Thick oil emulsifying viscosity breaker for tracing steam, and preparation method and application method thereof

A technology of emulsified viscosity reducer and viscosity reducer, which is applied in the preparation of heavy oil emulsified viscosity reducer with steam and in the field of heavy oil emulsified viscosity reducer with steam. Penetration ability, simple process, fast emulsification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

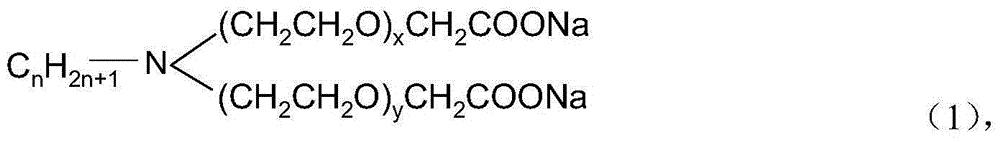

[0032] The emulsified viscosity reducer for heavy oil with steam in this embodiment includes the following components in parts by weight: 80 parts of fatty amine polyoxyethylene ether sodium carboxylate, 15 parts of sodium metaborate, and 5 parts of isobutanol; The molecular formula of fatty amine polyoxyethylene ether sodium carboxylate is:

[0033]

[0034] Among them, n is 18, x is 5, and y is 5.

[0035]The heavy oil emulsification (water-based) viscosity reducer with steam of the present embodiment includes the following components in parts by weight: 80 parts of fatty amine polyoxyethylene ether sodium carboxylate, 15 parts of sodium metaborate, and 5 parts of isobutanol , 30 parts of water, wherein, the molecular formula of the fatty amine polyoxyethylene ether sodium carboxylate is as shown in formula (1-1).

[0036] The preparation method of the heavy oil emulsification (water-based) viscosity reducer with steam of the present embodiment is carried out in the foll...

Embodiment 2

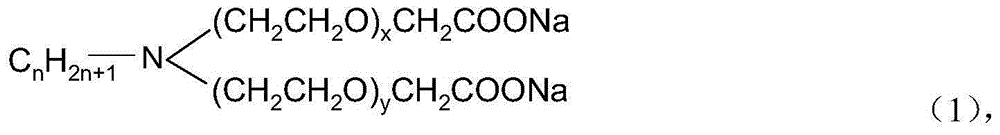

[0044] The heavy oil emulsified viscosity reducer with steam in this embodiment includes the following components in parts by weight: 75 parts of fatty amine polyoxyethylene ether sodium carboxylate, 10 parts of sodium bicarbonate, and 1 part of n-butanol; The molecular formula of fatty amine polyoxyethylene ether sodium carboxylate is:

[0045]

[0046] Among them, n is 12, x is 2, and y is 2.

[0047] The heavy oil emulsification (water-based) viscosity reducer with steam of the present embodiment includes the following components in parts by weight: 75 parts of fatty amine polyoxyethylene ether sodium carboxylate, 10 parts of sodium bicarbonate, and 1 part of n-butanol 10 parts of water, wherein, the molecular formula of the fatty amine polyoxyethylene ether sodium carboxylate is as shown in formula (1-2).

[0048] The preparation method of the heavy oil emulsification (water-based) viscosity reducer with steam of the present embodiment is carried out in the following s...

Embodiment 3

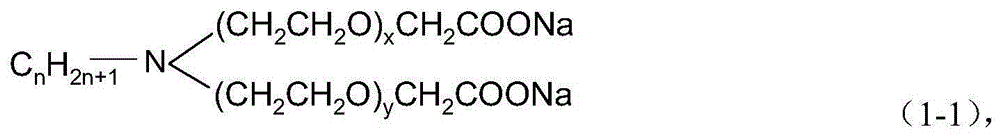

[0056] The emulsified viscosity reducer for heavy oil with steam in this embodiment includes the following components in parts by weight: 78 parts of fatty amine polyoxyethylene ether sodium carboxylate, 12 parts of triethanolamine, and 3 parts of isopropanol; wherein, the The molecular formula of fatty amine polyoxyethylene ether sodium carboxylate is:

[0057]

[0058] Among them, n is 15, x is 4, and y is 4.

[0059] The heavy oil emulsification (water base) viscosity reducer with steam of the present embodiment comprises the following components in parts by weight: 75 parts of fatty amine polyoxyethylene ether sodium carboxylate, 10 parts of triethanolamine, 1 part of isopropanol, 20 parts of water, wherein, the molecular formula of the fatty amine polyoxyethylene ether sodium carboxylate is shown in formula (1-3).

[0060] The preparation method of the heavy oil emulsification (water-based) viscosity reducer with steam of the present embodiment is carried out in the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com