot is 90°C, the stirring time is 3h, and the stirring speed is set at 300-500rpm; take 4mL honey into the reagent bottle with a syringe, then add 16mL polyvinyl alcohol solution, and magnetically stir at 400rpm After 12-24 hours, fully mix to form a homogeneous solution, that is, the inner tube solution, and the volume fraction of honey in the inner tube solution is 20% (v / v).

[0068] Then prepare the outer tube solution: add ε-polylysine with a molecular weight of 3600-4300 and polycaprolactone with a molecular weight ...

Embodiment 3

[0079] First prepare the inner tube solution: take polyvinyl alcohol particles with a molecular weight of 140,000 and mix them with distilled water. The content of polyvinyl alcohol in the mixed solution is 10% (w / v), and the mixed solution is placed in a round-bottomed flask. Put the mixed solution into a silicone oil bath magnetic stirring pot for stirring to obtain a polyvinyl alcohol solution. The set temperature of the silicone oil bath magnetic stirring pot is 90°C, the stirring time is 3 hours, and the stirring speed is set at 300-500rpm; take 6mL honey into the reagent bottle with a syringe, then add 14mL polyvinyl alcohol solution, and magnetically stir at 400rpm After 12 to 24 hours, fully mix to form a homogeneous solution, that is, the inner tube solution, and the volume fraction of honey in the inner tube solution is 30% (v / v).

[0080] Then prepare the outer tube solution: add ε-polylysine with a molecular weight of 3600-4300 and polycaprolactone with a molecular...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com