Nano antibacterial material and preparation method and application thereof

A kind of antibacterial material and nanotechnology, applied in the field of nano antibacterial material and its preparation, can solve the problems of many impurities and cumbersome subsequent operations, and achieve the effect of improving antibacterial performance, improving penetration ability and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] (1) Dihydrate zinc acetate Zn(Ac) of 6g at room temperature 2 ·H 2 O was dissolved in 40 mL of 50% PEG400 aqueous solution.

[0043] (2) Add 0.5g of nano-bentonite into (1), and stir for 4 hours.

[0044] (3) Prepare an ammonia solution with a mass concentration of 5% and slowly add it to (2), and adjust the pH of the solution to 8.

[0045] (4) Take 1g of rosin and dissolve it in 20mL of ethanol. After it is completely dissolved, add it dropwise to (3) and stir for 2h.

[0046] (5) Stir until it becomes a paste, transfer it to a reaction kettle, and react at 110° C. for 12 hours.

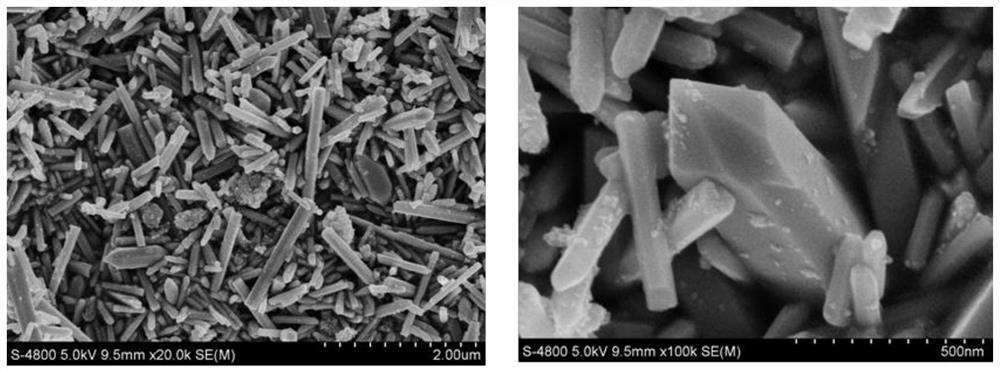

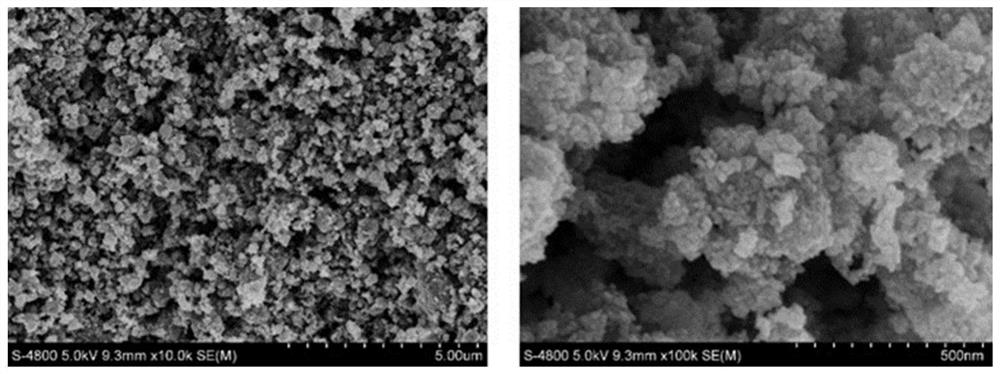

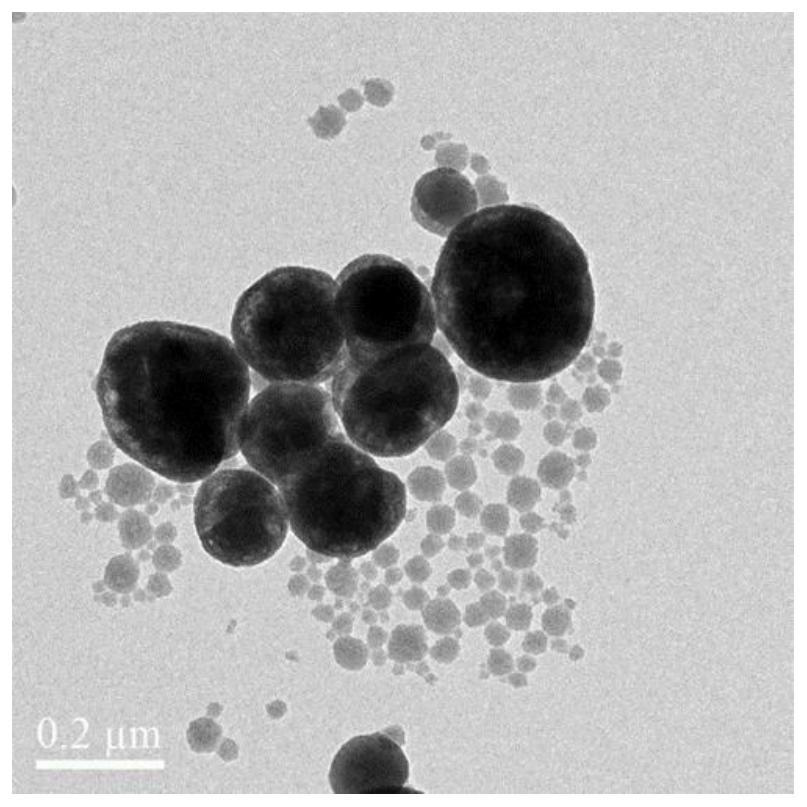

[0047] (6) The product in (5) was washed three times with ethanol and water successively, and the solid was transferred to a vacuum drying oven at 50° C. for 12 hours to obtain a spindle-shaped zinc oxide.

Embodiment 2

[0056] (1) Dihydrate zinc acetate Zn(Ac) of 6g at room temperature 2 ·H 2 O was dissolved in 40 mL of 50% PEG1000 solution.

[0057] (2) Add 0.5g of nano-bentonite into (1), and stir for 4 hours.

[0058] (3) Prepare an ammonia solution with a mass concentration of 5% and slowly add it to (2), and adjust the pH of the solution to 8.

[0059] (4) Take 1g of rosin and dissolve it in 20mL of ethanol. After it is completely dissolved, add it dropwise to (3) and stir for 2h.

[0060] (5) Stir until it becomes a paste, transfer it to a reaction kettle, and react at 110° C. for 18 hours.

[0061] (6) The product in (5) was washed three times with ethanol and water successively, and the solid was transferred to a vacuum drying oven at 50° C. for 12 hours to obtain spindle-shaped zinc oxide nanorods.

[0062] (7) Prepare a liquid culture medium, dissolve 20 g of nutrient broth in 1000 mL of high-purity water, put it into an autoclave for sterilization, and lower the temperature to ...

Embodiment 3

[0068] (1) Dihydrate zinc acetate Zn(Ac) of 6g at room temperature 2 ·H 2 O was dissolved in 40 mL of 50% PEG1000 solution.

[0069] (2) Add 0.5g of nano-bentonite into (1), and stir for 4 hours.

[0070] (3) Prepare an ammonia solution with a mass concentration of 5% and slowly add it to (2), and adjust the pH of the solution to 8.

[0071] (4) Take 1g of rosin and dissolve it in 20mL of ethanol. After it is completely dissolved, add it dropwise to (3) and stir for 2h.

[0072] (5) Stir until it becomes a paste, transfer it to a reaction kettle, and react at 110° C. for 18 hours.

[0073] (6) The product in (5) was washed three times with ethanol and water successively, and the solid was transferred to a vacuum drying oven at 50° C. for 12 hours to obtain spindle-shaped zinc oxide nanorods.

[0074] (7) Prepare a liquid culture medium, dissolve 20 g of nutrient broth in 1000 mL of ultrapure water, put it into an autoclave for sterilization, and lower the temperature to ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com